Corrugated plate type water evaporation and cooling type heat exchanging tampering device

A corrugated plate type, water evaporation technology, used in household heating, heating methods, lighting and heating equipment, etc., can solve the problems of inconvenient passage isolation and sealing, non-hydrophilic metal materials, poor corrosion resistance, etc. Easy to manufacture, good fluid distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

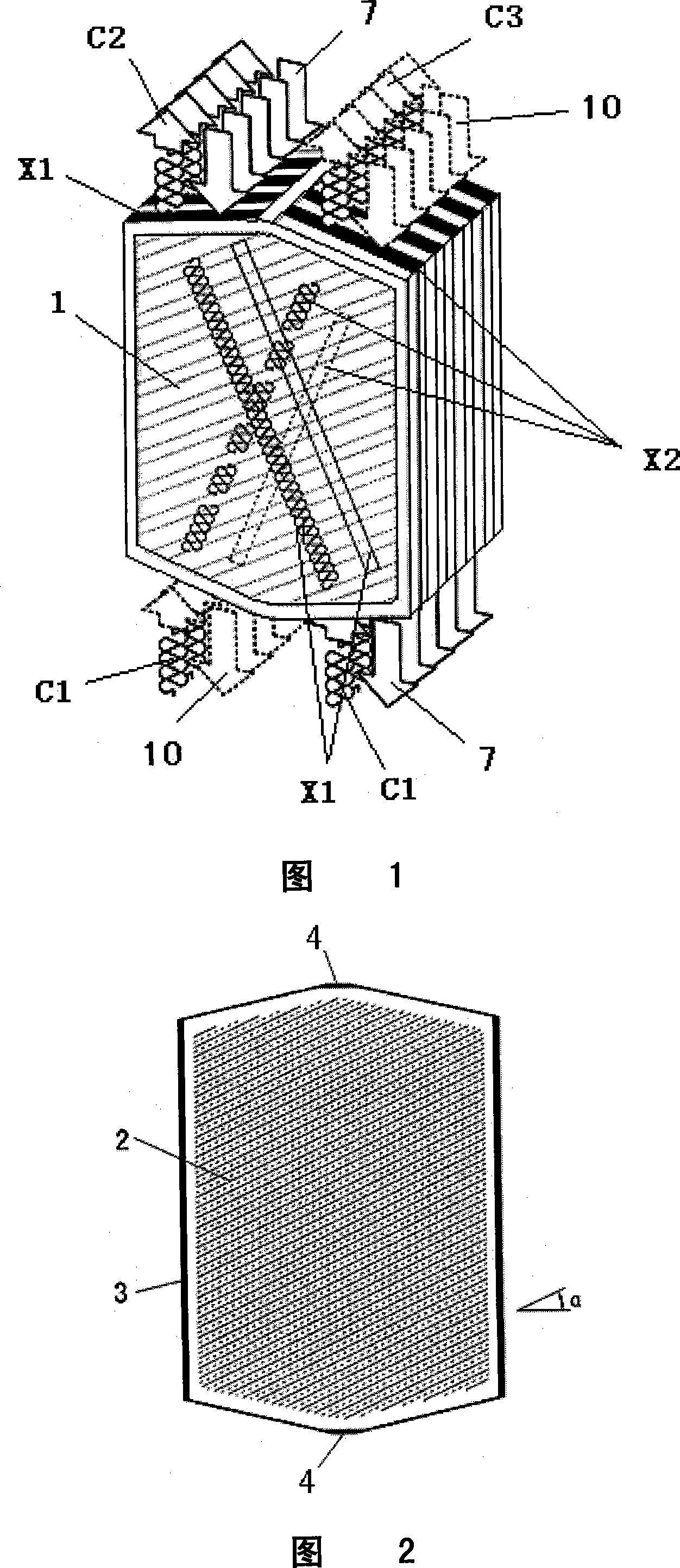

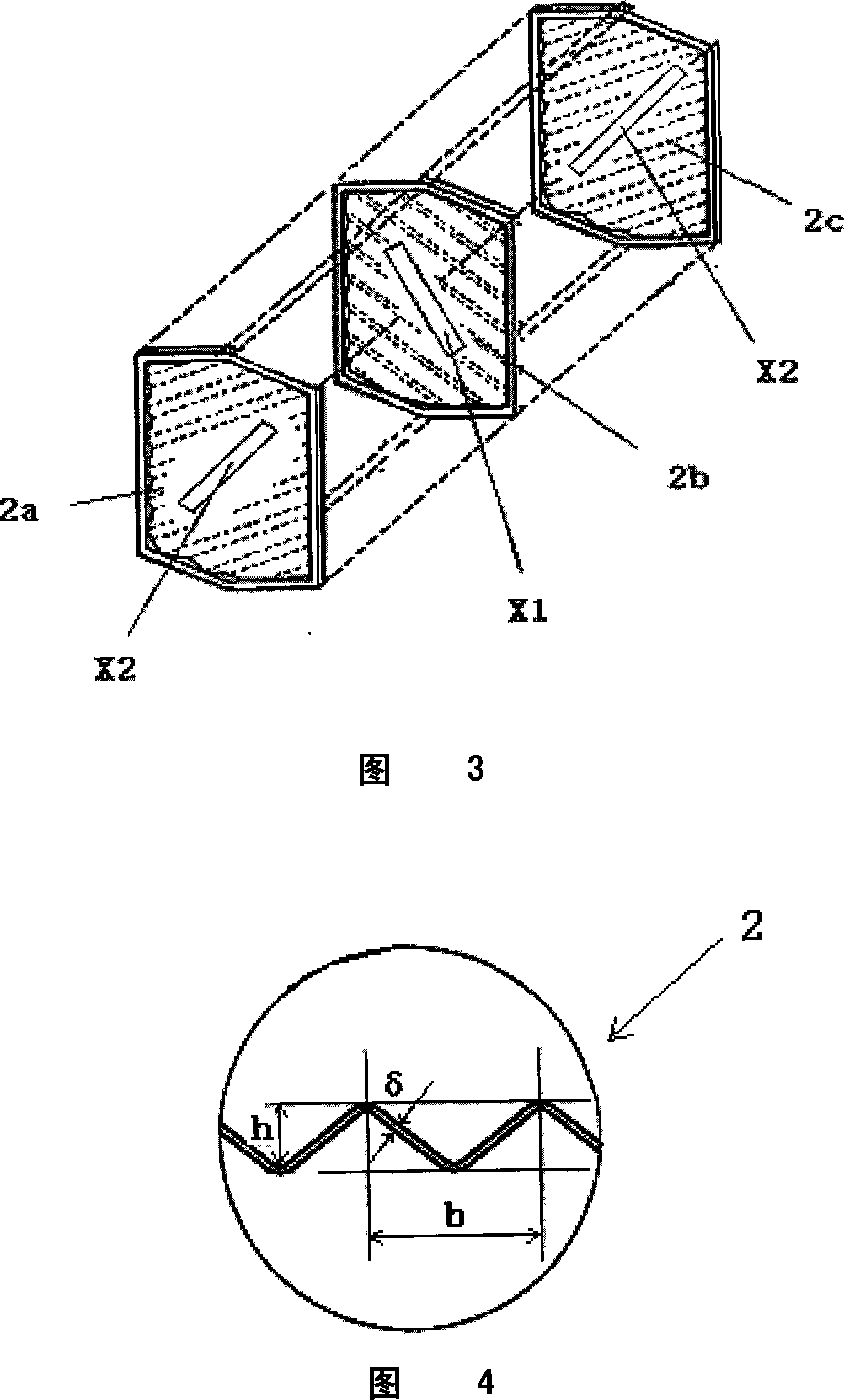

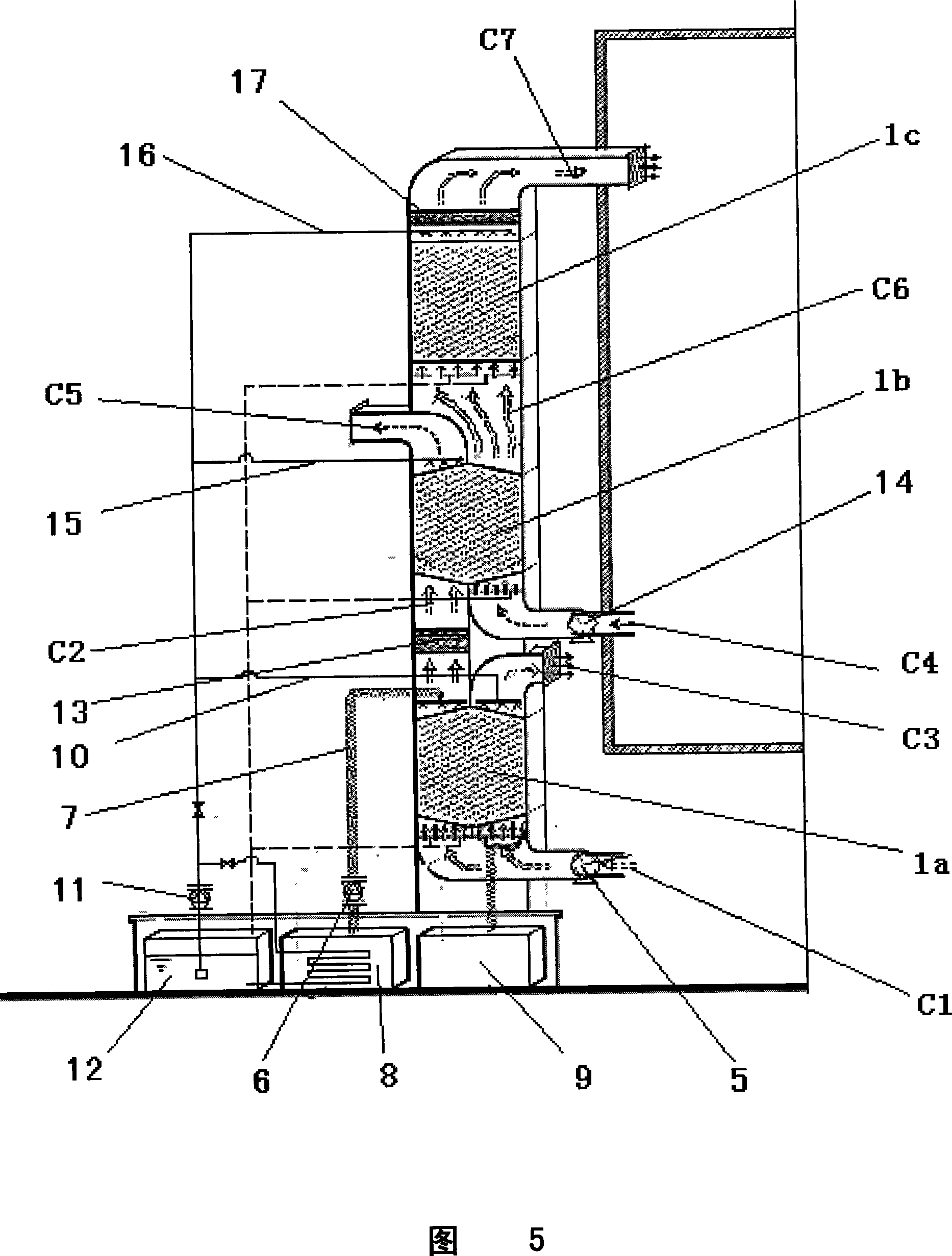

[0025] As shown in Figures 1 to 3, the heat and mass exchanger 1 of the present invention includes several plastic sheets 2 with oblique corrugations, and adjacent plastic sheets 2 are arranged alternately according to the corrugation direction, for example: the first layer of plastic sheets 2a and the second layer of plastic sheets The direction of corrugation of layer plastic sheet 2b is opposite, the direction of corrugation of the third layer of plastic sheet 2c is identical with the direction of corrugation of first layer of plastic sheet 2a, and so on. The two sides of each plastic sheet 2 are respectively bonded with the support frame 3 arranged on both sides, and the top and bottom of each plastic sheet 2 are respectively bonded with the support flat top 4 arranged at the top and bottom, and the support flat top 4 On the one hand, it is used as the reference plane during installation, and on the other hand, it is used as the interface between channels. On the left side...

Embodiment 2

[0028] In this embodiment, between every two layers of plastic sheets 2, only the passage in the same direction is kept unimpeded, such as: the passage of odd number or the passage of double number runs through, and another passage of double number or passage of single number is sealed, so that in the same passage exchange of the same nature.

Embodiment 3

[0030] In this embodiment, all passages between every two layers of plastic sheets 2 are kept unimpeded, that is, single-number passages and double passages are merged into one passage, and exchanges of the same nature are also carried out in the same passage.

[0031] As shown in Figures 2 and 4, in the above-mentioned embodiments, the corrugation angle α of the oblique corrugations on the plastic sheet 2 is the angle between the supporting flat top 4 and the oblique corrugations. If the corrugation angle α is too large, the water flow will be fast but The distribution is uneven, the corrugation slope angle is too small, and the water flow will be blocked when the water flow is slow. The best angle is to make the water form a thin liquid film on the surface of the plastic sheet 2, so the corrugation slope angle α is generally 25°~75°, The best range is 30°~60°. The wave height h of oblique corrugation is generally 4-9mm, and the optimal range is 5-7mm. If the wave height h is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com