Dithane M-22 Z-78 closed loop circulating drying method and apparatus

A mancozeb, closed-loop technology, applied in the direction of drying gas arrangement, drying solid materials, heating to dry solid materials, etc., can solve the problems of high power and thermal energy consumption, large number of equipment, large material dissipation, etc. The effect of good product quality, low material dissipation and pollution avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A closed-circuit cycle drying method for mancozeb using inert gas as the drying medium, using a feeding machine to send wet mancozeb into the dryer, and exchange heat and mass with nitrogen or carbon dioxide at a temperature of 140°C to 250°C after heating It is dried and separated in the cyclone separator and bag filter. The dry product is collected and sent to the cooler to cool to room temperature. After being discharged, it is measured and packaged. The dry tail gas is sent to the waste heat by a circulating fan and passed through the waste heat recovery device. After recovery, it is heated in a heater and circulated continuously. The temperature of the above-mentioned nitrogen or carbon dioxide can be selected from 140°C, 250°C, 165°C, 180°C or 240°C.

Embodiment 2

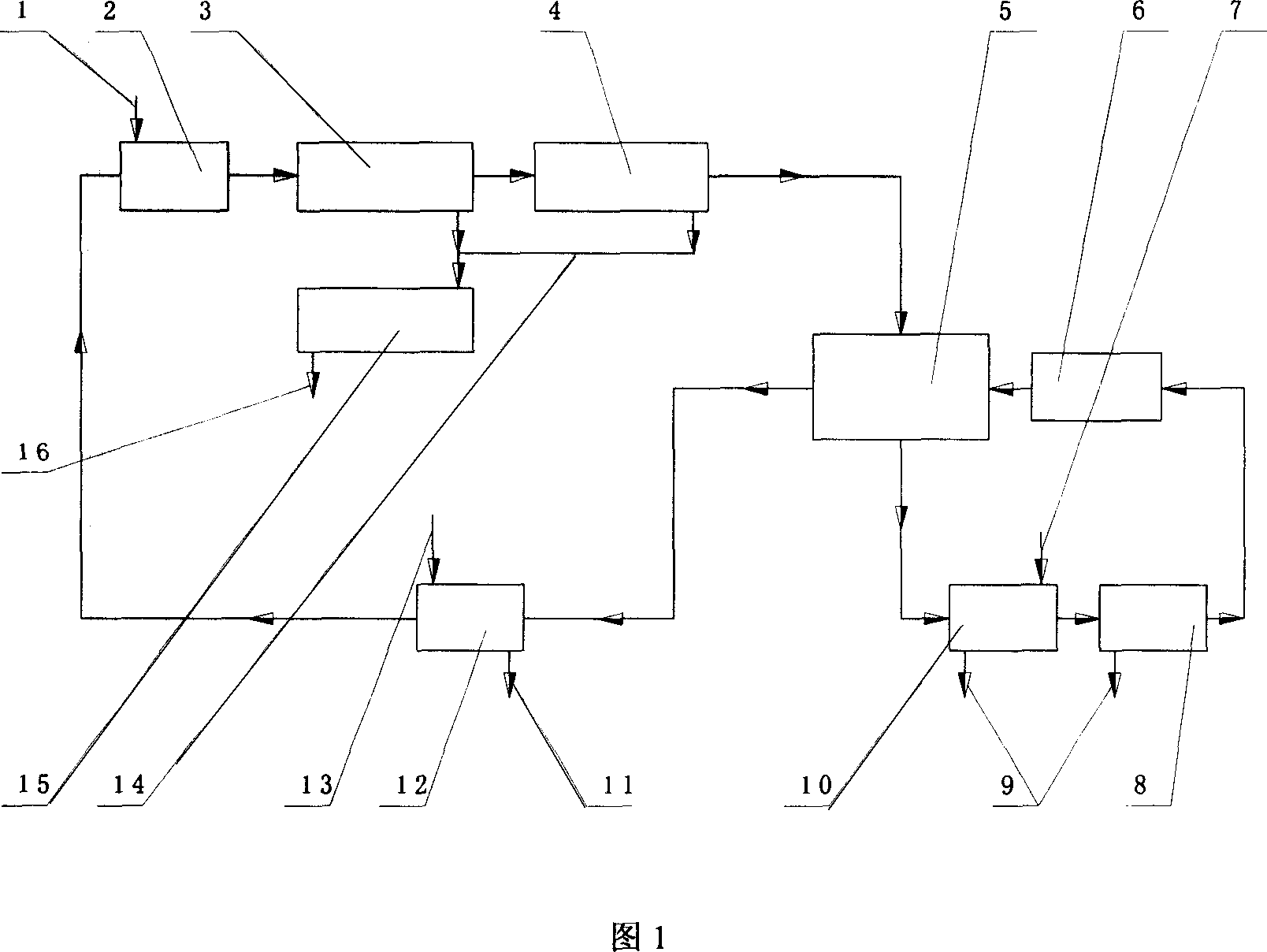

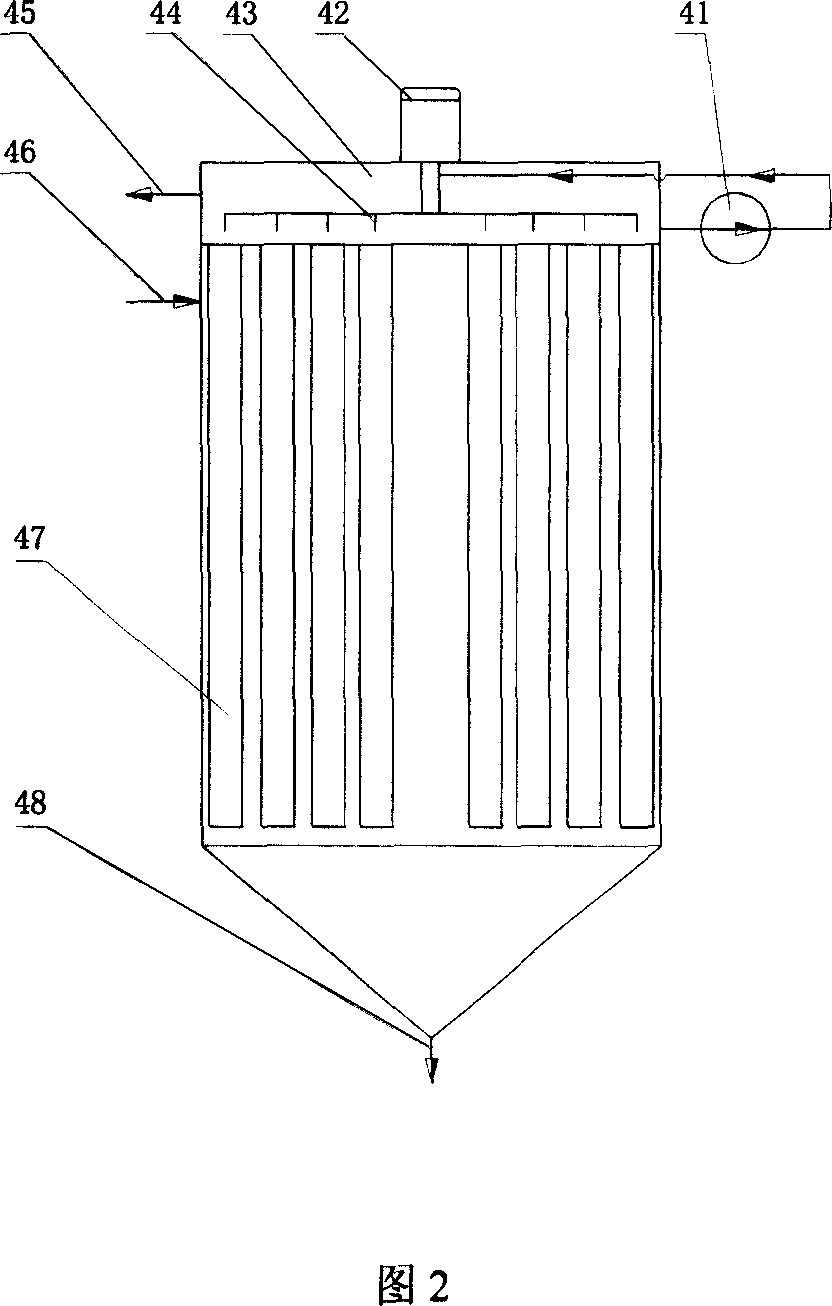

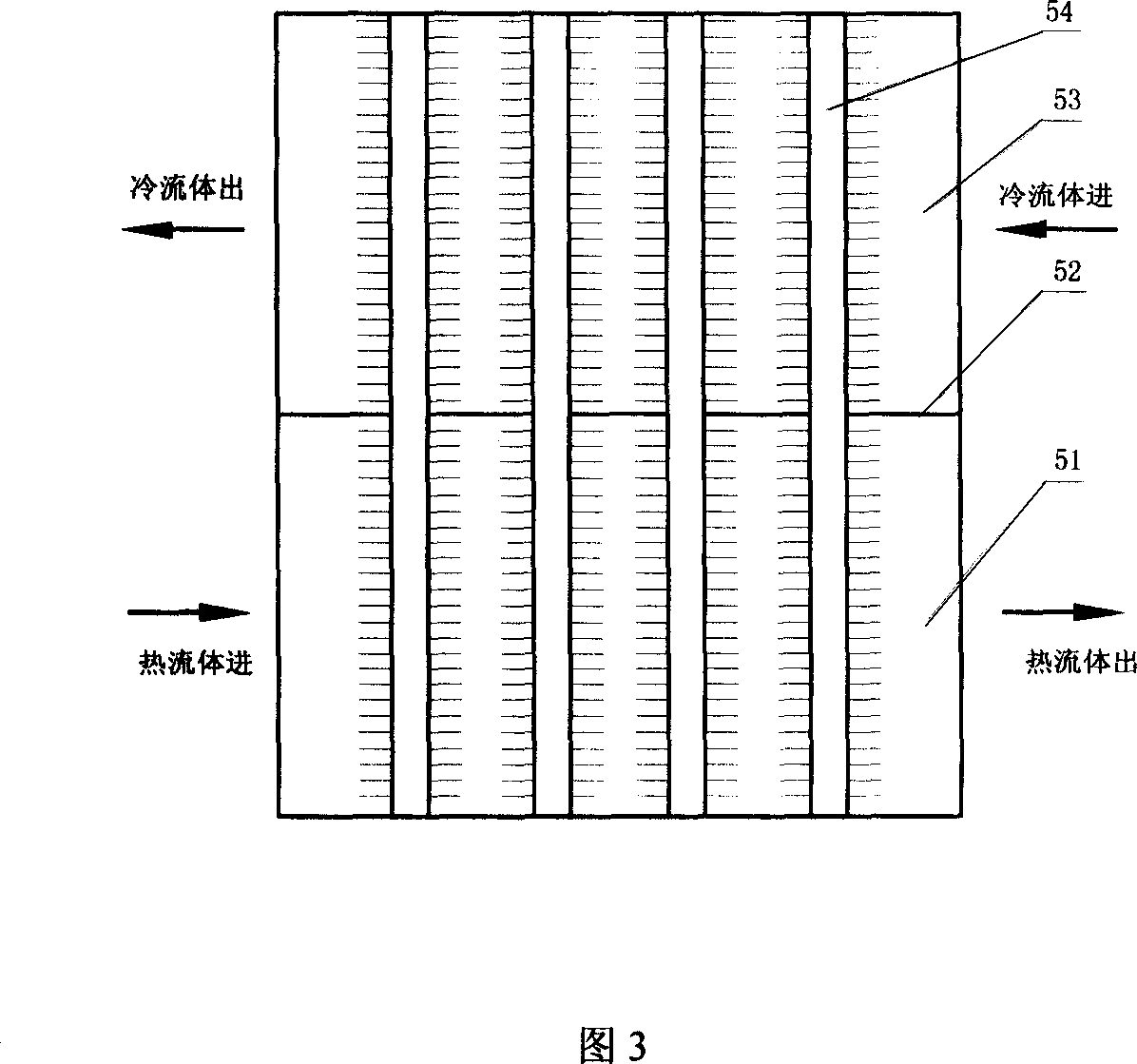

[0027] A drying device for implementing the above mancozeb closed-circuit circulation drying method, comprising a closed direct dryer 2, a cyclone separator 3, a heat pipe type waste heat recovery device 5, a circulating fan 6, a spray tower 10, and a heater 12 Composed of a dry product cooler 15, a feed port 1 is provided in the middle of the closed direct dryer 2. In the closed direct dryer 2, mancozeb from the feed port 1 is heated in the closed direct dryer 2 The final 140 ℃ ~ 250 ℃ nitrogen or carbon dioxide for heat and mass exchange, the air outlet of the closed direct dryer 2 is connected to the inlet of the cyclone separator 3, and the air outlet of the cyclone separator 3 is connected to the heat of the heat pipe type waste heat recovery device 5 The hot end air outlet is connected with the spray tower 10, the mist eliminator 8 and the circulation fan 6 in sequence, the air outlet of the circulation fan 6 is connected with the cold end air inlet of the heat pipe waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com