Semi-physical simulation platform and simulation method thereof used in cement clinker calcining process

A technology of semi-physical simulation and cement clinker, which is applied in software simulation/interpretation/simulation, program control devices, sustainable buildings, etc., can solve the problems of lack of theoretical guidance in operation, achieve strong repeatability, increase speed, and improve reliability. readability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

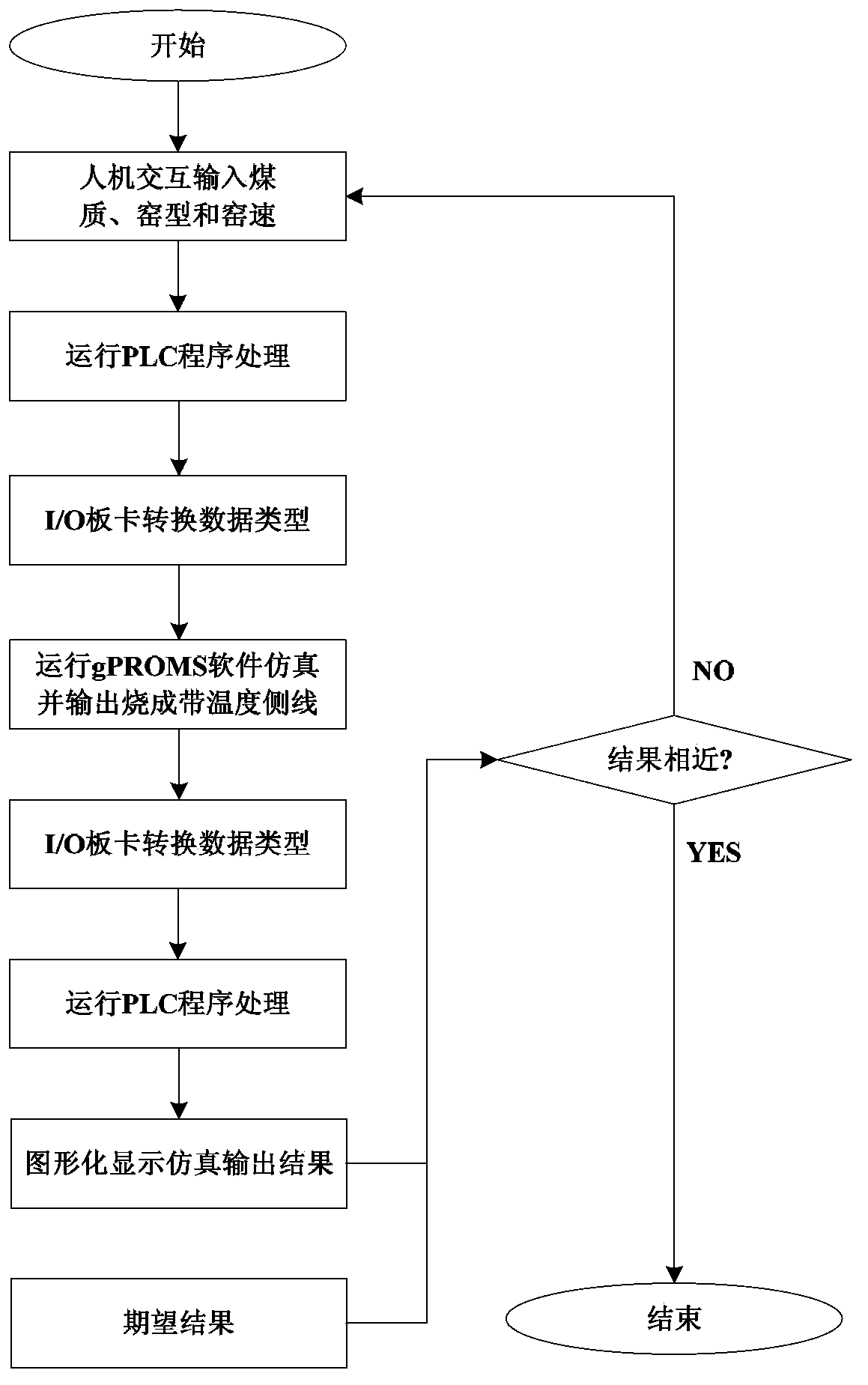

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

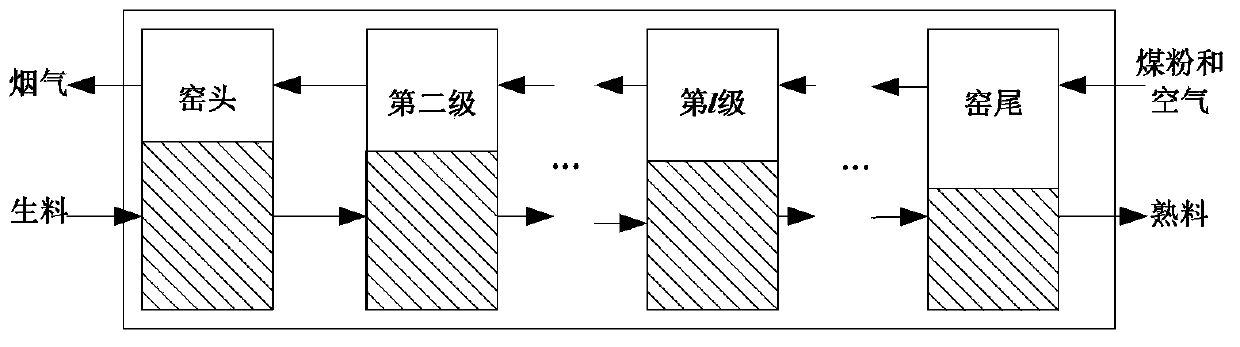

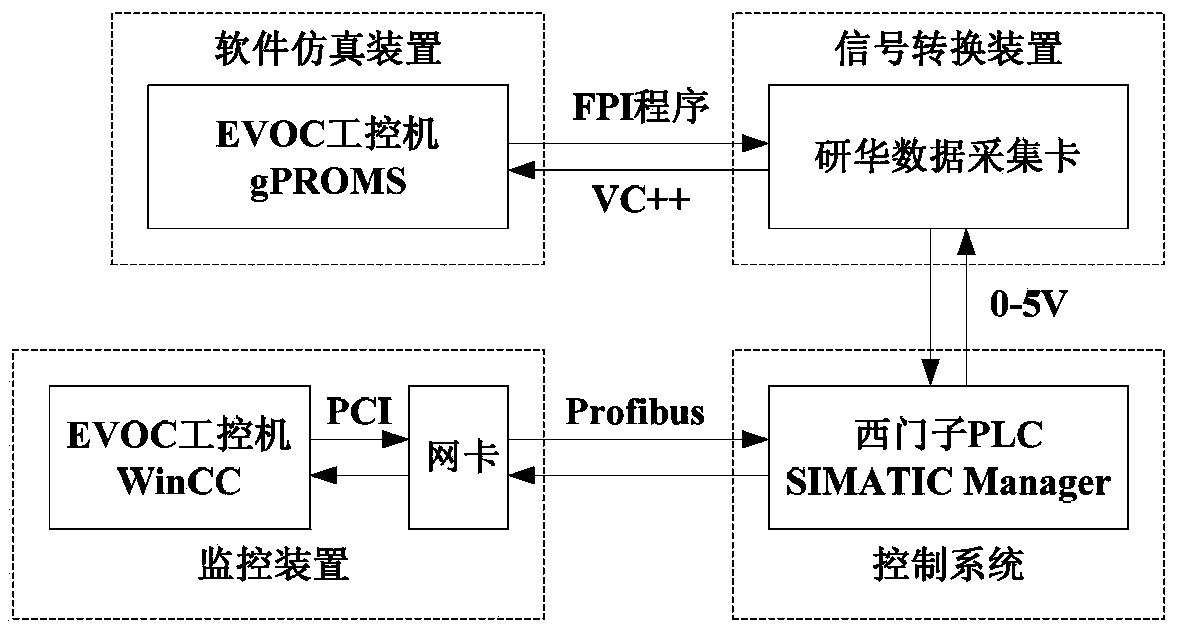

[0041] A semi-physical simulation platform for the cement clinker calcination process, including a sequentially connected software simulation device, a signal conversion device, a control system and a monitoring device.

[0042] The control system is a real programmable logic controller (PLC), which is connected with a data acquisition card; the monitoring device includes an industrial computer and a communication processing card connected with it. The software simulation device adopts an industrial control computer and is connected with the signal conversion device. The signal conversion device uses the real data acquisition I / O board (data acquisition card) as the information exchange medium to complete the process signal type conversion; the PLC hardware platform uses the actual PLC equipment to complete the closed-loop control and logic co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com