Method and system for preparing anhydrous hydrogen chloride gas

A hydrogen chloride gas and hydrogen chloride technology, applied in the direction of chlorine/hydrogen chloride, etc., can solve the problems of expensive equipment, low dehydration depth, serious problems, etc., and achieve the effect of low system equipment cost, easy operation, and deep dehydration depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

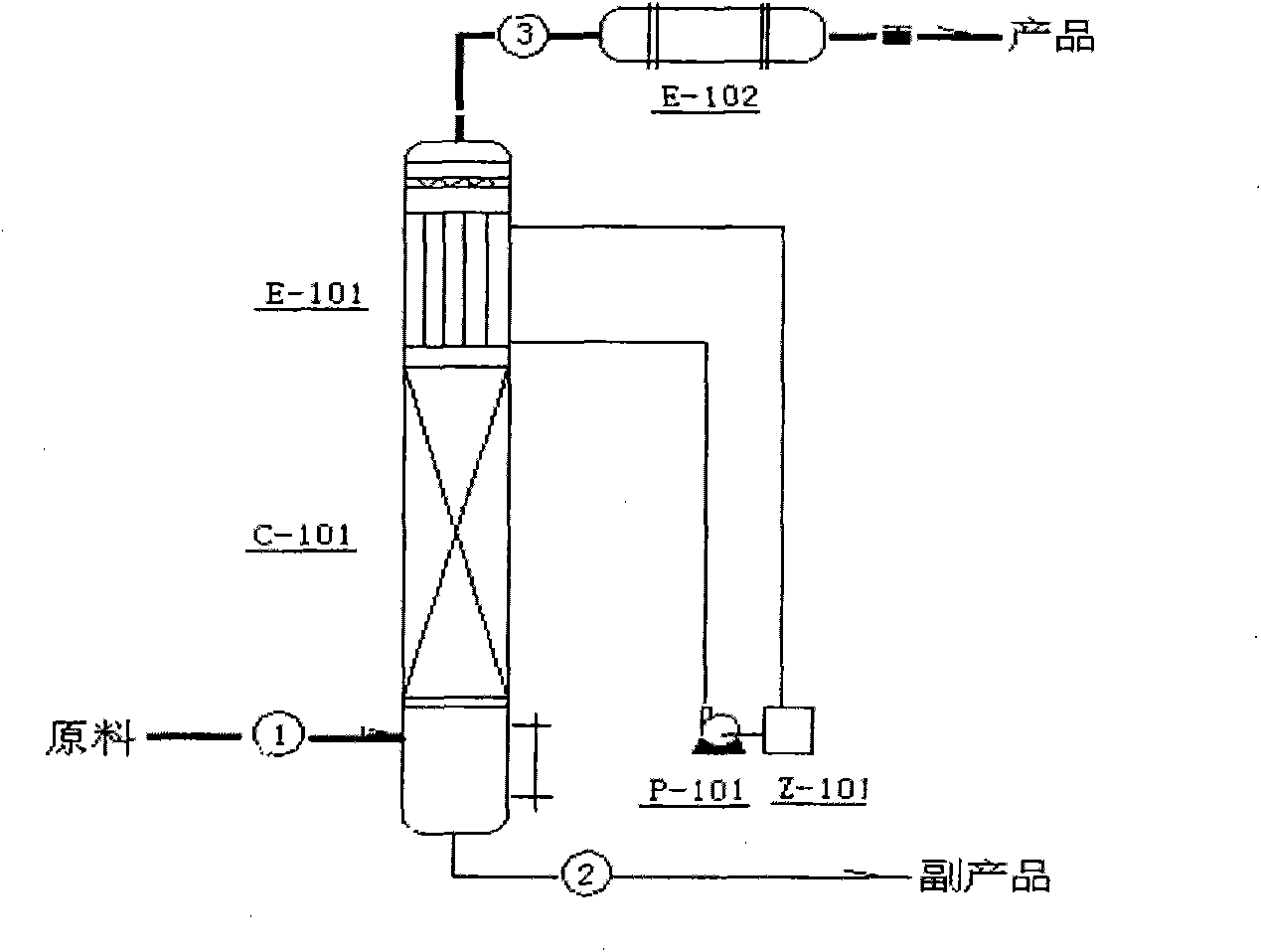

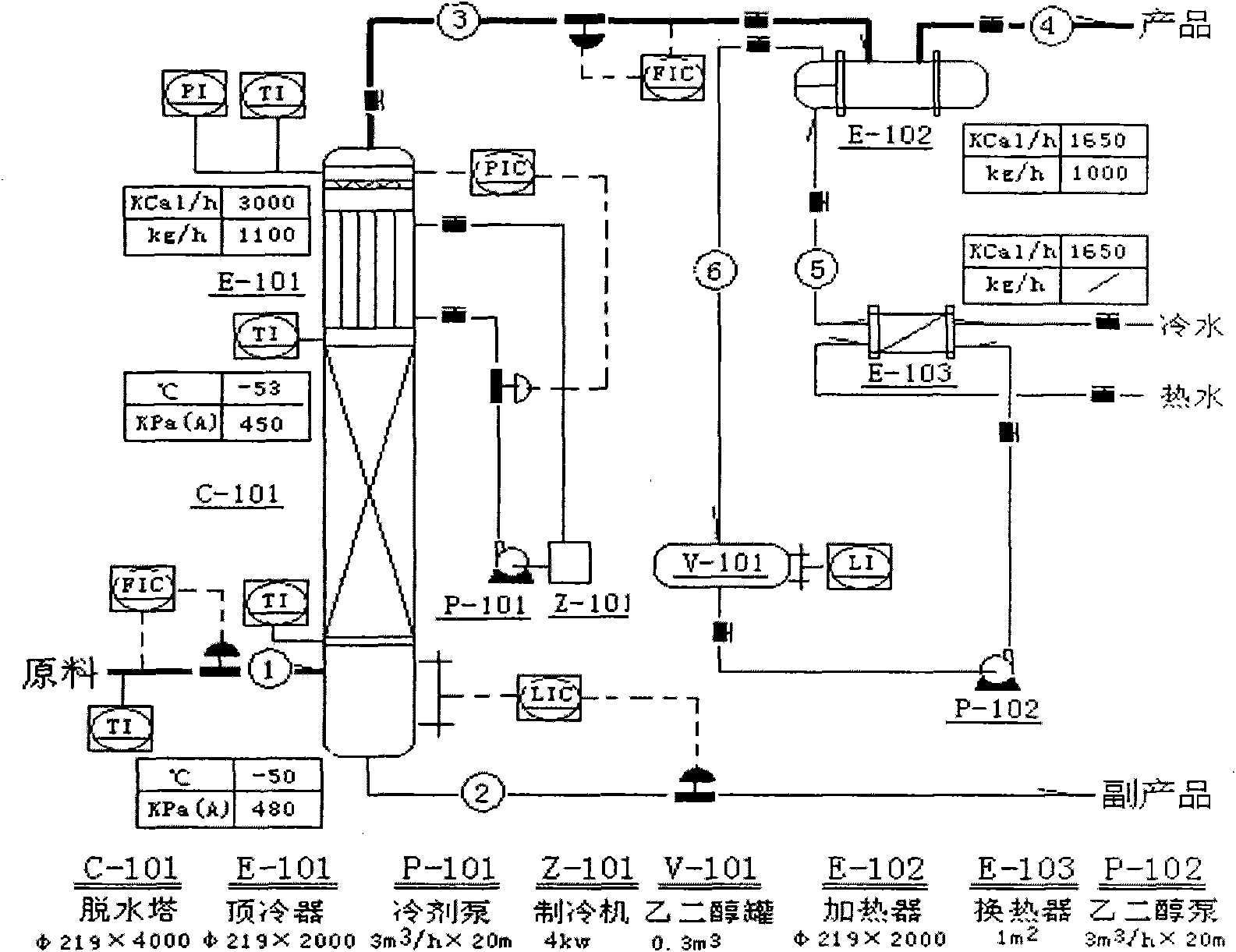

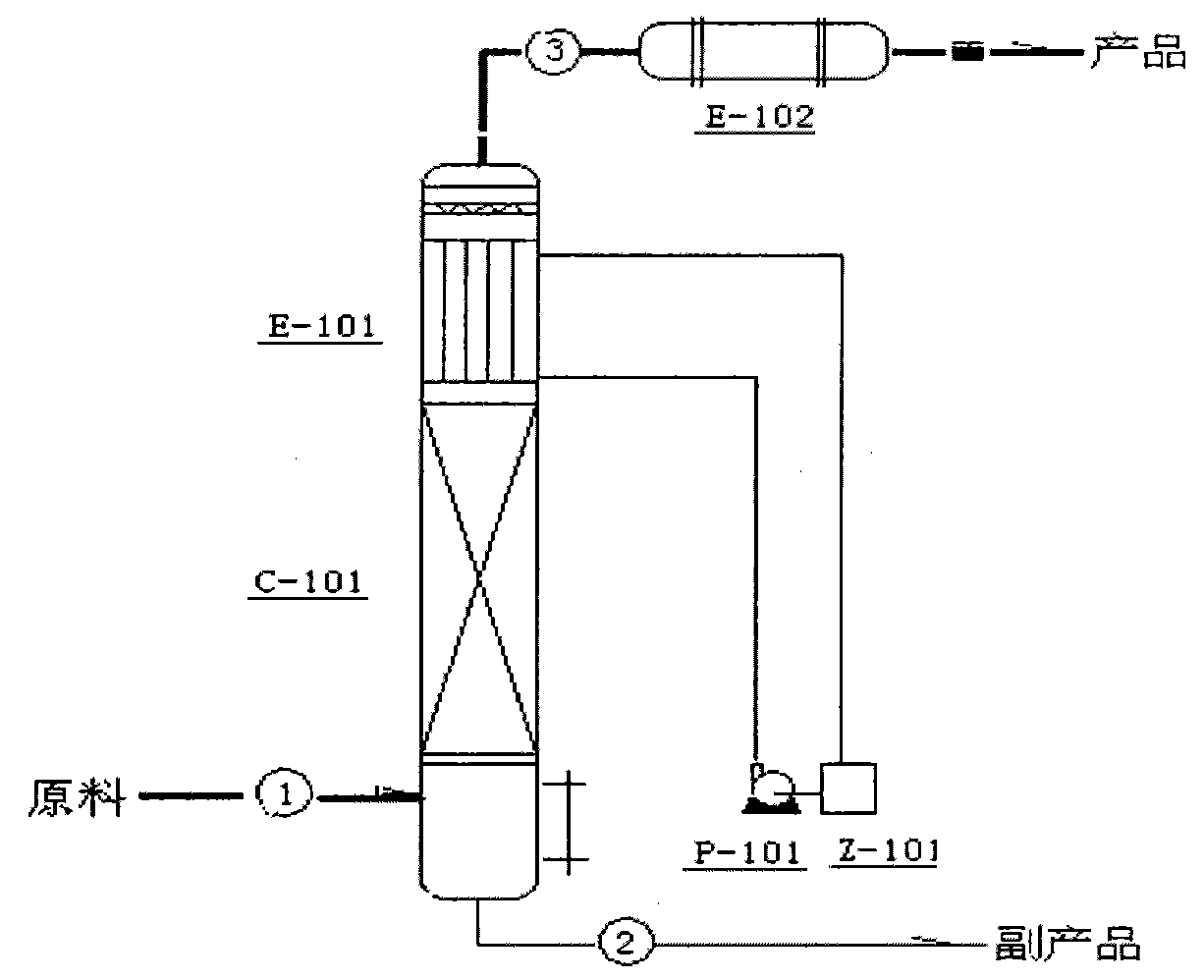

[0017] Flow Description:

[0018] The raw material gas ① enters from the upper part of the distillation column (C-101), flows upward, exchanges heat and mass with the condensate flowing downward from the top condenser (E-101) in the tower, and passes through the top condenser (E-101) After cooling and condensing, it is released from the top, and the product gas ③ discharged from the top is heated by the product heater (E-102) to form the final product gas ④; while the downward flowing liquid in the tower is discharged through the tower kettle to form a by-product ②.

[0019] The top condenser (E-101) pipes the hydrogen chloride gas, and the cooling medium outside the pipe. The cooling medium can be dichloroethane, which is cooled by the refrigerator (Z-101) and transported by the pump (P-101). The heat exchange medium used by the product heater (E-102) is ethylene glycol ⑤, and the cold ethylene glycol ⑥ is heated by hot water through the plate heat exchanger (E-103).

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com