Method for dehydrating and concentrating formaldehyde solution

A formaldehyde solution and formaldehyde technology, applied in chemical instruments and methods, preparation of organic compounds, separation/purification of carbonyl compounds, etc., can solve the problems of increased side reactions and increased separation difficulty, and achieve reduced energy consumption and reduced water content , The effect of increasing permeation flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

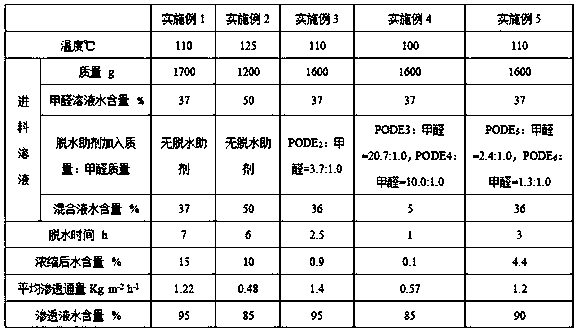

Embodiment 1

[0025] In this example, no dehydration aid is added, and as a comparative example, the intermittent membrane dehydration process is described with 37% formaldehyde aqueous solution.

[0026] Add 37% formaldehyde solution into the dehydration storage tank, heat the formaldehyde solution to 110°C with a heater, and adjust the formaldehyde solution to flow into the membrane module at a flow rate of 200ml / min through the feed pump and the regulating valve (5 grades of NaA molecular sieve membranes in series, The total membrane area is 0.14m 2 ), concentrated and dehydrated at a constant temperature of 110°C. The vacuum pump maintains an absolute pressure of 5000Pa on the permeate side, and the permeate is condensed by the vacuum condenser and collected in the permeate storage tank. After a certain period of concentration and dehydration, measure the water content in the formaldehyde solution.

[0027] The permeate flux of the concentrated dehydration performance, the water conte...

Embodiment 2

[0032] In this example, no dehydration aid is added, and as a comparative example, the intermittent membrane dehydration process is described with 50% formaldehyde aqueous solution.

[0033] Using 50% formaldehyde aqueous solution as a raw material, the concentration and dehydration temperature is 125° C., and flows through the membrane surface at a flow rate of 300 ml / min. Concentration and dehydration were carried out using the same dehydration process as in Example 1.

Embodiment 3

[0035] The present embodiment is to 37% formaldehyde aqueous solution and PODE 2 The mixture is subjected to a membrane dehydration process.

[0036] 37% formaldehyde solution and PODE 2 Mixed, as a dehydrated concentrated raw material, where PODE 2 The mass ratio of the added amount to formaldehyde is 3.7:1.0. The concentration and dehydration temperature is 110°C, and the flow rate of 100ml / min flows through the membrane surface. Concentration and dehydration were carried out using the same dehydration process as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com