Sludge deep dehydration process

A deep dehydration and sludge technology, applied in water/sludge/sewage treatment, sludge treatment, fixed/solidified sludge treatment, etc., can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the embodiments. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

[0017] A sludge deep dewatering process, comprising the following steps:

[0018] (1) Add modifiers and catalysts to the sludge with a moisture content of 80-85%, and mix well;

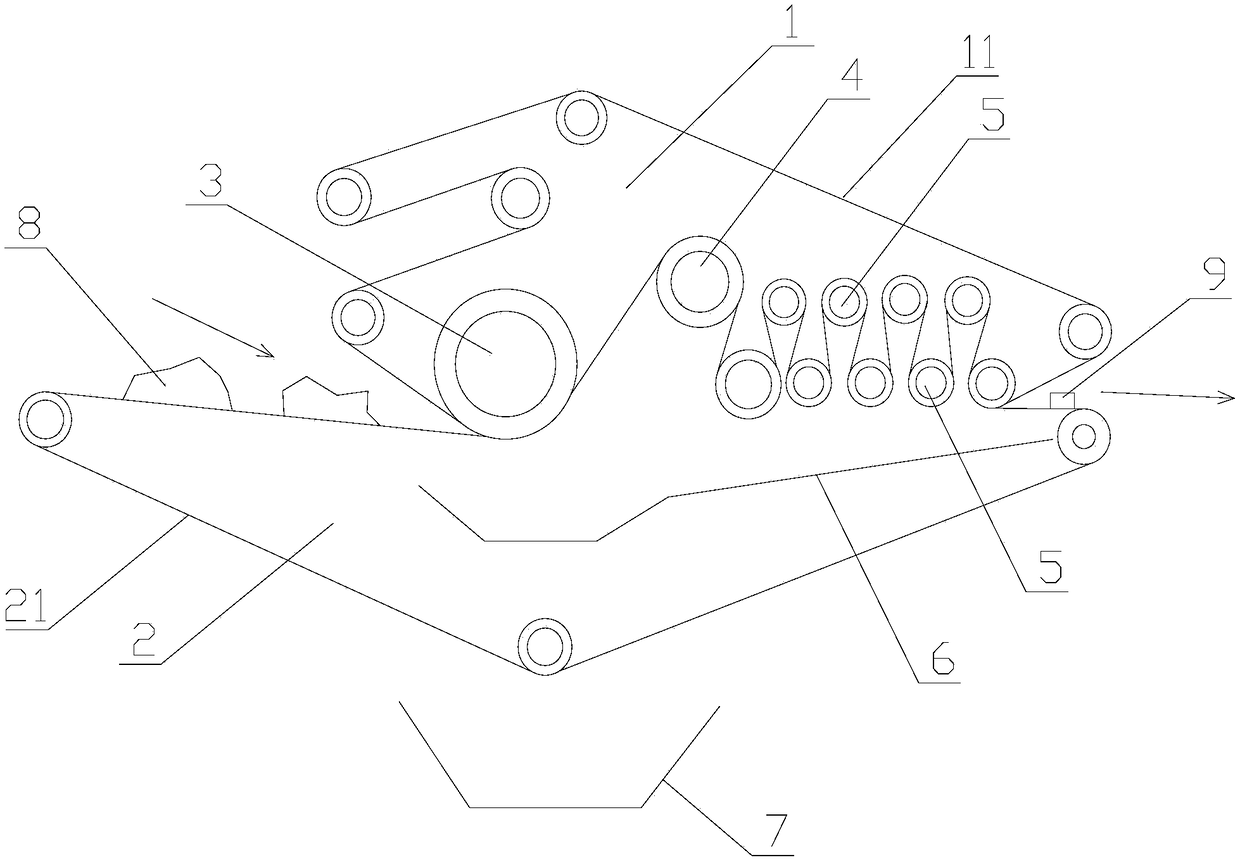

[0019] ⑵The modified sludge is sent to the deep sludge dehydrator, and then undergoes low-pressure, medium-pressure and high-pressure filtration dehydration treatment in sequence.

[0020] The sludge is quantitatively transported to the mixing reactor through the screw conveyor, and the sludge modifier and catalyst are added quantitatively, and fully mixed under the action of mechanical stirring. The modified sludge is quantitatively conveyed to the sludge deep dewatering machine by the screw for extrusion dehydration.

[0021] Wherein, the modifyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com