Two-sided liquid film reversal intercrossing double-dimension corrugated board absorber heat exchanging elements

A heat exchange element and corrugated plate technology, which is applied in the field of double-sided liquid film reverse cross double-scale corrugated plate absorber heat exchange element, can solve the problem of neglecting the utilization of heat transfer surface, and achieve the increase of effective heat transfer area and the The effect of increased heat and mass transfer coefficient and uniform distribution of liquid film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

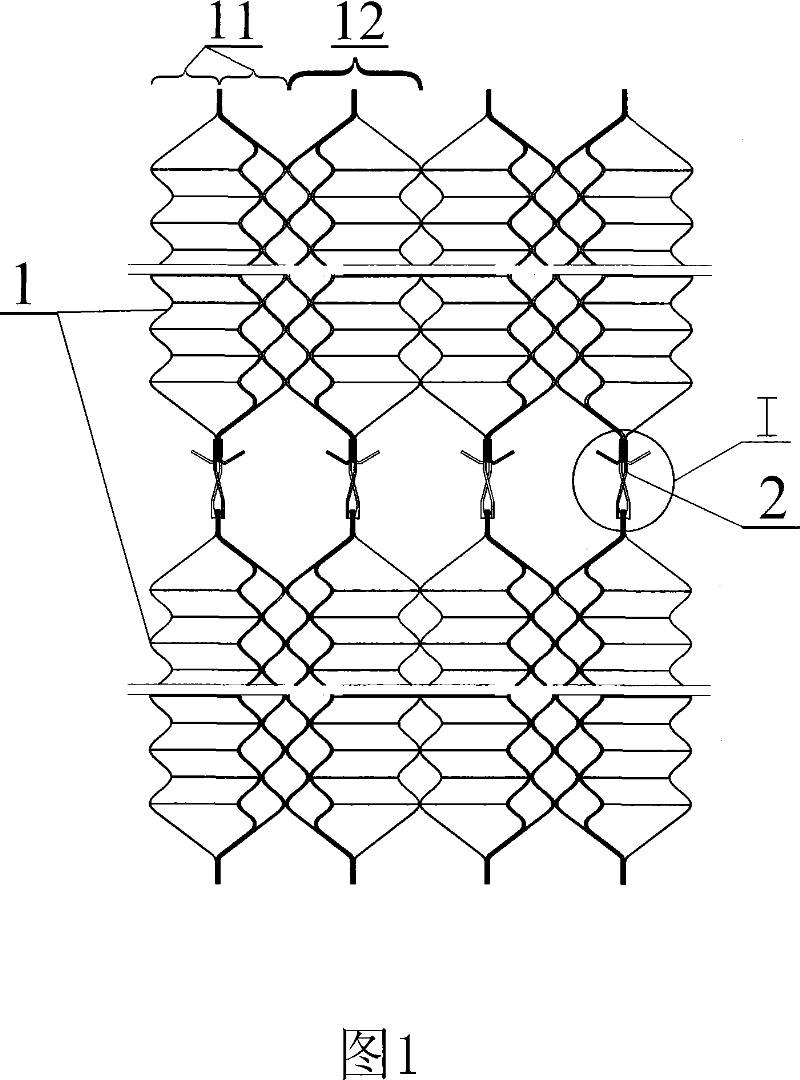

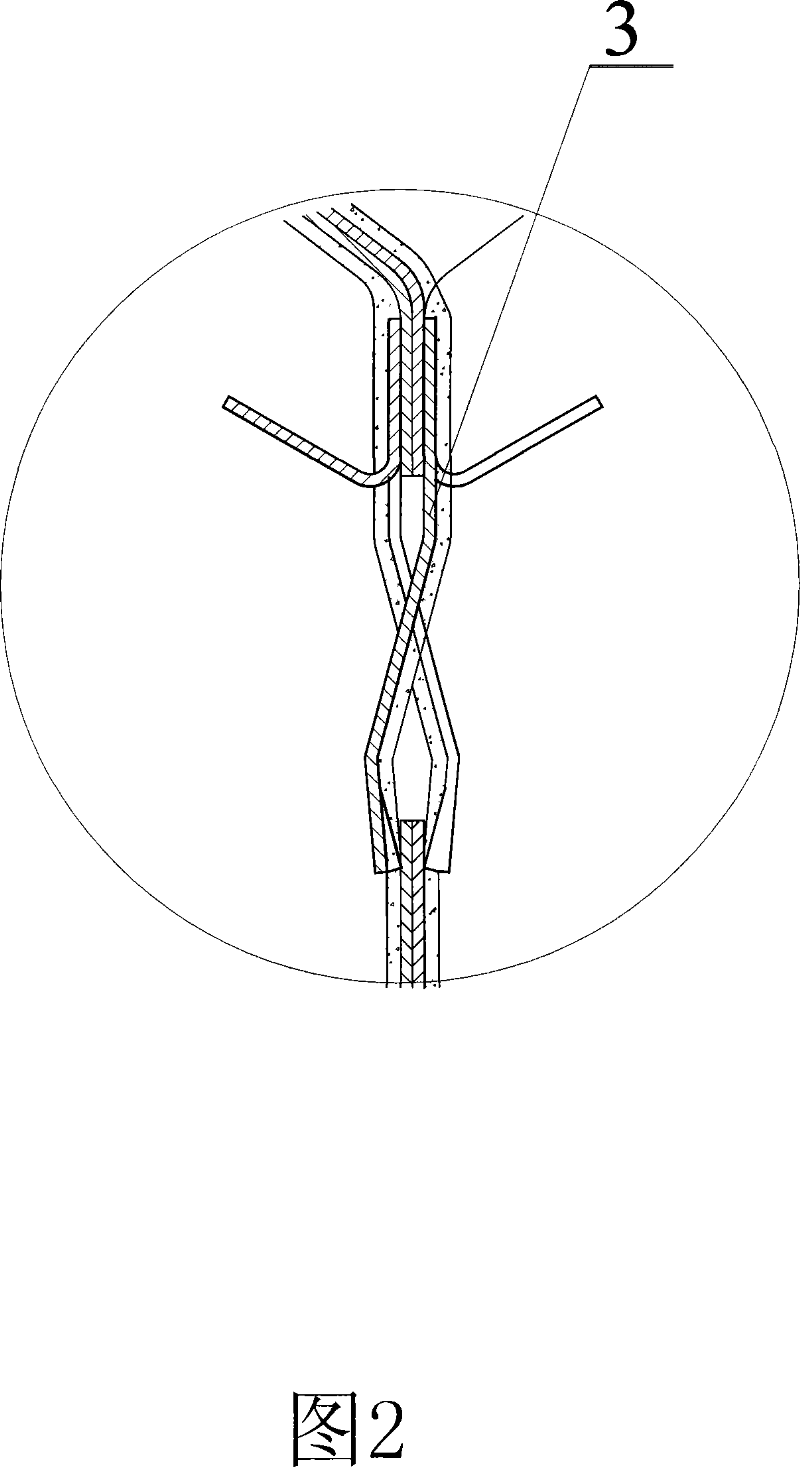

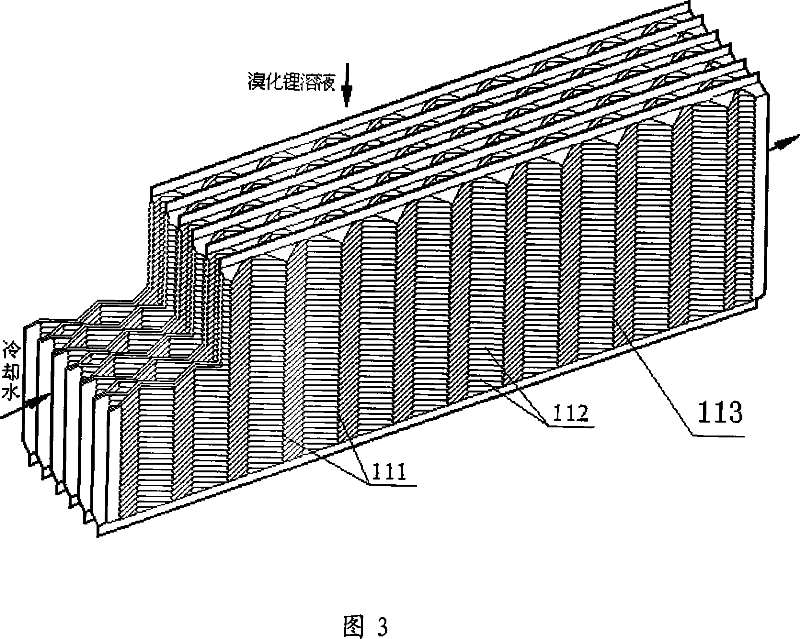

[0015] A double-sided liquid film inverted cross double-scale corrugated plate absorber heat exchange element, including at least two sets of double-scale corrugated plate heat transfer plate bundles 1, the two sets of double-scale corrugated plate heat transfer plate bundles 1 are arranged up and down, and A pair of intersecting rake-shaped deflectors 2 are arranged between each corresponding pair of plates 12 of two sets of double-scale corrugated plate heat transfer plate bundles 1. The rake-shaped deflectors 2 include an upper side 21, and below the upper side 21 there is a The guide tongue 22 is provided with a liquid barrier 23 on the side of the upper side 21, the liquid barrier 23 is located between two adjacent guide tongues 22, and the width of the liquid barrier 23 along the length direction of the upper side 21 is larger than that of the guide The width of the tongue 22, the double-scale corrugated plate heat transfer plate bundle 1 is composed of double-scale corru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com