Horizontal polyester solid phase polycondensation reaction device

A solid-phase polycondensation and reaction device technology, which is applied in the field of horizontal polyester solid-phase polycondensation reaction devices, can solve the problems of poor uniformity of reaction temperature, inconvenient manufacturing and installation, and high height, and achieve low equipment height, improved uniformity, and heat transfer. The effect of high mass transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

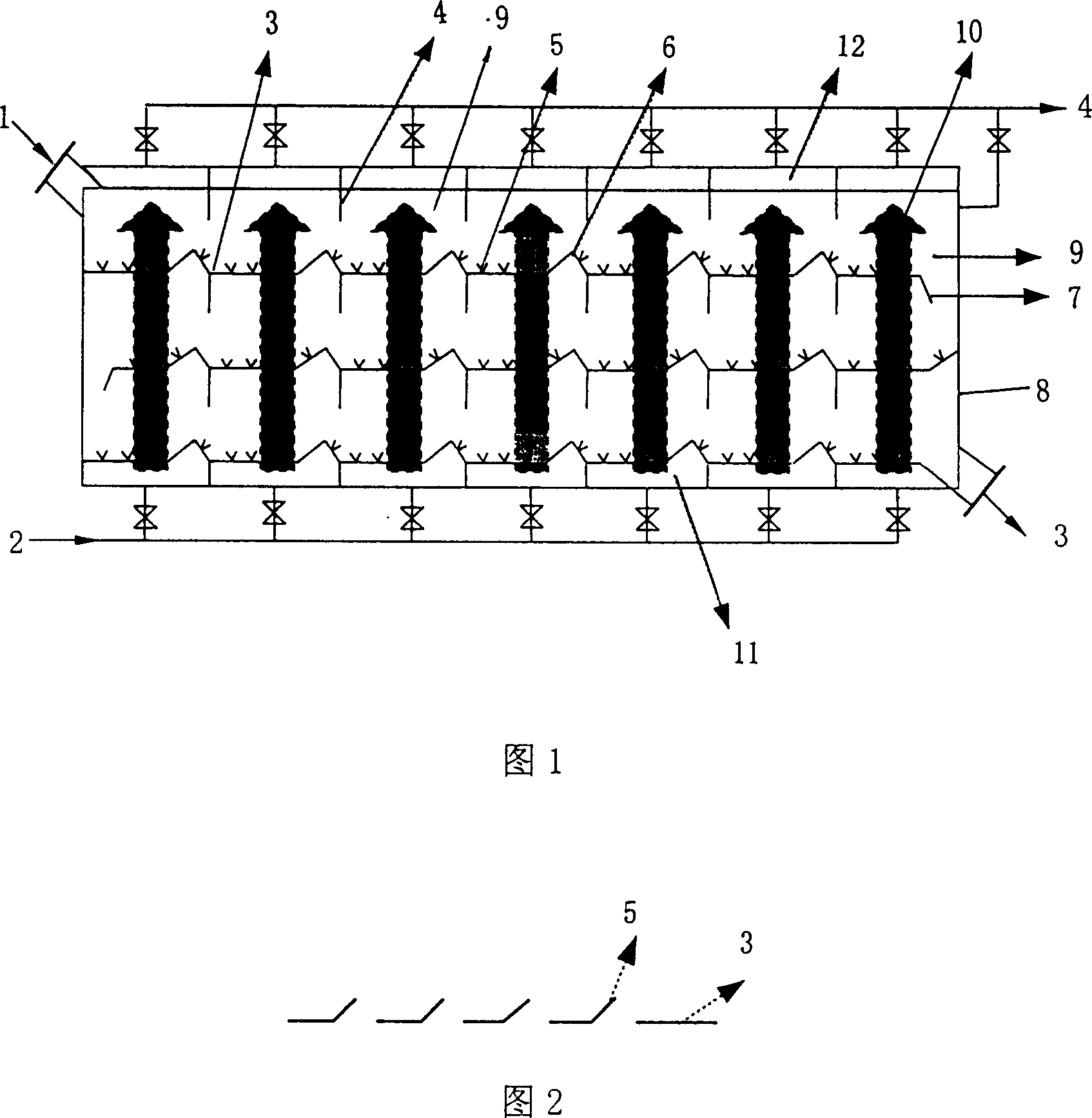

[0017] The following structural drawings and embodiments further illustrate the present invention.

[0018] As shown in Figure 1.

[0019] A kind of horizontal polyester solid-phase polycondensation reaction device, it comprises the tank body 8 of a horizontal arrangement, the top of this tank body 8 is provided with feed port 1, and its bottom is provided with discharge port 3; 8 is equipped with several layers of fluidized bed boards 3 arranged in an inclined shape, and each layer of fluidized bed boards 3 is provided with a ventilation slant hole 5, and the inclination angle of the ventilation slant hole 5 is between 0-90 degrees. Optionally, the shape of the hole can be one of square, rectangular, semi-circular or semi-elliptical or a combination thereof (the structure of the ventilation inclined hole 5 is shown in Figure 2). The inclination angles of the adjacent fluidized bed decks 3 are opposite, that is, the first layer is inclined to the right, the second layer is in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com