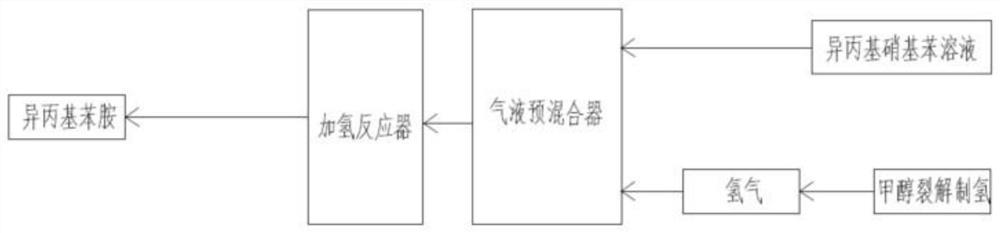

Method for preparing iso-propylaniline by novel hydrogenation technology

A technology of isopropylaniline and isopropyl, which is applied in the field of preparing isopropylaniline by novel hydrogenation technology, can solve the problems of cumbersome operation steps, high safety hazard, long reaction time and the like, and achieves high heat and mass transfer coefficient, The effect of saving production cost and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1) Crack isopropyl nitrobenzene 80kg / h with methanol to transport H with isopropyl nitrobenzene delivery pump 2 64NM 3 / h After being mixed in the slit vortex pre-reactor, it is transported to the millimeter-tube fixed-bed hydrogenation reactor for hydrogenation reaction;

[0048] 2) Control the reaction temperature at 90°C and the reaction pressure at about 2MPa;

[0049] 3) The hydrogenation product after hydrogenation goes to the gas-liquid separation tank, and the exhaust gas after gas-liquid separation is sent to the combustion furnace, and the cumene mixture of the separated gas enters the product rectification tower for separation.

[0050] The conversion rate of hydrogenation reduction was 100% through chromatographic analysis.

Embodiment 2

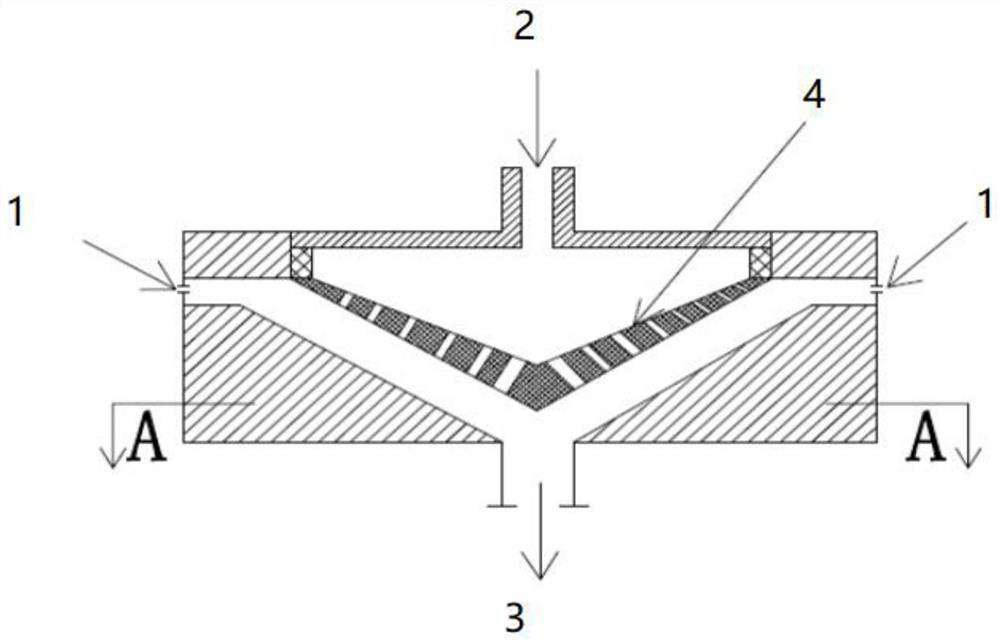

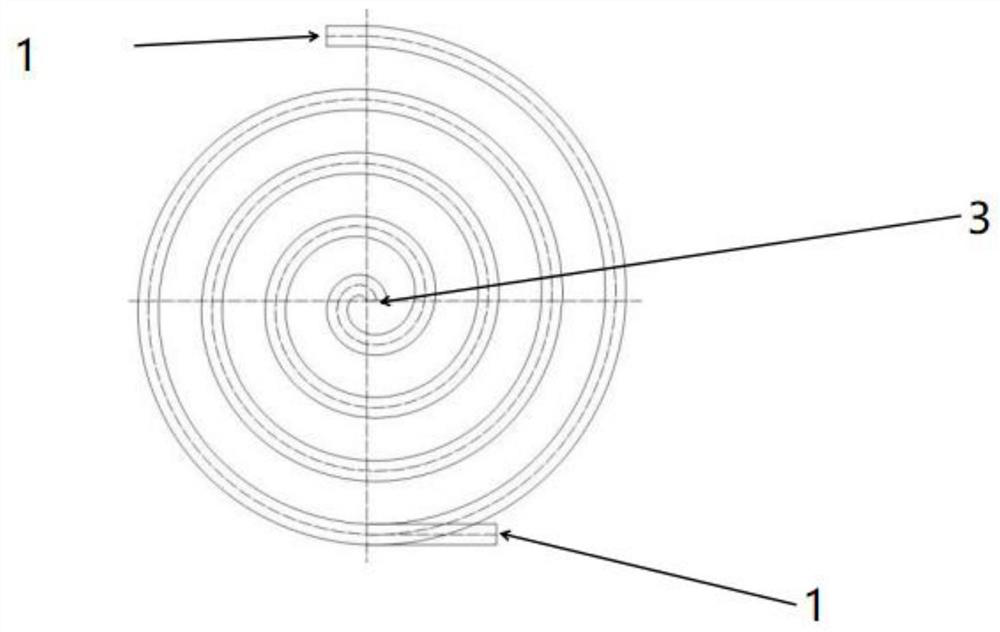

[0052]1) Crack isopropyl nitrobenzene 120kg / h with methanol to transport H with isopropyl nitrobenzene delivery pump 2 96NM 3 / h is mixed in the slit vortex pre-reactor and then sent to the mm tube fixed-bed hydrogenation reactor (see the attached Figure 4 , 5 Shown, wherein 5 is millimeter tube)), carry out hydrogenation reaction;

[0053] 2) Control the reaction temperature at 85°C and the reaction pressure at about 2.5MPa;

[0054] 3) The hydrogenation product after hydrogenation goes to the gas-liquid separation tank, and the exhaust gas after gas-liquid separation is sent to the combustion furnace, and the cumene mixture of the separated gas enters the product rectification tower for separation.

[0055] The conversion rate of hydrogenation reduction was 100% through chromatographic analysis.

Embodiment 3

[0057] 1) Crack isopropyl nitrobenzene 150kg / h with methanol to transport H with isopropyl nitrobenzene delivery pump 2 300NM 3 / h is mixed in the slit vortex pre-reactor and then transported to the millimeter plate hydrogenation reactor (see the attached Image 6 , 7 As shown, wherein 6 is the reactor main body, 7 is the material port, and 8 is the heat exchange port), carrying out the hydrogenation reaction;

[0058] 2) Control the reaction temperature at 90°C and the reaction pressure at about 2MPa;

[0059] 3) The hydrogenation product after hydrogenation goes to the gas-liquid separation tank, and the exhaust gas after gas-liquid separation is sent to the combustion furnace, and the cumene mixture of the separated gas enters the product rectification tower for separation.

[0060] The conversion rate of hydrogenation reduction was 100% through chromatographic analysis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com