Light hydrocarbon pulse type ejection atomizing gas making method and device

A jet atomization and pulse type technology, applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems affecting the stability of gas production calorific value, complex and high cost of gas production equipment, and increased equipment volume, etc., to achieve compact structure, Low cost and stable gas production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

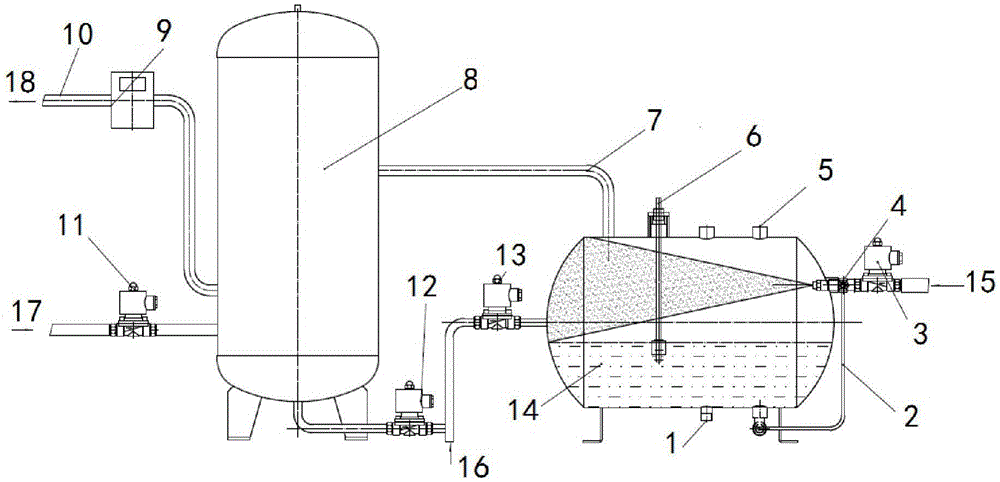

[0030] Embodiment 1: as figure 1 as shown,

[0031] A light hydrocarbon pulse jet atomization gas production method, comprising an oil-gas mixed injection step, the oil-gas mixed injection step includes a power high-pressure air injection step, an electric spray injection step, and a high-pressure oil pump injection step, and also includes a atomized gasification light hydrocarbon step ; Contains the step of producing light hydrocarbon gas with high calorific value first, and then balancing to light hydrocarbon gas with low calorific value;

[0032] Power high-pressure air injection steps: use compressed air as the power, use the siphon effect, spray the heavy and difficult-to-volatile part of the bottom of the raw material first, and fully mix the atomization and air; achieve the purpose of light hydrocarbon mixing; at the same time, the light hydrocarbon raw material In the dynamic balance of dissolution and condensation, the functions of circulation and stirring are realiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com