Double-fuel car power economizer

A dual-fuel vehicle and economizer technology, used in combustion engines, machines/engines, internal combustion piston engines, etc., can solve problems such as increased consumption, reduced natural gas thermal power, and reduced power, so as to improve combustion efficiency and increase mixing. Concentration and exhaust emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

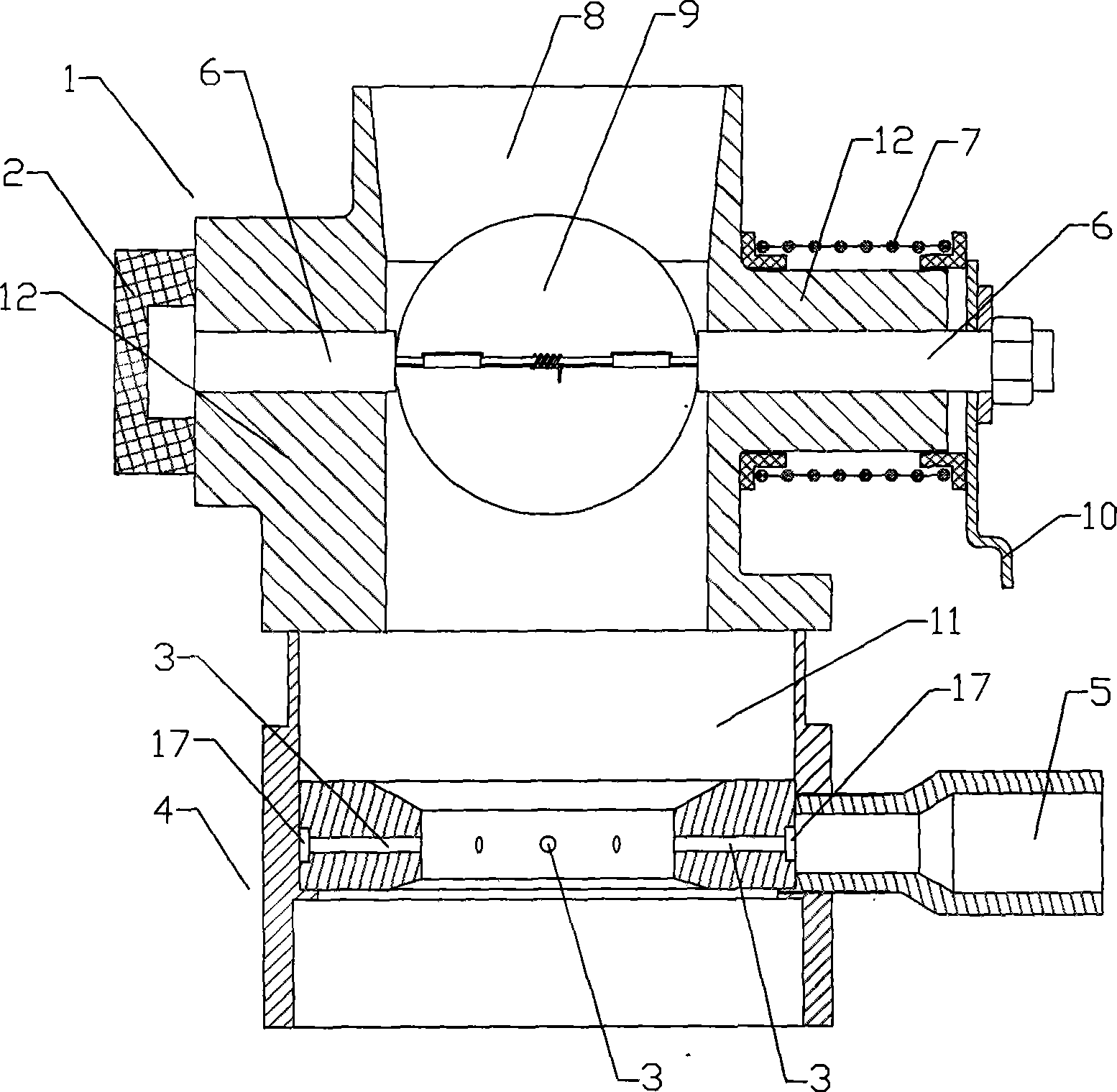

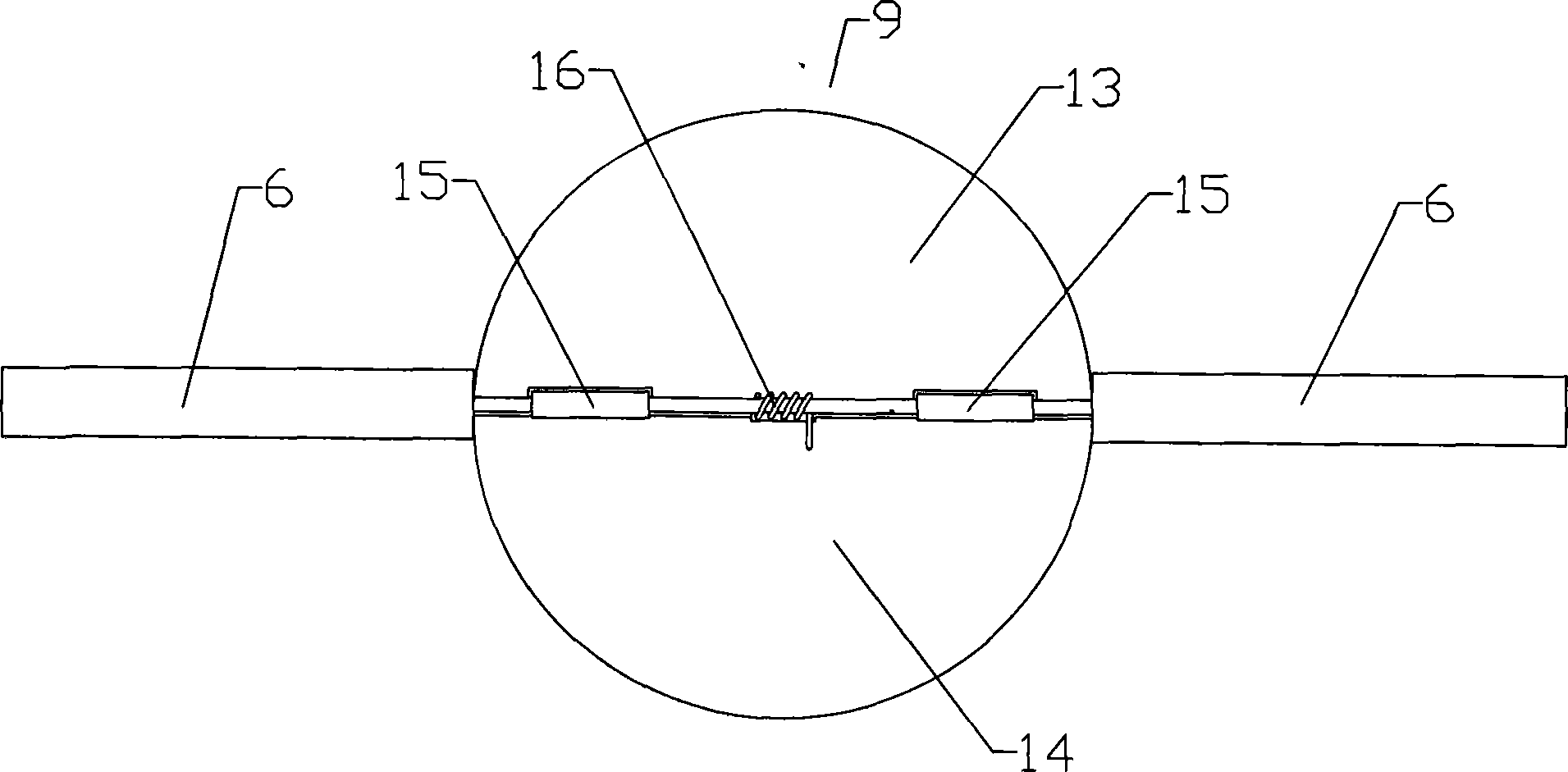

[0018] Such as figure 1 As shown, the economizer for dual-fuel vehicles includes a mixer 4, which has an air intake passage 11, and the mixer 4 is provided with a natural gas intake pipe 5, and the mixer 4 is provided with an annular Intake chamber 17, the natural gas inlet pipe 5 communicates with the inlet chamber 17, and several natural gas injection holes 3 are evenly arranged in a ring shape between the air inlet chamber 17 and the air inlet channel 11, and the several natural gas injection holes 3 are connected with the air inlet chamber 17. The air intake chamber 17 communicates with the air intake passage 11, and the mixer 4 is equipped with a regulating valve 1, the regulating valve 1 includes a valve body 12, and the valve body 12 is provided with a regulating valve communicating with the air intake passage 11 Air intake passage 8, the air intake passage 8 of the regulating valve is provided with a valve plate 9 for adjusting the intake air volume, the valve plate 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com