Dual utilization device and method for exhaust steam waste heat produced during superheat steam drying of sludge

A superheated steam and sludge technology, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of high system safety requirements, waste of energy, large energy loss, etc., to achieve Large heat and mass transfer coefficient, prevent moisture content increase, and increase added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

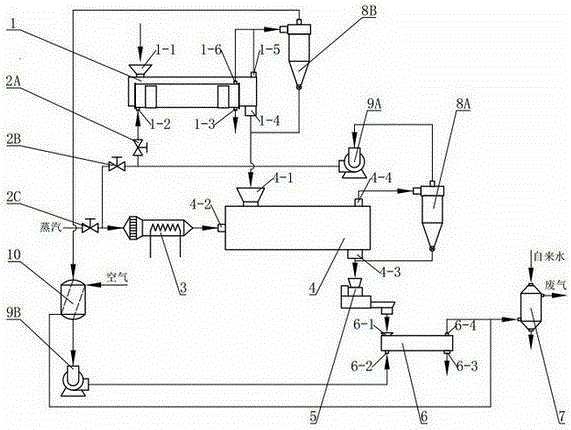

[0032] Such as figure 1 As shown, a sludge superheated steam drying exhaust steam waste heat dual utilization device, including shaftless screw feeder 1, air valves (2A, 2B, 2C), heater 3, double-shaft stirring dryer 4, sludge granules Forming machine 5, mesh belt dryer 6, tail gas scrubber 7, cyclone separator (8A, 8B), fan (9A, 9B), heat exchanger 10. The shaftless screw feeder 1 is provided with a material inlet 1-1, a material outlet 1-4, and a steam exhaust port 1-5. There is a jacket on the outer layer of the shaftless screw feeder 1, and the jacket is provided with a jacket steam inlet. 1-2. Condensed water outlet 1-3 and jacket steam outlet 1-6; shaftless screw feeder 1 outlet 1-4, cyclone separator 8B outlet and double-shaft stirring dryer 4 feed at the same time The port 4-1 is connected, the discharge port 4-3 of the double-shaft stirring dryer 4, and the disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com