Screw type pneumatic drying machine and method

A technology of airflow drying and drying equipment, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve many problems, achieve the effects of reducing centrifugal force, prolonging the drying process, and improving sludge drying efficiency

Inactive Publication Date: 2011-06-15

SOUTHEAST UNIV

View PDF1 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, there are various types of drying devices, but due to the viscosity of sludge itself and its inherent characteristics, there are not many drying devices that can be directly applied to sludge drying

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

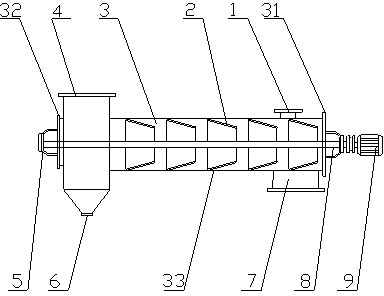

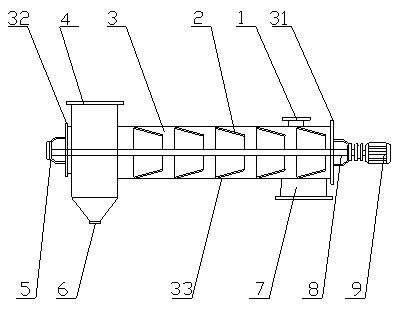

The invention relates to a screw type pneumatic drying machine and method. The screw type pneumatic drying machine comprises an airtight drying machine body (3), wherein the drying machine body (3) comprises a first end part (31), a second end part (32) and a shell (33); the first end part (31) and the second end part (32) are oppositely arranged, and the first end part (31); the first end part (31) and the second end part (32) are connected through the shell (33); and the second end part (32) and the shell (33) form an airtight working space. The drying machine also comprises a screw propulsion unit (2), a wet sludge feed port (1), high temperature smoke inlet (7) and a low temperature smoke outlet (4), wherein the screw propulsion unit (2) is installed in the working space; the wet sludge feed port (1) and the high temperature smoke inlet (7) are respectively arranged on the drying machine body (3); and the low temperature smoke outlet (4) is arranged on the drying machine body (3) and penetrates through the shell (33). The device and method are suitable for drying sludge, and have the advantages that the operation is continuous, the labor intensity is low, and the heat consumption is low.

Description

Spiral airflow drying device and method technical field The invention relates to a drying device and a drying method for sludge disposal. Background technique Sludge is the product of sewage treatment. Due to its high water content, complex composition, and more organic matter, it has a certain viscosity. At present, the disposal methods of sludge are mainly landfill and composting. Landfill disposal method will occupy a large amount of land resources and easily cause secondary pollution. According to the methods of sterilization and aging, compost has different fertilizer efficiency and safety. This disposal method can achieve the purpose of recycling, but the processing process is longer, and it will also occupy a large amount of land resources, and the disposal cost is also high; in addition, Sludge containing harmful components such as heavy metals should not be disposed of in this way. After drying, the sludge can be greatly reduced, harmless and resourceful. The ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F11/12

Inventor 鲁维加郭宏伟

Owner SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com