An environmentally friendly coal-fired boiler with staged combustion and its treatment method

A technology of a coal-fired boiler and a treatment method, which is applied in the combustion method, combustion air/fuel supply, combustion equipment, etc., can solve the problems of black smoke, insufficient smoke elimination, and increased emission concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

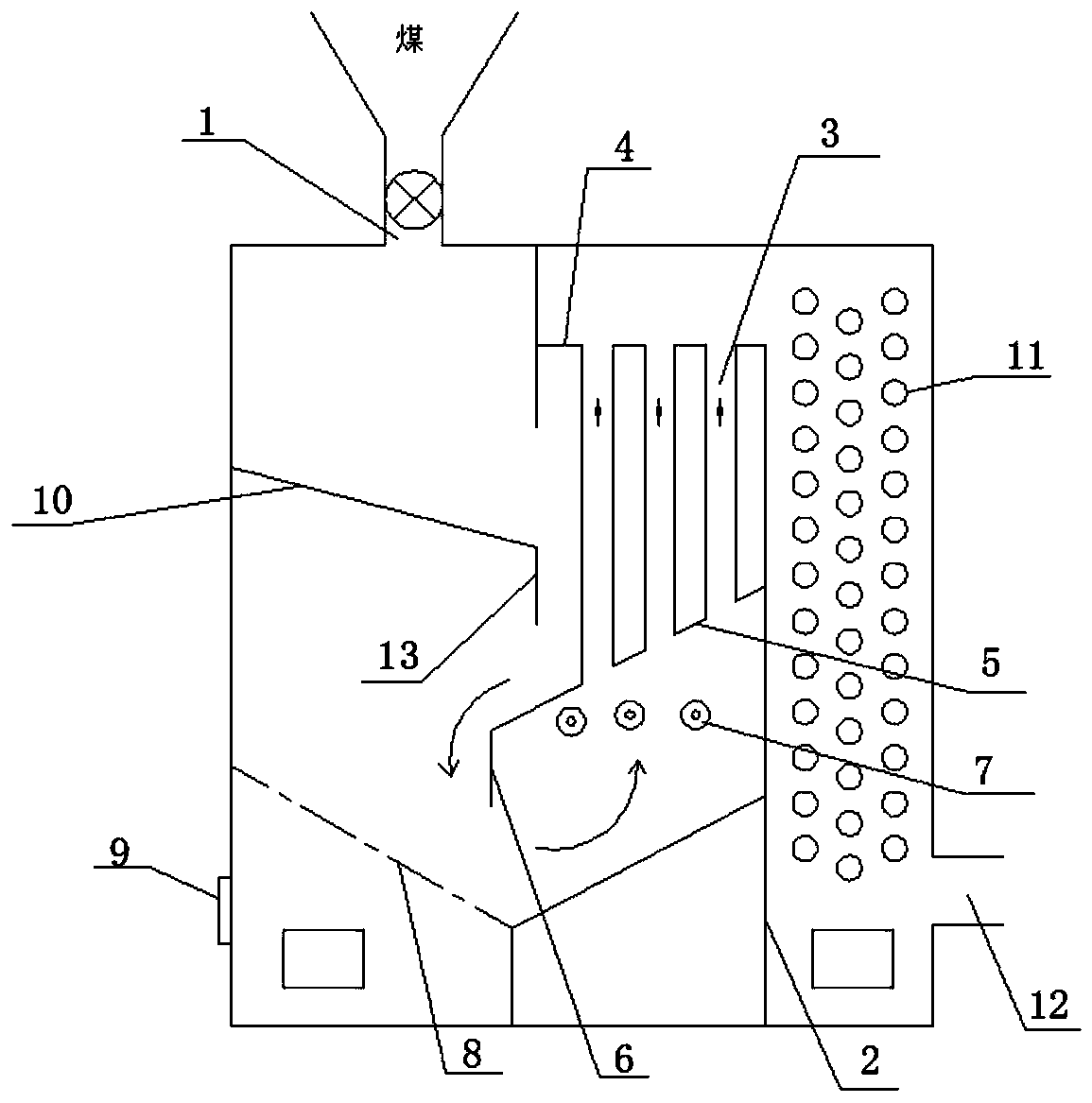

[0078] This embodiment provides a coal-fired boiler with staged combustion, such as figure 1 As shown, the coal-fired boiler includes a furnace body and a furnace. A coal filling port 1 is provided on the top of the first chamber in the furnace body. The plate 2 divides the inner area of the furnace into two chambers connected at the top, which are respectively the first chamber and the second chamber;

[0079] Among them, in the upper part of the first chamber, 3 to 4 rows of fire tubes 3 are arranged on the side 2 of the first longitudinal partition, and the tops of the fire tubes 3 are fixed to the first longitudinal partition 2 and the furnace roof through the first partition 4 with holes. , the bottom of the fire tube 3 is fixed on the first longitudinal partition 2 through the second partition with holes 5, the second partition with holes 5 is inclined to the bottom of the furnace and is 65° with the first longitudinal partition 2; the second partition with holes One ...

Embodiment 2

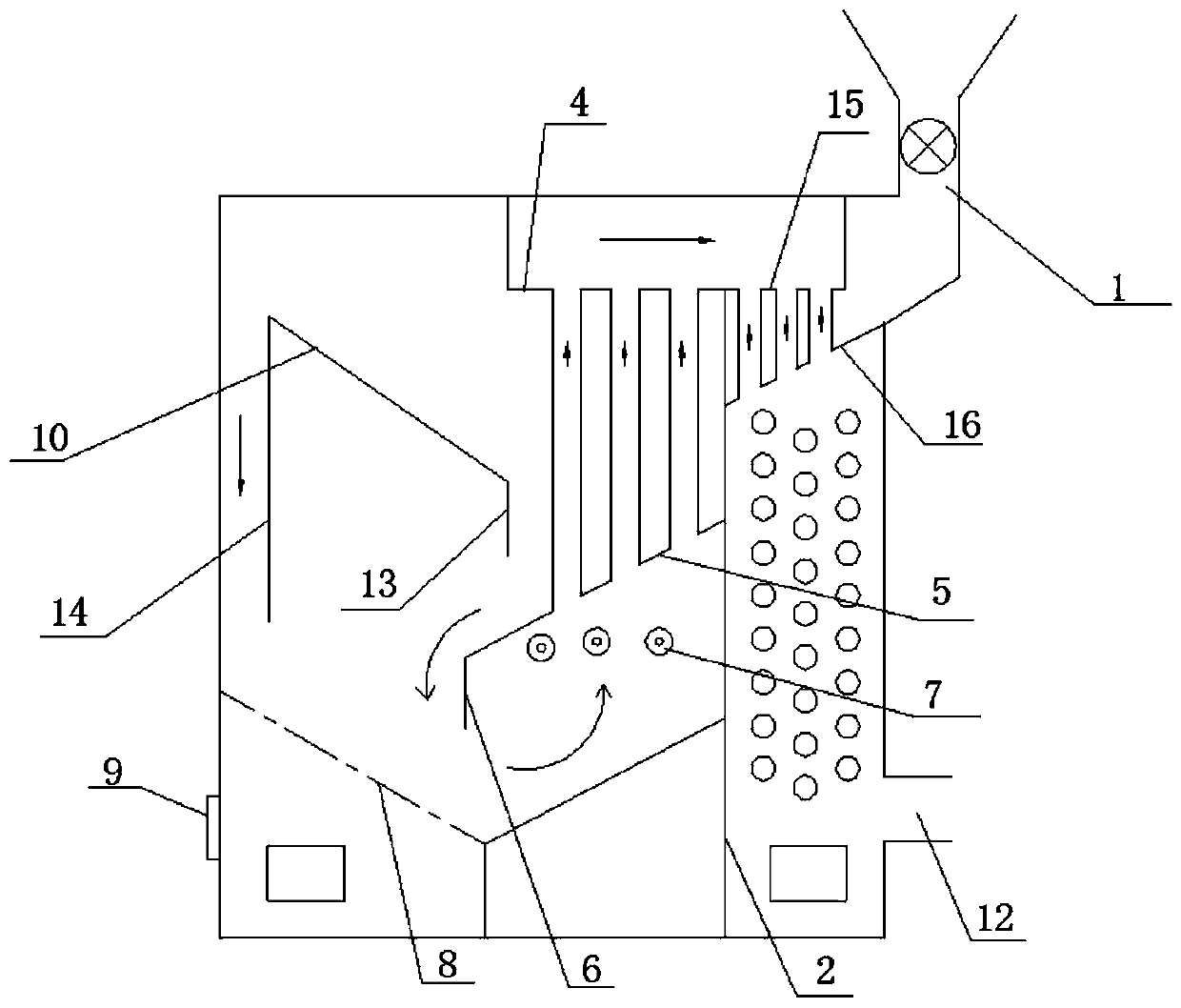

[0088] This embodiment provides a coal-fired boiler with staged combustion, such as figure 2 As shown, the coal-fired boiler includes a furnace body and a furnace. A coal filling port 1 is provided on the top of the first chamber in the furnace body. The plate 2 divides the inner area of the furnace into two chambers connected at the top, which are respectively the first chamber and the second chamber;

[0089] Among them, in the upper part of the first chamber, there are 3 to 4 rows of fire tubes 3 on the side of the first longitudinal partition 2, and the tops of the fire tubes 3 are fixed to the first longitudinal partition 2 and the furnace roof through the first partition 4 with holes. , the bottom of the fire tube 3 is fixed on the first longitudinal partition 2 through the second partition with holes 5, the second partition with holes 5 is inclined to the bottom of the furnace and is 60° with the first longitudinal partition; the second partition with holes The end ...

Embodiment 3

[0099] This embodiment provides a coal-fired boiler with staged combustion. The structure of the coal-fired boiler refers to the structure in Embodiment 2, the difference is that the top of the first inclined partition 10 is fixed on the furnace wall away from the first longitudinal partition 2 Above, the second perforated partition 5 is inclined to the bottom of the furnace and is 70° to the first longitudinal partition, the first inclined partition 10 is inclined to the lower part of the furnace body and is 20° to the furnace wall, and the fourth perforated partition is The plate 16 is inclined to the side of the first longitudinal partition 2 and forms an angle of 20° to the first longitudinal partition 2 .

[0100] The treatment method of the coal-fired boiler refers to the method in Example 2, the only difference is that the temperature of pyrolysis and gasification in step (a) is 700°C, the temperature of coke combustion in step (b) is 950°C, and the temperature of semi-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com