Swirl spouting device for drying sludge

A sludge drying and drying technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of low drying rate, easy leakage of air, increased deflagration, etc., to reduce the possibility of sticking to the wall and keep the device airtight Good performance and reduce airflow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

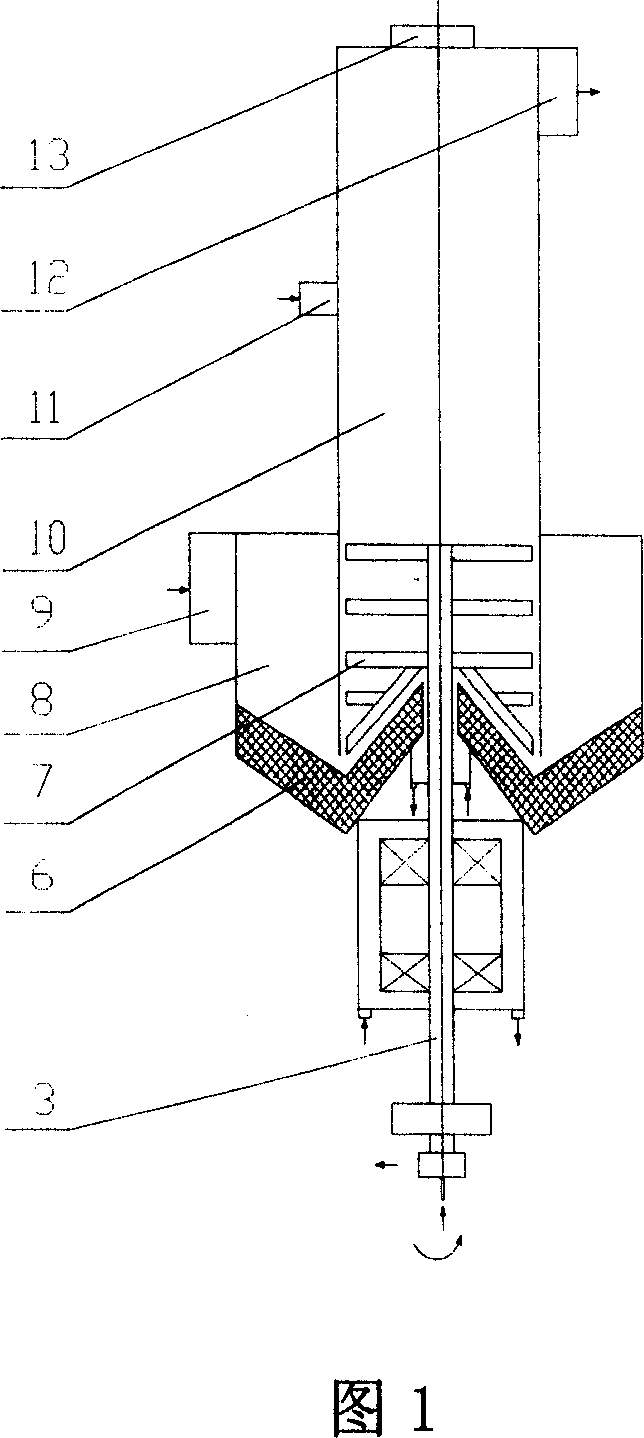

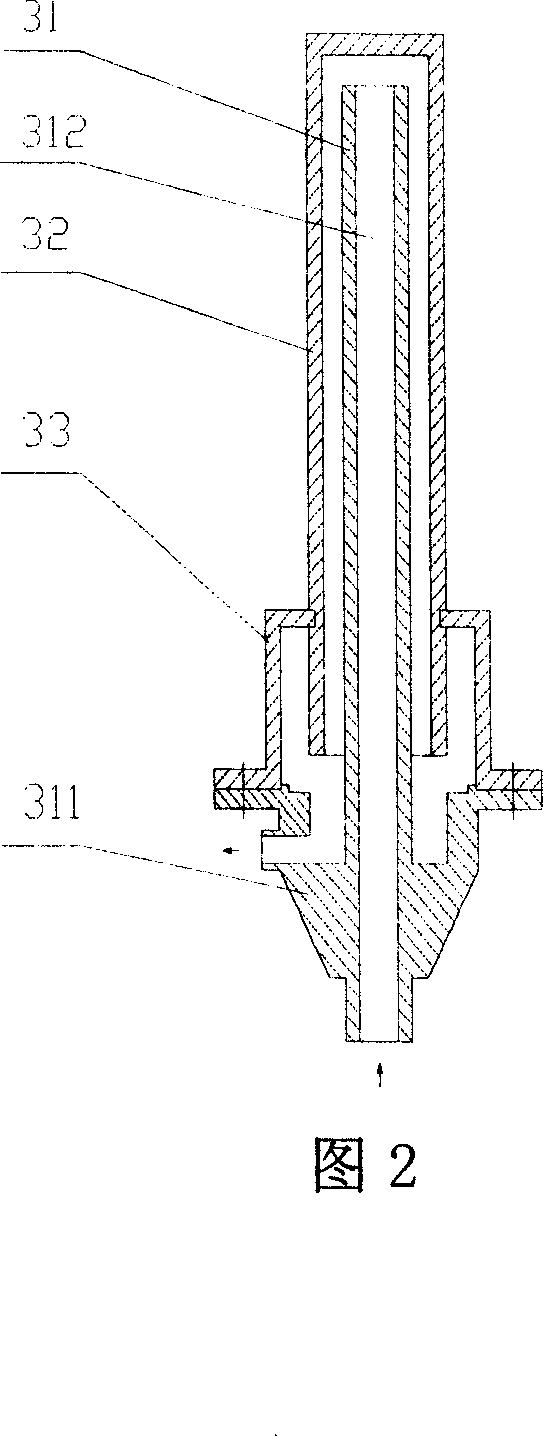

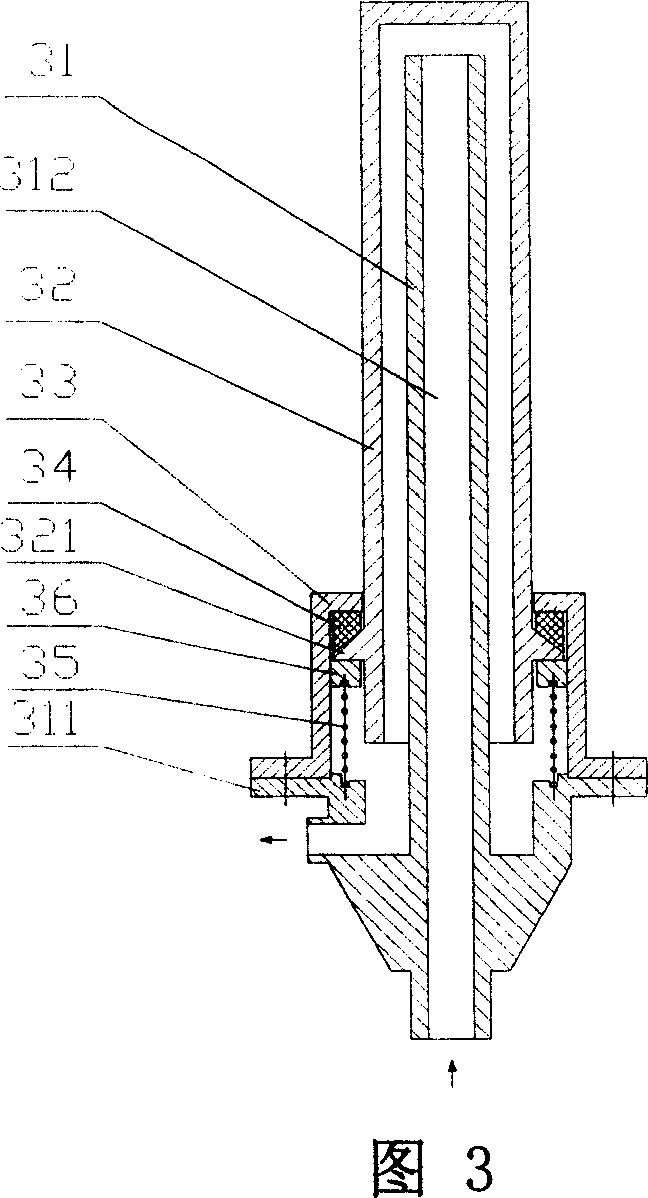

[0018] A swirling spray device for sludge drying, which is composed of a main tower body 10, a wind chamber 8, a transmission shaft 3 and a drying stirring blade 7. The wind chamber 8 is arranged in the lower part of the main tower body 10, and the drying stirring blade 7 Set on the drive shaft 3, the main tower body 10 is provided with a feeding port 11 and an exhaust port 12, and an air inlet 9 is provided on the air chamber 8. The axial section of the bottom surface of the air chamber 8 is "W"-shaped, The air inlet 9 is a tangential air inlet, the main tower body 10 is located above the "W" shaped bottom of the wind chamber 8 and the lower part of the main tower body 10 extends into the wind chamber 8, and the exhaust port 12 is the same as the air inlet 9 A tangential exhaust port that rotates in a forward direction. The transmission shaft 3 is composed of a central inner shaft 31, a central outer shaft 32 and a connecting sleeve 33. The central outer shaft 32 is sleeved outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com