Automatic dust removal board type falling film generation device utilizing waste heat of exhaust gas

A flue gas waste heat generation device technology, applied in the direction of generator/analyzer, lighting and heating equipment, refrigeration components, etc., can solve the problem of increasing heat transfer resistance, reducing the heat transfer performance of falling film tubes, and affecting the overall performance of generators. Performance and other issues, to achieve the effect of preventing falling film dry pipe, enhancing liquid film disturbance, and increasing driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

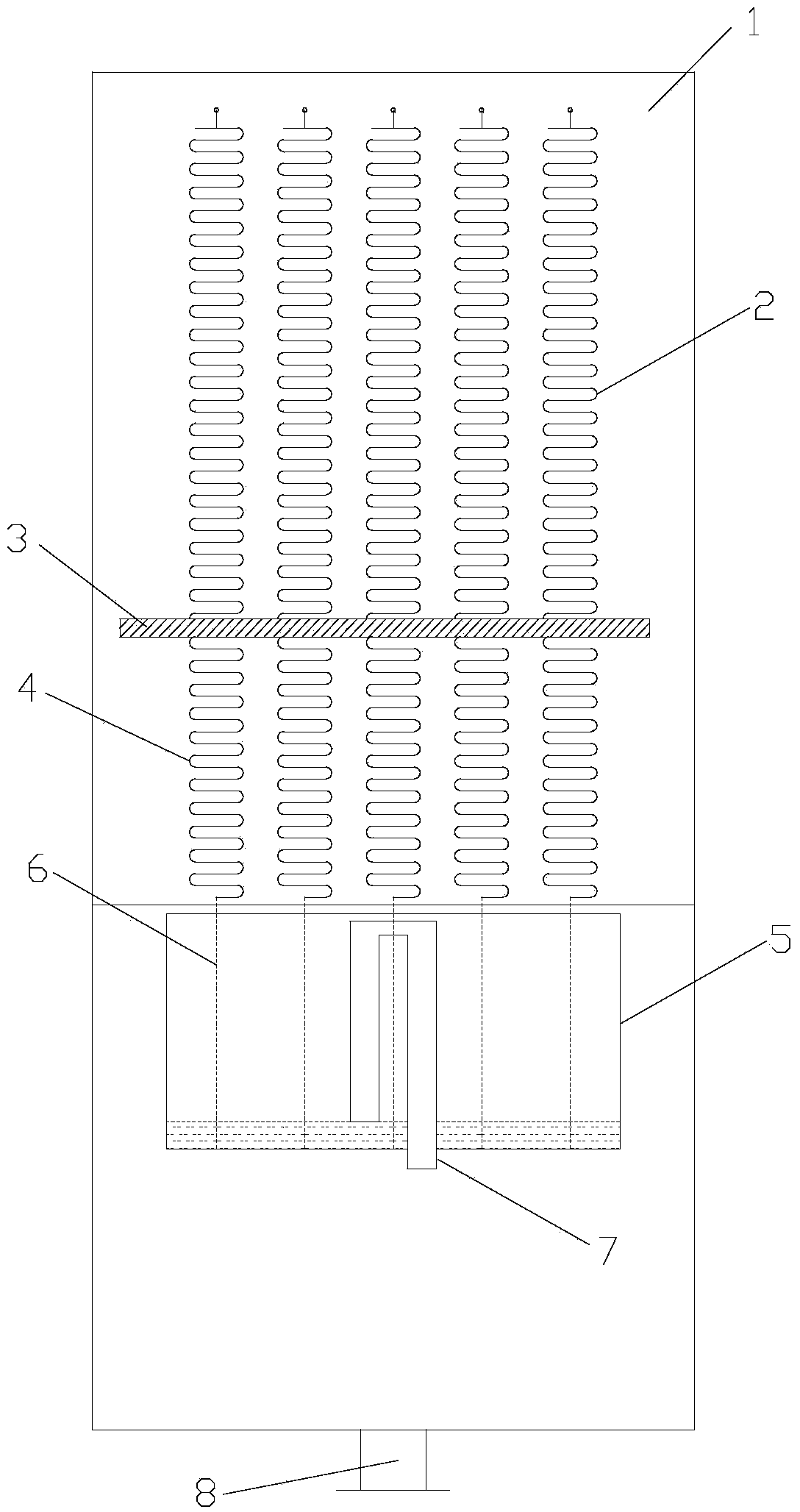

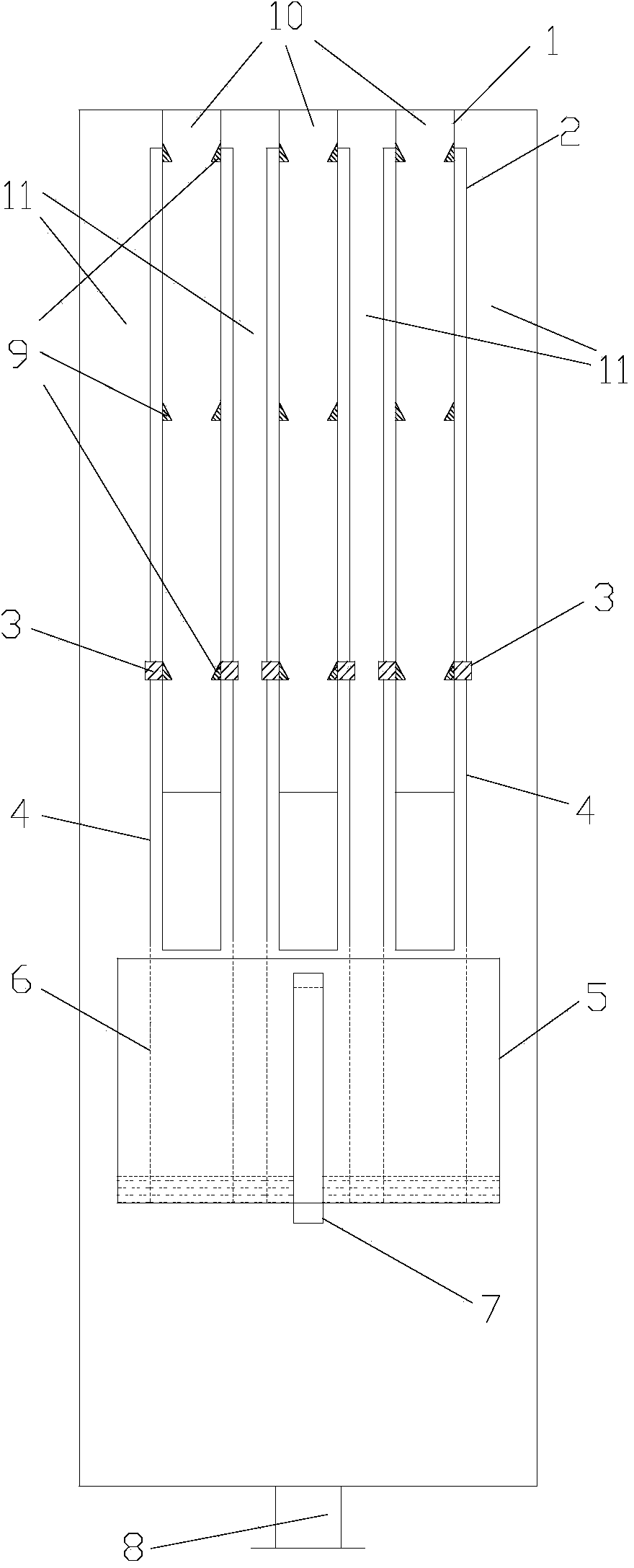

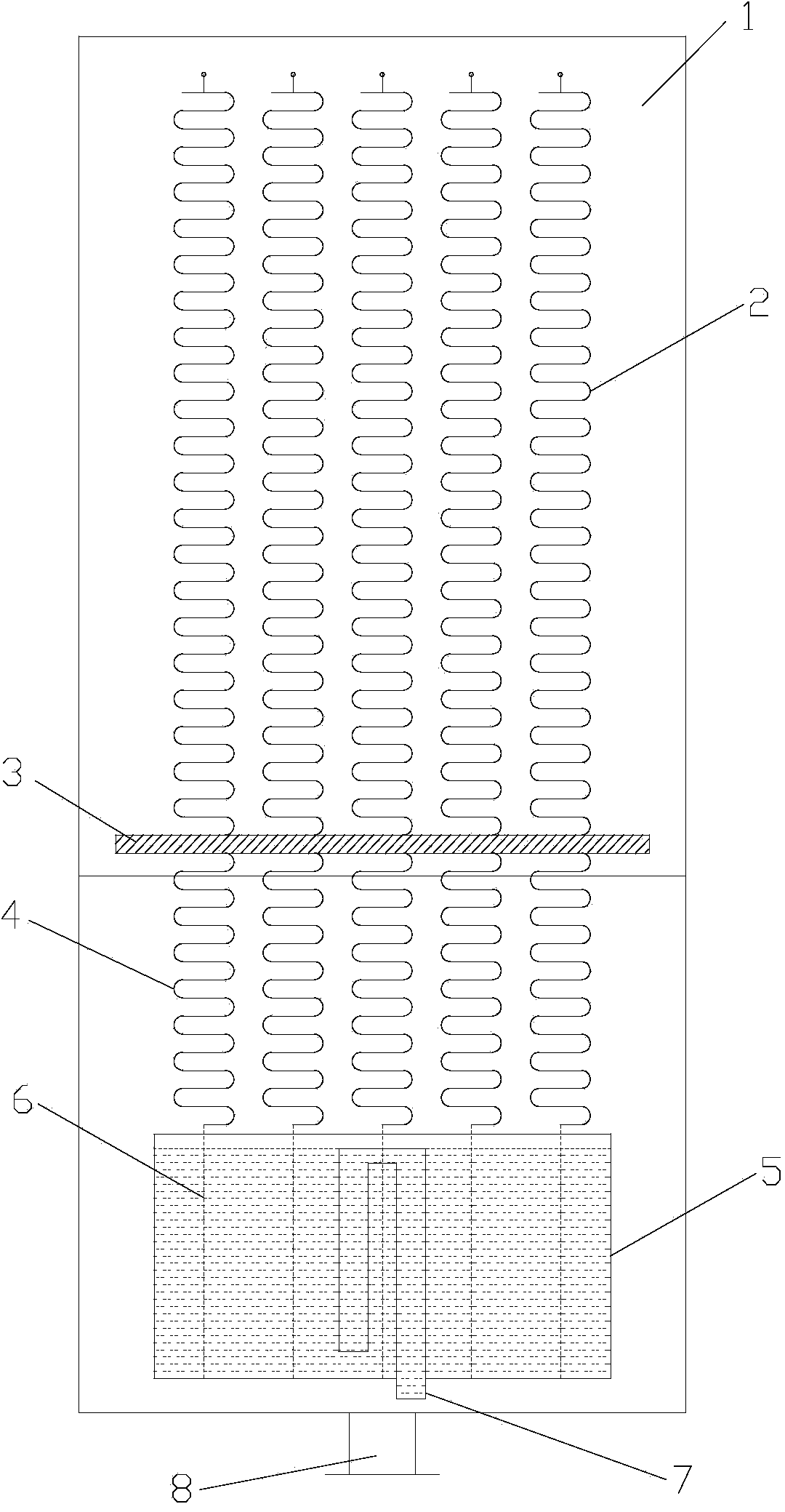

[0026] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] like Figure 1 to Figure 8 As shown, the automatic ash removal plate-type falling film generating device utilizing flue gas waste heat of the present invention includes a housing, n falling film units located in the housing, a suspended liquid contact box 5 , a suspension wire 6 and a siphon 7 . A solution outlet 8 is provided at the bottom of the housing. Each falling film unit includes a falling film plate 1 , an upper S-shaped planar spring 2 , a lower S-shaped planar spring 4 , a bar magnet 3 and a dust scraping device 9 . The falling film plate 1 in the n falling film units divides the inner cavity of the upper part of the casing into a flue gas heat source layer 10 and a solution layer 11 arranged at intervals. In each falling film unit, the upper S-shaped planar spring 2 , the lower S-shaped planar spring 4 and the bar magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com