Ammonia water absorption refrigerator absorber for improving ammonia water falling film type absorption performance

An absorption performance, falling film technology, applied in the field of absorbers for ammonia absorption refrigerators, can solve the problem of large concentration difference of saturated solutions, achieve enhanced cooling effect, increase gas-liquid contact area, and improve the efficiency of mass transfer in liquid. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] DETAILED DESCRIPTION OF THE PREFERRED Here in the following view will be described below.

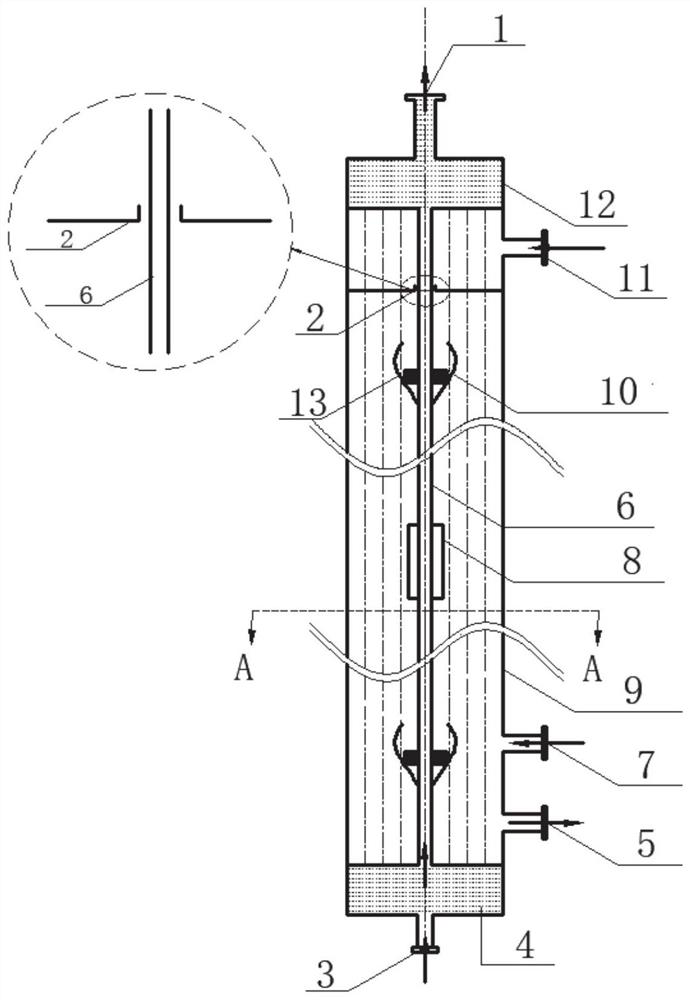

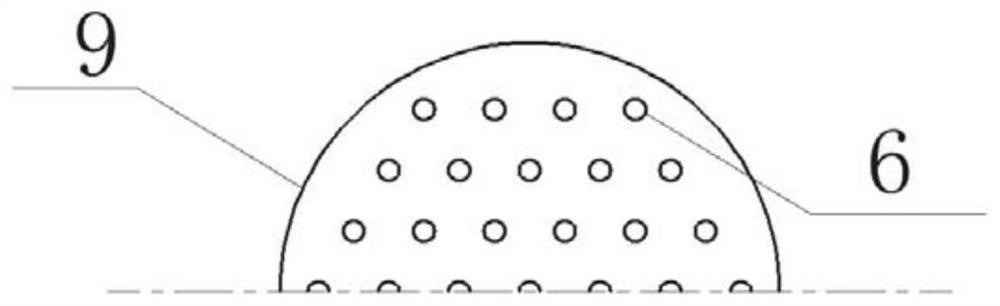

[0030] Such as figure 1 with figure 2 As shown, the ammonia water absorption refrigerator absorber absorbent absorption refrigerator of this embodiment, including the housing 9, and the casing 9, and the outer portion of the refinement tube 6 forms absorption liquid and ammonia. The gas reverse flowing pathway, the cooling water passage is formed inside the refining film 6, and the cooling water is reversed in the absorbent liquid;

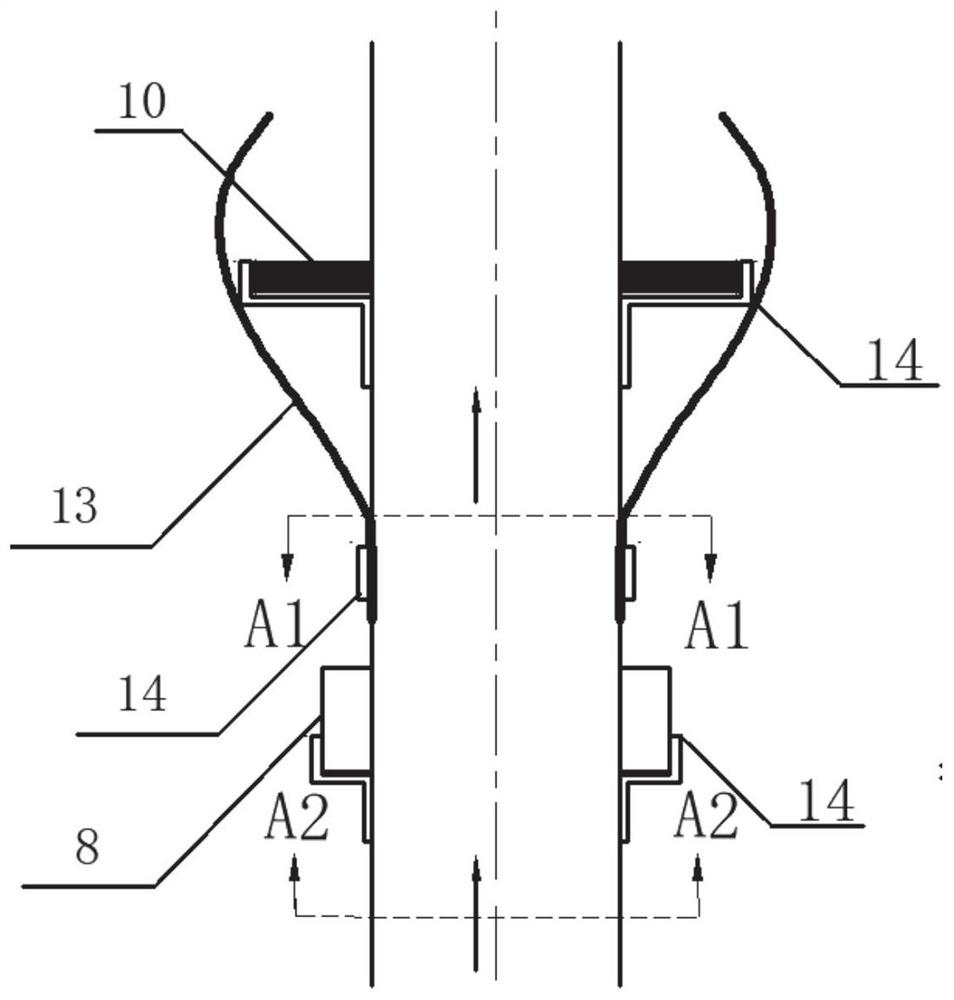

[0031] A plurality of ultrasonic nebulizers 10 are provided at the flow direction of the absorbing liquid in the outer wall of each of the films 6.

[0032] The ultrasonic atomizer 10 produces high-frequency oscillating, and the solution flowing through the outer wall of the refining tube 6 becomes a fine droplet and diffuses to each of the cavities formed from the casing 9 and the casing 9.

[0033] As an embodiment, the outer wall of each of the film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com