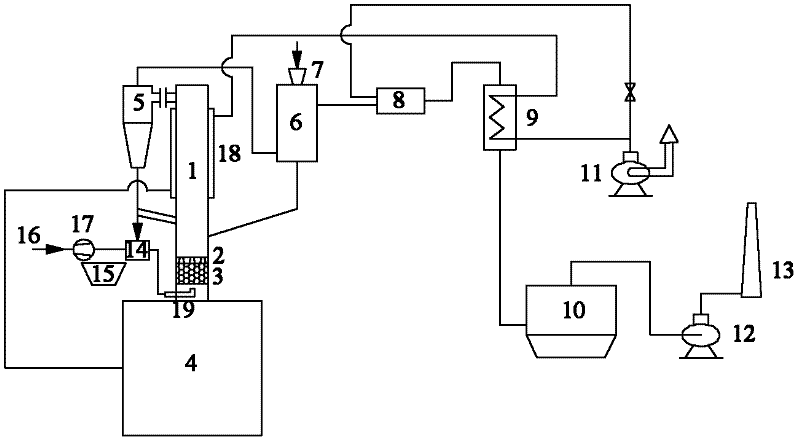

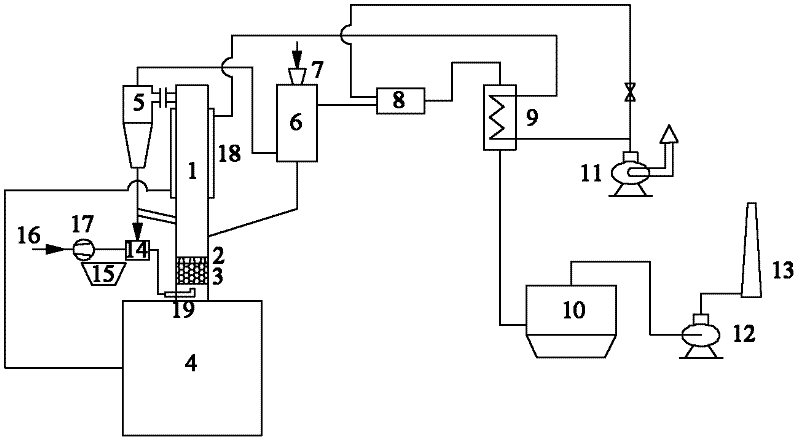

Refractory poor iron ore pulsating fluidized bed magnetizing roasting device and roasting method

A magnetized roasting and fluidized bed technology, which is used in the chemical and metallurgical fields, can solve the problems of wide residence time distribution of iron ore powder, reduce the reaction time and the volume of the roaster reactor, narrow the residence time distribution, and save fixed time. effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A pulsating fluidized bed magnetic roasting method for refractory lean iron ore, the method is coal gas, for example, the calorific value is greater than 850Kcal / Nm 3 The blast furnace gas, coke oven gas or coal gasification gas is compressed by the gas compressor 17 and preheated by the iron concentrate cooler 14, and the preheated air from the gas-gas heat exchanger 9 passes through the acoustic decoupling chamber 4 together into the pulsating fluidized bed for partial combustion, and the heat generated makes the temperature of the magnetization roasting reactor reach 500°C to 950°C. In this range, the weakly magnetic Fe 2 o 3 is rapidly reduced to strongly magnetic Fe 3 o 4 , and then high-quality iron concentrate (grade > 70%, iron recovery > 90%) can be obtained by magnetic separation in a weak magnetic field. After the reaction, the high-temperature roasted ore undergoes gas-solid separation through the cyclone separator 5 and enters the iron concentrate cooler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com