Patents

Literature

47 results about "Residence time distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for polishing ion beam with high-gradient mirror surface

InactiveCN101898324ASolve the problems in polishingAchieving Deterministic PolishingOptical surface grinding machinesElectric discharge tubesNumerical controlOptical axis

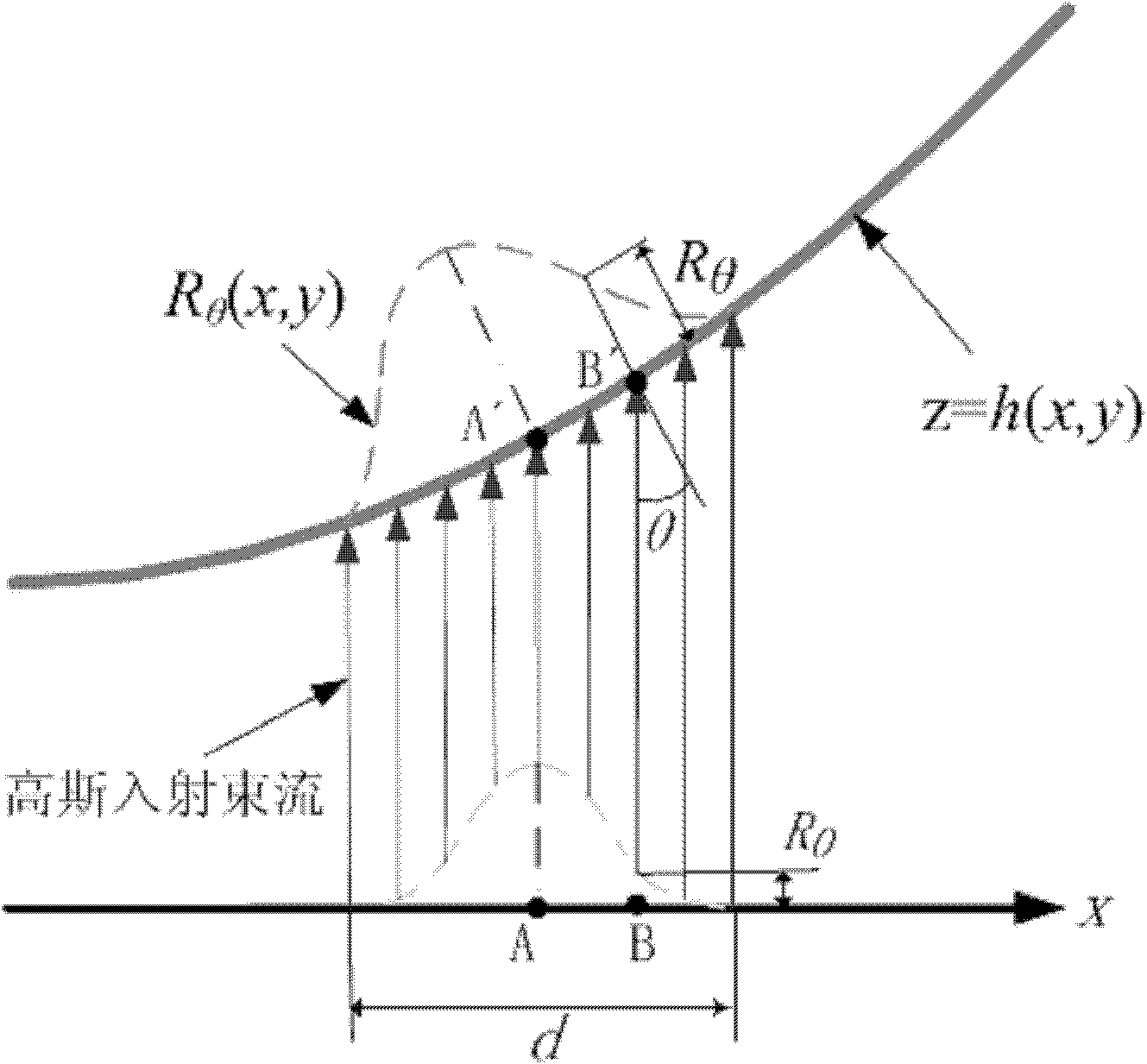

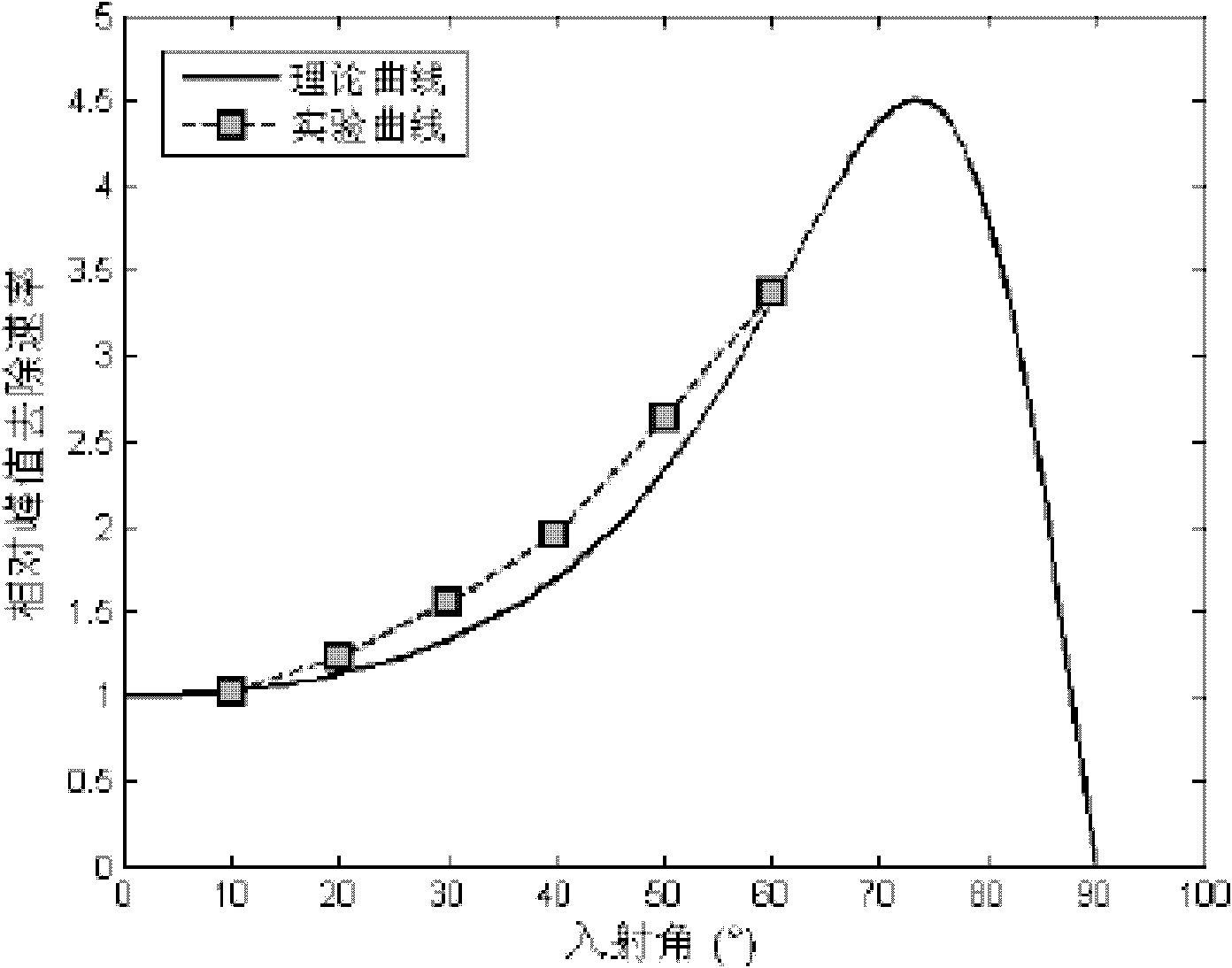

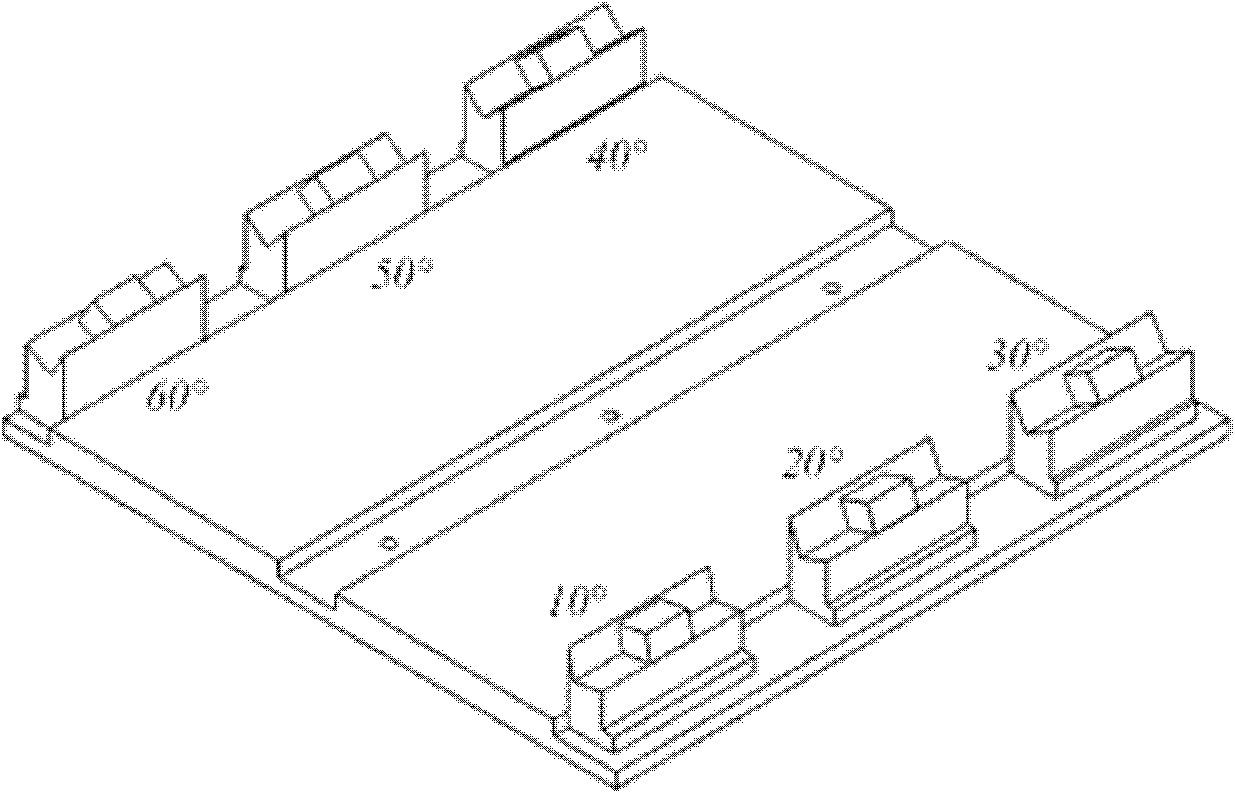

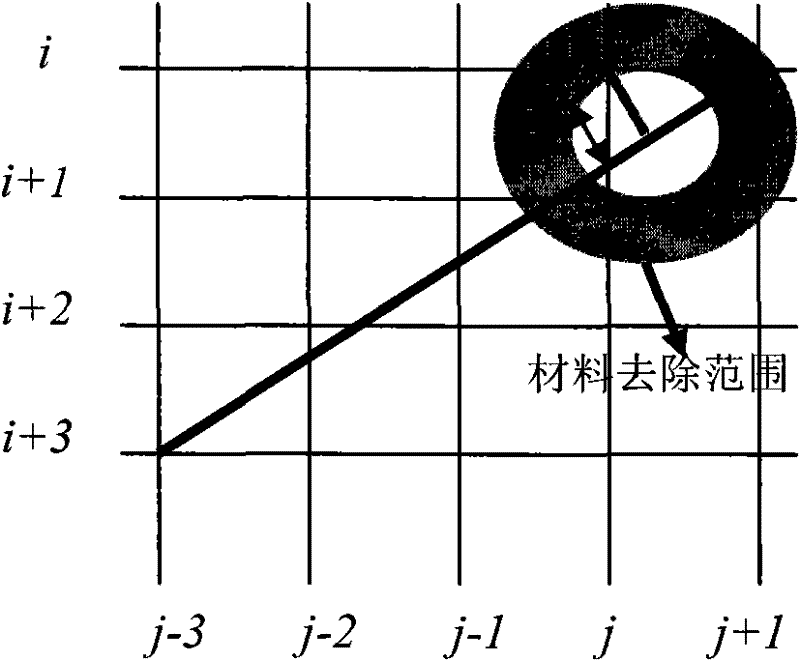

The invention discloses a method for polishing an ion beam with a high-gradient mirror surface. The method comprises the following steps of: (1) measuring incidence angles theta of all points on the mirror surface; (2) confirming a compensation factor K of each point according to a model; (3) measuring an initial surface error E of a workpiece by utilizing interferometry; (4) compensating the E according to the K to acquire a compensation surface error E'; (5) acquiring a removal function R of an ion beam in the vertical incidence of the mirror surface through removal function experiment; (6) confirming residence time distribution T and generating a numerical control code according to E' and R; (7) processing by utilizing a generating device of the removal function and the generated numerical control code, enabling the ion beam to enter the mirror surface along a direction parallel to the optical axis direction of the workpiece in processing and trimming the mirror surface through a triaxiality linkage system; and (8) repeating the steps until the trimming result satisfies the requirement of surface convergence accuracy. The method of the invention has the advantages of simple operation, good stability, high processing accuracy, strong controllability, low requirement for equipment, and the like in processing the high-gradient mirror surface.

Owner:NAT UNIV OF DEFENSE TECH

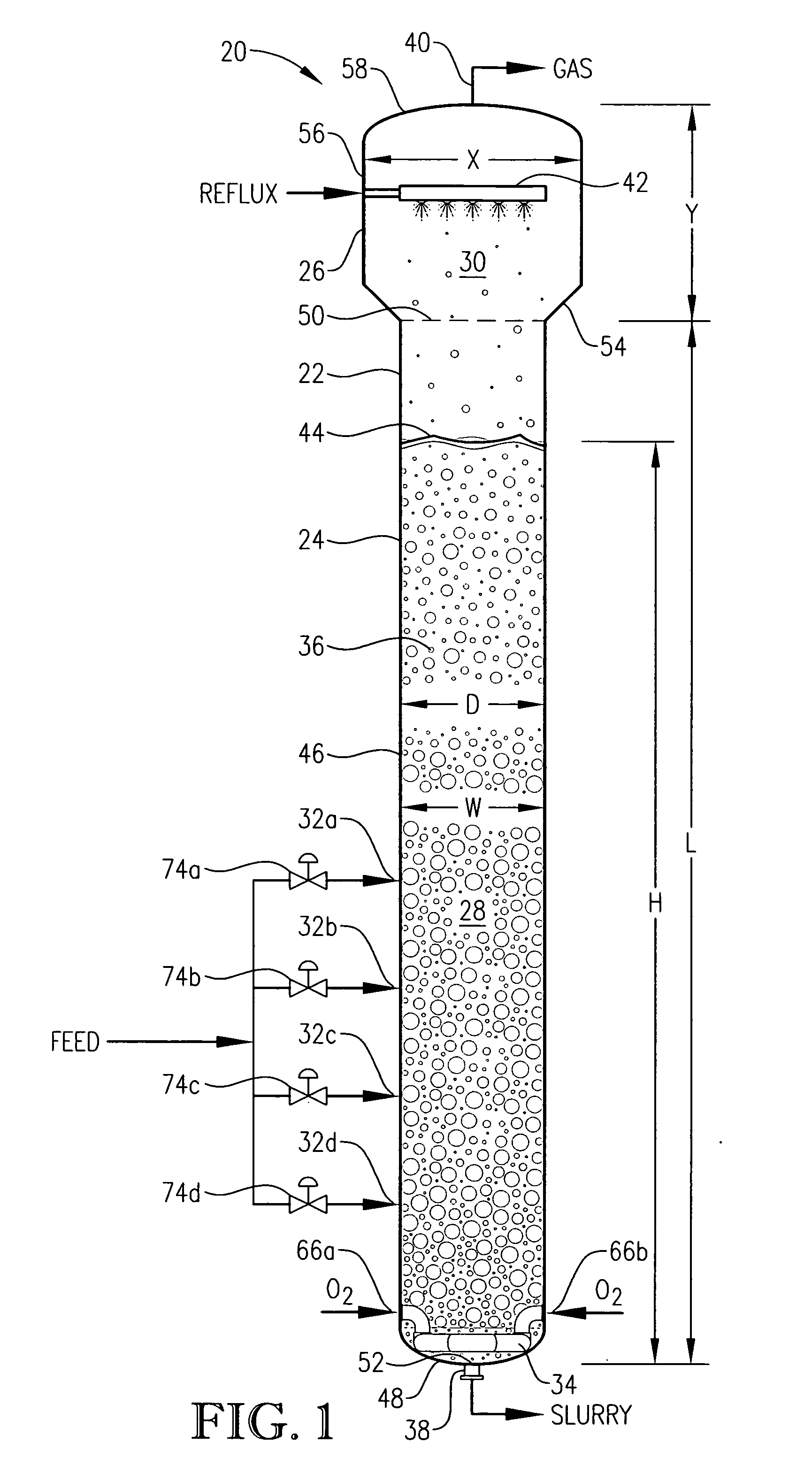

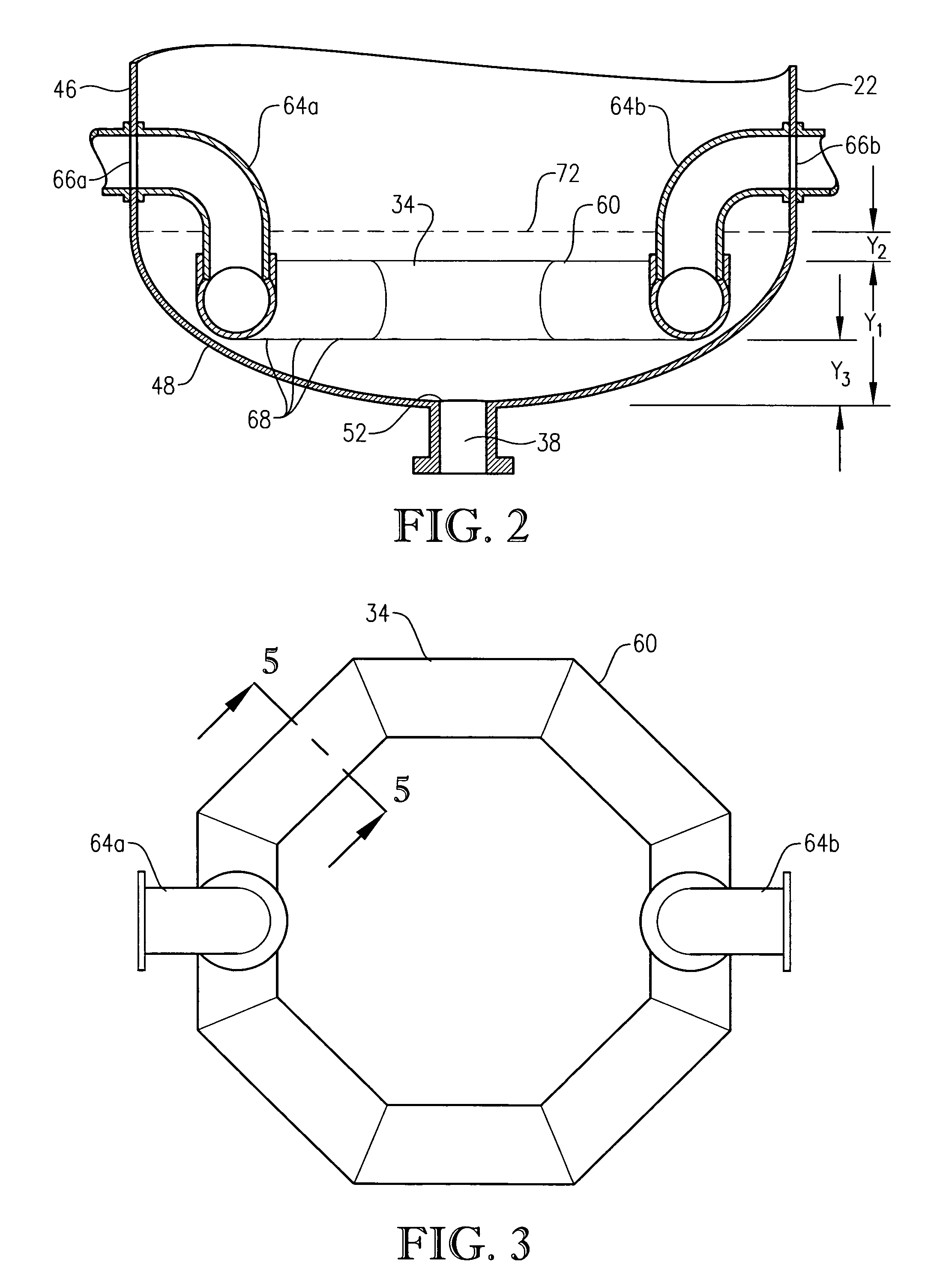

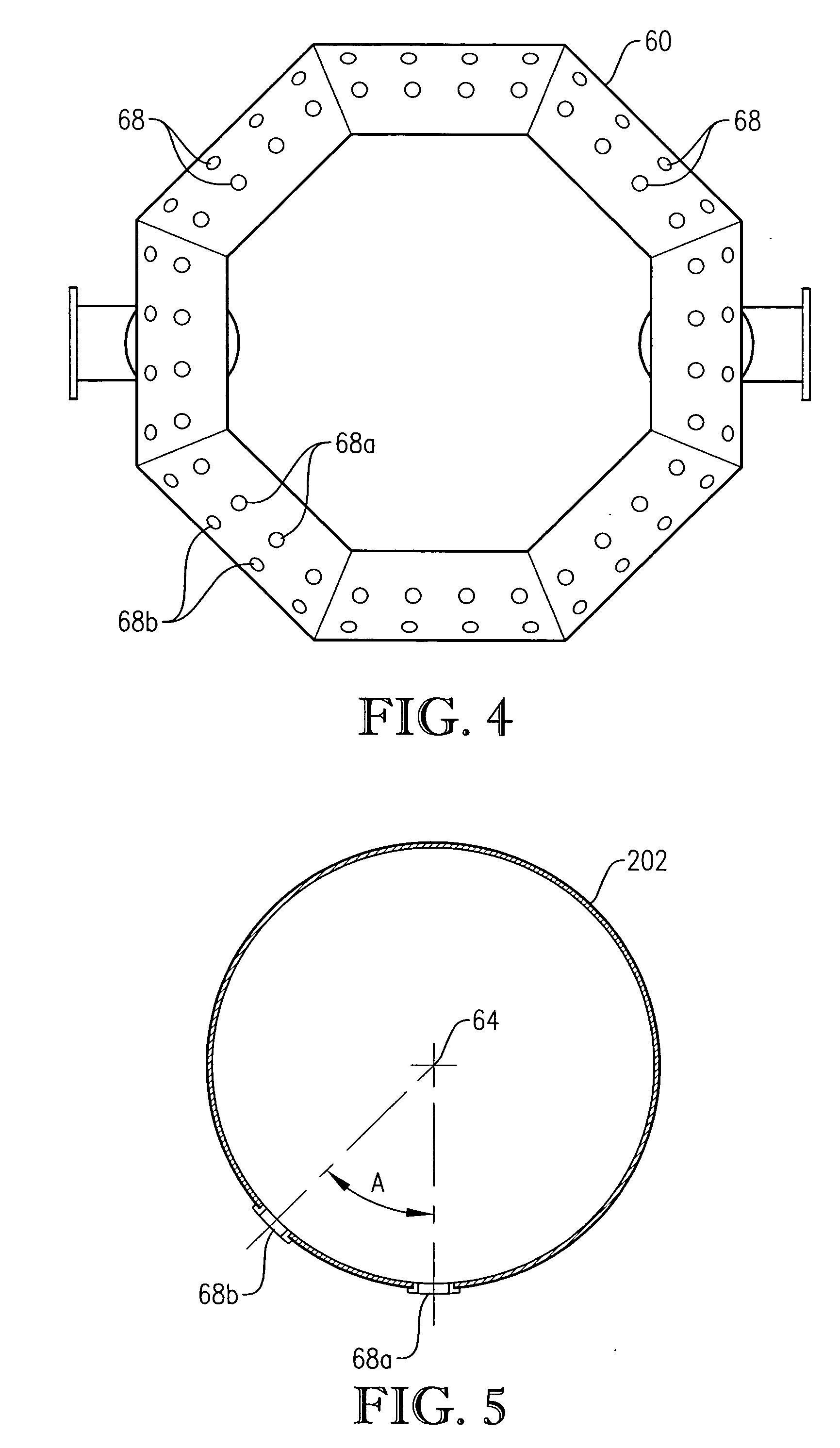

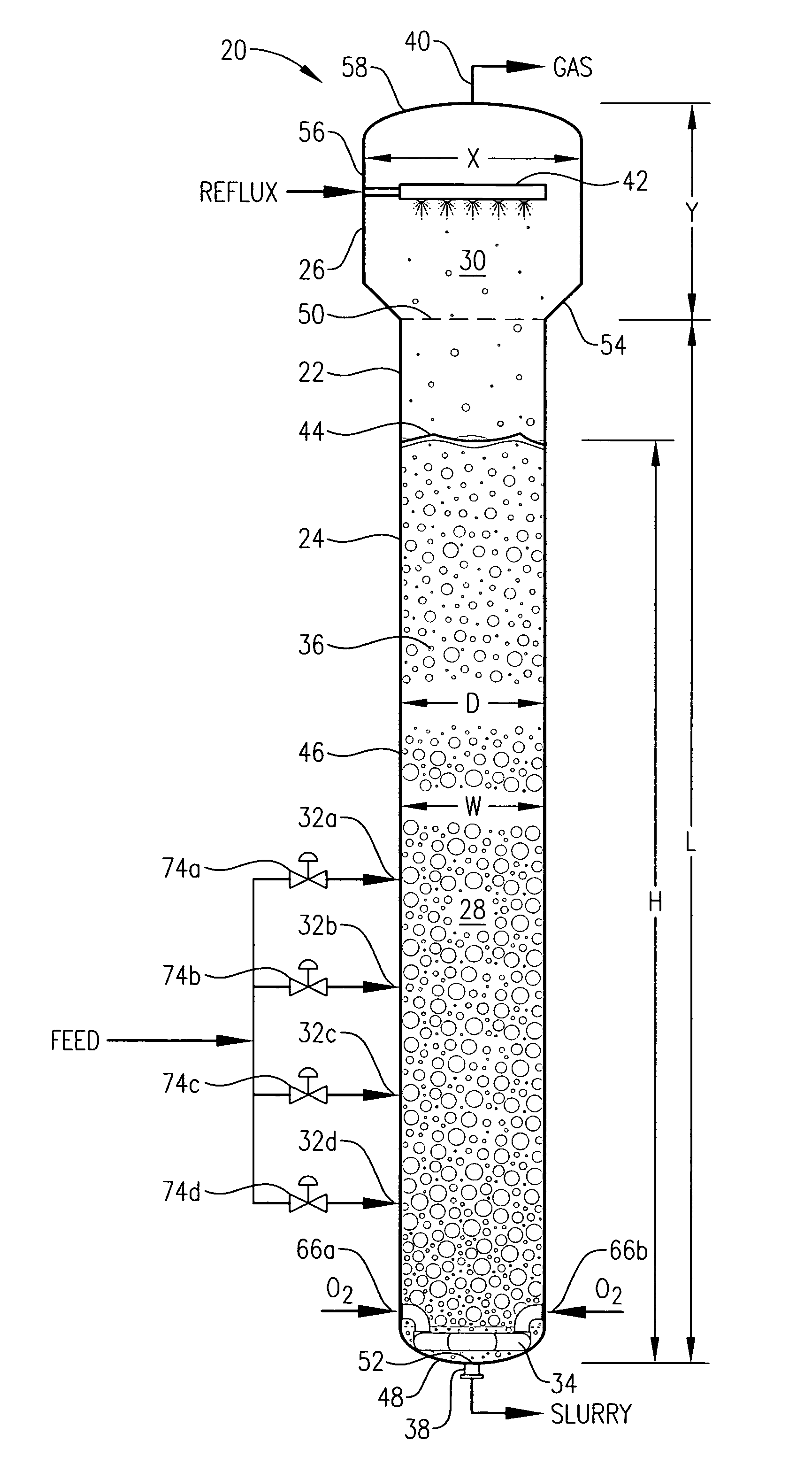

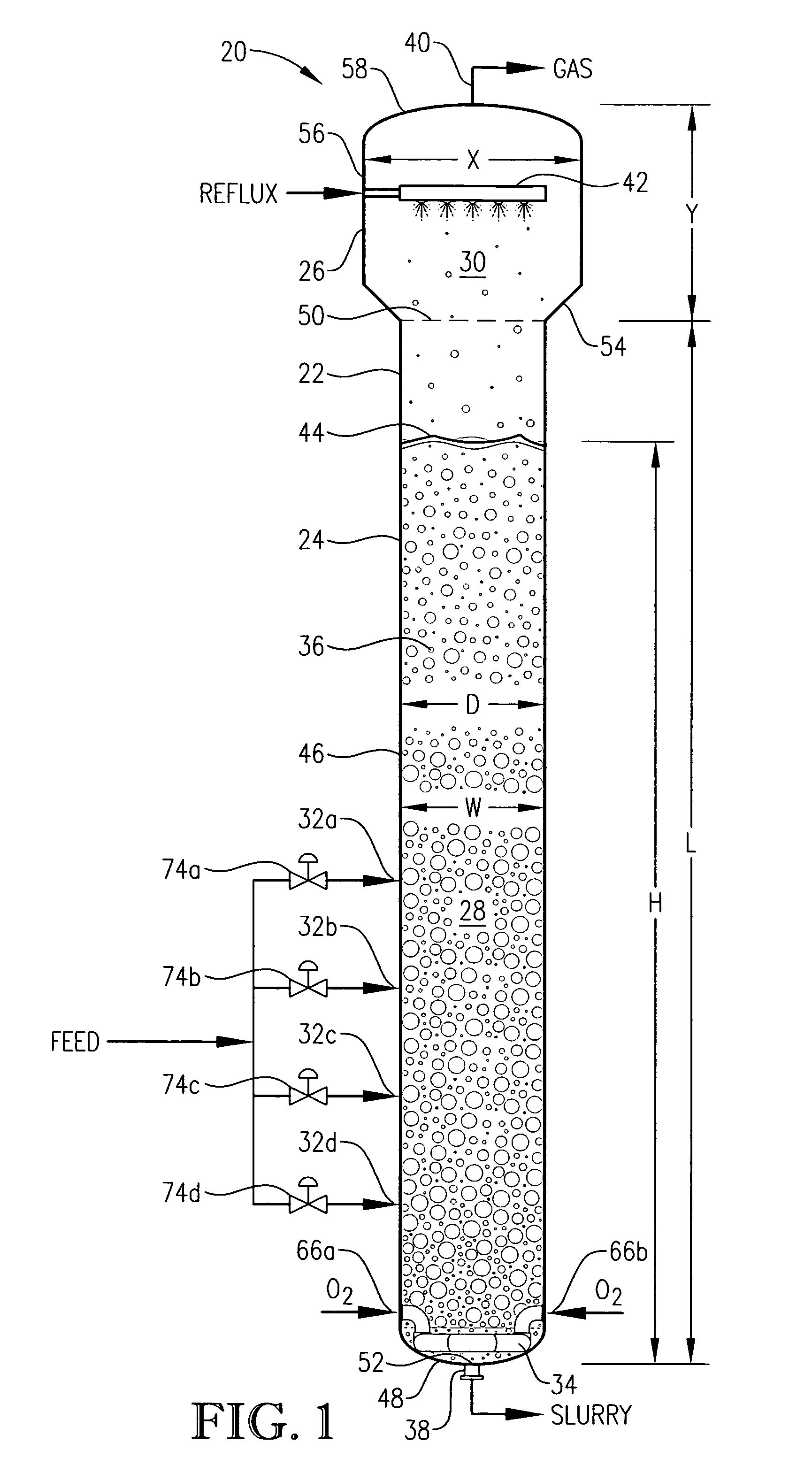

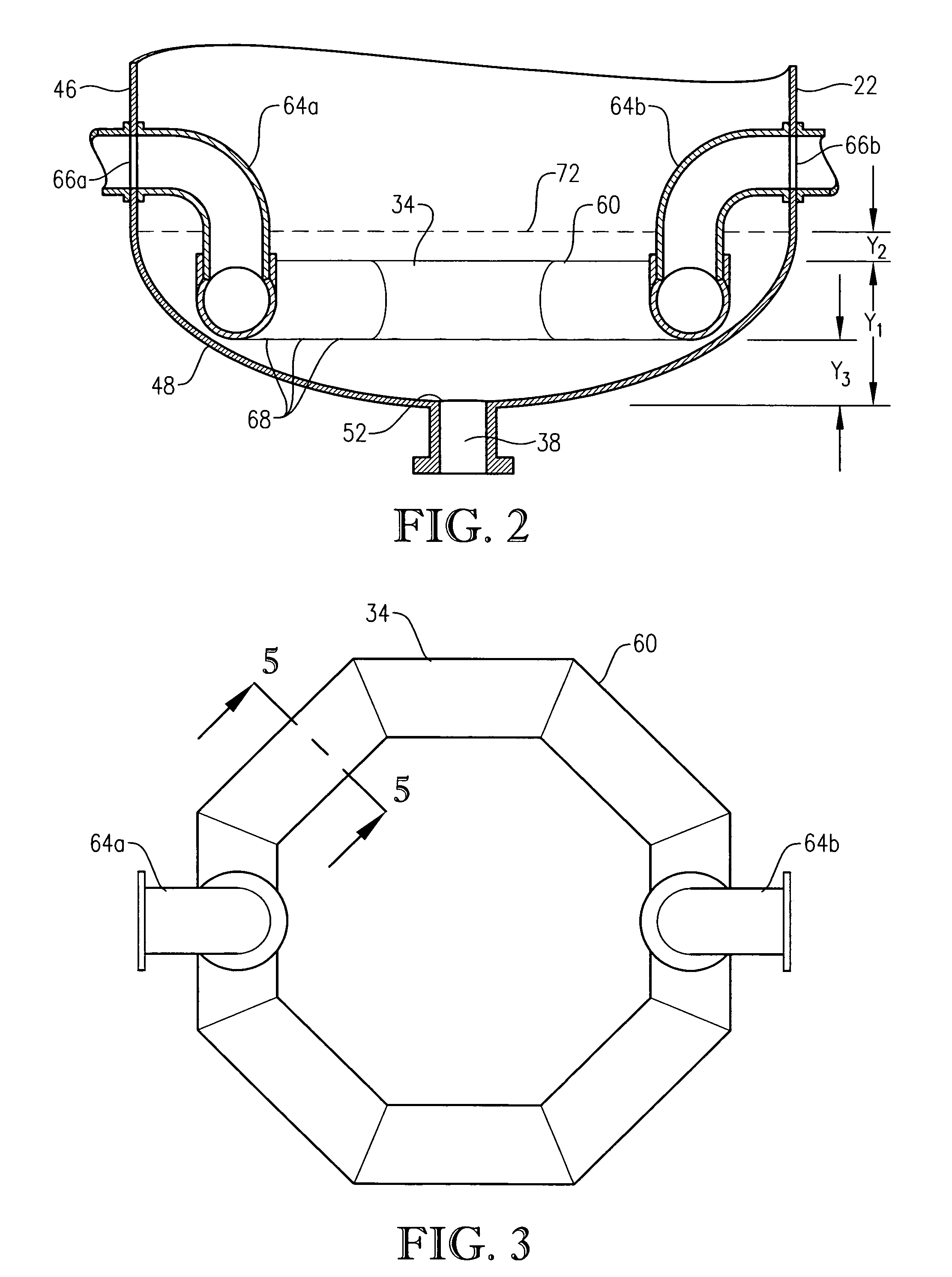

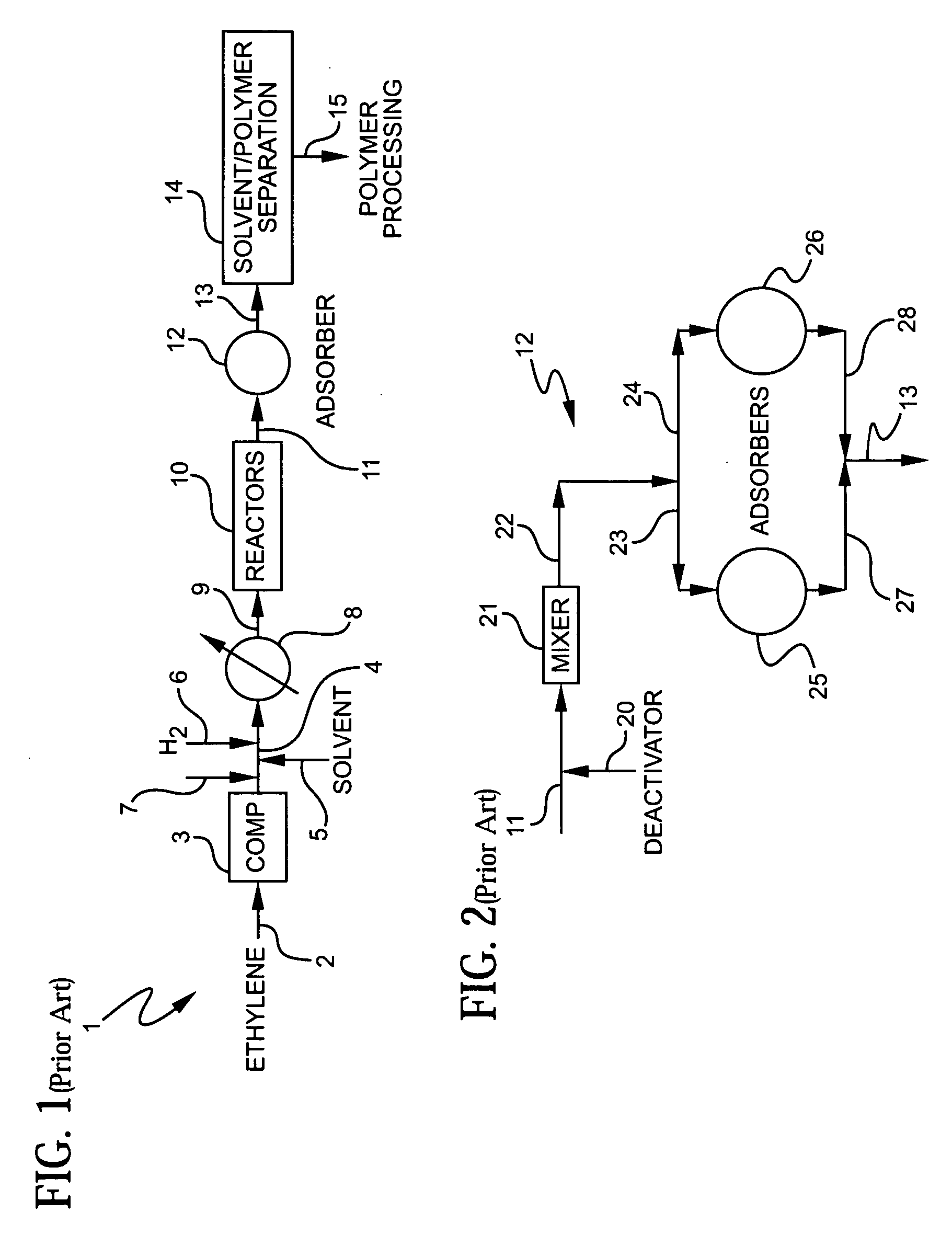

Polycarboxylic acid production system with enhanced residence time distribution for oxidative digestion

ActiveUS20070219393A1Reduce formationPromote oxidationOrganic compound preparationExhaust apparatusDigestionOrganic chemistry

Disclosed is an optimized system for more efficiently and economically producing terephthalic acid. The system includes an oxidative digestion reactor / zone configured to provide optimized residence time distribution for the solid and liquid phases of the reaction medium processed therein.

Owner:ALPEK POLYESTER SA DE CV

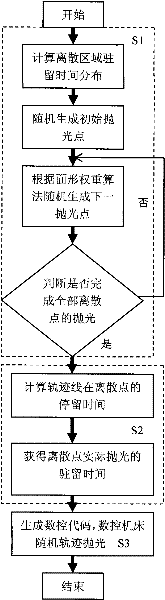

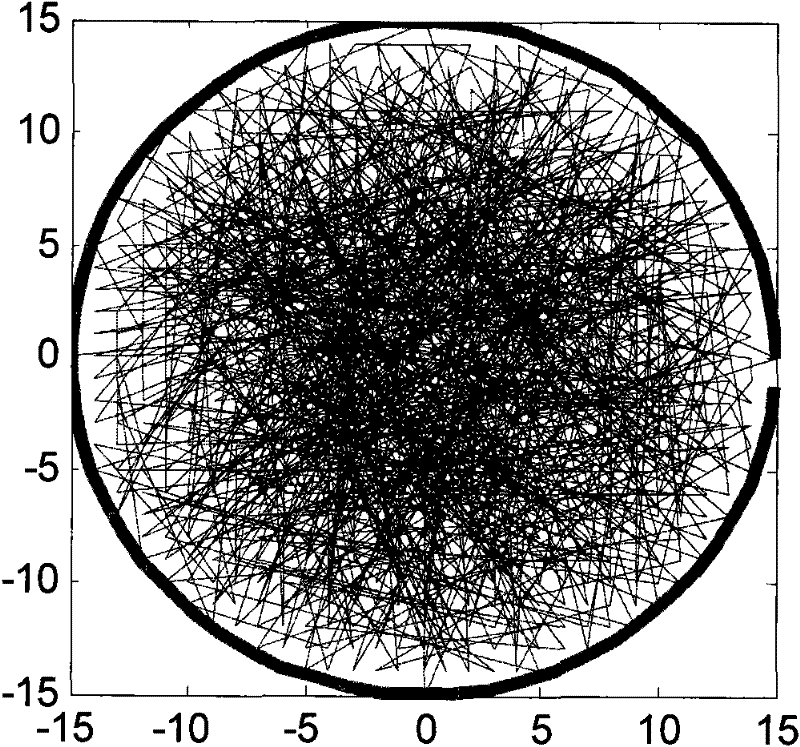

Random polishing track motion method for restraining track error

InactiveCN102248461AHigh precisionOptimize motion trajectoryOptical surface grinding machinesNumerical controlLitter

The invention relates to a random polishing track motion method for restraining a track error, which comprises the following steps: confirming to-be-polished points and residence time distribution on a surface of a to-be-polished optical element and utilizing a random track algorithm to generate a polishing sequence and a polishing track of dispersed points on the surface of the to-be-polished optical element; utilizing a residence time compensation method to calculate the residence time distribution for a polishing head motion track to pass through by the polishing points, thereby acquiring the accurate residence time of the dispersed points on the surface of the to-be-polished optical element; generating a random track numerical control polishing program code by a machine tool code conversion program according to the residence time distribution; and polishing all the points on the surface of the to-be-polished optical element by executing the random track numerical control polishingprogram code on a numerical control polishing machine tool. A random track polishing method is used for enabling the motion tracks of the polishing head and polishing grains to approach to random litter distribution according to surface figure distribution, thoroughly removing regular track scratches from the to-be-polished optical element, uniformly spreading the removal function iteration errors among regular tracks on the whole surface figure, and promoting the surface figure accuracy.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

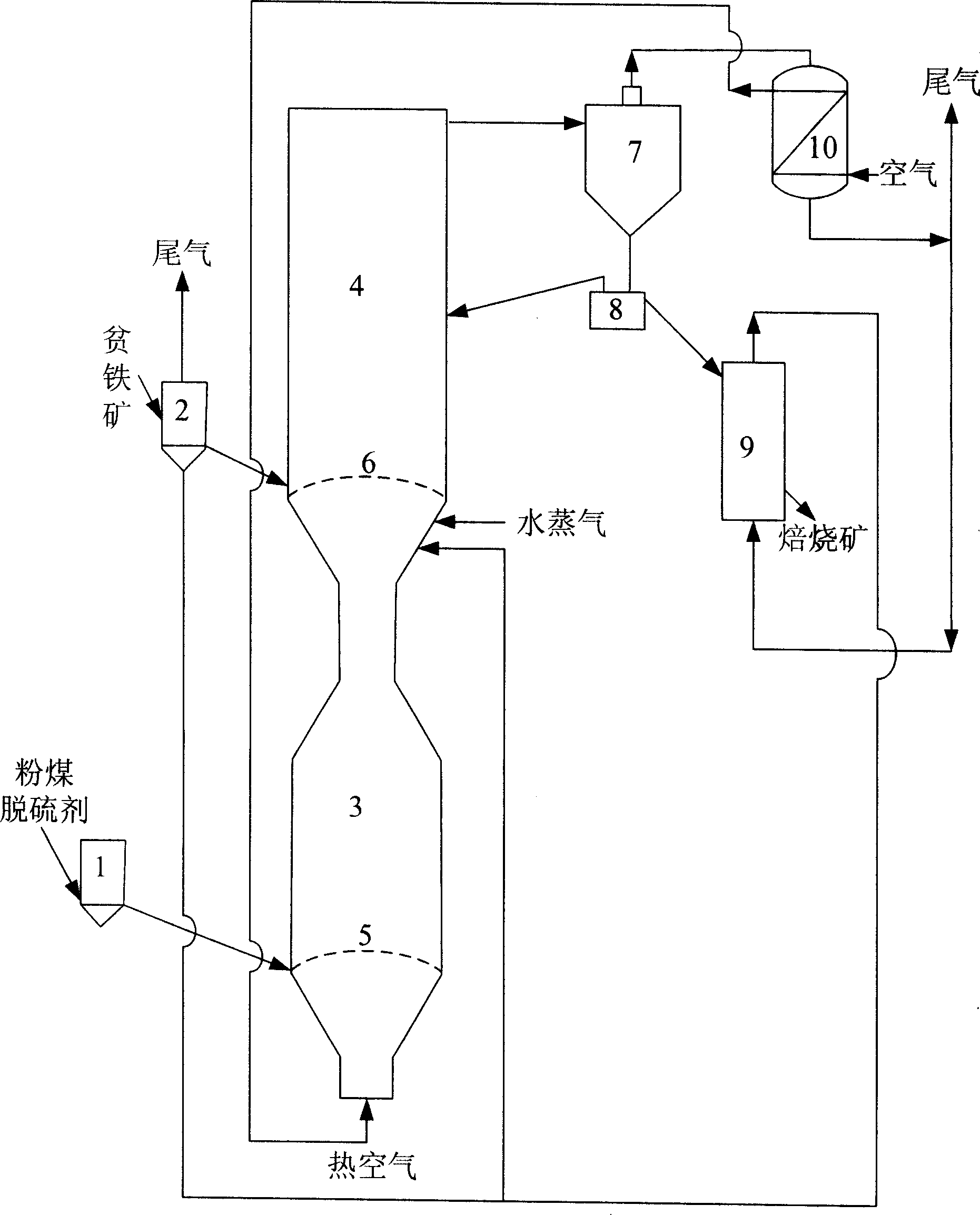

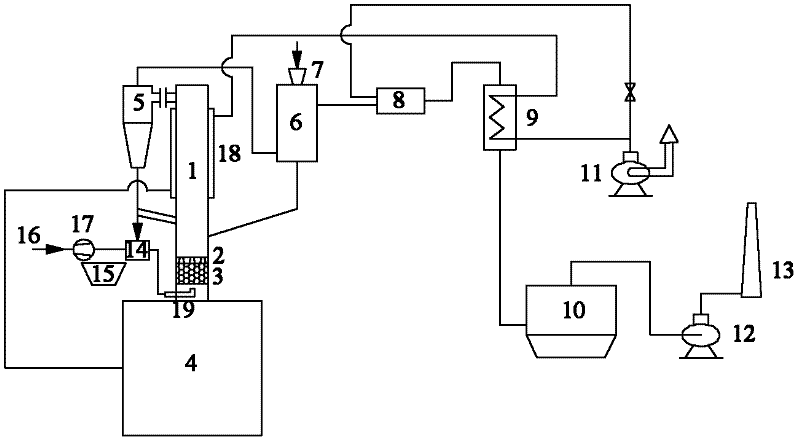

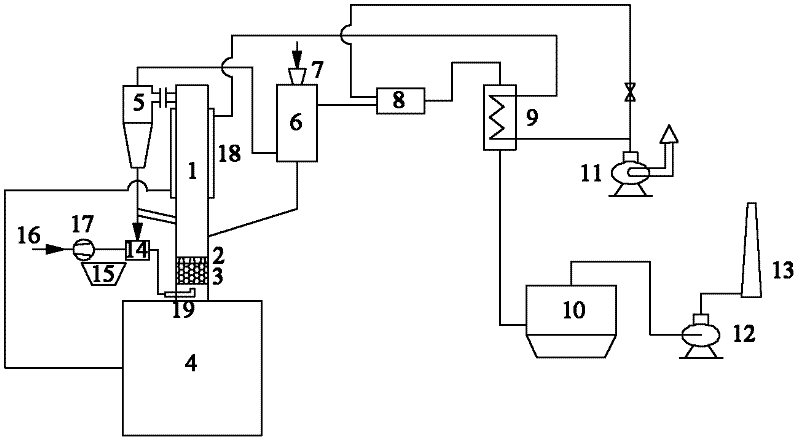

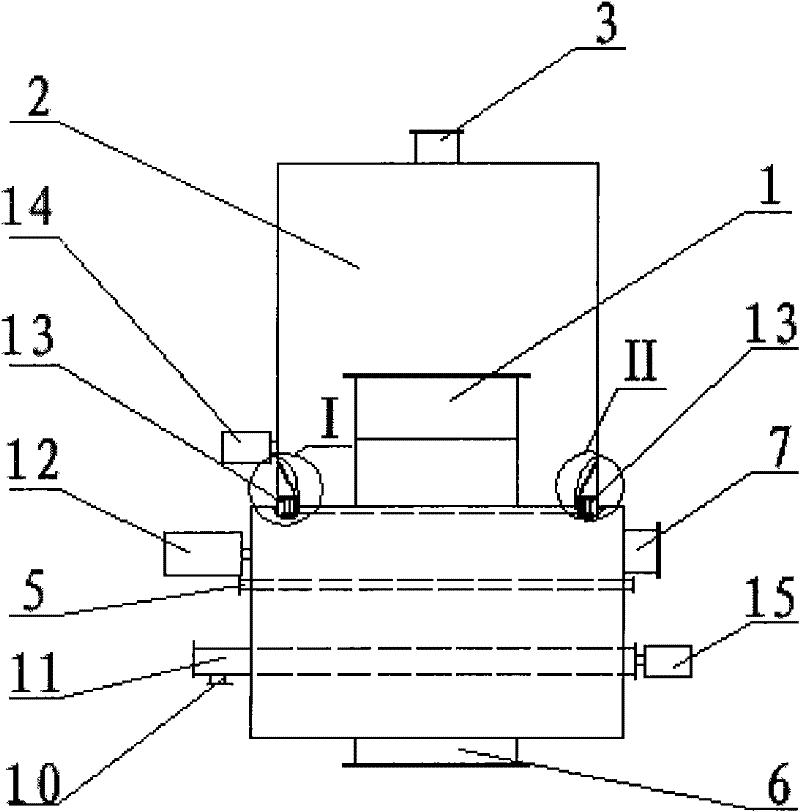

Coal gasification-pore iron ore magnetic roasting coupling technique and device

ActiveCN101191149AControl the gasification processIncrease profitFurnace typesChemical industryIronstone

The invention relates to the chemical industry and metallurgy field, in particular to coal gasification - lean iron ore magnetizing roasting coupling technique and a coal gasification - lean iron ore magnetizing roasting coupling device. The invention is characterized in that: gasification reaction of coal and reduction action of iron ores are respectively performed in independent reaction chambers, and coal gasification and iron ore reduction are guaranteed to be able to be performed under independent optimal conditions; simultaneously, a coal gasification chamber and an iron ore reduction chamber are also coupled with each other to form a reaction device; the coal gasification is performed in the gasification chamber on the lower part of the reaction device, and reducing gas obtained after gasification enters into a roasting chamber for reducing roasting reaction together with powdery refractory lean iron ores; three to six abnormal tube sinkings are arranged inside a lean iron ore roasting chamber which is divided into four to seven levels of fluidized beds; residence time distribution of lean iron ore particles is guaranteed to be close to plug flow. The invention has the advantages of simple technique, capability of respectively optimizing the gasification reaction of the coal and magnetizing roasting reaction of lean iron ores in one reaction device, even residence time distribution in the lean iron ore particles of the roasting chamber, capability of improving roasting and magnetic separation efficiency, and obtaining of good grade of iron concentrate and iron recovery rate.

Owner:深圳中科九台资源利用研究院有限公司

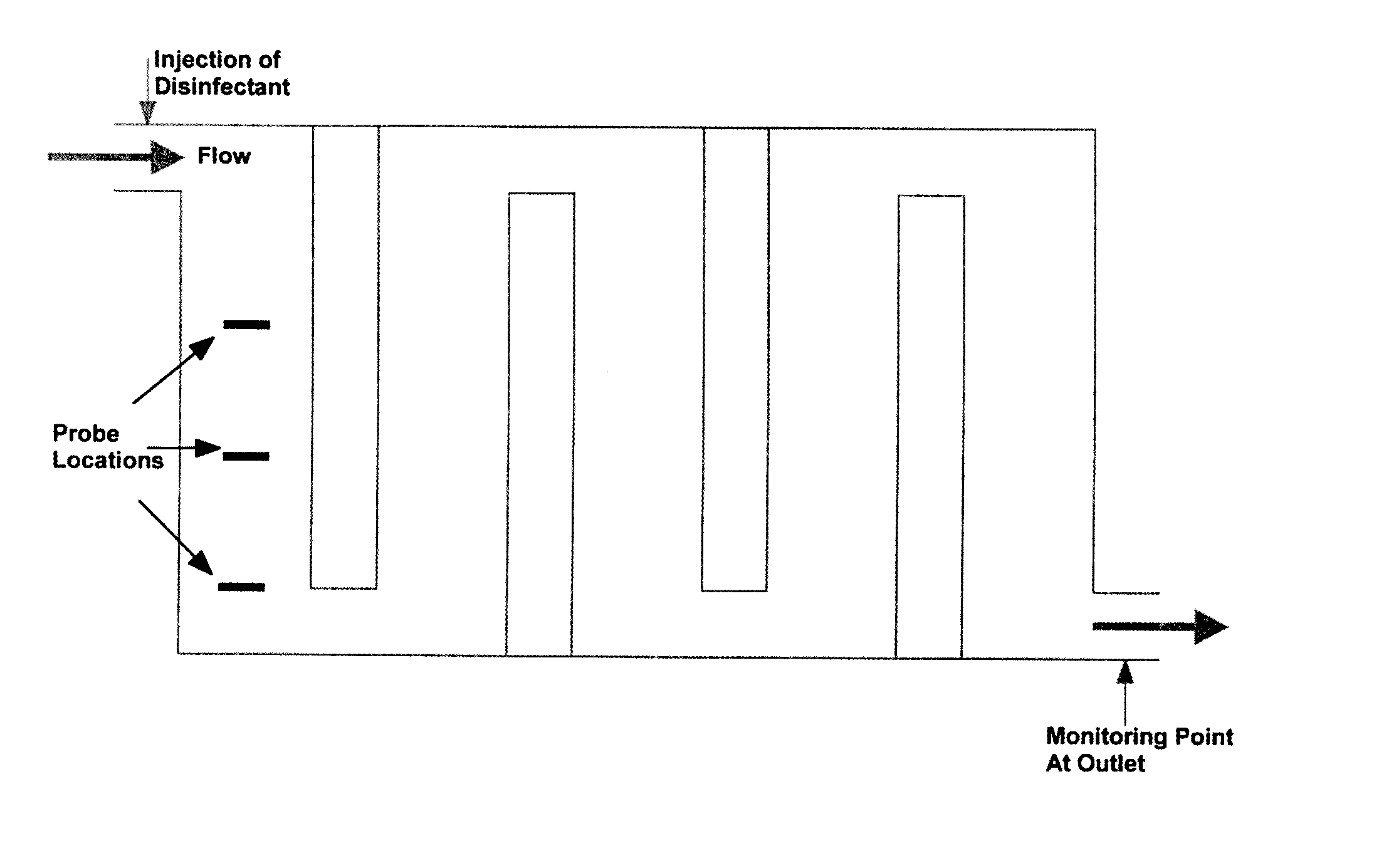

Process and Device for the Treatment of a Fluid Containing a Contaminant

ActiveUS20160376166A1Accurately control performanceAccurately predict performanceWater treatment parameter controlWater/sewage treatment by irradiationMedicineTreatment system

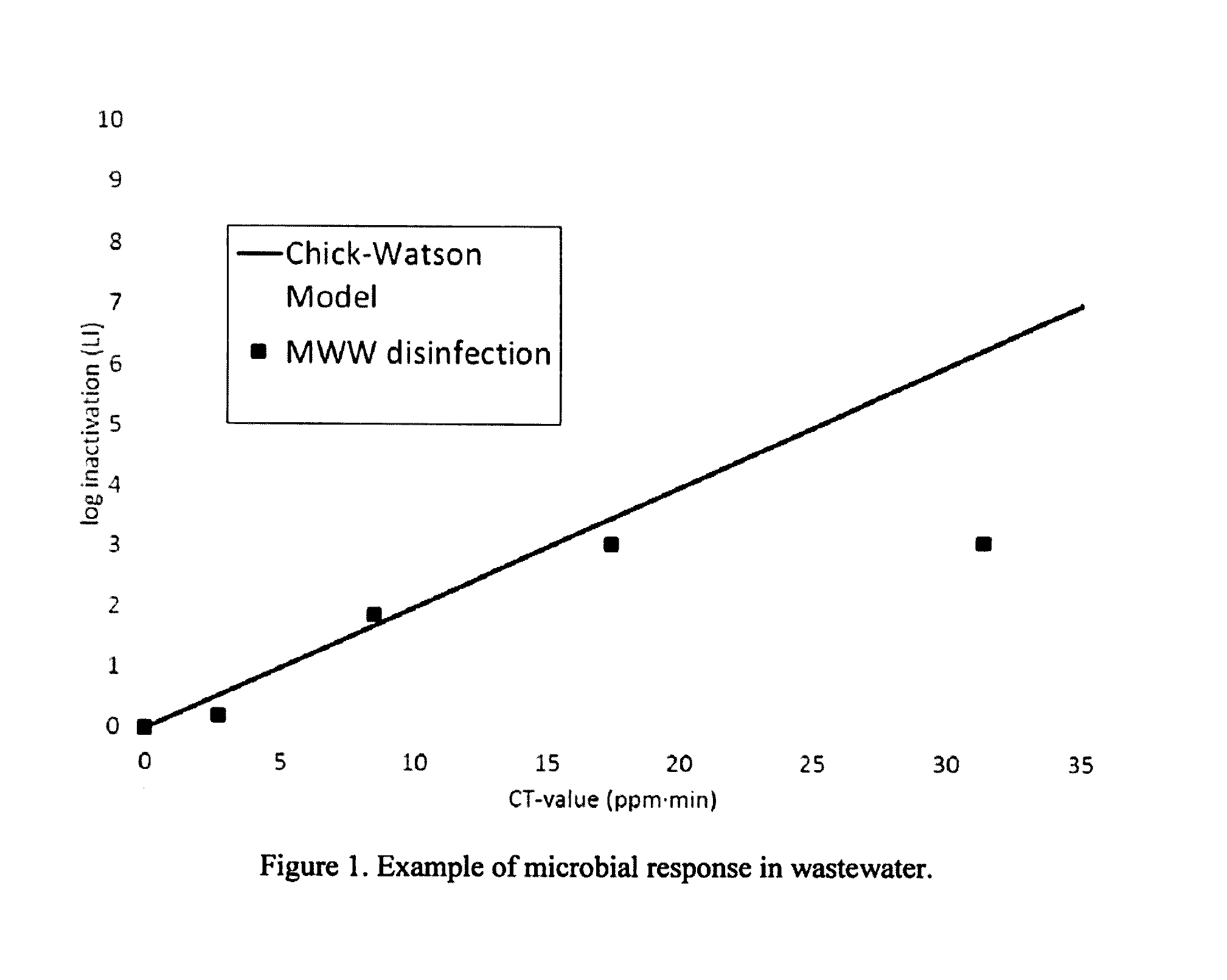

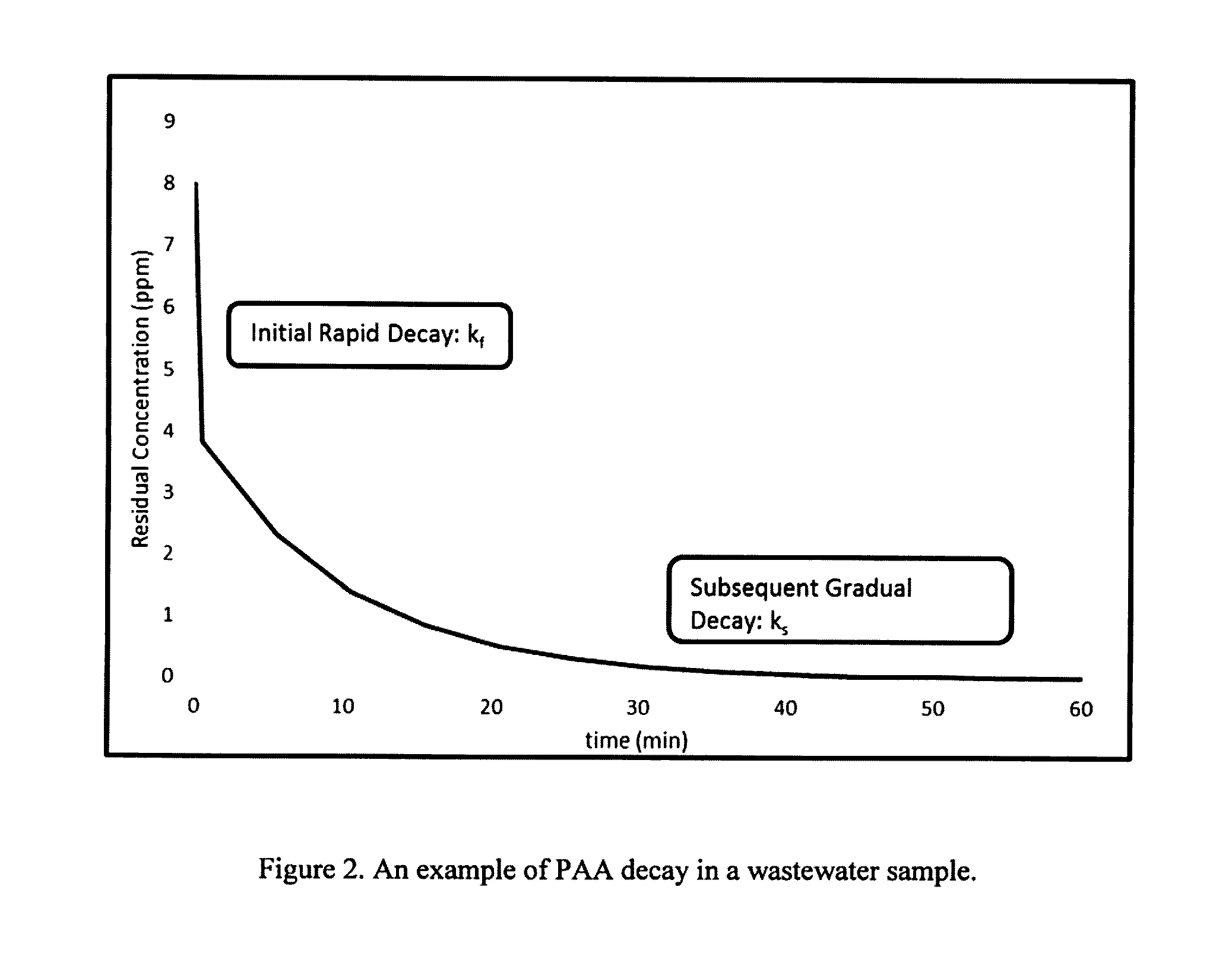

In one of its aspects, the invention relates to a process to optimize the dose of a treatment agent for the treatment of a fluid comprising a contaminant. In this first aspect the process comprises the steps of: (a) calculating the dose of the treatment agent based on the relationship between concentration of the treatment agent at one or more points and residence time distribution of the treatment system, and (b) contacting the fluid with the treatment agent in the concentration required to meet the dose calculated in step (a). In another one of its aspects, the invention relates to a process to optimize the dose of a treatment agent for reduction of a contaminant in a fluid.

Owner:TROJAN TECH

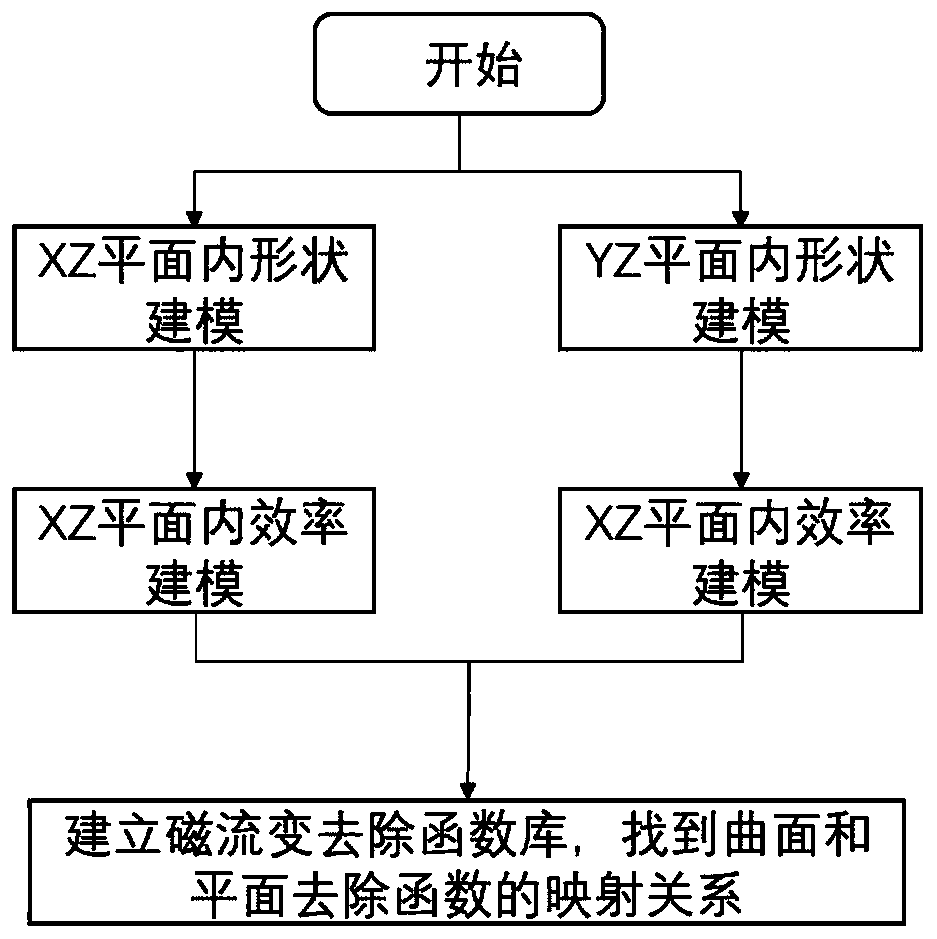

Magneto-rheological polishing compensation machining method and system for optical complex curved surface element and medium

ActiveCN109909815AImprove efficiencyImprove convergence rateOptical surface grinding machinesGrinding feed controlMagnetic currentResidence

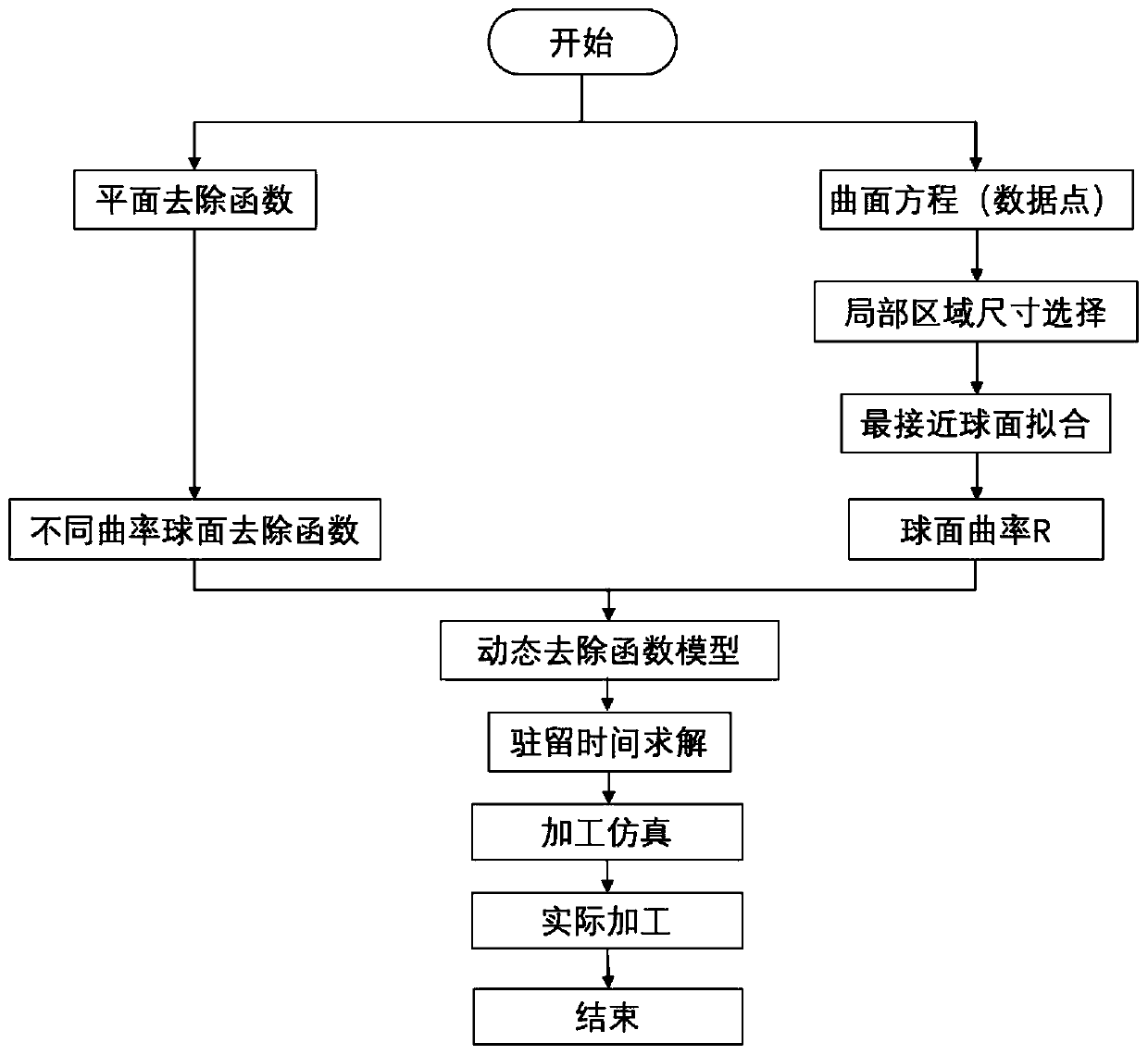

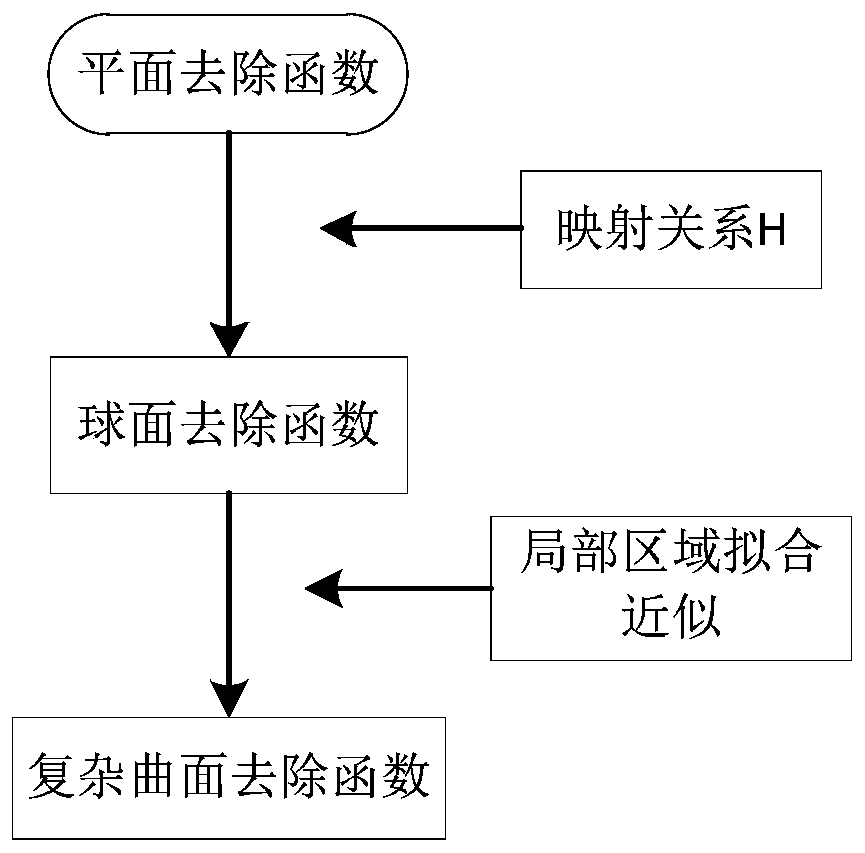

The invention discloses a magneto-rheological polishing compensation machining method and system for an optical complex curved surface element and a medium. The magneto-rheological polishing compensation machining method comprises the steps that a flat removal function is acquired; sphere removal functions under different curvatures are obtained through mapping; for each residence point in a to-be-machined workpiece surface shape area, the best fitting sphere of the complex curved surface local area nearby the residence point is calculated through fitting, and the sphere removal function corresponding to the curvature of the best fitting sphere of the complex curved surface local area is approximately taken as a removal function of the complex curved surface local area nearby the residencepoint; and a residence time solution algorithm based on a linear equation system model is built, and residence time distribution and surface shape residual errors of all the residence points are solved through simulation to guide magneto-rheological polishing of a to-be-machined workpiece. According to the magneto-rheological polishing compensation machining method and system for the optical complex curved surface element and the medium, the determinacy in the machining process can be effectively guaranteed, and the convergence rate in the machining process is increased.

Owner:NAT UNIV OF DEFENSE TECH

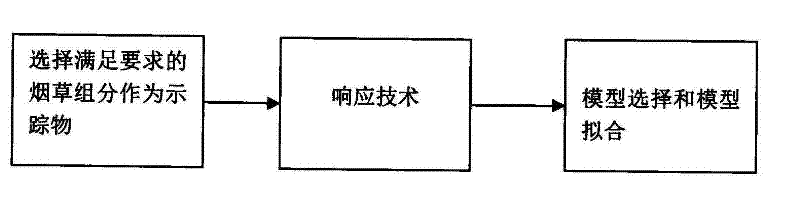

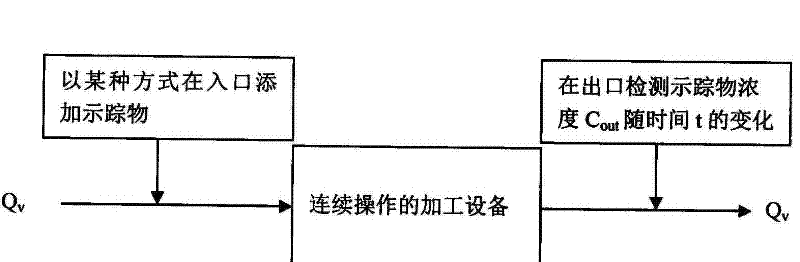

Method for measuring residence time distribution of tobacco material in processing equipment

A method for measuring residence time distribution of tobacco material in processing equipment comprises the following steps: a, a common component is selected from the tobacco material to work as a tracer to meet accuracy detection requirements; b, the tracer is added into a stably working material flow at the equipment inlet through adopting a tracing method, and response value of the variationon the concentration of the tracer along with time is detected with a certain time interval at the outlet, so as to get a residence time distribution (RTD) function; and c, the function is fitted in a nonlinear manner by a proper flowing model to get the model equation of the function, as well as the average residence time of the material and blending rate in the axial direction of the equipment.The invention has the advantages that firstly, a common component is selected from the tobacco material to work as the tracer for measuring the RTD of tobacco material in processing equipment, so that the testing time is short, the influenced area is small, the detect method has high accuracy, less influence is caused to the product quality, and no threatening is caused to the safety of consumers; and secondly, by adopting the method, the WIP (work in process) quality can be predicted, optimized, and controlled.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +1

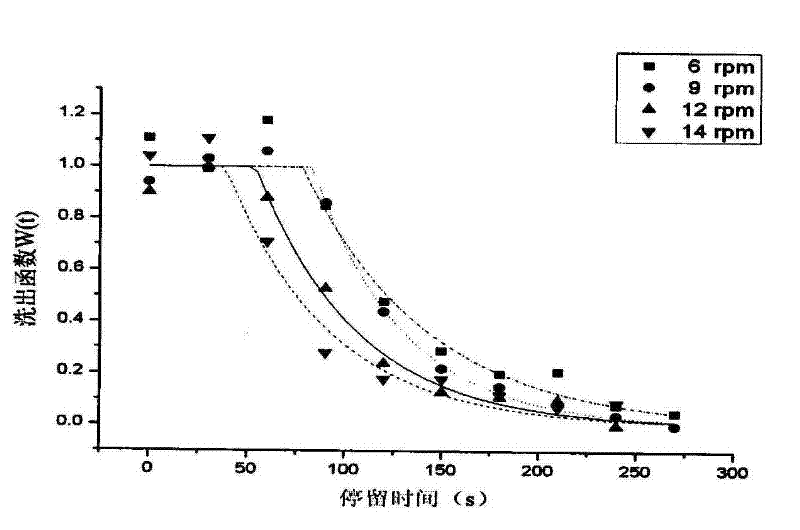

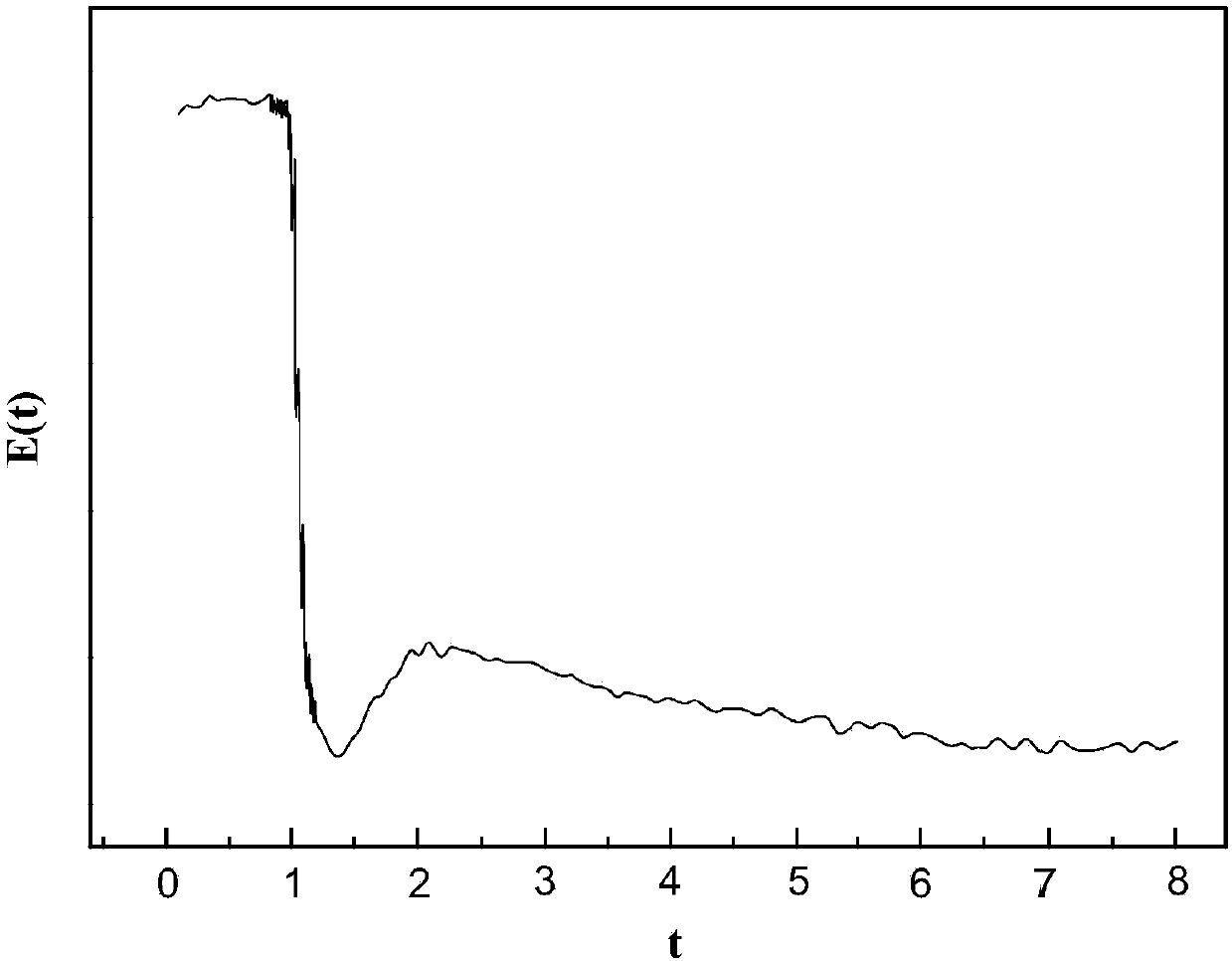

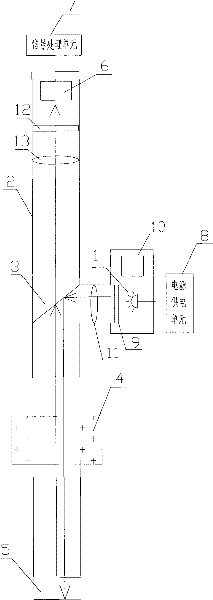

Device and method for online measurement of residence time distribution of rotating packed bed

InactiveCN101793854AGuaranteed online outputGuaranteed safe placementMaterial resistanceFluorescenceData acquisition

The invention relates to a device and a method for the online measurement of the residence time distribution of a rotating packed bed, belonging to the technical field of the online determination of the residence time distribution. The device comprises an electrode and an internal pipe, wherein the electrode is installed on the internal side and the external side of the non-conductive packing of the rotating packed bed, and the internal pipe is filled with tracer liquid. The electrode is connected with a slip ring through a conducting wire. The slip ring and a rotating shaft rotate synchronously and the slip ring is connected with a data acquisition system. The method is that gas and liquid with fixed flow are injected into the liquid distributor of the rotating packed bed, the tracer liquid is filled, the slip ring transmits electrical signals to the outside, electric signal data is acquired and residence time distribution function E (t) is obtained by adopting data integral calculation. The invention realizes the online measurement of the residence time distribution and has the advantages of that the real-time performance is high, the continuity is good, the detailed features ofliquid holdup can be comprehensively reflected and the like; and by adopting the conductance method, not only the error caused by the x-ray method, the ultrasonic method, the conductivity method andthe fluorescence method is overcome, but also the online measurement can facilitate the detection of the impacts of all kinds of impact factors of the residence time distribution on the liquid holdup.

Owner:ZHONGBEI UNIV

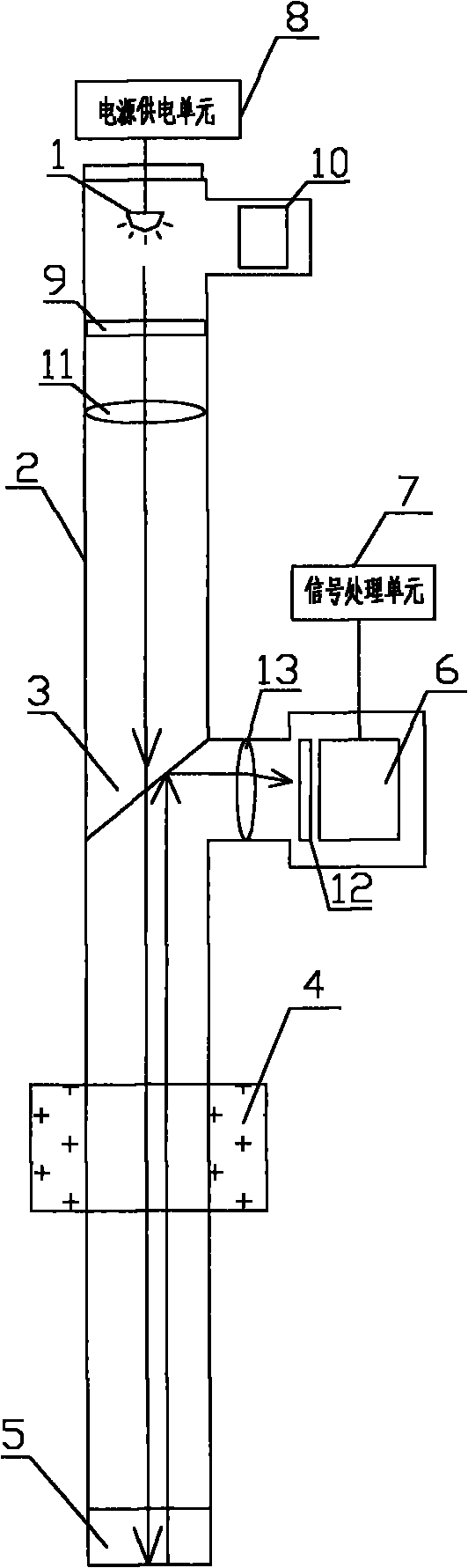

Device for testing residence time distribution (RTD) of material

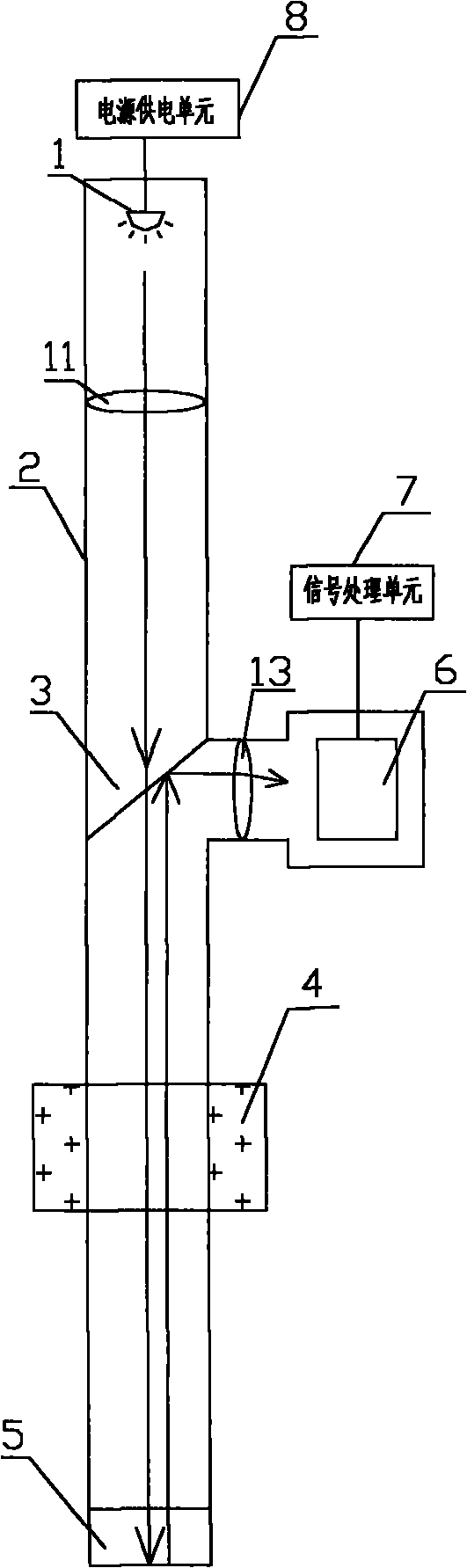

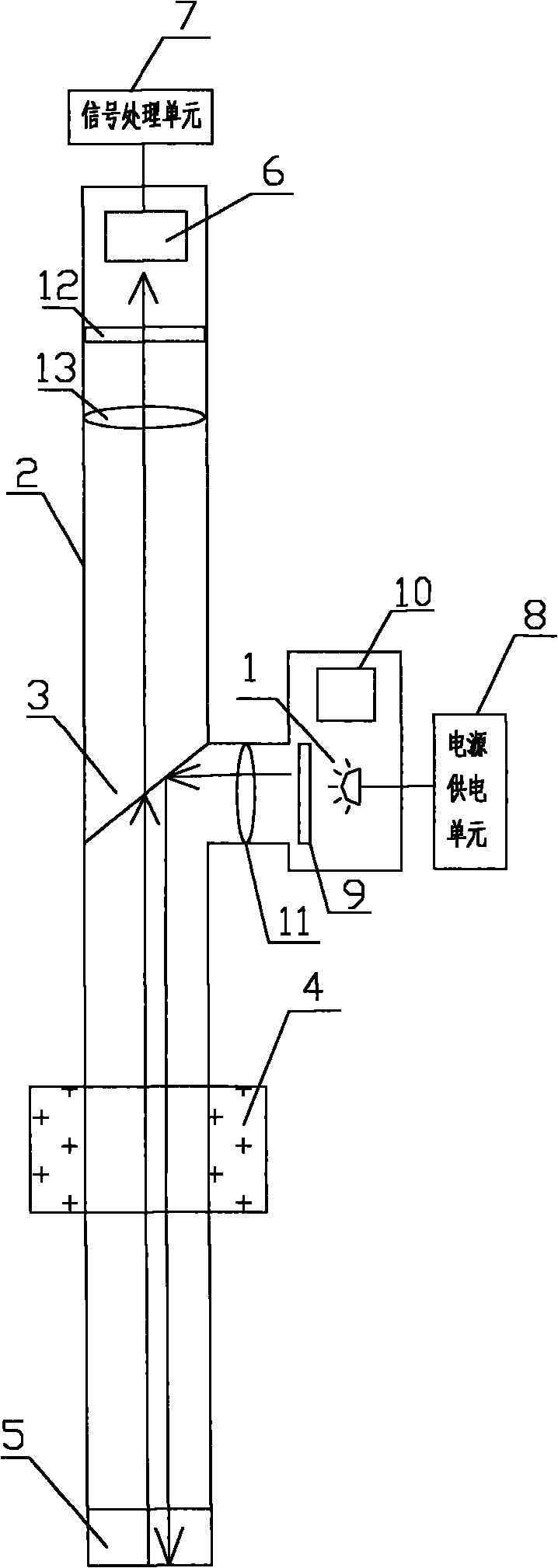

InactiveCN101839859AReduce volumeCompact layoutFluorescence/phosphorescenceCoupling lossEffect light

The invention discloses a device for testing residence time distribution (RTD) of a material. The device comprises a lighting tube, an optical window, a fluorescence detector, a signal processing unit, an excitation light source, a transflective mirror, a light source power supply unit and the like, wherein the beam emitted from the excitation light source strikes a detected material after passing through the transflective mirror; a tracer in the detected material is excited to emit fluorescence which is transmitted to the fluorescence detector after passing through the transflective mirror; and through the analysis of the signal processing unit, the RTD of the material is calculated. The device for testing the RTD of the material has the advantages of capability of greatly reducing coupling loss and cost because the excitation beam and the fluorescence do not need coupling to an optical fiber in the emitting process, compact light path arrangement, small volume, very convenient use by only being electrically connected with the signal processing unit and the light source power supply unit and capability of conveniently isolating the detected material from the high-temperature and high-pressure environment.

Owner:HANGZHOU EVERFINE PHOTO E INFO

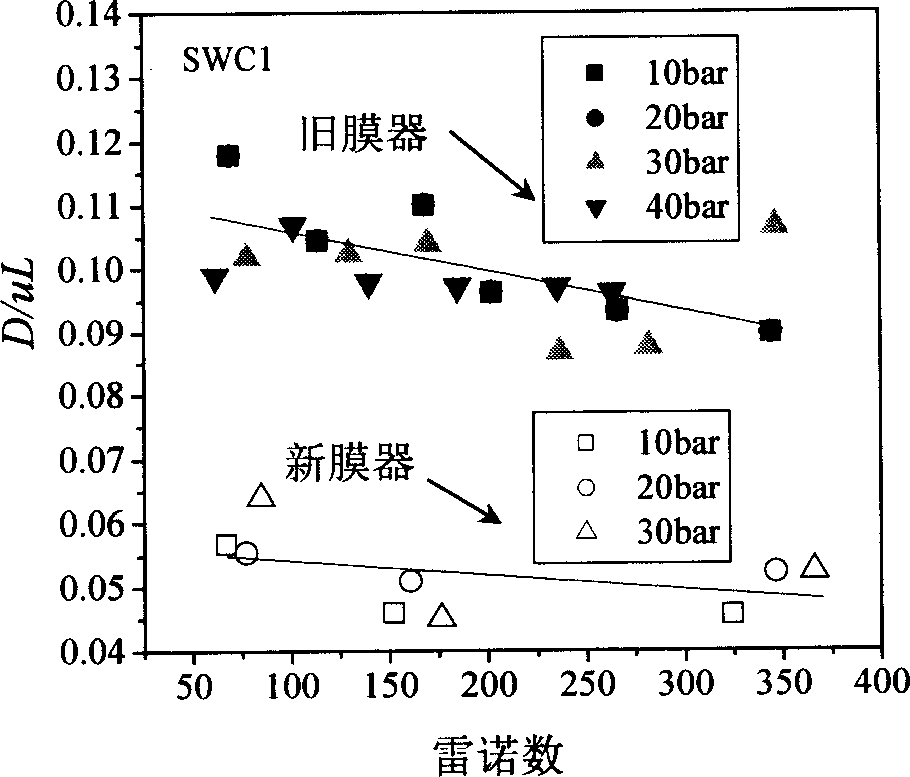

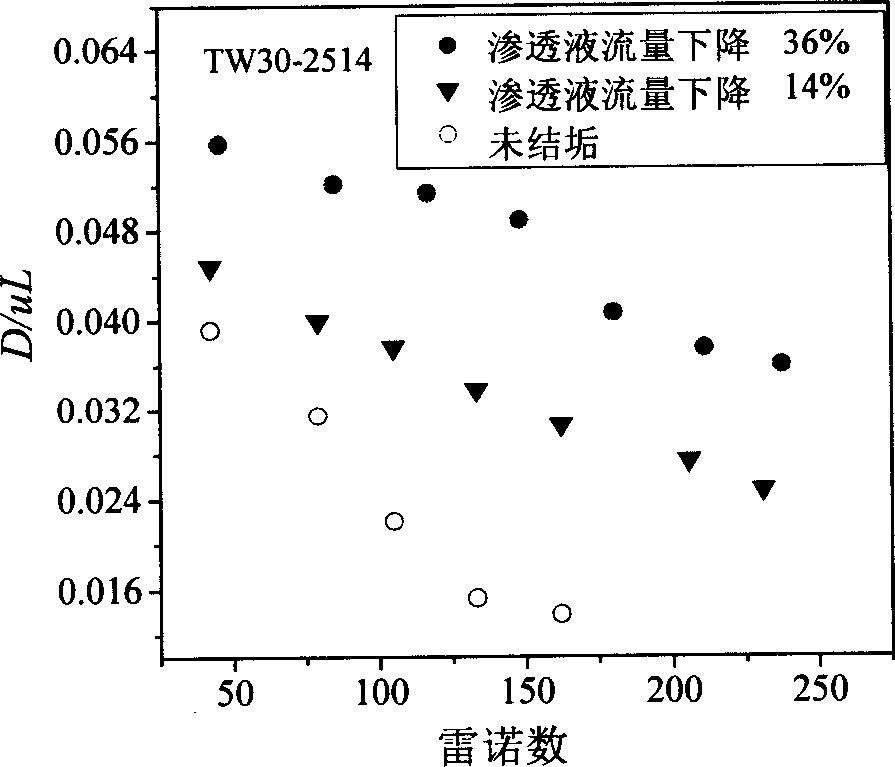

On-line defect diagnosis method for rolling type reverse osmosis membrane device

InactiveCN1721049ADiagnostic procedures are simple and convenientLow costReverse osmosisDiagnosis methodsReverse osmosis

In-line diagnosis method for faults of roll-type reverse osmosis membrane uses residence time distribution (RTD) technique. Use NaCl as tracer and inject the inlet of running reverse osmosis membrane by high pressure impulse injecting technique; detect variety curve of NaCl concentration vs. time with conductivity meter on outlet; take numerical conversion with computer to obtain membrane fault characteristic parameter D / ul and corresponding information. This invention has simple process, low cost and high speed, and can provide basis for the optimization design.

Owner:SHANGHAI JIAO TONG UNIV

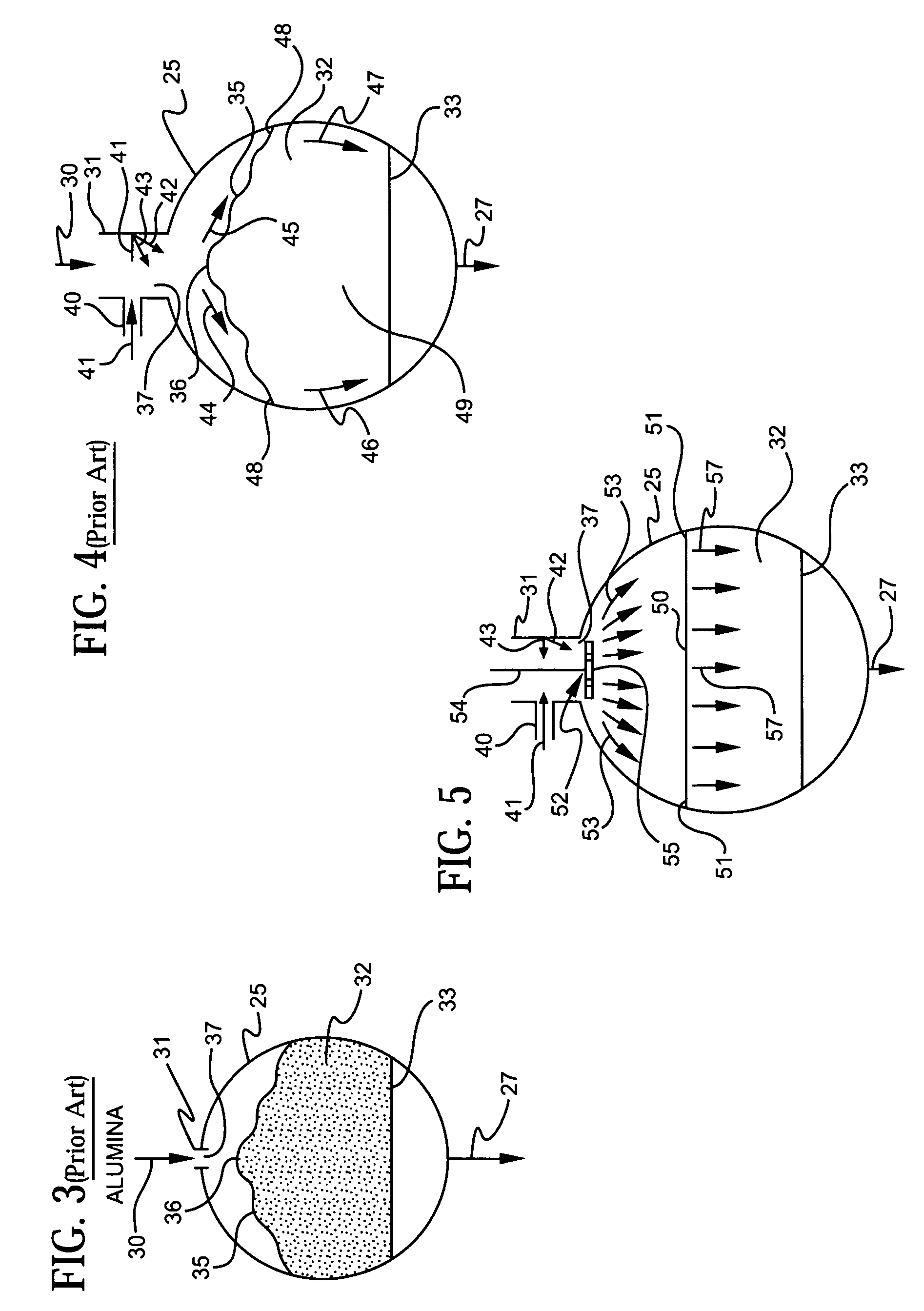

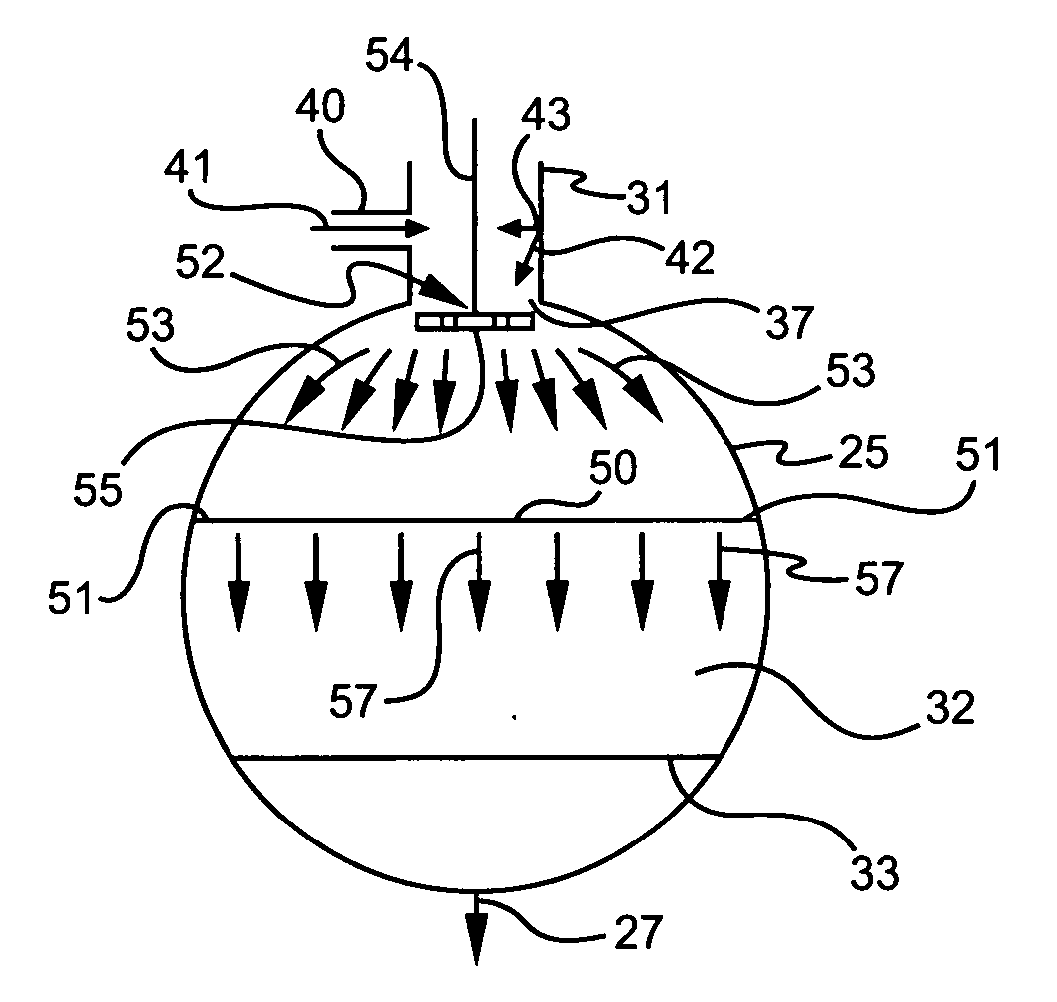

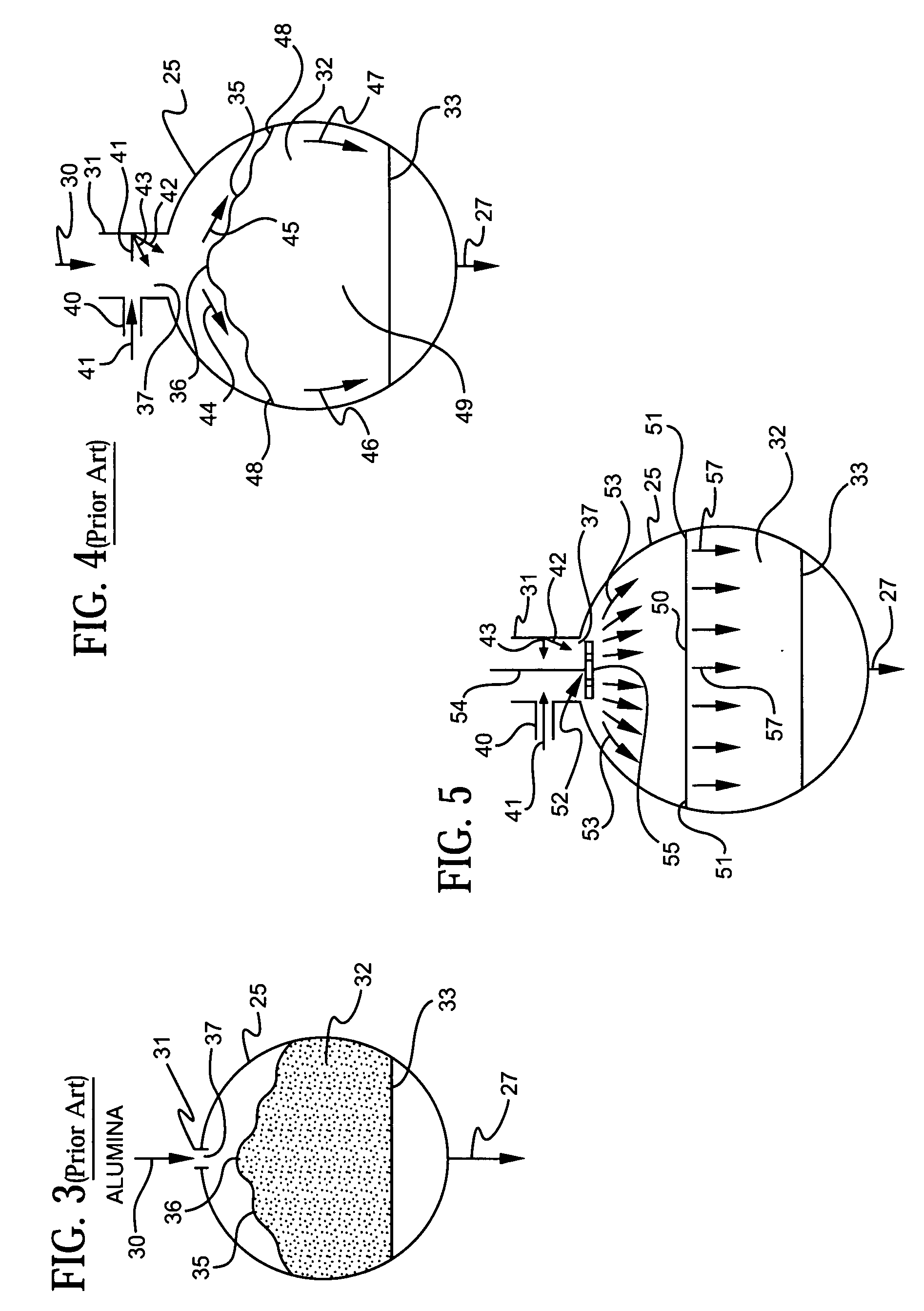

Residence time distribution method and apparatus for operating a curvilinear pressure vessel where transport phenomena take place

InactiveUS7491259B2Physical/chemical process catalystsIsotope separationReactor pressure vesselEngineering

Owner:EQUSR CHEM LP

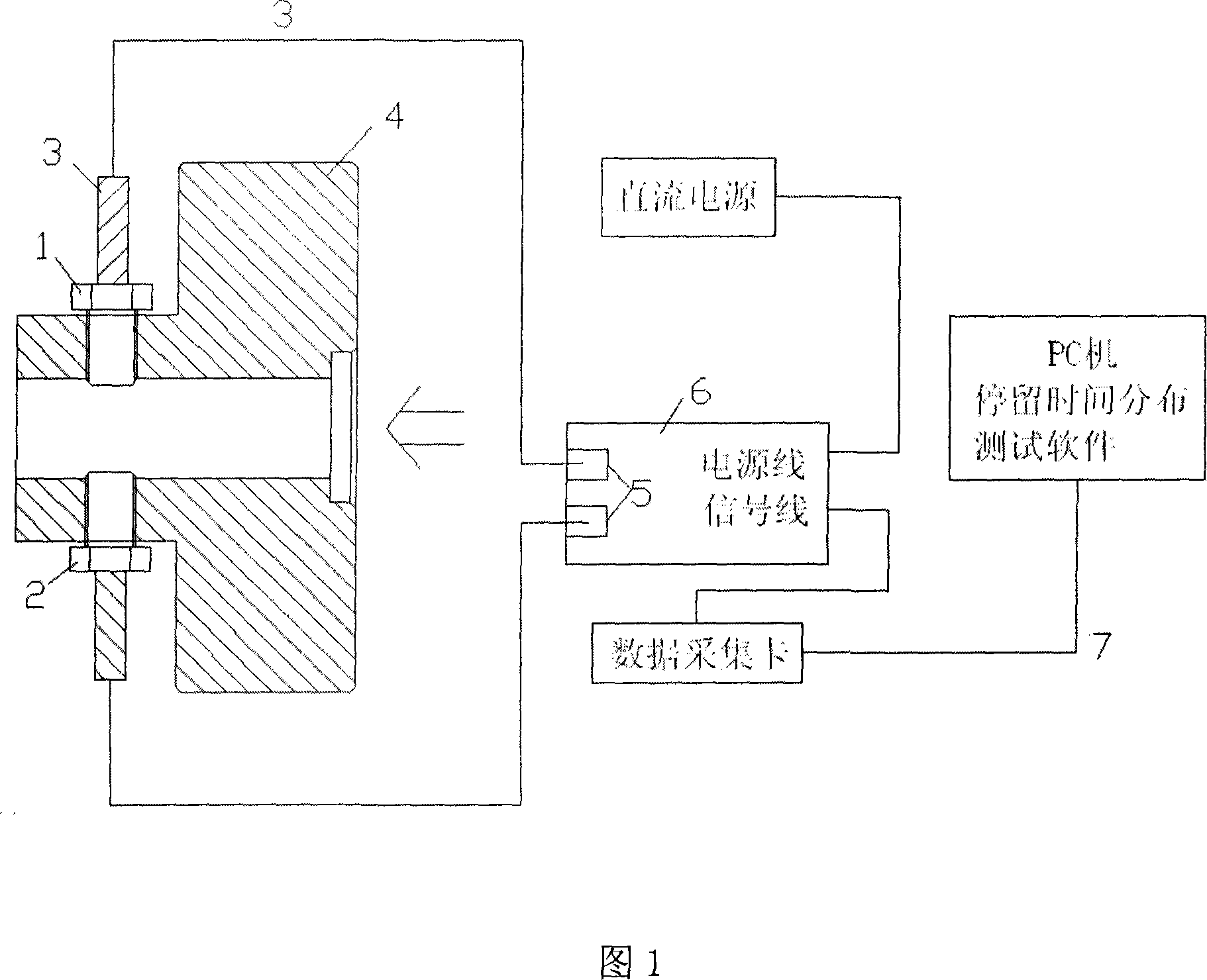

Material detention period and distributing on-line measurement system and method

InactiveCN101183051ARealize online measurementEasy accessAnalysis by material excitationStructural/machines measurementLinear relationshipData acquisition

The present invention relates to an online measuring system and a method for the residence time distribution of polymer, which belongs to the field of polymer processing. The present invention is used for evaluating the mixing performance of mixing equipment. The PC machine of the system is connected with an optical fiber sensor (6) through a data acquisition card. The optical fiber probe (1) of the optical fiber sensor (6) is arranged on an extruder head (4) and is directly contacted with the melted polymer which is mixed with tracer in the extruder head (4). The transmission light intensity received by the optical fiber has linear relationship with the index of the tracer concentration. So the transmission light is tested and the residence time distribution is obtained. The transmission received by the other optical fiber probe (2) is returned to the optical fiber sensor. The optical fiber sensor generates the corresponding analog quantity according to the intensity of the light received by the optical fiber sensor. A computer samples, so the curve of the residence time distribution analog signal changing with time is real-timely displayed. The present invention has the advantages that the structure is simple, the testing cost is low, the tracer used for measurement is easy to be obtained and so on.

Owner:BEIJING UNIV OF CHEM TECH

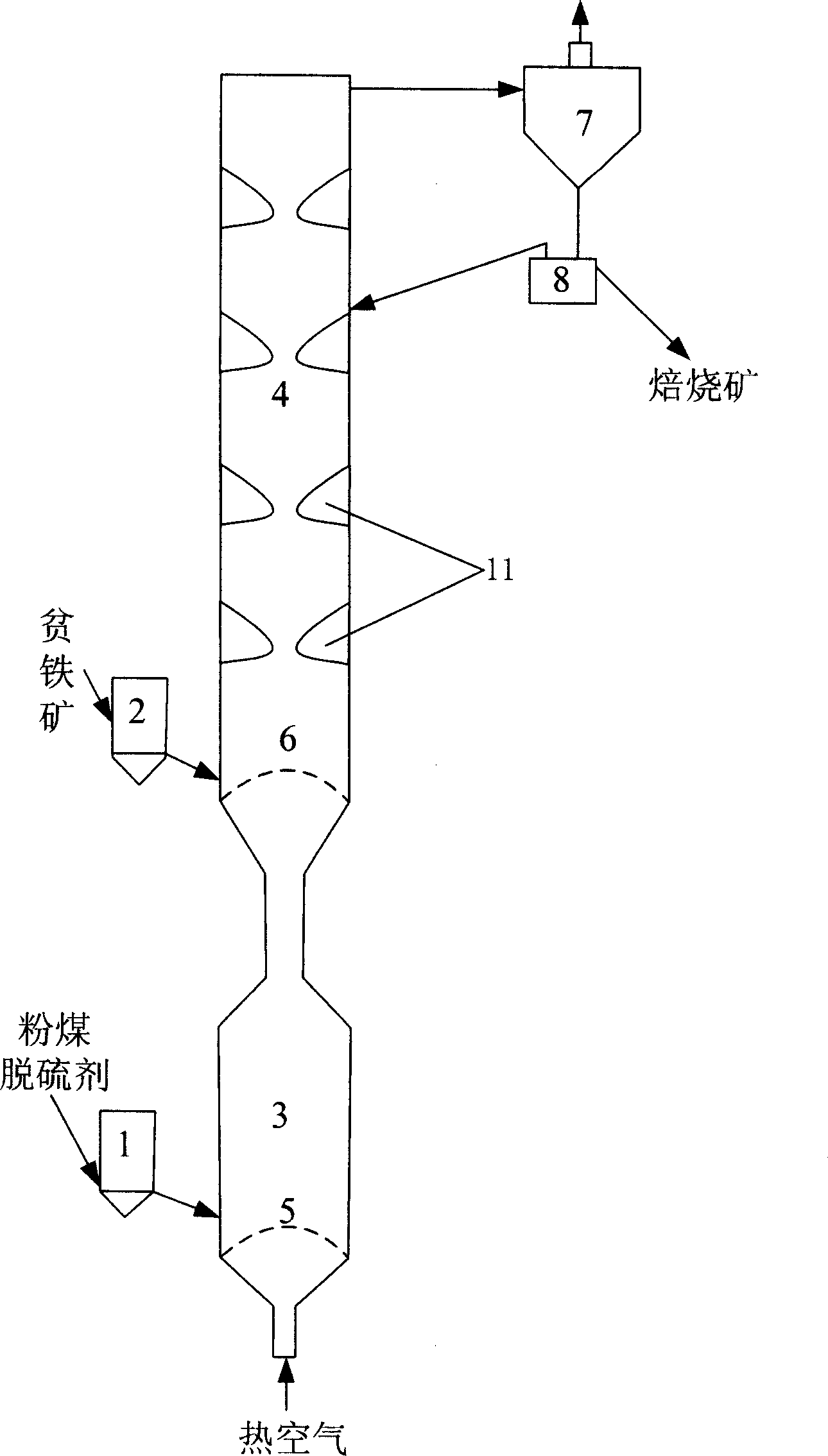

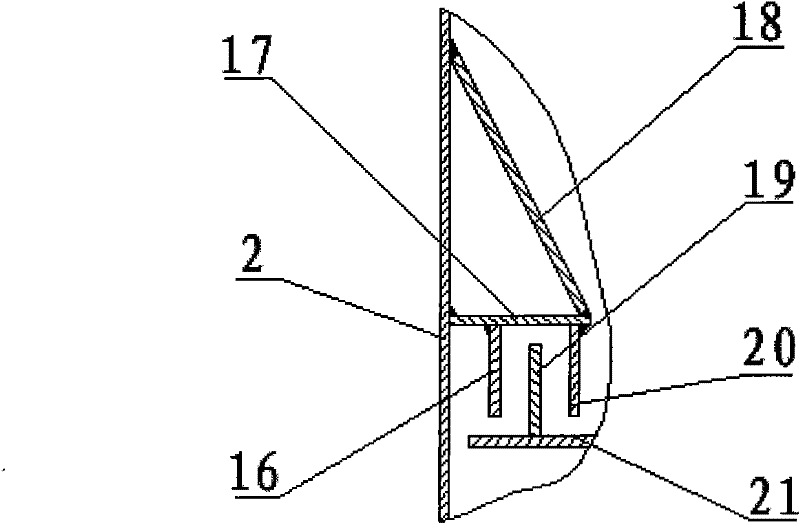

Refractory poor iron ore pulsating fluidized bed magnetizing roasting device and roasting method

The invention relates to a refractory poor iron ore pulsating fluidized bed magnetizing roasting device and a refractory poor iron ore pulsating fluidized bed magnetizing roasting method. Iron ore powder is magnetized and roasted by adopting a pulsating fluidized bed formed by direct coupling of Rick tube type pulsating combustion and a fluidized bed. The iron ore powder is preheated by an ore heater (6) in a bin (7) and then delivered to a roasting furnace (1), the roasting exhaust is cooled by the ore heater (6) and then delivered to a burner (8) and burnt, and the burnt exhaust is cooled by a gas-gas pre-heater (9), delivered to a bag-type dust remover (10) and then discharged to the atmosphere. Sensible heat of high-temperature iron ore concentrate is reclaimed by an ore cooler (14). The device has the advantages of simple system, compact structure, low energy consumption, reduced resistance, short roasting time and the like; and by using the device and the method, poor phenomena of channeling, dead zone, short circuit and the like of common fluidized bed magnetizing roasting and the problem of over wide residence time distribution of a reactor are effectively solved, and the roasting quality and the roasting efficiency are improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

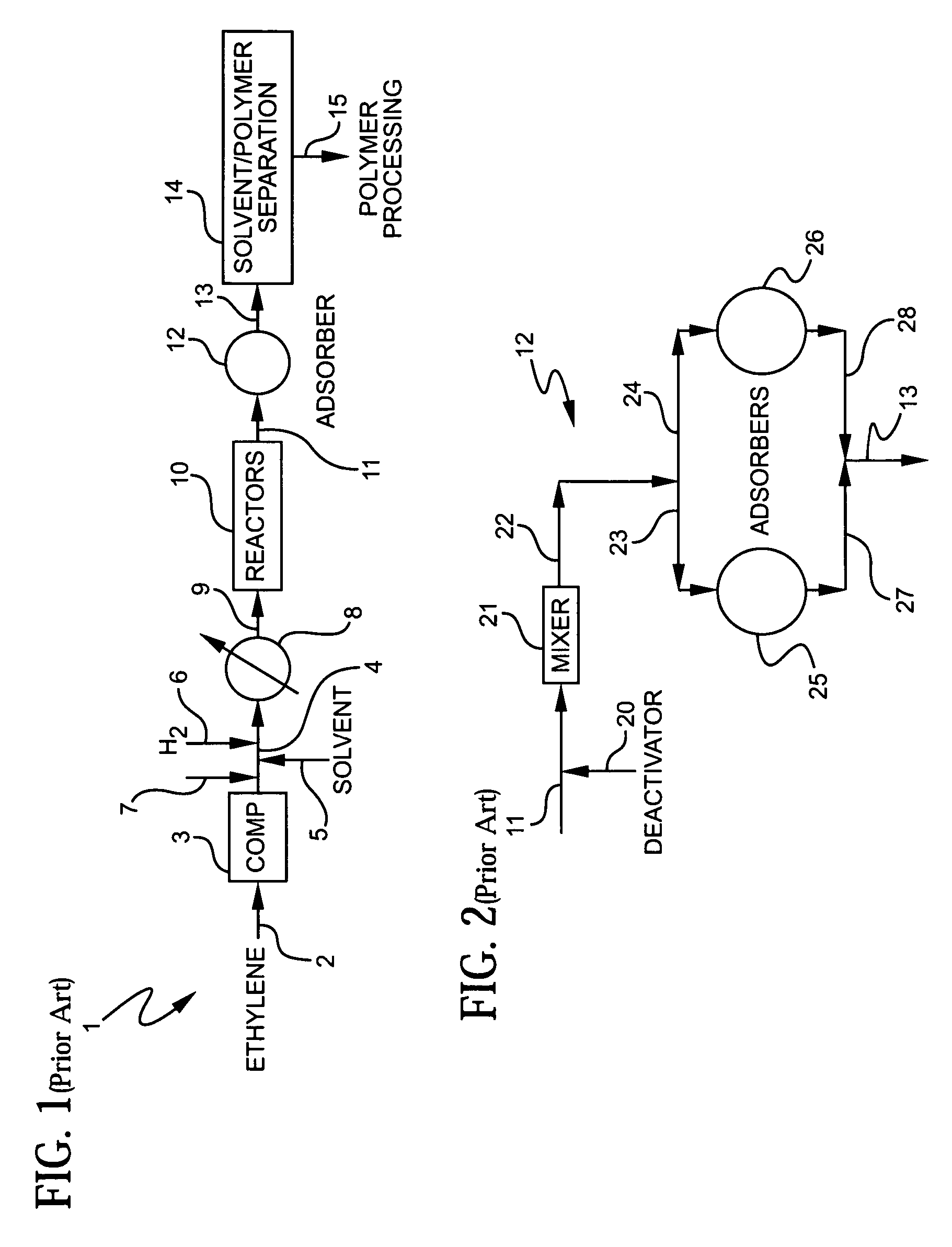

Polycarboxylic acid production system with enhanced residence time distribution for oxidative digestion

ActiveUS7393973B2Reduce formationPromote oxidationOrganic compound preparationExhaust apparatusDigestionOrganic chemistry

Disclosed is an optimized system for more efficiently and economically producing terephthalic acid. The system includes an oxidative digestion reactor / zone configured to provide optimized residence time distribution for the solid and liquid phases of the reaction medium processed therein.

Owner:ALPEK POLYESTER SA DE CV

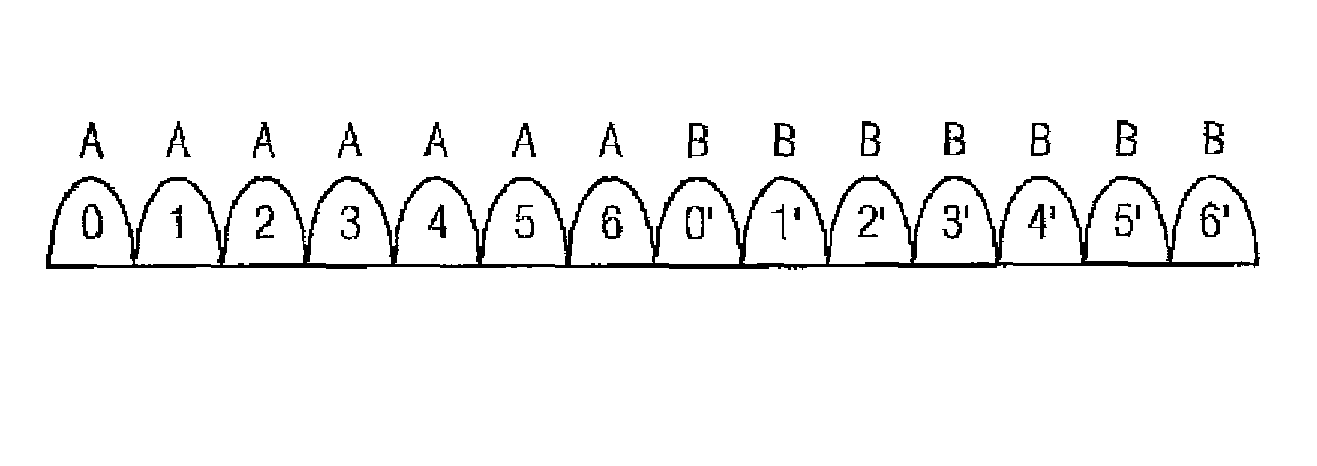

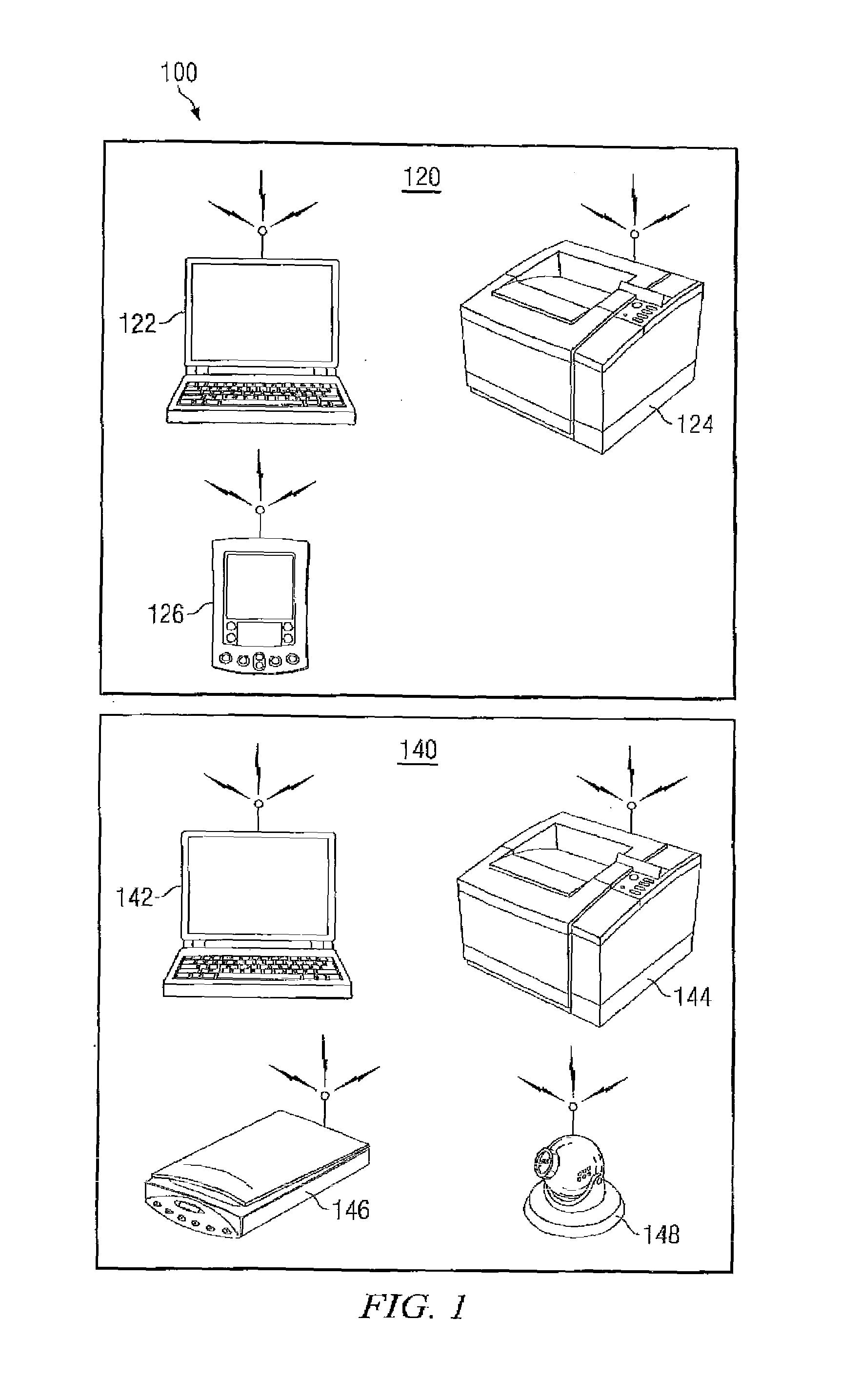

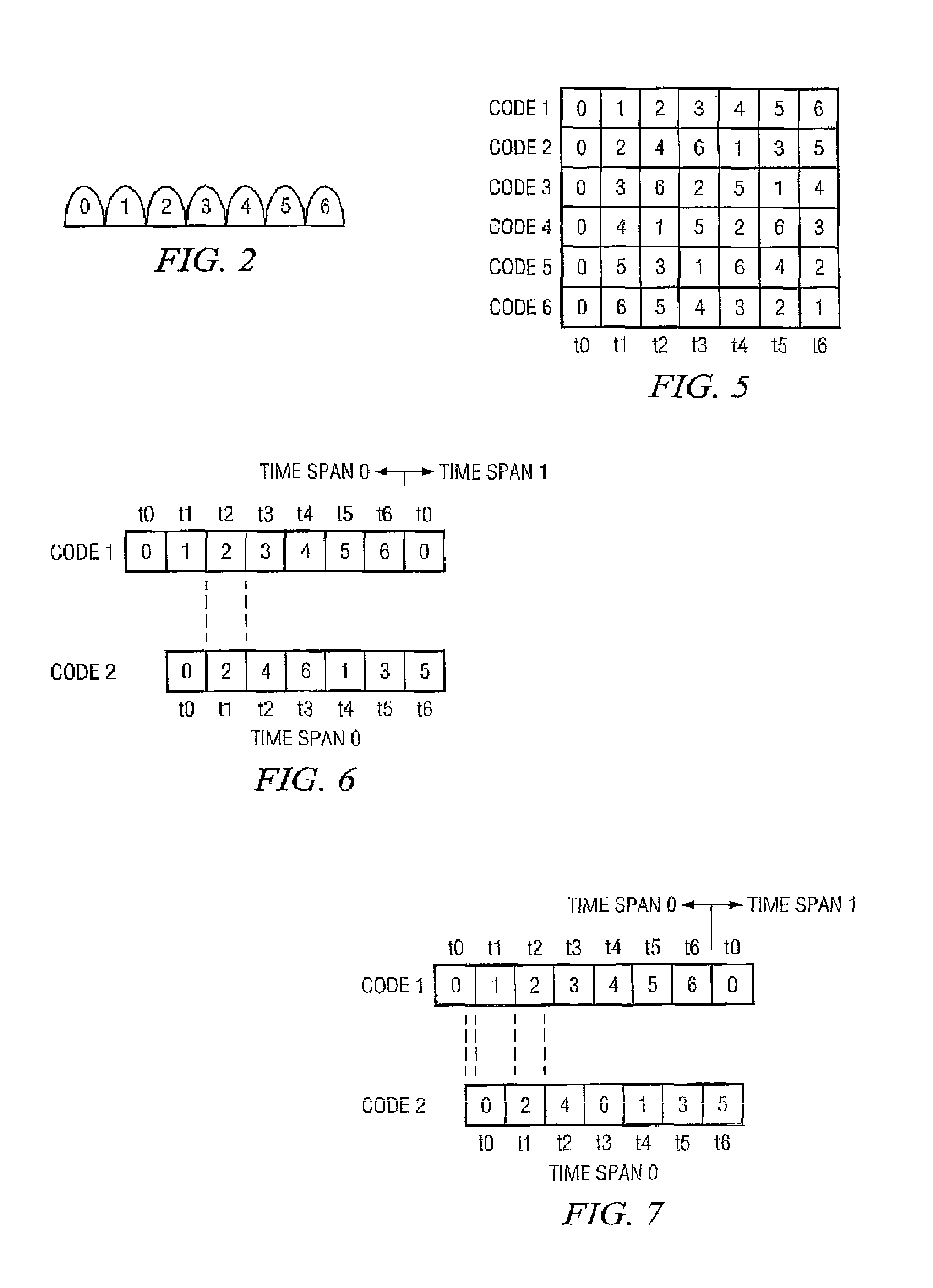

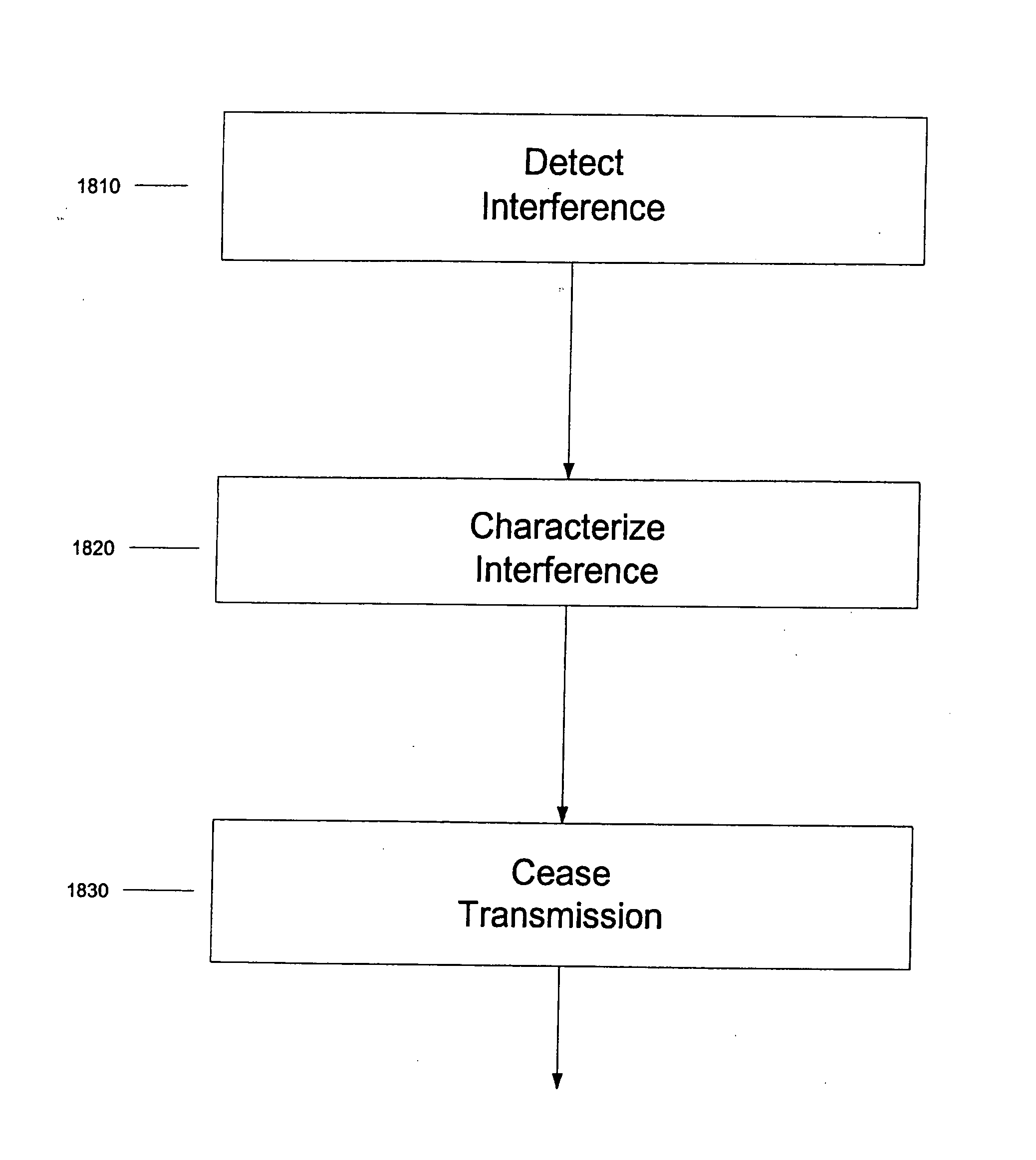

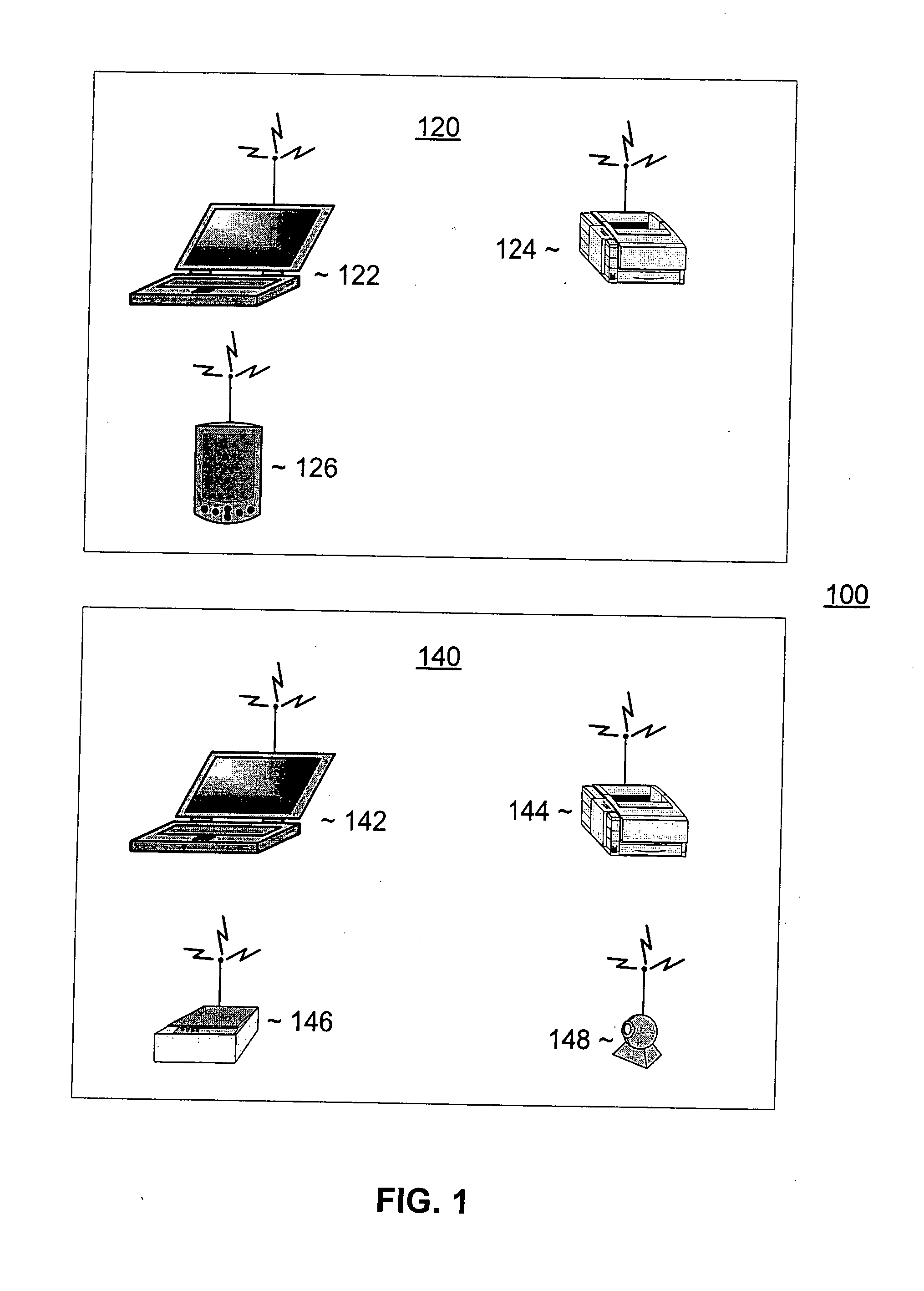

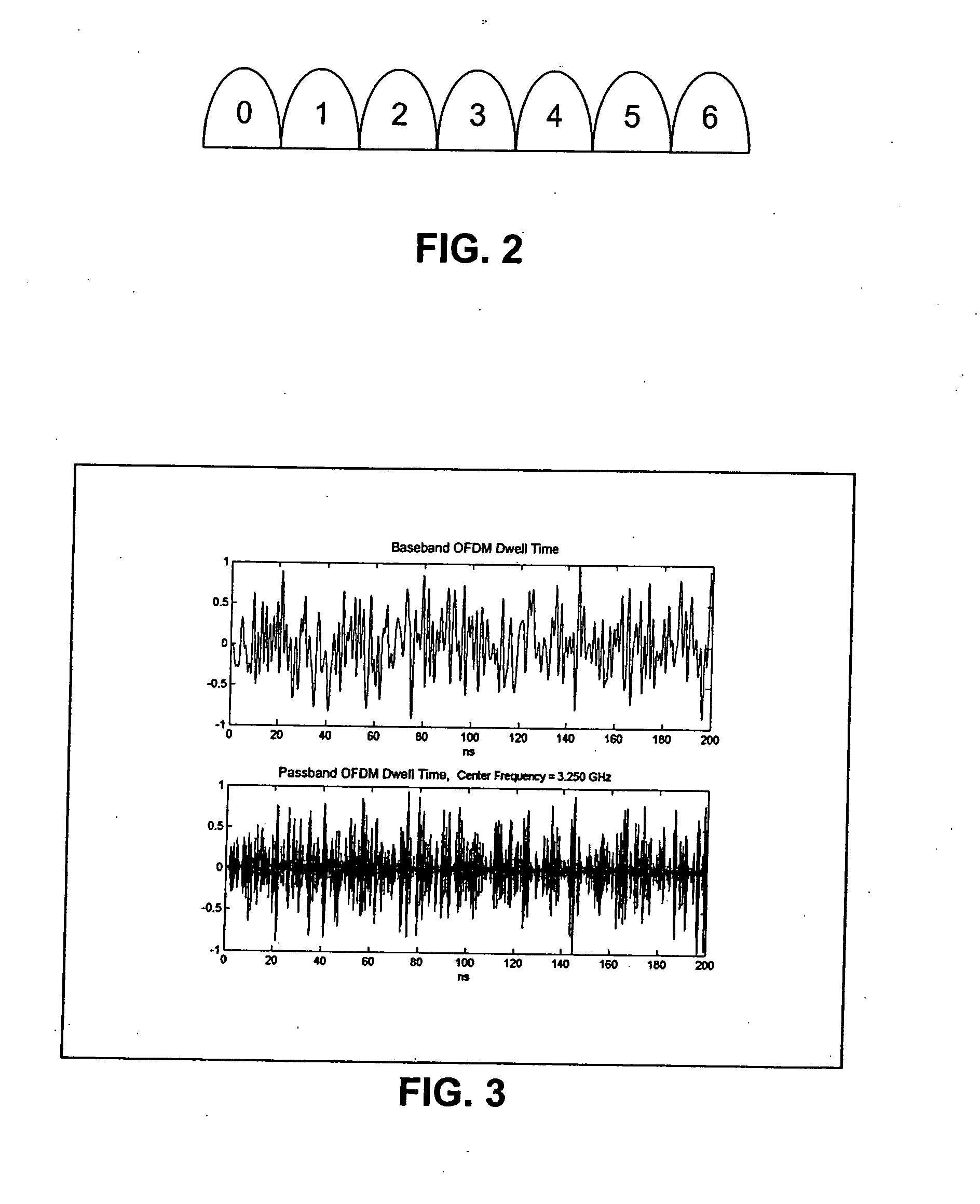

Methods and sets of piconets using time frequency division multiple access

InactiveUS7460559B2Shorten the timeNetwork traffic/resource managementCriteria allocationTime division multiple accessFrequency-division multiple access

A set of piconets and corresponding methods and computer programs may reduce contention time between piconets. In one embodiment, a seven-length code architecture may be used with group(s) of bands so that contention time cannot exceed 1 / 7 of the time. Up to seven different bands can be used within each group. When less than seven bands are used (e.g., three or six), at least one of the bands may be assigned to more than one dwell time during a time span. Alternatively, each dwell time within the time span may be assigned to a different band. The state may be changed as needed or desired. Substitution of extra bands may also be used. Using either scheme (repeated bands or changing states), a prime-number architecture can be used with a non-prime number of different bands. Simultaneous communications using at least two bands within a piconet may be used.

Owner:ALEREON

Method for generating digital combined pulse signals with continuous phase positions

InactiveCN104063008AThe amplitude is stable in the time domainSolve the problem of multiple triggersDigital function generatorsRadar systemsPhased array

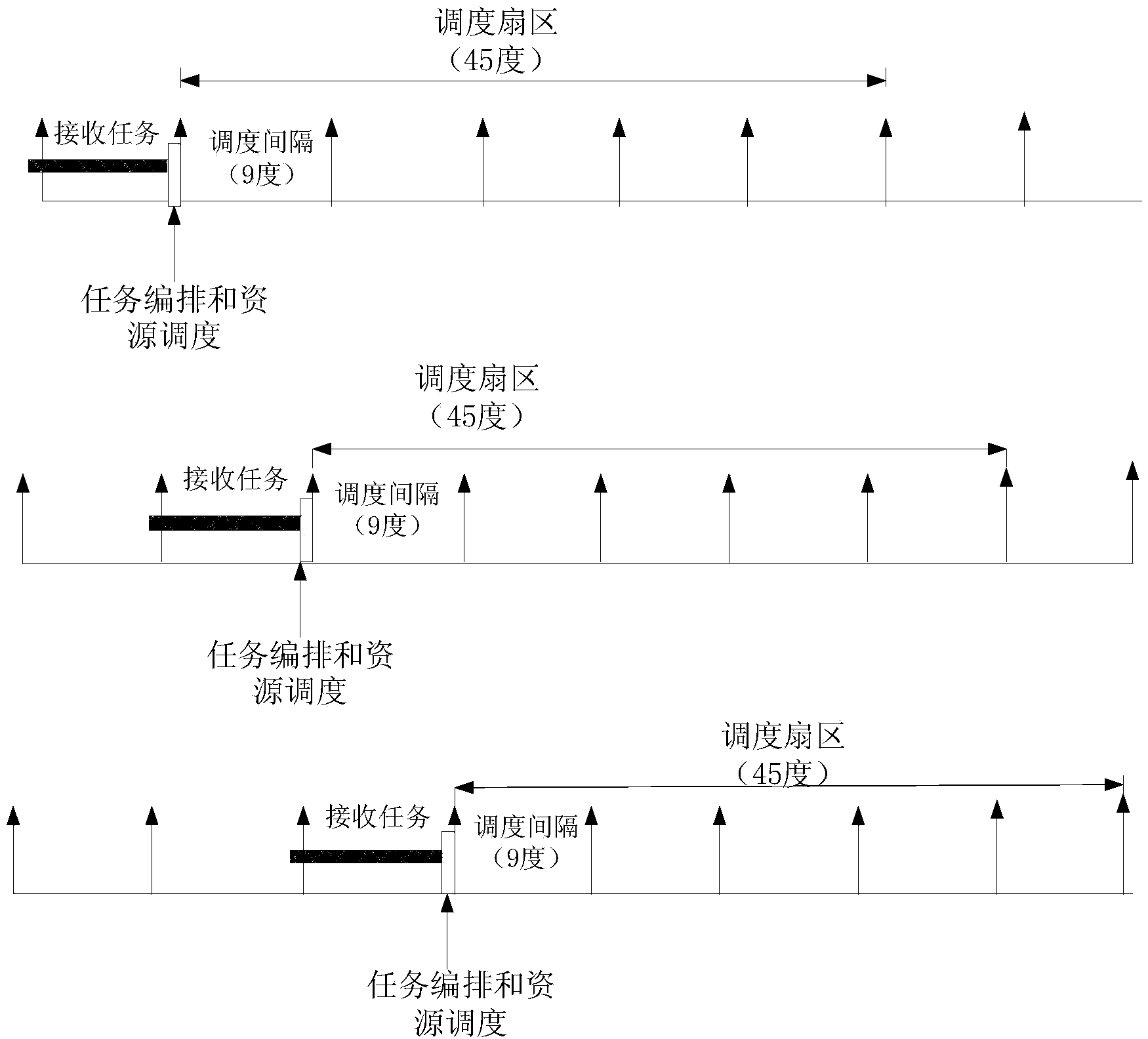

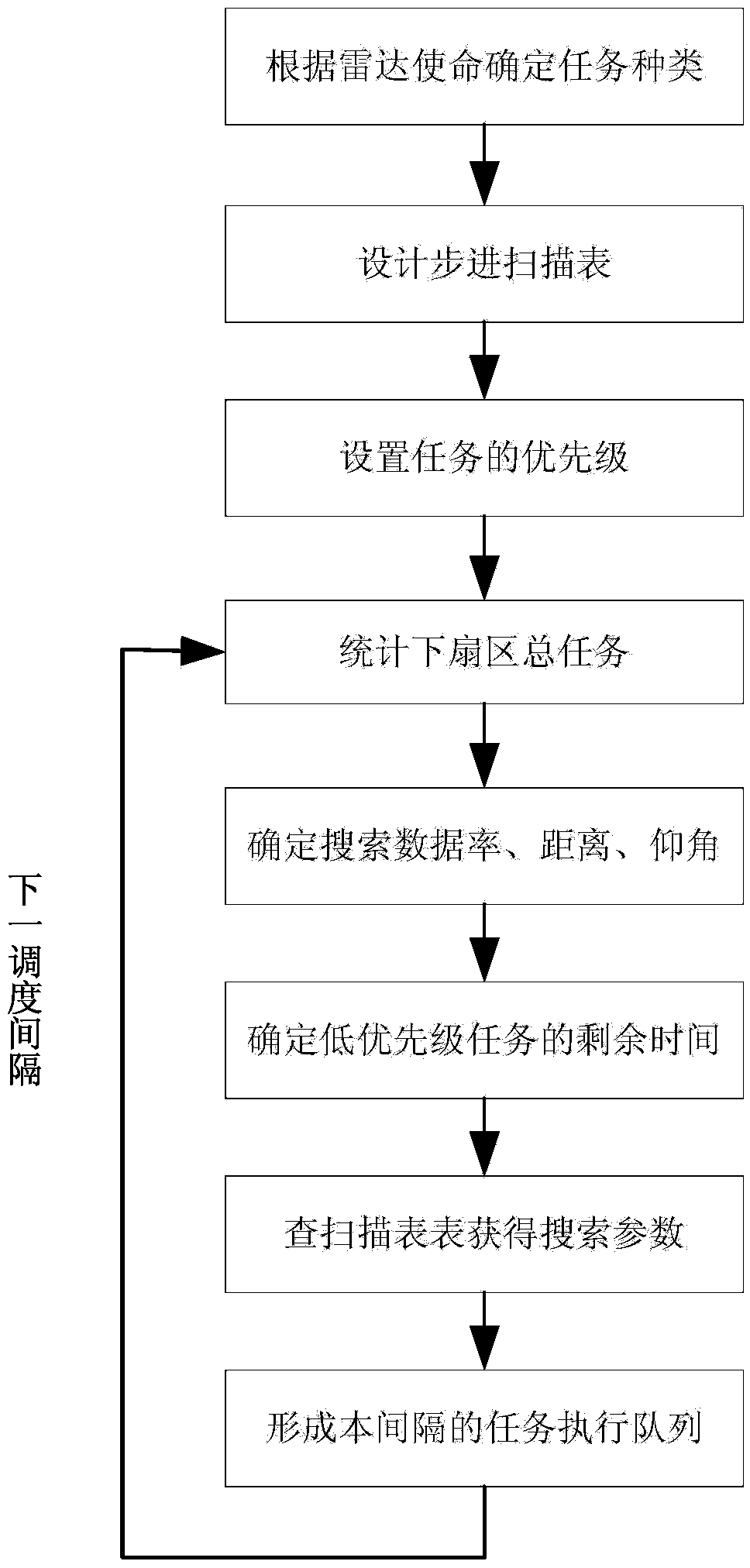

The invention belongs to the field of phased array radar resource scheduling, and relates to a sliding window resource scheduling technology based on sectors, in particular to a method for generating digital combined pulse signals with continuous phase positions. The technology is mainly suitable for resource management and distribution of a two-dimensional rotary phased array radar. A radar system carries out resource distribution on multiple functions and multiple tasks according to the sectors, and the residence time of various tasks is adjusted in the sectors in a self-adaptive mode according to loads of the tasks. According to the sliding window resource scheduling technology, when resource distribution is carried out on a current scheduling interval, the task load condition of one sector starting from the current scheduling interval is considered, the task load of one sector starting from the next interval is considered when the next scheduling interval is carried out, and sliding window type resource scheduling is formed. The residence time distribution ratio of the various tasks is determined according to the different work modes of the radar, the detection range, the search data rate, the fine batch number, the determination batch number and the like of the radar are adjusted in a self-adaptive mode according to the time obtaining the tasks, the multiple functions and the multiple tasks are achieved at the same time, and the flexibility and operational effectiveness of the two-dimensional rotary phased array radar are improved.

Owner:THE 724TH RES INST OF CHINA SHIPBUILDING IND

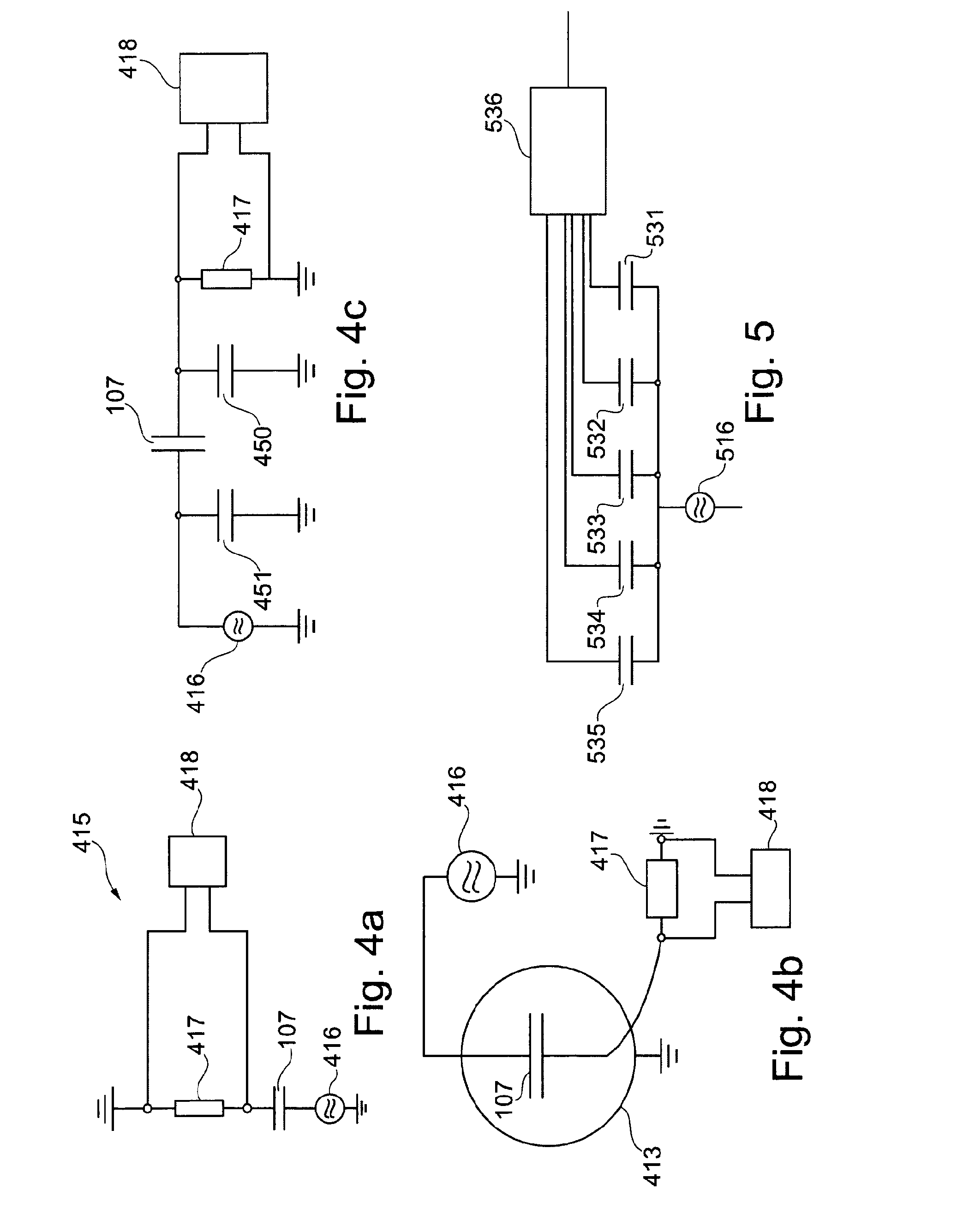

Device For And Method Of Determining Residence Time Distributions

InactiveUS20110074058A1Easy to handleNot easy to make mistakesAuxillary shaping apparatusCapacitanceEngineering

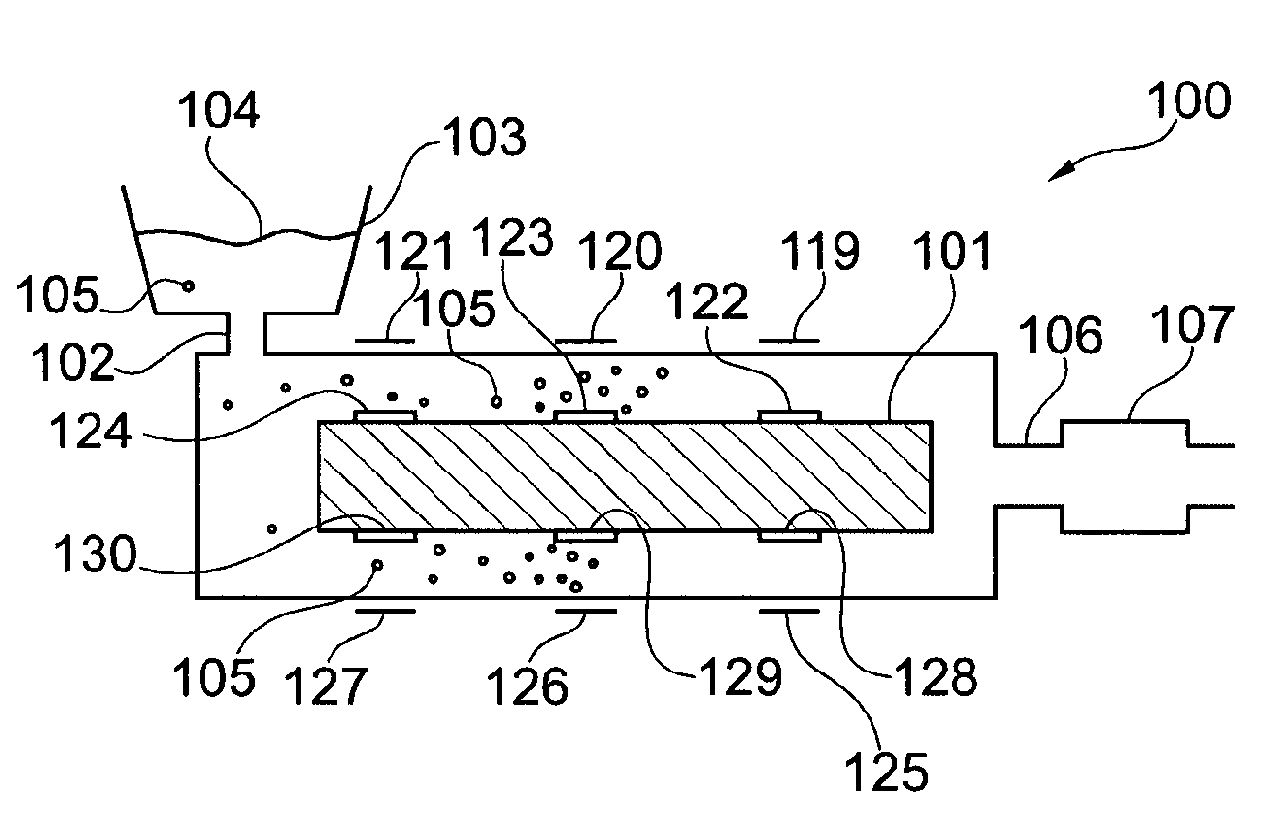

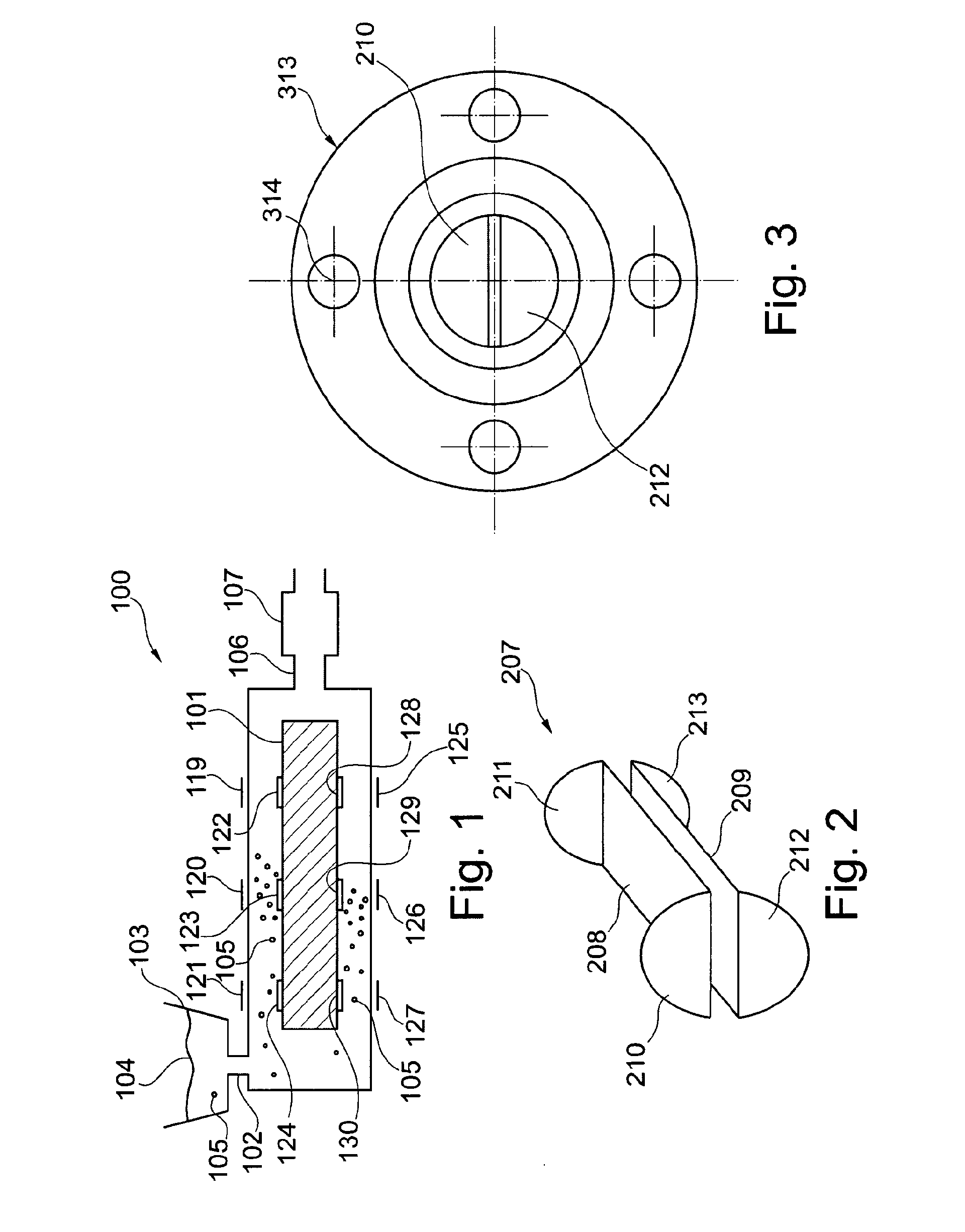

A method of determining a residence time distribution comprises mixing a molding batch (104) and a tracer (105), wherein the tracer has a ferroelectric curie temperature above 120° C., and transmitting the mixture through a capacitor (107). Further, the method comprises measuring a capacitance of the capacitor, and determining a residence time distribution based on the measured capacitance. In particular, the ferroelectric curie temperature of the tracer may be above 150° C. and preferably the ferroelectric curie temperature of the tracer is above 200° C.

Owner:MONTANUNIV LEOBEN

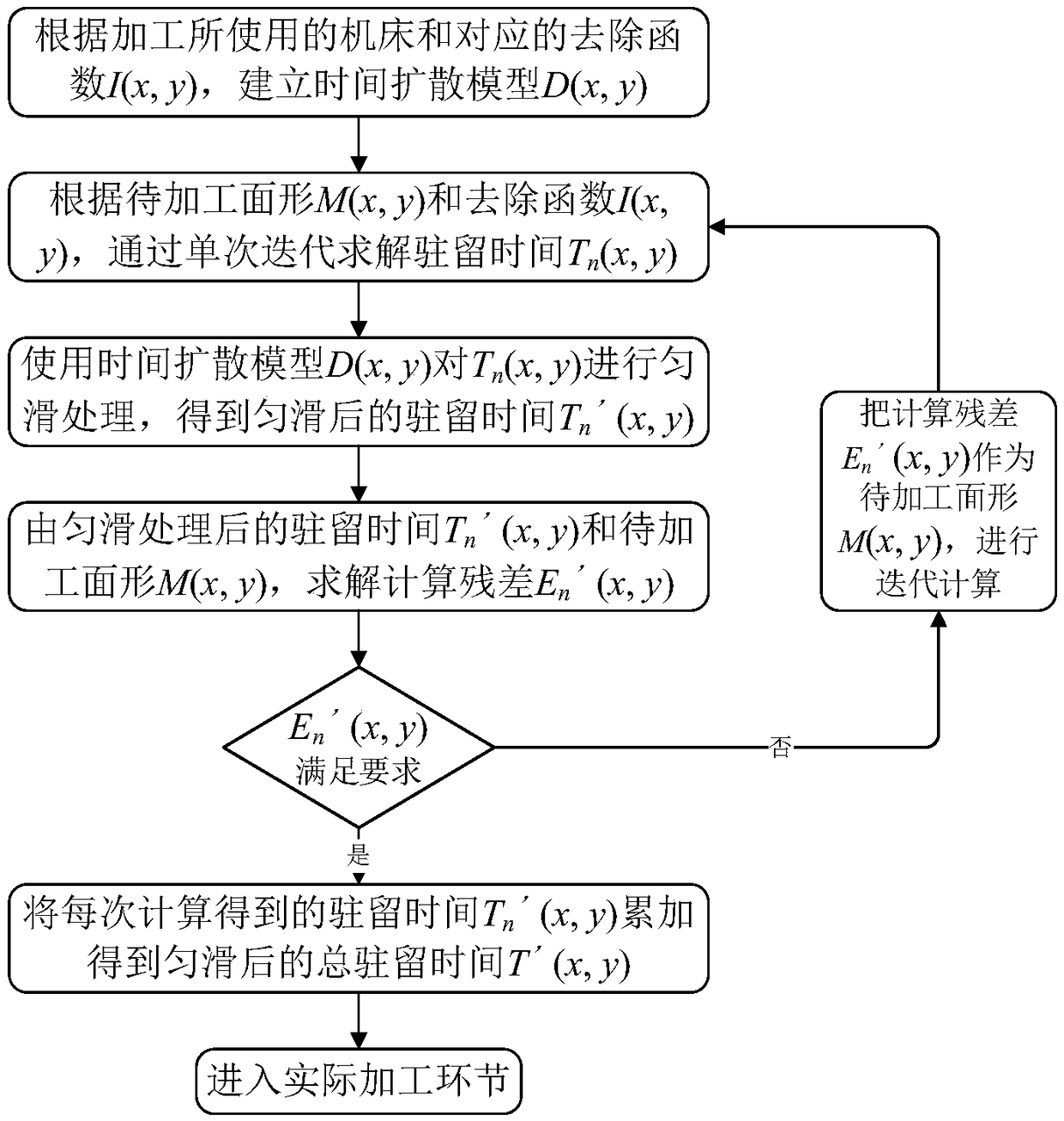

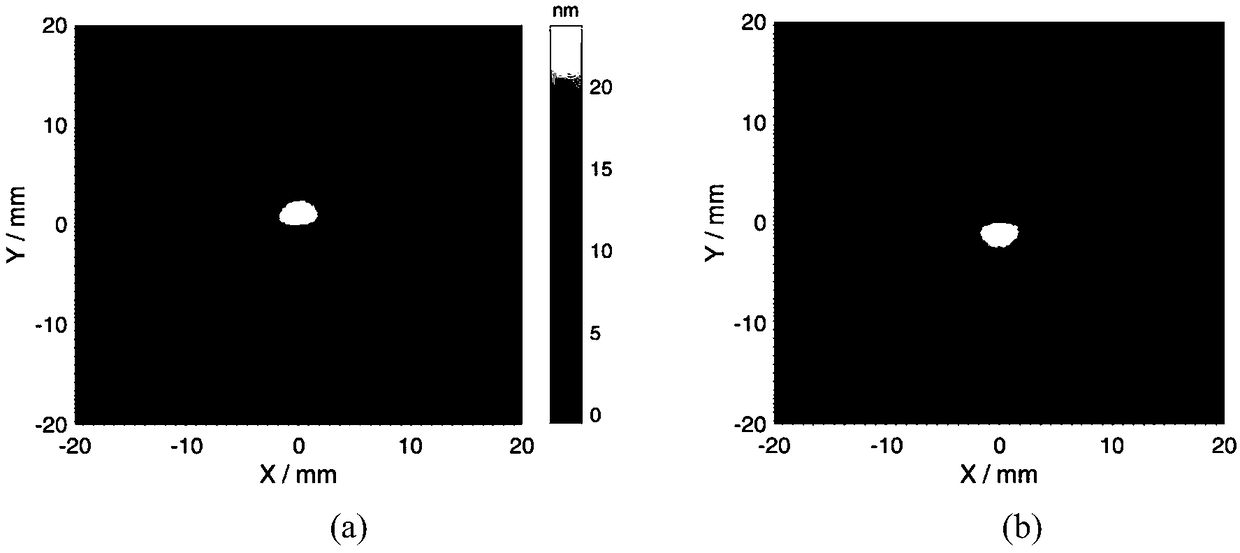

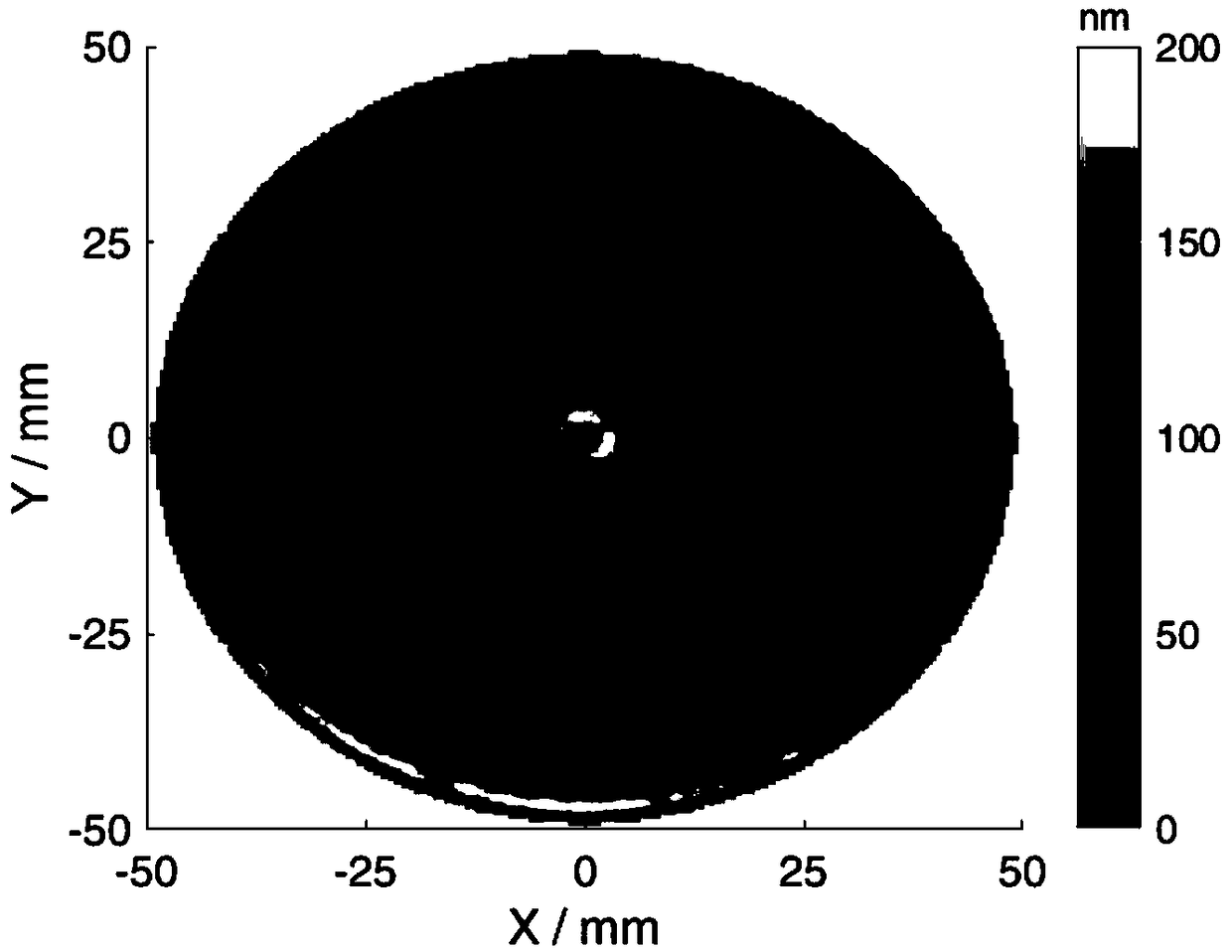

Smoothing method for residence time in optical-element processing process

ActiveCN109227226APlay a compensatory effectFast convergenceOptical surface grinding machinesGrinding feed controlNumerical controlMedium frequency

The invention discloses a smoothing method for residence time in the optical-element processing process. In the method, a time diffusion model is introduced, residence time distribution obtained afterconventional calculation is diffused, and therefore it is achieved that the residence time is smoothed. Compared with original residence time, in the residence time after smoothing treatment, time difference values on adjacent diffusion points are relatively small, smooth transition between the adjacent diffusion points is achieved accordingly, and the influence when a polishing tool is frequently accelerated and decelerated in the processing process on the tool stability is thus reduced. By means of the smoothing method for the residence time in the optical-element processing process, the convergence effect of calculation can be improved through time diffusion treatment, the jumping degree of the residence time between the adjacent diffusion points can also be reduced by smoothing the residence time, the stability of numerical control machining can be improved, and the medium frequency error and the high frequency error which are introduced in an element are thus reduced since the polishing tool frequently shakes.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

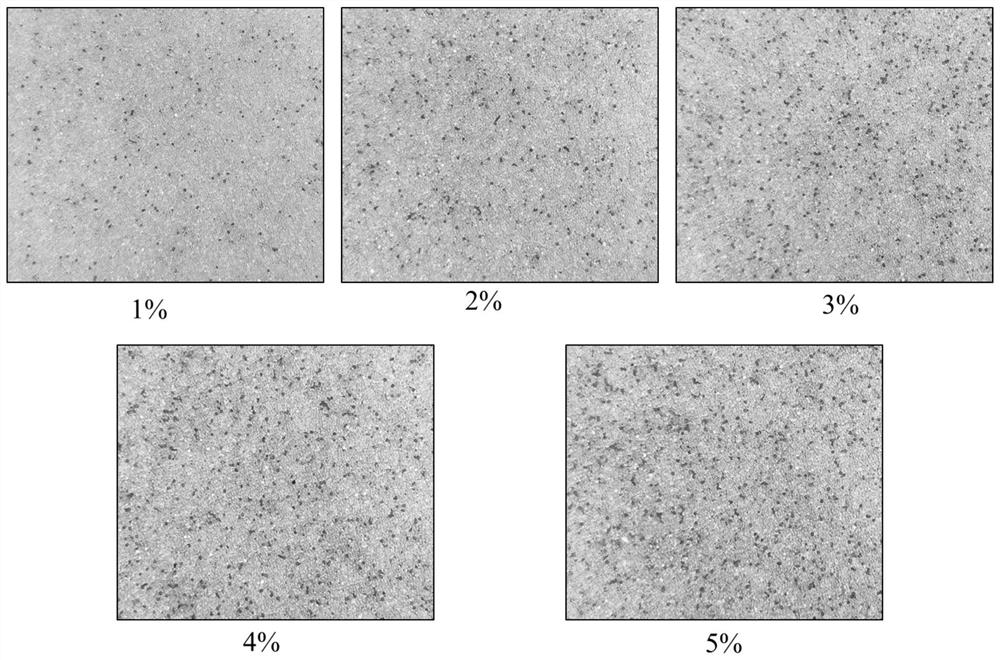

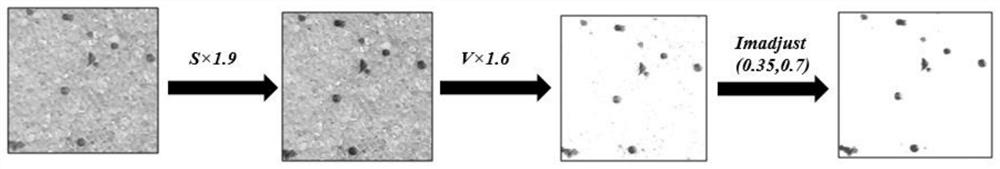

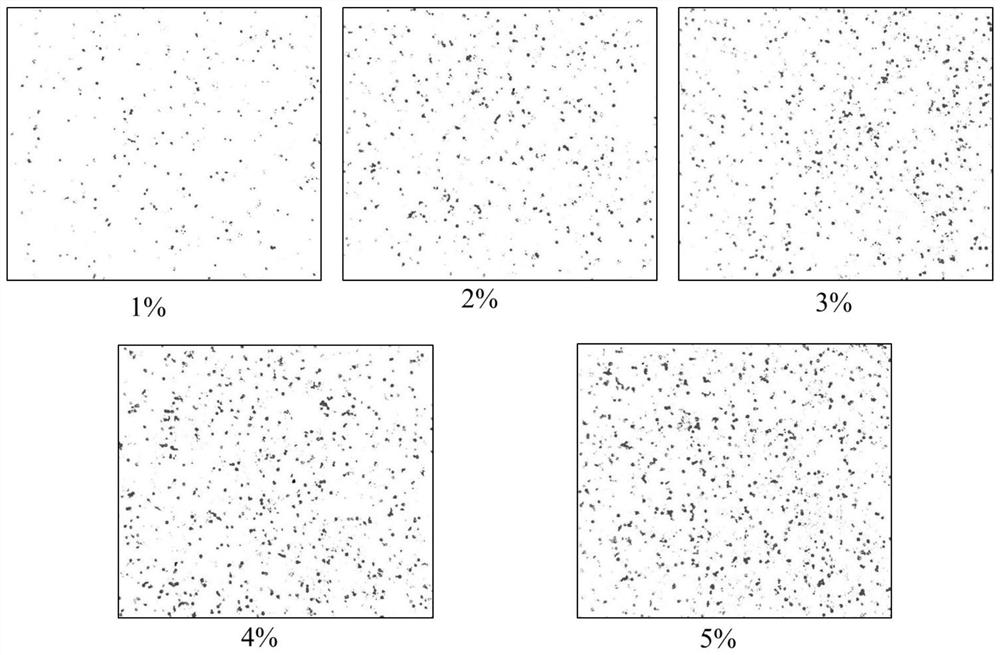

Method for measuring solid particle residence time distribution in fluidized bed based on image recognition principle and test bed thereof

ActiveCN112098283AEasy to operateImprove efficiencyParticle suspension analysisMicroscopic object acquisitionFluidized bedComputational physics

The invention provides a method for measuring solid particle residence time distribution in a fluidized bed based on an image recognition principle and a test bed thereof. Particles different from bedmaterial particles in color are adopted for tracing, the tracing particles are injected into a bed and then sampled at the discharging end regularly, and all samples are photographed under the same light source condition. By performing background elimination, color enhancement and gray scale adjustment processing on a sample image and identifying pixels representing tracer particles by means of RGB threshold segmentation, the concentration of the tracer particles in the image is calculated, and the particle retention time distribution in a fluidized bed can be calculated by combining the change rule of the concentration of the tracer particles with time. The particle residence time distribution measurement method is simple to operate, high in experiment efficiency, few in error generationlinks and high in accuracy.

Owner:SOUTHEAST UNIV

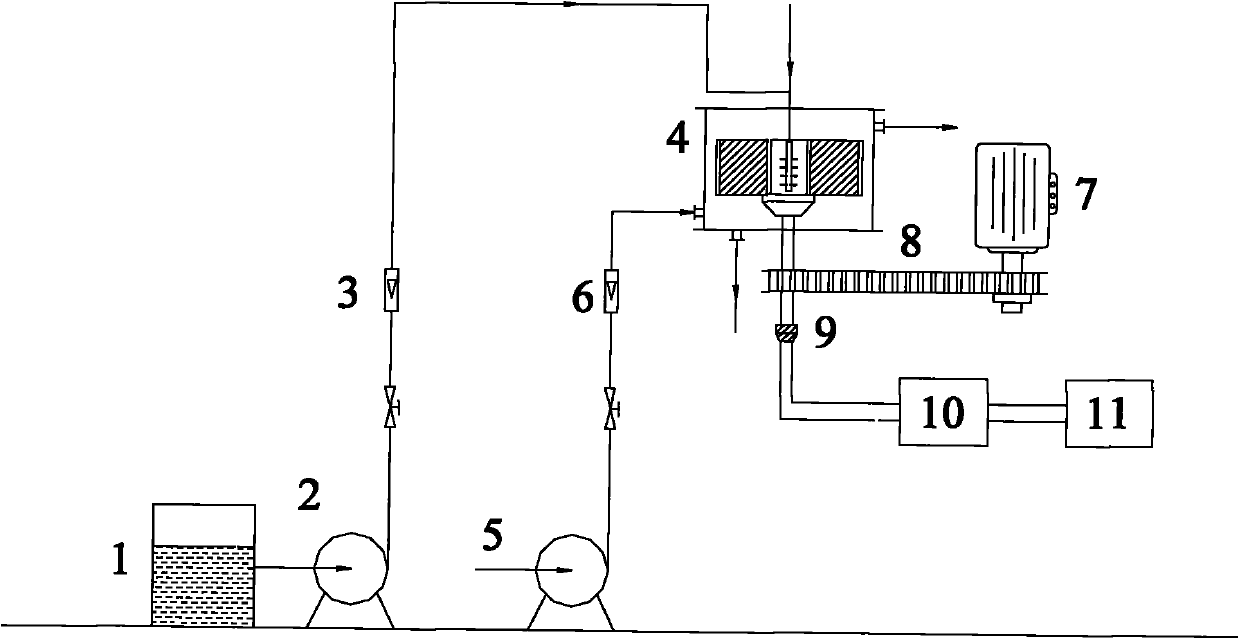

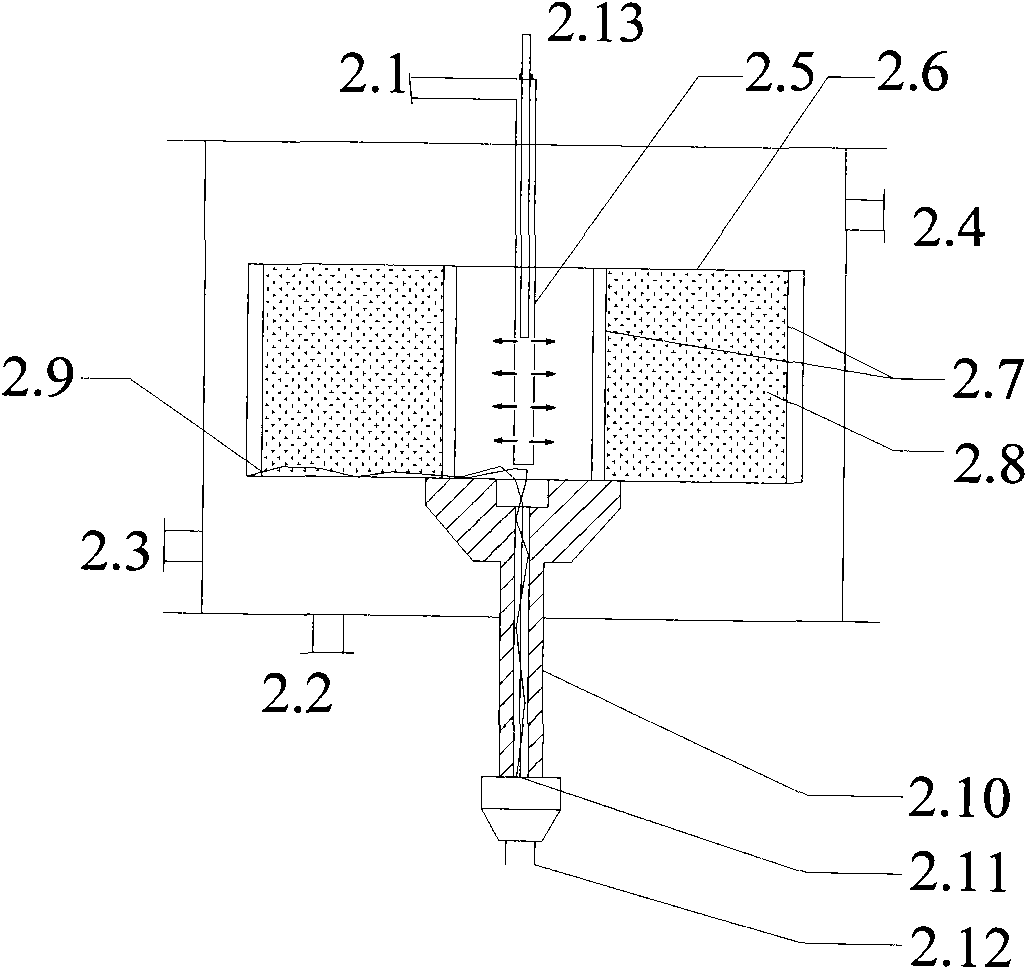

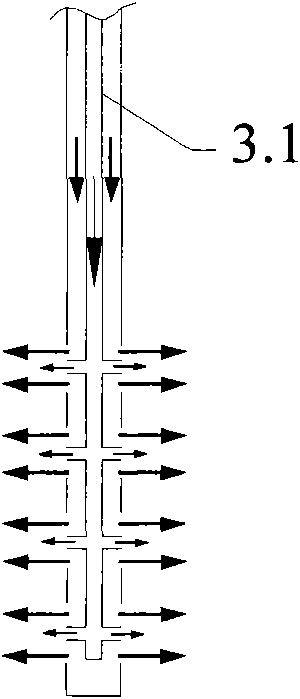

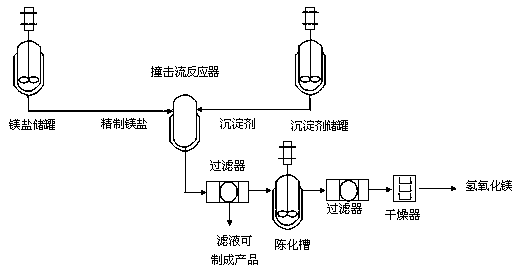

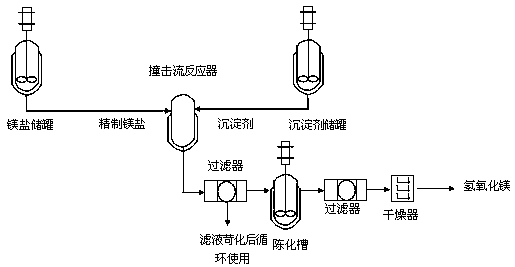

Impinging-stream-based continuous magnesium hydroxide production process

InactiveCN110117021AIncrease production capacityImprove sealingMagnesium hydroxideMagnesium saltStorage tank

The invention discloses an impinging-stream-based continuous magnesium hydroxide production process, and relates to a magnesium hydroxide production process. The process comprises the steps that a magnesium salt and precipitant with certain concentration serve as raw materials, an impinging stream reactor is adopted, in the impinging stream reactor, the magnesium salt and the precipitant react at20-90 DEG C, magnesium hydroxide precipitates are generated, the obtained precipitates are aged at 50-120 DEG C for 1-10 hours, then filtering and drying are conducted, and a magnesium hydroxide product is finally obtained. Auxiliary equipment of the process comprises a raw material storage tank, a pump, a flowmeter, a filter, an ageing tank, a dryer and the like. Accordingly, the impinging streamreactor is adopted, the magnesium salt and the precipitant serve as the raw materials, and the magnesium hydroxide product which is high in dispersion, small in specific surface area, uniform in particle size and consistent in crystal form can be obtained. By means of the continuous magnesium hydroxide production process, the materials are mixed rapidly, the reaction is efficient, and residence time distribution is narrow. The process flow is short, the equipment is less, and the product quality is good and stable.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Methods and sets of piconets using time frequency division multiple access

InactiveUS20070155330A1Reduce contention timeShorten the timeNetwork traffic/resource managementCriteria allocationTime division multiple accessFrequency-division multiple access

A set of piconets and corresponding methods and computer programs may reduce contention time between piconets. In one embodiment, a seven-length code architecture may be used with group(s) of bands so that contention time cannot exceed 1 / 7 of the time. Up to seven different bands can be used within each group. When less than seven bands are used (e.g., three or six), at least one of the bands may be assigned to more than one dwell time during a time span. Alternatively, each dwell time within the time span may be assigned to a different band. The state may be changed as needed or desired. Substitution of extra bands may also be used. Using either scheme (repeated bands or changing states), a prime-number architecture can be used with a non-prime number of different bands. Simultaneous communications using at least two bands within a piconet may be used.

Owner:ALEREON

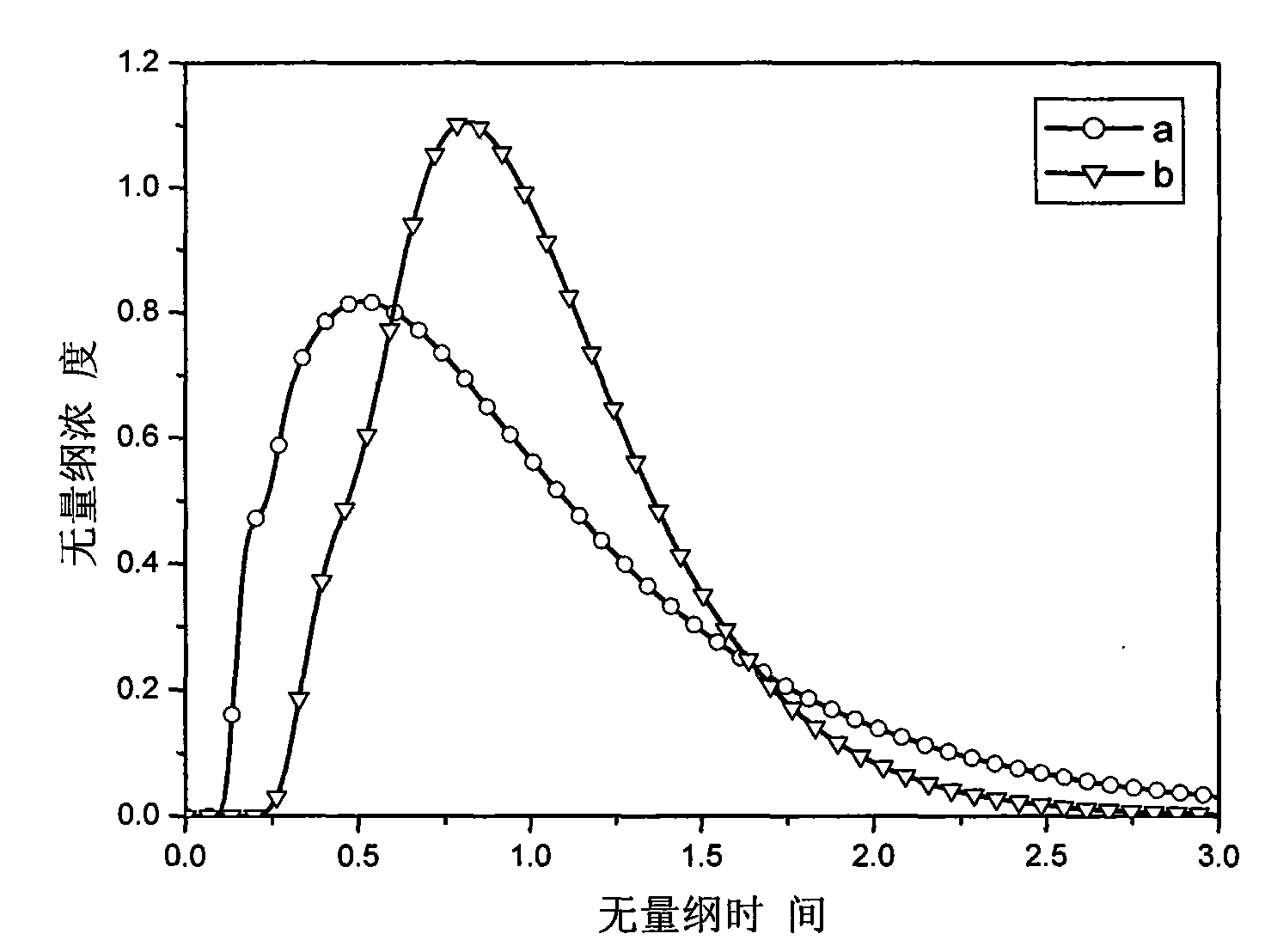

Mathematical modeling evaluation method for tundish flow control effect

The invention is a mathematical modeling evaluation method for tundish flow control effect, comprising the following steps: adopting numerical technique to simulate and track the characteristic value of residence time distribution (RTD) curves of a tracer agent to evaluate the quality on the tundish packet type and a flow control device; establishing evaluation standard for RTD curve quality; the tundish flow control effect being better when dimensionless concentration at peak value of the RTD curve is more than 1, and the dimensionless time corresponding to the peak value is more than 0.75. The method provided in the invention is suitable for evaluating the quality of the tundish packet type and the flow control device, can evaluate the metallurgical effect of the tundish rapidly and effectively, and plays a leading role in optiming and revamping the tundish packet type and the flow control device in site. The method also can be applied to the analysis of water modeling experiment results.

Owner:SHOUGANG CORPORATION

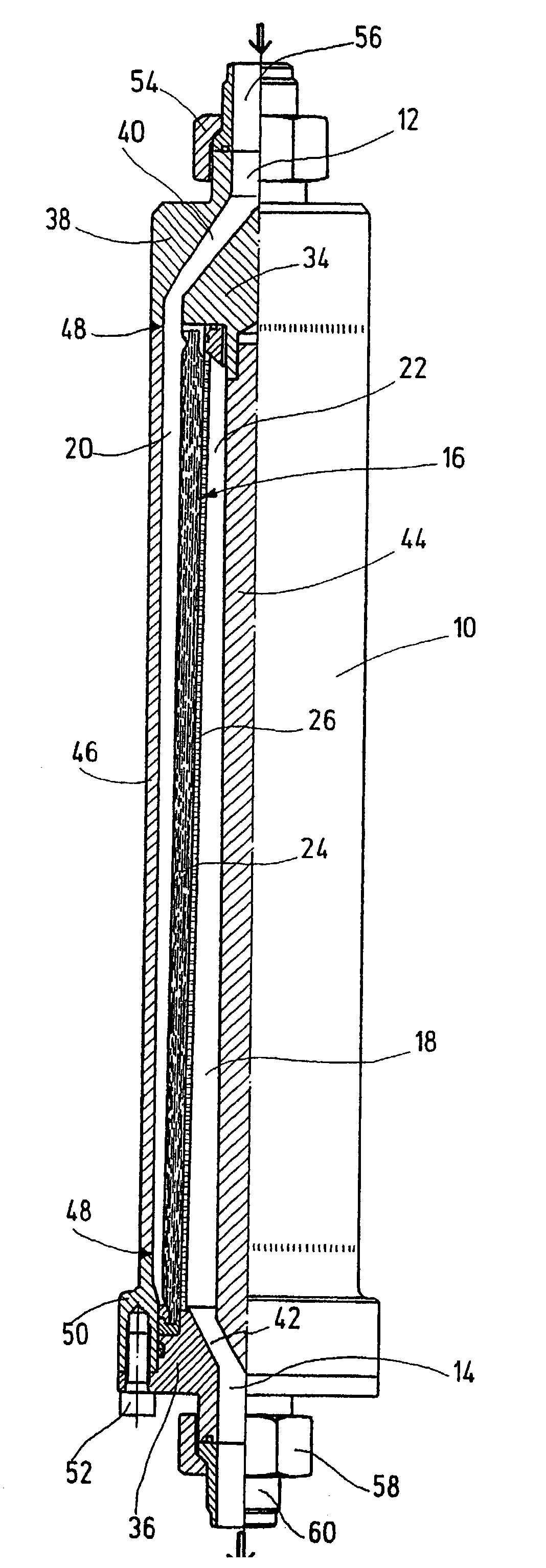

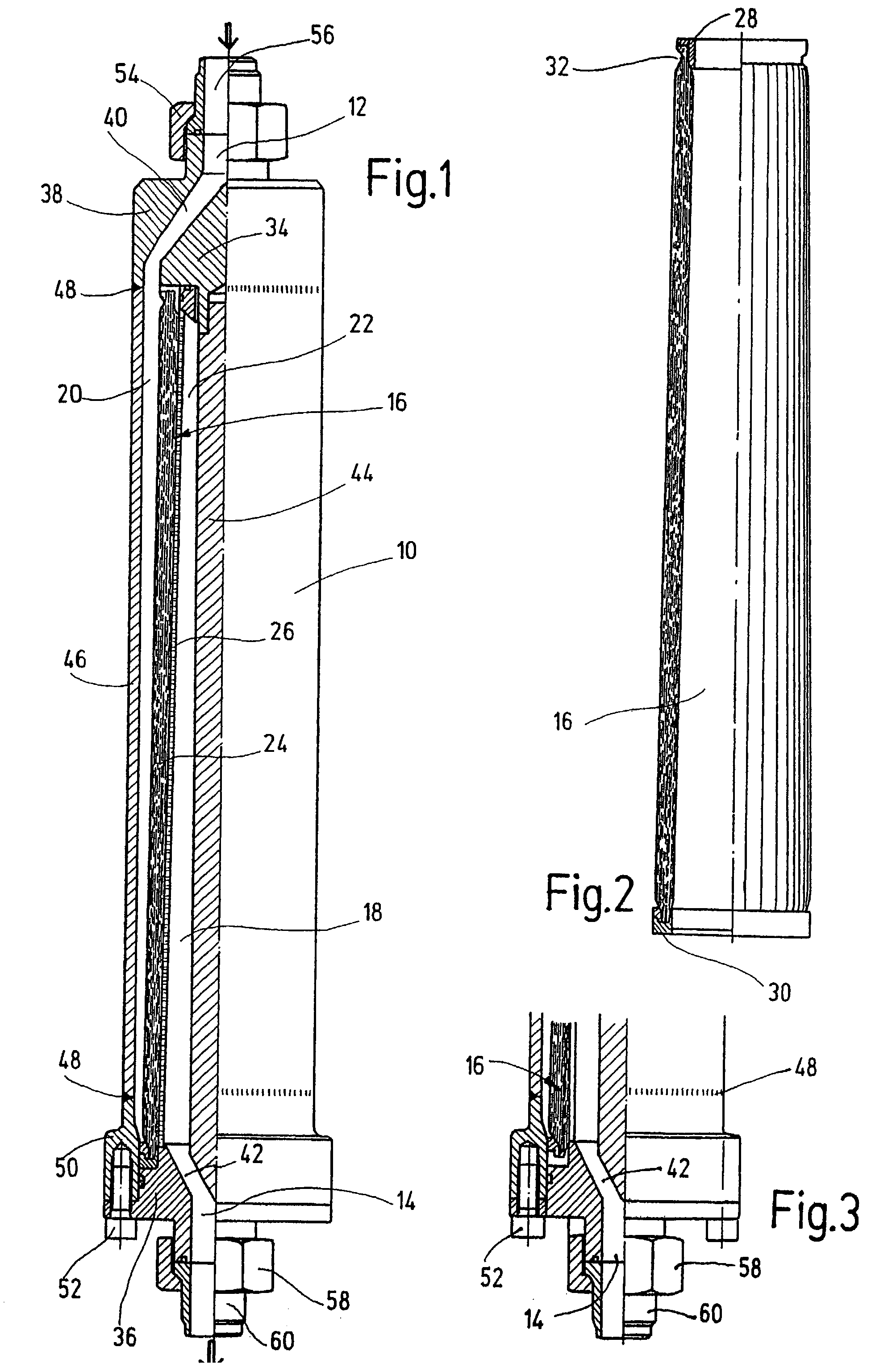

Filter device

InactiveUS7681739B2Improved filter operationImprove operationSettling tanks feed/dischargeMembrane filtersEngineeringPolymer melt

A filter device includes a filter housing (10), a filter inlet (12), a filter outlet (14), and a filter element (16). The filter element divides a filter area (18) into two partial areas (20, 22). One partial filter areas is conical in form with the cross-section of that partial area (20) being tapered from the filter inlet (12) to the filter outlet (14). The partial areas are separated from each other by the filter element. This arrangement results in an optimum residence time distribution inside the filter device at a uniform flow rate, which is particularly useful for highly viscous fluids such as polymer melts or similar.

Owner:HYDAC PROCESS TECH

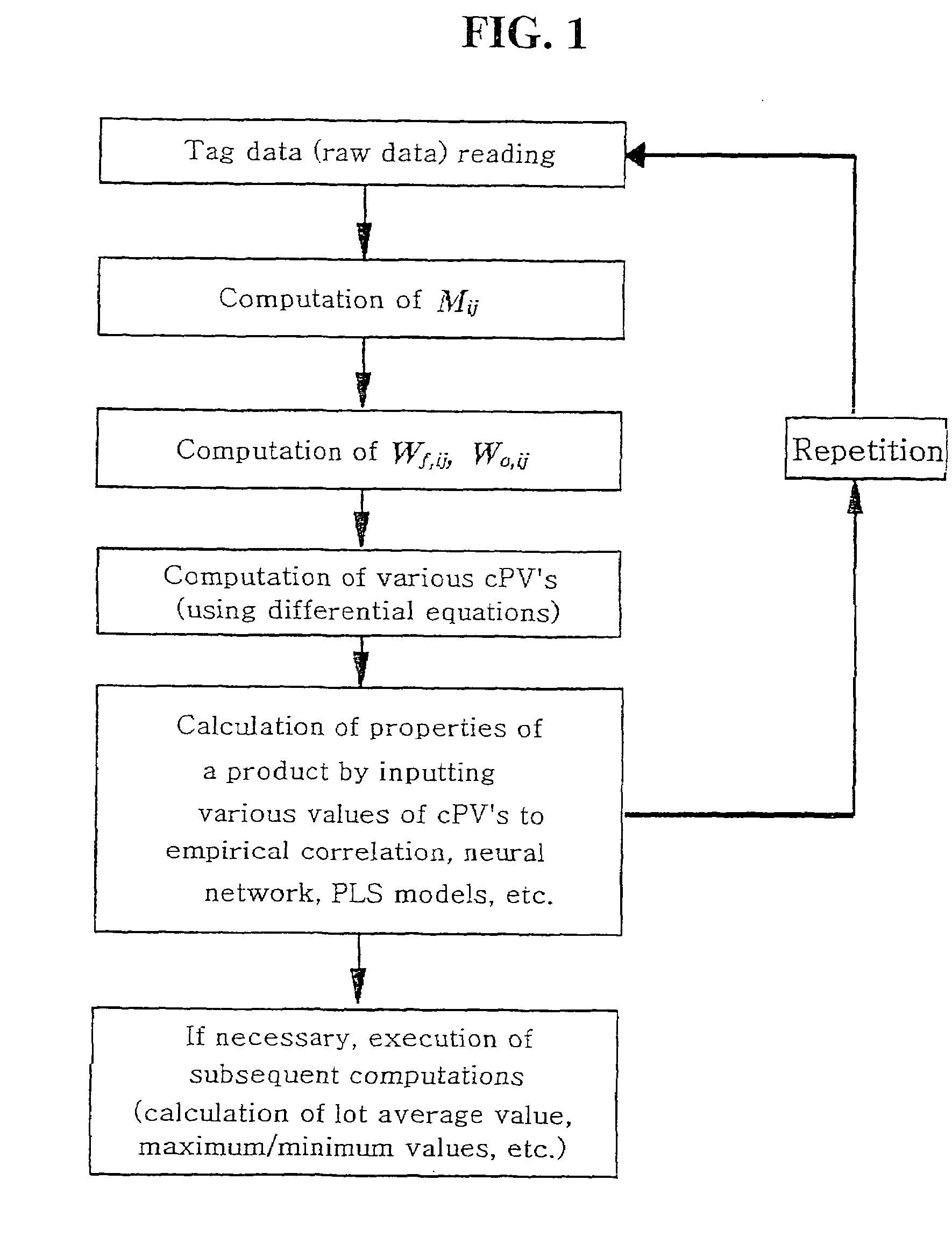

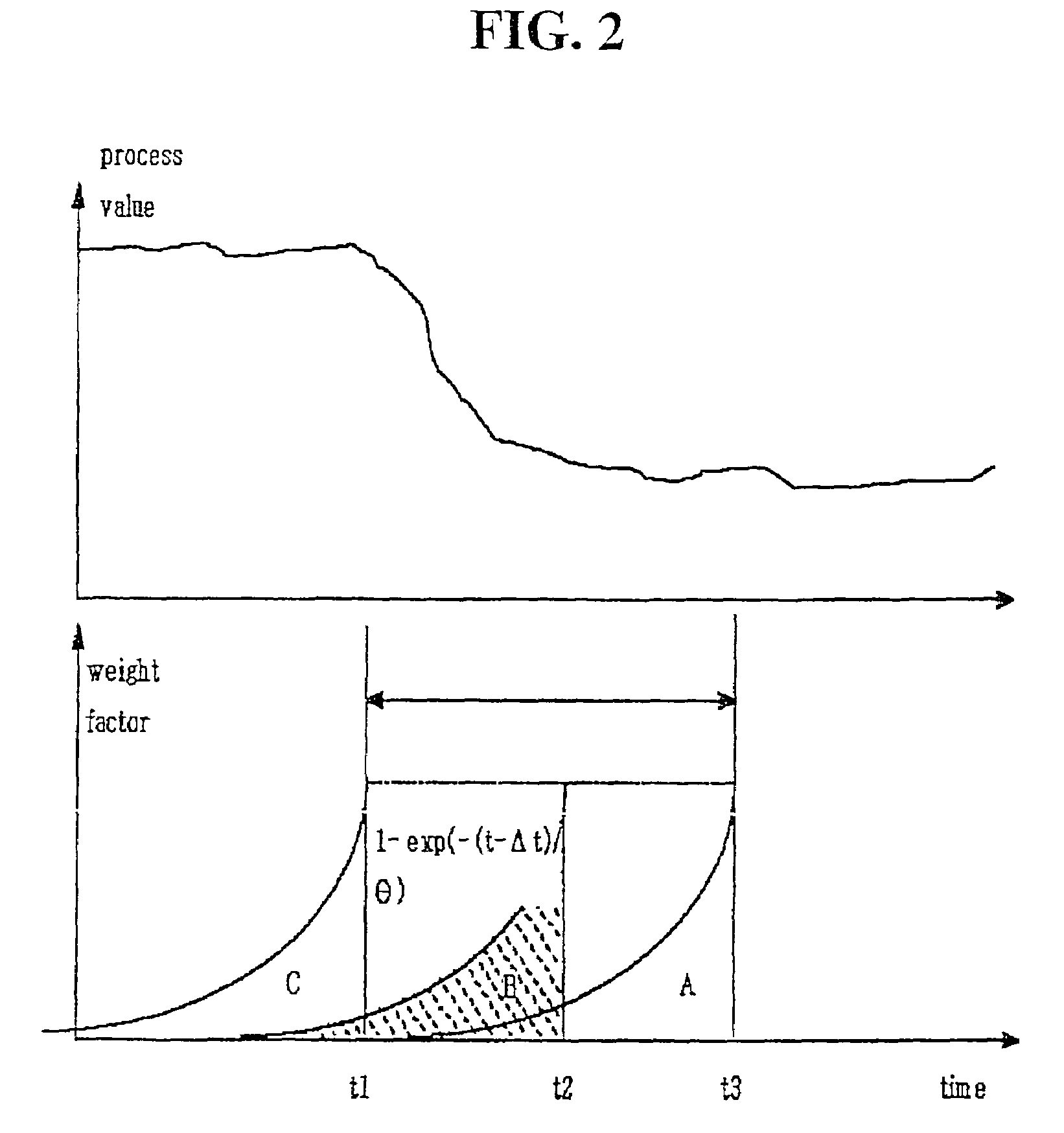

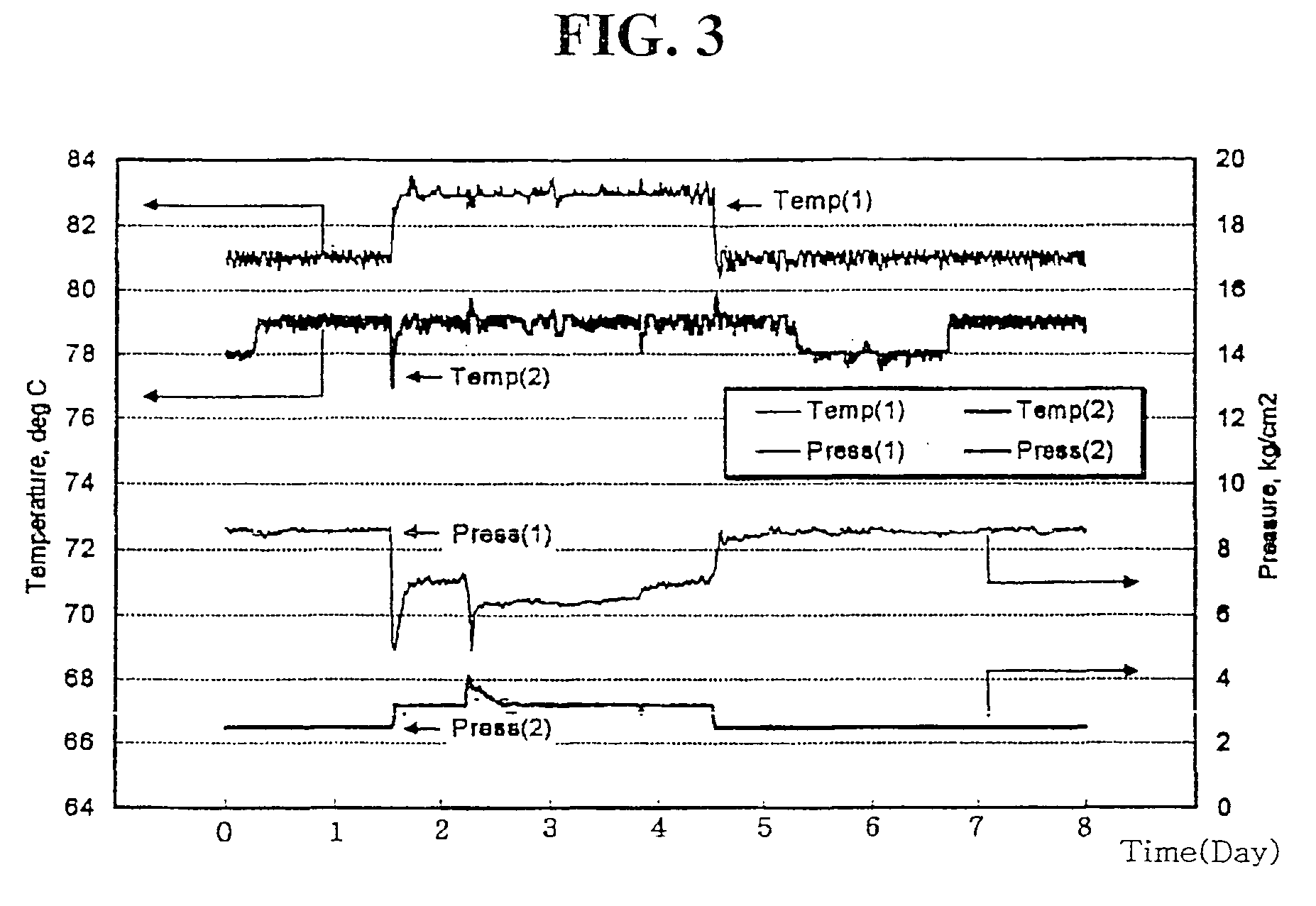

Method of estimating the properties of a polymer product

InactiveUS7024313B2Process control/regulationSampled-variable control systemsTime distributionPolymer

The present invention relates to a method of estimating the properties of a polymer product by using converted process variables (cPV's) which means process variable that final or intermediate product experienced earlier in average in the reactors by stage with respect to the final product, which incorporates residence time distribution to process variables, wherein said method comprises the following steps of: computing cPV's by incorporating the residence time distribution to said process variables by means of theoretically determining the amounts of content and discharge of the product in the process, and then solving the balance equations of a hypothetical substance by taking the respective process variables as those of the hypothetical substance: and estimating the properties of the product by inputting to various property estimation models cPV's in the reactors by stage with respect to the final product after incorporating the residence time distribution to said process variables.

Owner:HANWHA TOTAL PETROCHEMICAL CO LTD

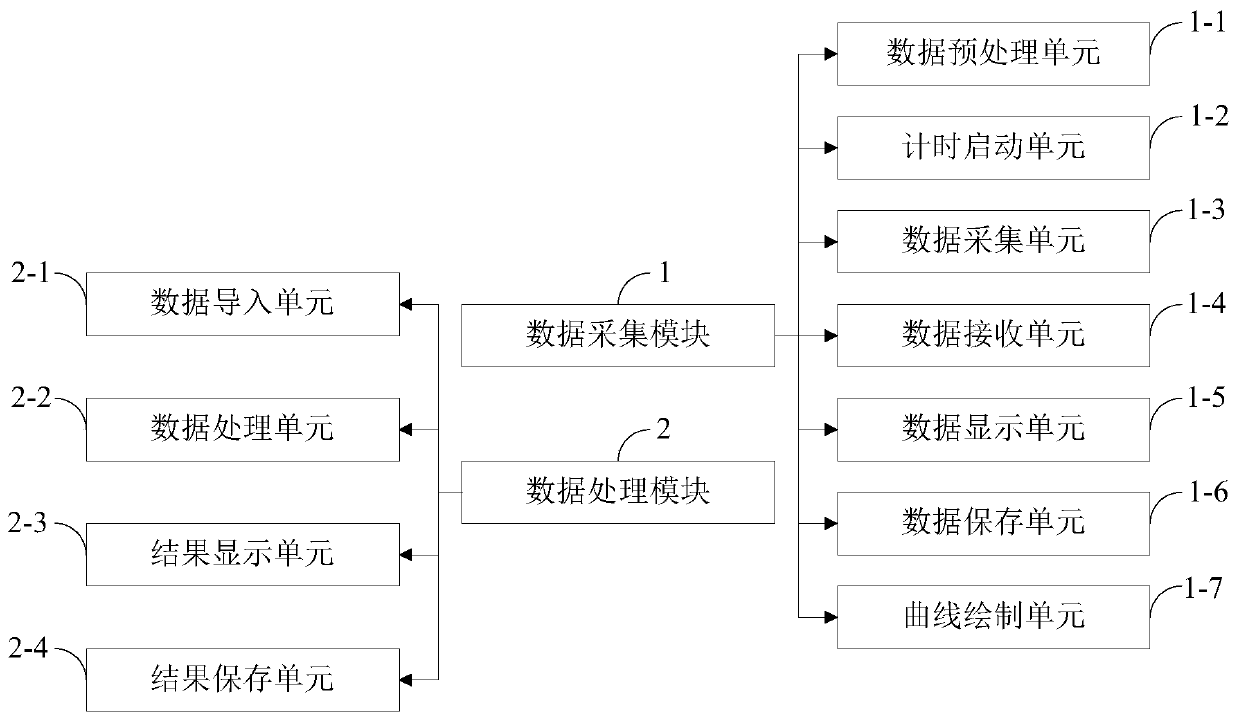

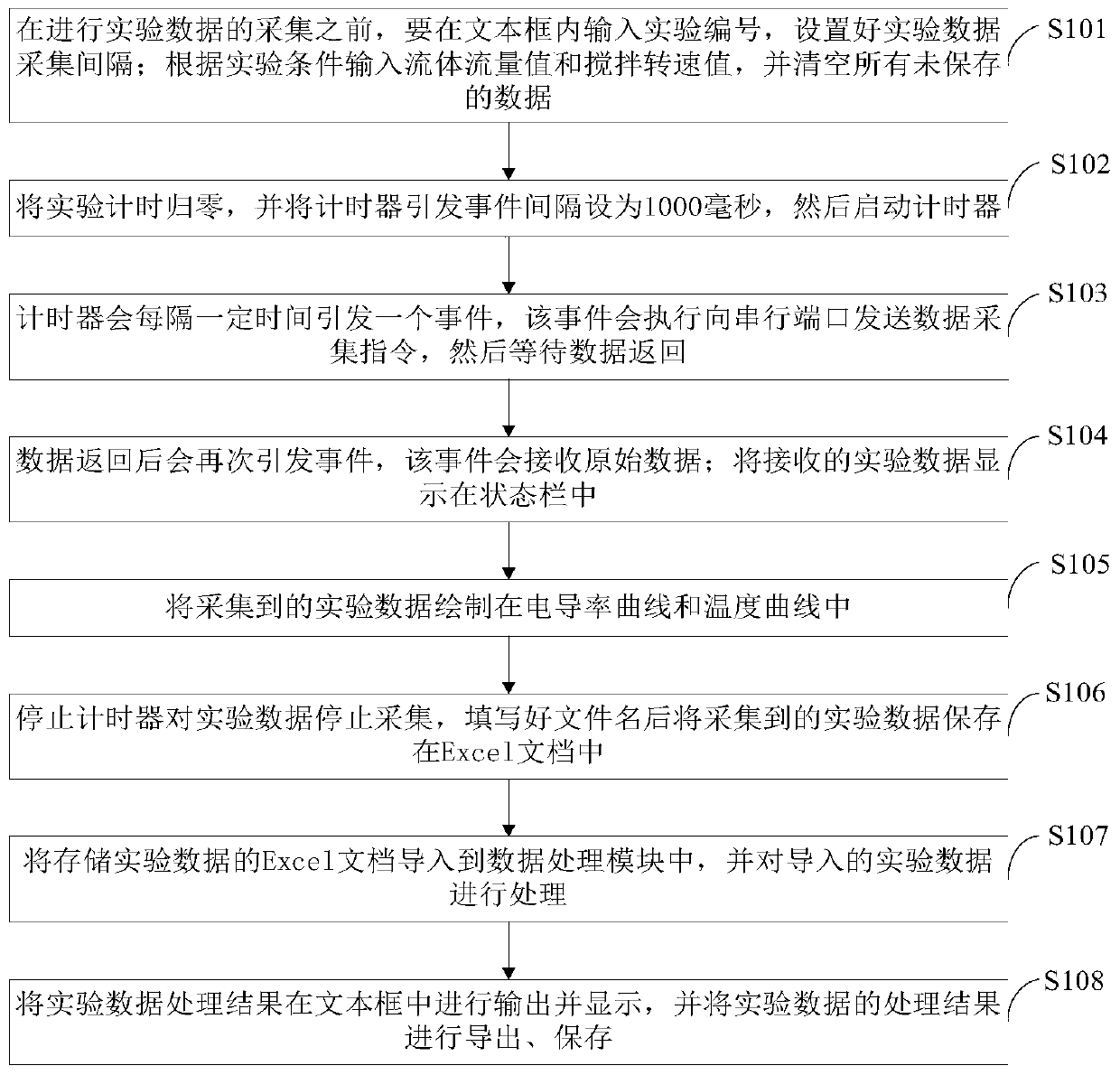

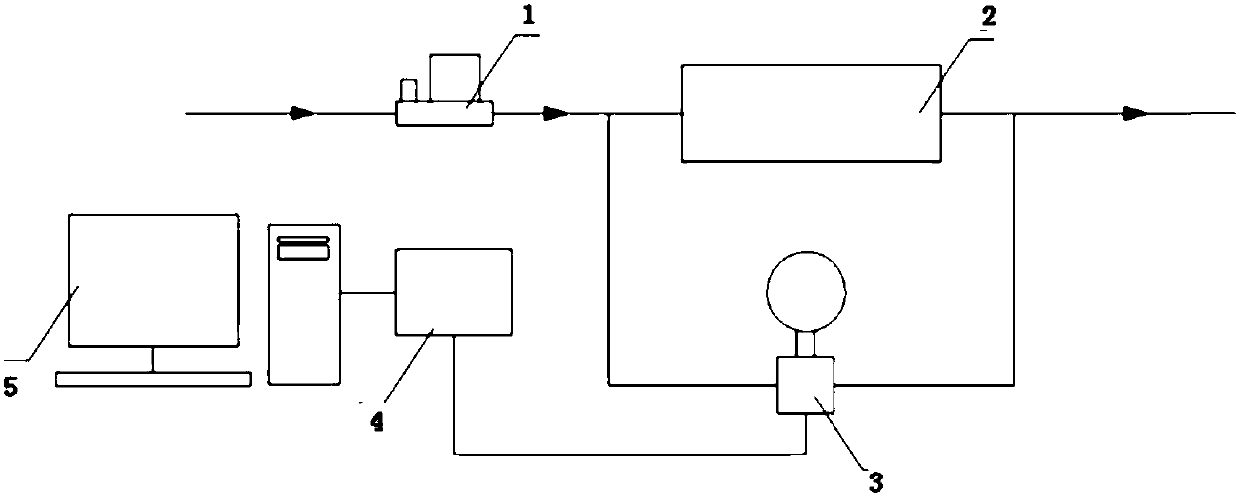

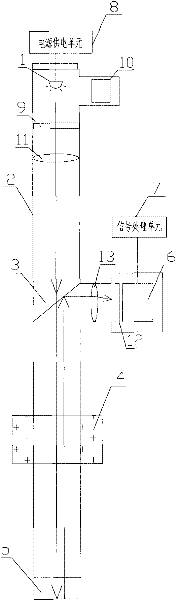

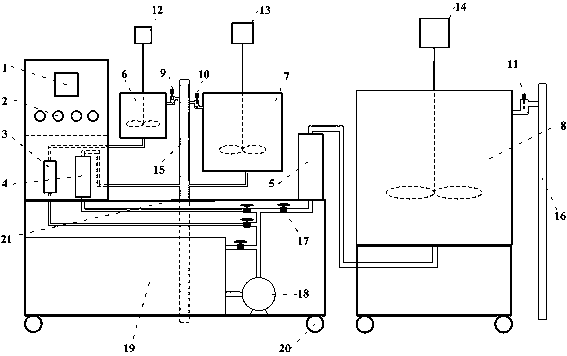

System and method for acquisition and processing of residence time distribution measurement experimental data

InactiveCN110729027AReal-time acquisitionAcquisition stableCheminformatics data warehousingChemical processes analysis/designEngineeringTime distribution

The invention belongs to the technical field of experimental data acquisition and processing, and discloses a residence time distribution measurement experimental data acquisition and processing system. A data acquisition module acquires and saves experimental data. A data processing module imports the acquired and saved experimental data and draws a curve chart. The data acquisition module of theinvention can stably and accurately acquire data of relevant chemical engineering experiments in real time and display the experimental data in the form of the curve chart on a user interface of thesoftware, so that experiment personnel can timely understand the state of the experiments; after the relevant chemical engineering experiments are completed, the data acquisition module will save theexperimental data in an Excel workbook; and the experimental data processing module can import the experimental data saved by the experimental data acquisition software and draw a curve chart, and then process and calculate the experimental data according to different processing schemes and display the results to users according to requirements of the relevant chemical engineering experiments.

Owner:HUAZHONG UNIV OF SCI & TECH

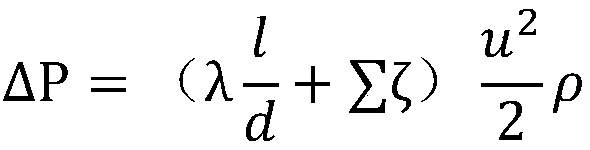

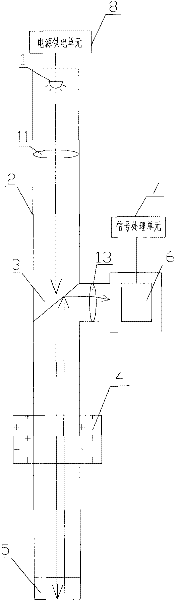

Fixed bed reactor gas phase residence time distribution measuring system and method

The invention discloses a fixed bed reactor gas phase residence time distribution measuring system and method. The system comprises a gas mass flow meter which is used for detecting the mass value andthe flow value of gas entering a fixed bed reactor in real time, a pressure sensor which is used for detecting pressure change electrical signals on both sides of the inlet / outlet of the fixed bed reactor in real time, a data collector which is used for collecting digital signals corresponding to the pressure change electrical signals at set sampling frequency, and a data calculation unit which is used for acquiring a gas phase residence time distribution curve corresponding to fluid in the fixed bed reactor based on each digital signal. According to the invention, the disadvantages that massspectrometry has high cost and complex operation, response time is too long, precision is not enough and the concentration change of a tracer cannot be truly reflected in an RTD determination methodare solved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

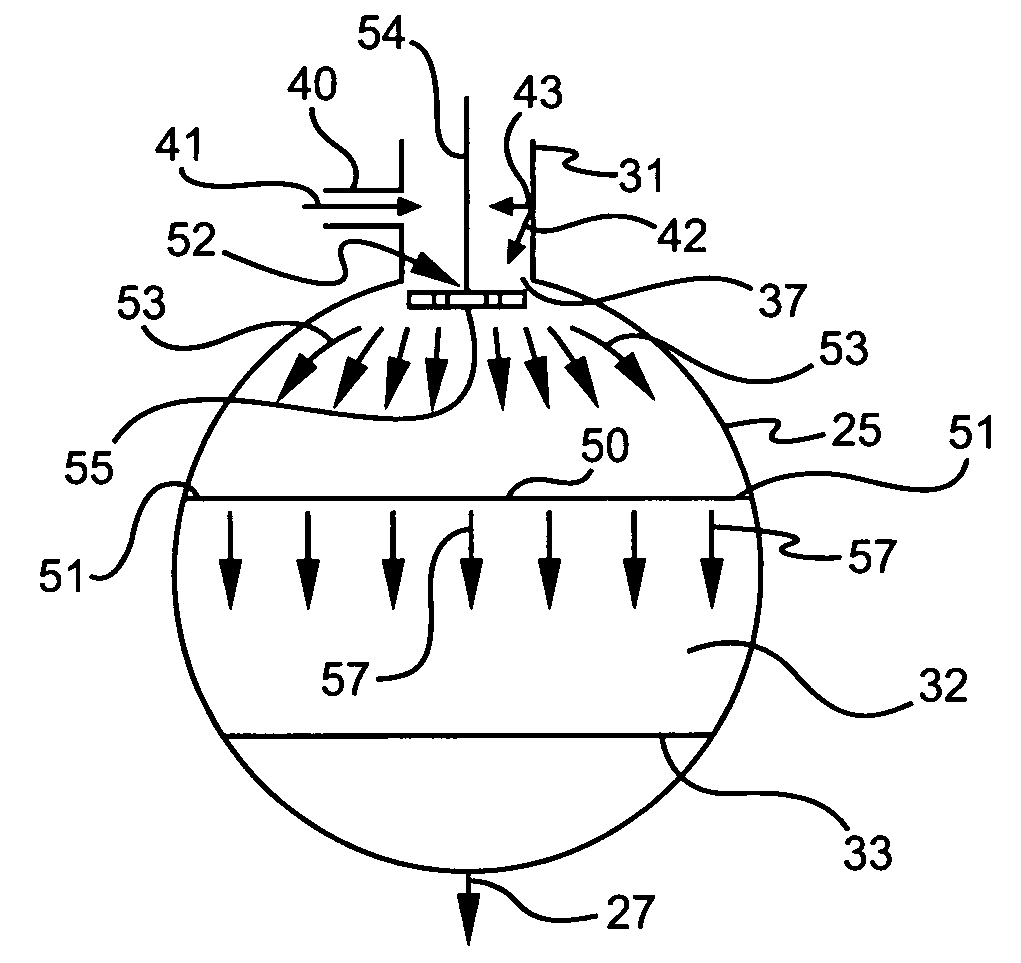

Residence time distribution method and apparatus for operating a curvilinear pressure vessel where transport phenomena take place

A method and apparatus for operating a pressure vessel containing a bed of particulate material comprising substantially leveling the bed and employing a fluid flow distributor above the bed.

Owner:EQUSR CHEM LP

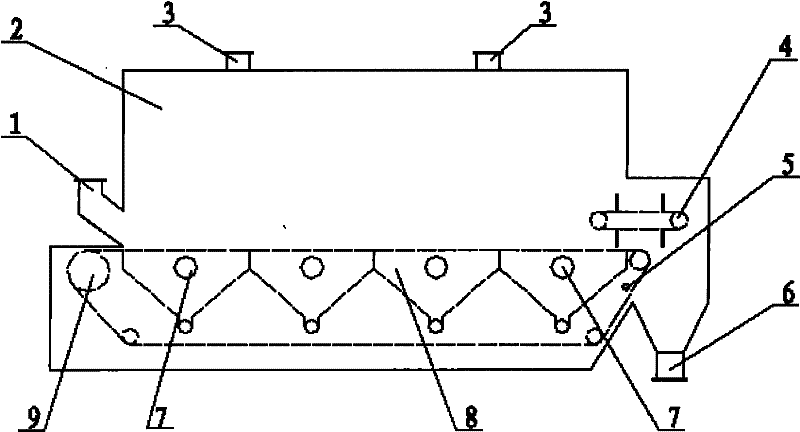

Mobile hot air distribution plate type fluidized bed dryer

ActiveCN102252501ANarrow residence time distributionThere is no problem that cannot be sorted outDrying solid materials with heatHearth type furnacesFluidized bed dryingSmall footprint

The invention discloses a mobile hot air distribution plate type fluidized bed dryer, and belongs to the technical field of drying equipment and engineering. The dryer is characterized by comprising a box body, a hot air distribution chamber, a mobile hot air distribution plate assembly, a mobile weir plate assembly, a material seal type hot air sealing structure, an air knife, a hot air inlet, awaste gas outlet, a wet material inlet, a product outlet and the like. A drying method using the drying equipment comprises the following steps of: adding a wet material onto a hot air distribution plate through the wet material inlet, performing fluidized drying on fine granules by means of hot air in a mobile hot air distribution plate type fluidized bed, drying coarse granules and the mobile hot air distribution plate together while moving, discharging the dried qualified product from the product outlet, and exhausting the waste gas from the waste gas outlet. The dryer has the advantages of simple structure, easiness in manufacture, small floor area, narrow material residence time distribution, uniform water content of the product, and safety and convenience in the operation process.

Owner:DALIAN UNIV OF TECH +1

Device for testing residence time distribution (RTD) of material

InactiveCN101839859BReduce volumeCompact layoutFluorescence/phosphorescenceCoupling lossHigh pressure

The invention discloses a device for testing residence time distribution (RTD) of a material. The device comprises a lighting tube, an optical window, a fluorescence detector, a signal processing unit, an excitation light source, a transflective mirror, a light source power supply unit and the like, wherein the beam emitted from the excitation light source strikes a detected material after passing through the transflective mirror; a tracer in the detected material is excited to emit fluorescence which is transmitted to the fluorescence detector after passing through the transflective mirror; and through the analysis of the signal processing unit, the RTD of the material is calculated. The device for testing the RTD of the material has the advantages of capability of greatly reducing coupling loss and cost because the excitation beam and the fluorescence do not need coupling to an optical fiber in the emitting process, compact light path arrangement, small volume, very convenient use by only being electrically connected with the signal processing unit and the light source power supply unit and capability of conveniently isolating the detected material from the high-temperature and high-pressure environment.

Owner:HANGZHOU EVERFINE PHOTO E INFO

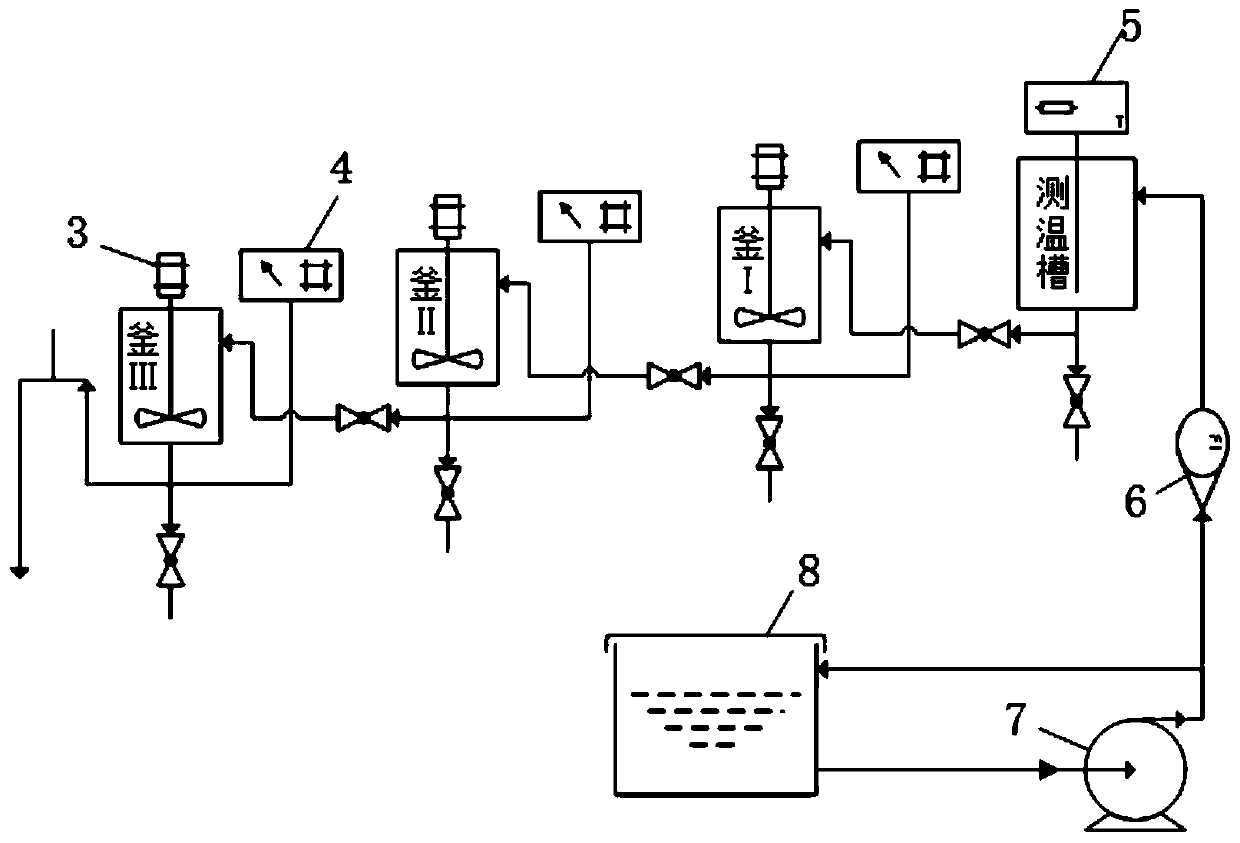

Integrated experiment system for measuring tank reactor amplification effect

PendingCN109126668AIncrease changeSmall fluctuationProcess control/regulationChemical/physical/physico-chemical stationary reactorsWater storageProcess engineering

The invention discloses an integrated experiment system for measuring tank reactor amplification effect. Residence time distribution functions of three tank reactors with similar geometric structuresand same feeding and discharging positions are measured, so that the amplification effect of the tank reactors can be acquired. The system is provided with a water storage box, the electrical conductivity of inlet materials consistently keeps stable, effectiveness of experiment data is improved, generation of surface dead zones can be effectively avoided by the aid of an overflowing mode and an electrical conductivity probe, liquid level of reaction materials in the tank reactors can be controlled, amplification factors of the tank reactors are changed, a circular branch is arranged at an outlet of a water pump, the requirements of the three reactors for different feeding flow rates are met by one water pump, the system is simple in structure and convenient and rapid to operate, all experiment devices are integrated, functional partitions are reasonable, appearances are simple and elegant, and an experimenter can know definition of the reactor amplification effect and measuring methodof amplification rules through the system.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com