Smoothing method for residence time in optical-element processing process

A technology of dwell time and optical components, applied in optical surface grinders, metal processing equipment, control of workpiece feed movement, etc., to reduce frequent acceleration, reduce the degree of jumping, and improve the effect of convergence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

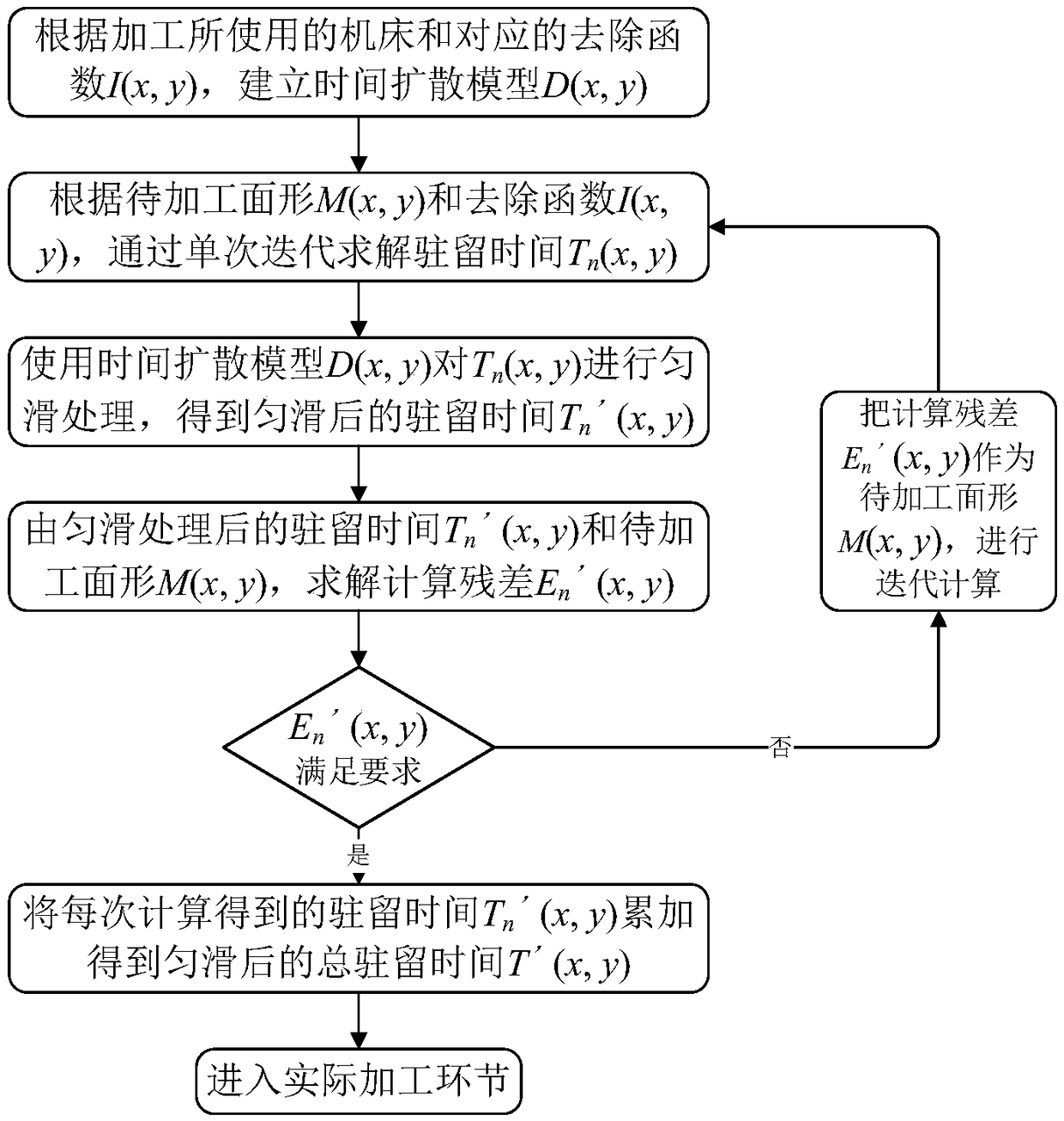

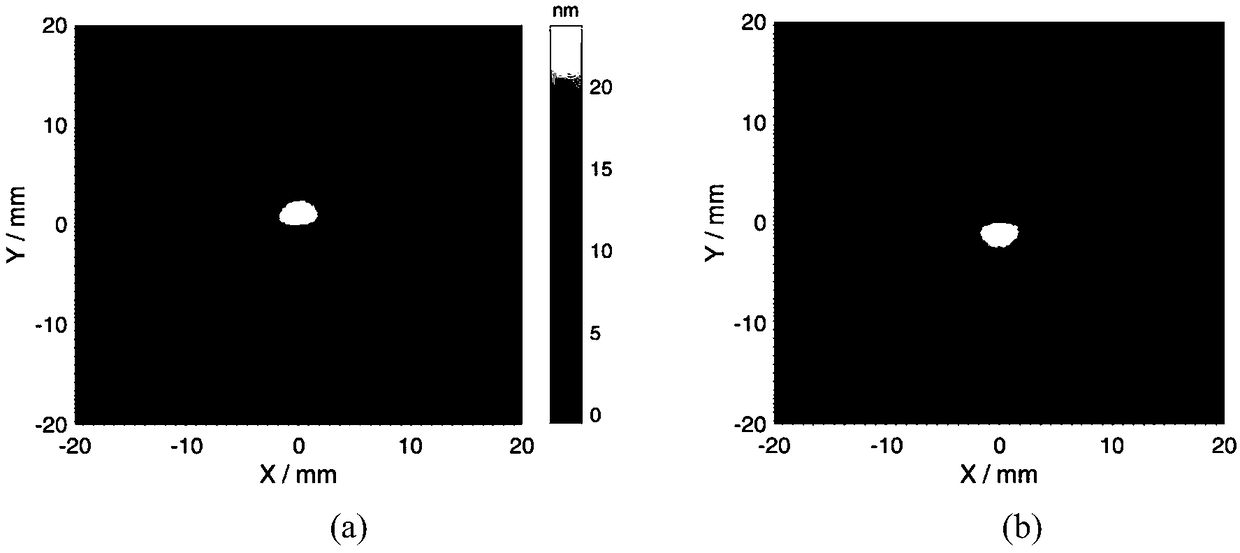

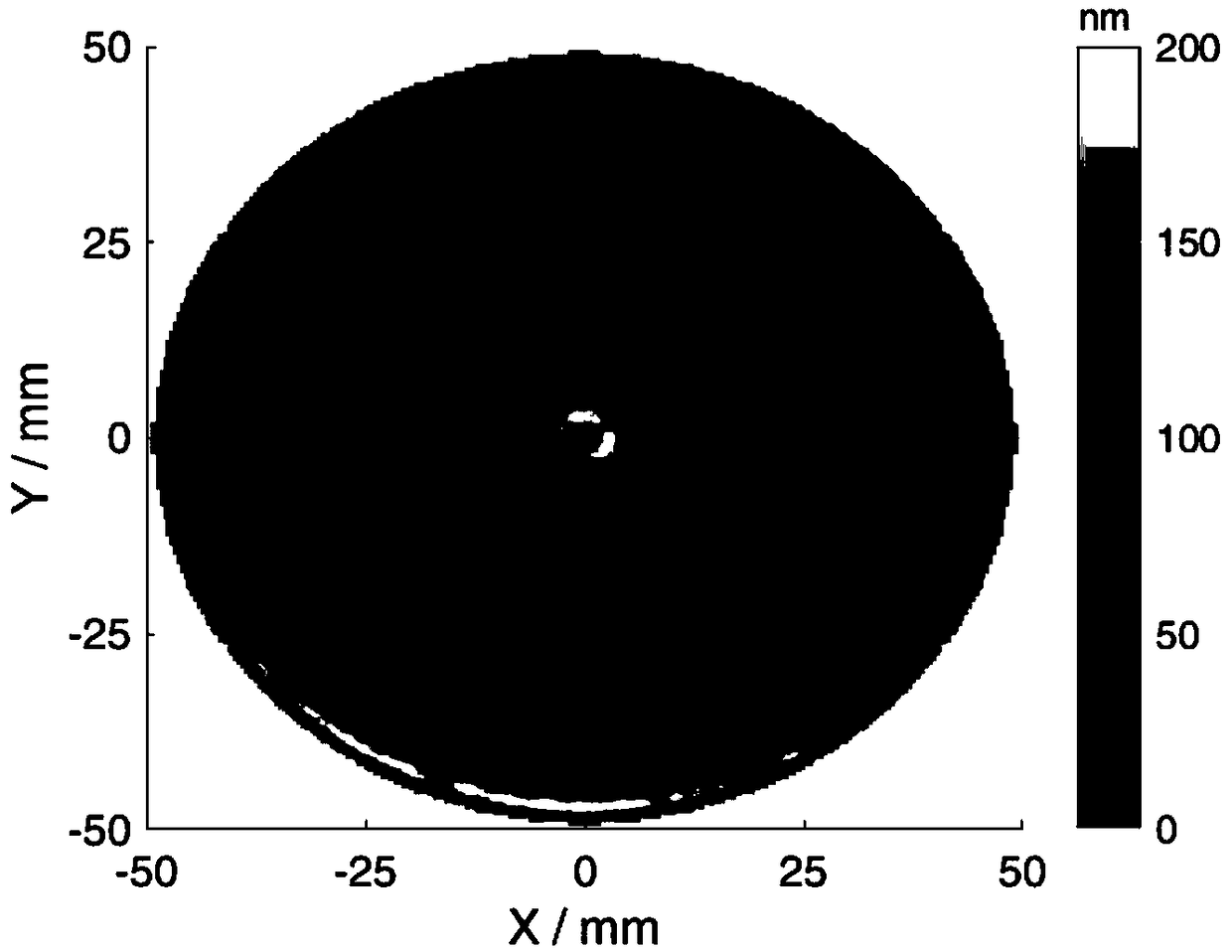

[0053] In this embodiment, the magnetorheological numerical control polishing machine is used as the processing equipment, and the circular flat mirror with a diameter of 100 mm is used as the component to be processed, and combined with Figure 2 to Figure 7 , to illustrate the specific embodiments of the present invention. In the following description, the method for smoothing the residence time during the processing of the optical element according to the present invention is referred to as the smoothing method for short. Under normal circumstances, the removal function of the magnetorheological polishing machine is non-circularly symmetrical, figure 2 (a) is the removal function distribution I(x, y) when the magneto-rheological polishing head stays at the coordinate point x=0, y=0 for 3 seconds. This embodiment takes figure 2 The shape distribution of the removal function distribution shown in (a) about x=0, y=0 coordinate point rotated 180 degrees is used as the time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com