Feeding device convenient for multi-blade saw cutting

A technology of multi-blade saws and material racks, which is applied in the direction of sawing components, feeding devices, sawing equipment, etc., can solve the problems of the health of operators, the inability to cut thickly, and the generation of a large amount of dust, etc., and achieve the smoothness of the upper and lower end surfaces , uniform thickness, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below the attachment in the embodiments of the invention will be clearly and fully described in the technical solutions in the embodiments of the present invention. Obviously, the embodiment described is only a part of the embodiments of the invention, not all the embodiments. Based on the embodiments in the present invention, all other embodiments obtained by ordinary technical personnel in the art under the premise of not creating creative labor belong to the protection of the present invention.

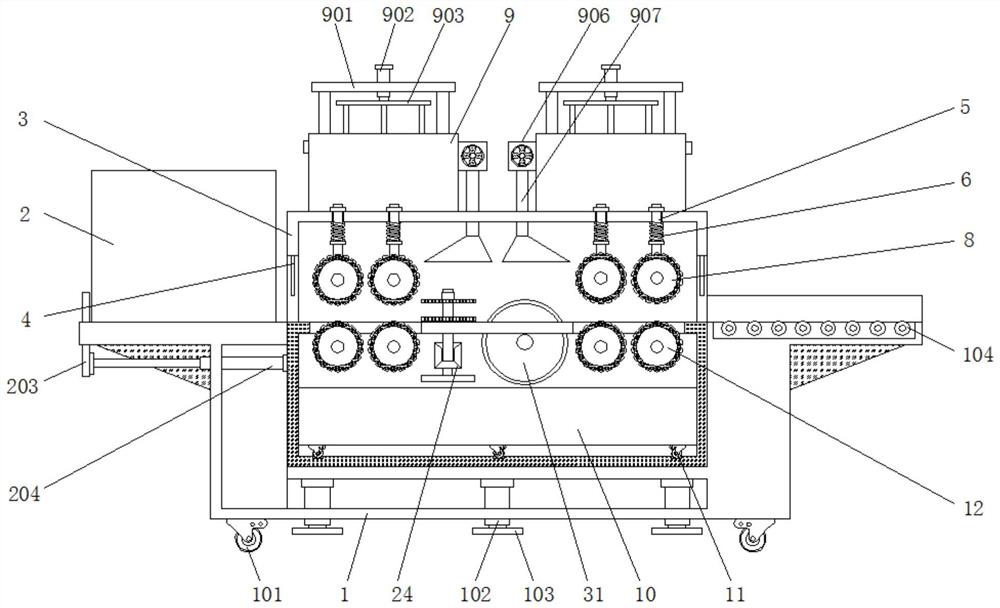

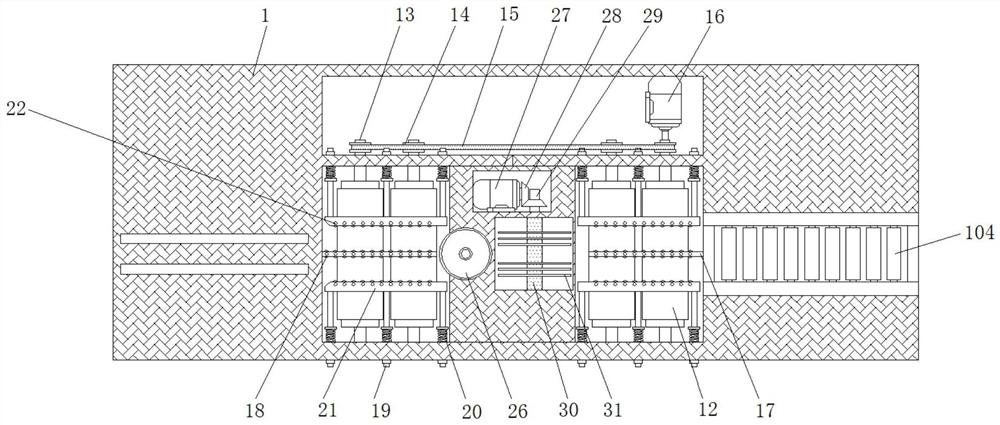

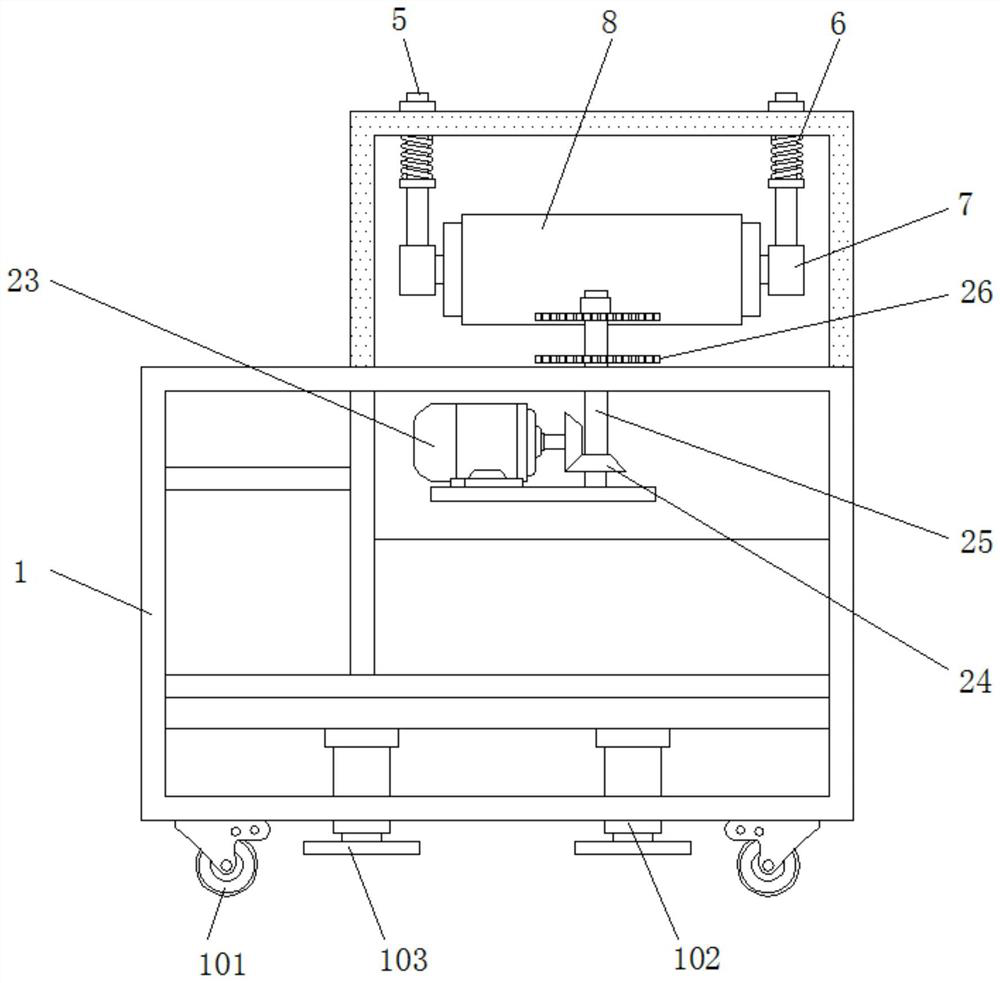

[0032] See Figure 1-6 , The present invention provides a technical solution: one is convenient for multiple saw cutting devices, such as figure 1 As well as image 3 As well as Figure 5 and Image 6Show, the upper end of the device body 1 is set up with the material rack 2 near the left, and the upper end surface of the device 1 has an outer cover 3, the device 1 includes a mobile wheel 101, the first liquid pressure telescopic lever 102, the arrival board 103 and the transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com