Roadbed reinforcing structure for highway construction and construction technology of roadbed reinforcing structure

A technology for strengthening structures and subgrades, which is applied to road construction reinforcements, roads, roads, etc., can solve the problems of affecting the safety of groundwater source water quality, single use of reinforcement structures, failure to detect and give feedback in time, and achieve water quality protection. Improve driving comfort and reduce construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

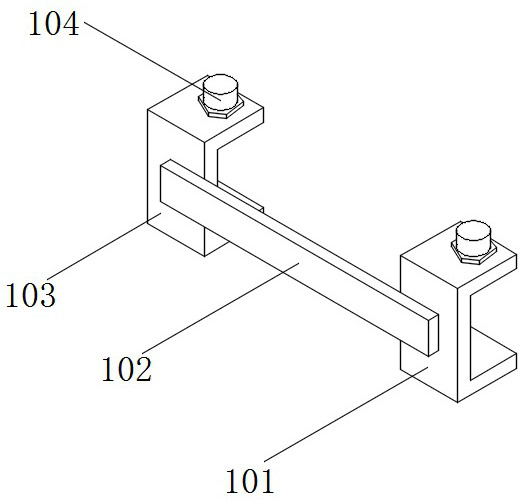

[0045] see figure 1 , figure 2 , Figure 5 with Image 6 , an embodiment provided by the present invention: a roadbed reinforcement structure for road construction, including a connection module 1 and a reinforcement module 5, and the connection module 1 is installed on the front and back of the reinforcement module 5;

[0046] Reinforcing module 5 comprises steel plate 501, steel bar fence 502, arc support plate 503, compression spring 504 and steel bar filter screen 505, and the inner wall of steel bar fence 502 is equipped with the steel bar frame that vertically and horizontally arranges, and the bottom wall of steel bar fence 502 is equipped with steel bar filter screen. Net 505, the top of the reinforced fence 502 is equipped with equidistantly arranged arc-shaped support plates 503, and the inner top wall of the arc-shaped support plates 503 is equipped with parallel arranged compression springs 504, and the bottom of the compression springs 504 is connected to the t...

Embodiment 2

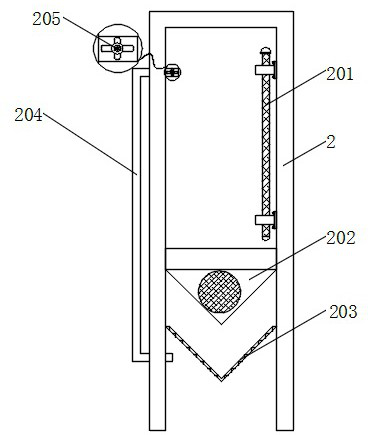

[0053] see figure 1 with image 3 , an embodiment provided by the present invention: a roadbed reinforcement structure for road construction, including a connection module 1 and an early warning prompt box 2, the front and back of the reinforcement module 5 are equipped with an early warning prompt box 2, and the early warning prompt box 2 is far away from the reinforcement A return pipe 204 is installed through the inner wall of one side of the module 5, and the tail end and the head end of the return pipe 204 are all located inside the early warning prompt box 2. The surface of the return pipe 204 is equipped with an electronic valve 205, and the inner wall of the early warning prompt box There is a liquid level sensor 201, and the liquid level sensor 201 is electrically connected to the electronic valve 205. The inner wall of the early warning prompt box 2 is equipped with a one-way valve 202 and an intercepting screen 203, and the one-way valve 202 is located at the liquid...

Embodiment 3

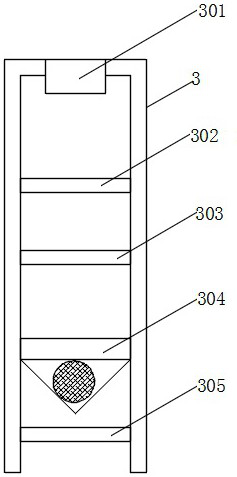

[0059] see figure 1 with Figure 4 , an embodiment provided by the present invention: a roadbed reinforcement structure for road construction, comprising a connection module 1 and an anti-filter tank 3, an anti-filter tank 3 is installed in the middle of two groups of reinforcement modules 5, and an anti-filter tank 3 is installed on the top of the anti-filter tank 3 Water inlet 301 is arranged, fine sand layer 302 and charcoal layer 303 are installed on the inwall of anti-filter tank 3, and charcoal layer 303 is positioned at the below of fine sand layer 302, No. two one-way valve 304 and stopper are installed on the inwall of anti-filter tank 3 Net 305, retaining net 305 is positioned at the bottom of No. 2 one-way valve 304, and No. 2 check valve 304 is positioned at the bottom of charcoal layer 303, and the bottom of anti-filtration tank 3 is open design.

[0060] Specifically, during use, the rainwater on the road surface contains pollutants. In order to reduce the pollu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com