Method for measuring residence time distribution of tobacco material in processing equipment

A technology of residence time and tobacco materials, applied in the direction of measuring devices, analysis materials, instruments, etc., can solve the problems of no development, etc., and achieve the effect of short test time, small influence range and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

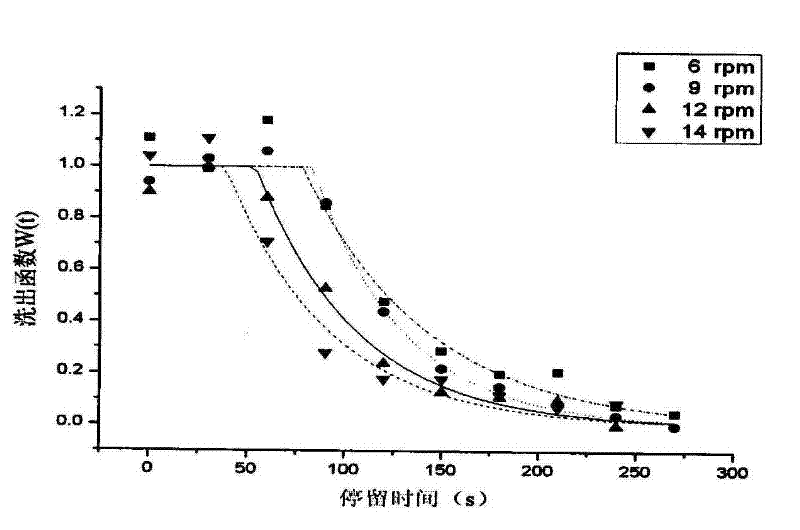

[0026] A certain brand of formula shredded tobacco of the company was selected on the flavoring machine of a domestic tobacco company for testing. The flow rate of the formula shredded tobacco was 2000 kg / h, and the flow rate of the expanded shredded leaf with tracer was set at 105 kg / h (that is, the instantaneous addition ratio was the total 5% of the flow rate), measured the RTD of cut tobacco in the flavoring drum under different drum speed conditions (6 rpm, 9 rpm, 12 rpm and 16 rpm) and established its model equation, of which 12 rpm was the normal production Rotating speed.

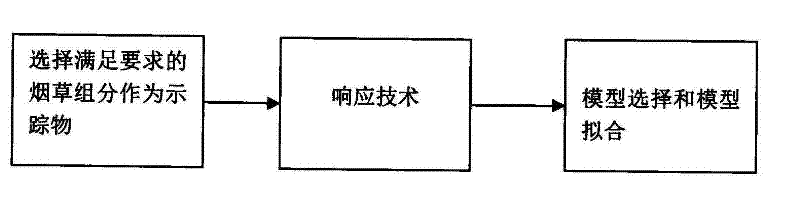

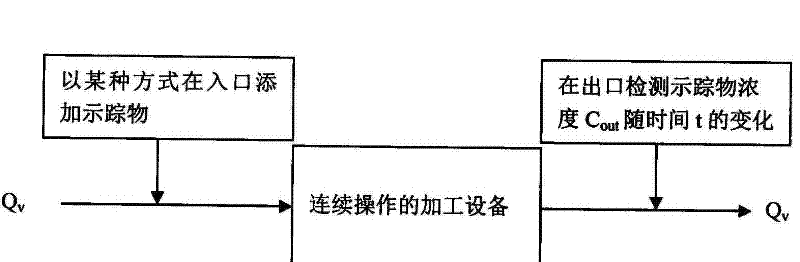

[0027] Such as figure 1 As shown, its specific implementation is as follows:

[0028] 1. The determination of RTD needs to sample and measure the tracer concentration at a certain time interval from time zero at the outlet of the equipment, and the sampling time is in seconds. The determination of the sampling amount is based on the tracer content that can represent the entire discharge section at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com