On-line defect diagnosis method for rolling type reverse osmosis membrane device

A technology of reverse osmosis membrane and diagnosis method is applied in the field of online diagnosis of defects of roll reverse osmosis membrane device, which can solve the problems of reducing membrane device performance, membrane fouling, uneven fluid flow, etc., and achieves low equipment cost and application scope. Wide, simple and convenient diagnostic procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

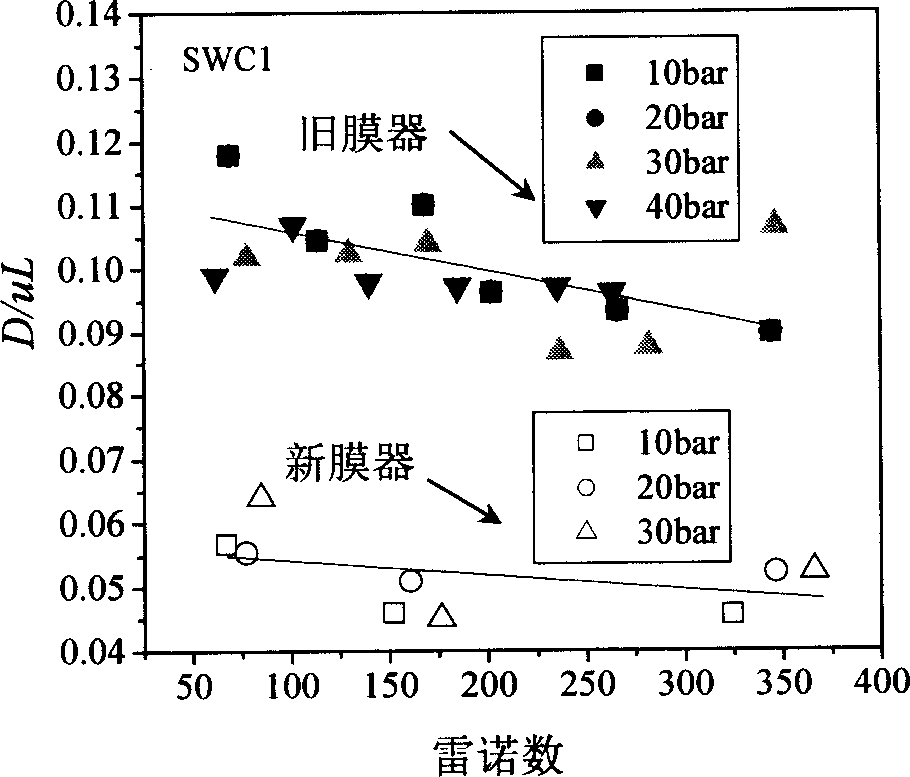

[0017] In this example, a diagnostic test is performed on a new 8-inch-diameter SWCl roll-type reverse osmosis membrane device of Hyde Energy Company.

[0018] Install the tracer NaCl solution injection container and injection valve at the inlet of the roll-type reverse osmosis membrane device, and connect it to a 60bar high-pressure air bottle; install a high-speed response conductivity meter at the outlet of the roll-type reverse osmosis membrane device and connect it to the computer.

[0019] Adjust the inlet water pressure and the inlet water flow rate of the membrane device to stabilize to the set value. When performing the residence time distribution test, the pulse mode is used. Open the valve for 1 second, and use 60bar high-pressure air to inject the NaCl injected into the container into the roll-type reverse osmosis membrane device. The NaCl concentration used was 300 g / L. The tracer outlet concentration value corresponding to every 0.1 second is collected at the o...

Embodiment 2

[0025] In this example, a diagnostic test is performed on an old 8-inch-diameter SWC1 roll-type reverse osmosis membrane device of Hyde Energy Company.

[0026] Install the tracer NaCl solution injection container and injection valve at the inlet of the roll-type reverse osmosis membrane device, and connect it to a 60bar high-pressure air bottle; install a high-speed response conductivity meter at the outlet of the roll-type reverse osmosis membrane device and connect it to the computer.

[0027] Adjust the inlet water pressure and the inlet water flow rate of the membrane device to stabilize to the set value. When performing the residence time distribution test, the pulse mode is used. Open the valve for 1 second, and use 60bar high-pressure air to inject the NaCl injected into the container into the roll-type reverse osmosis membrane device. The NaCl concentration used was 300 g / L. The tracer outlet concentration value corresponding to every 0.1 second is collected at the ...

Embodiment 3

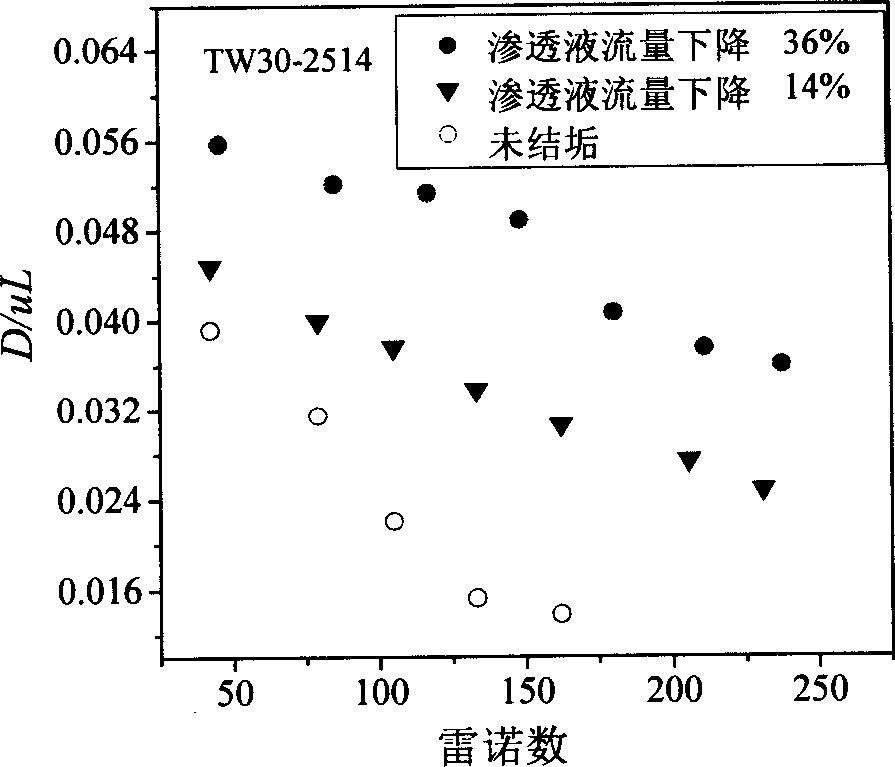

[0033] In this example, a diagnostic test is performed on a new 2.5-inch TW30-2514 roll-type reverse osmosis membrane device from Dow Company.

[0034] Install the tracer NaCl solution injection container and injection valve at the inlet of the roll-type reverse osmosis membrane device, and connect it to a 60bar high-pressure air bottle; install a high-speed response conductivity meter at the outlet of the roll-type reverse osmosis membrane device and connect it to the computer.

[0035] When performing the residence time distribution test, the pulse mode is used. Open the valve for 1 second, and use 60bar high-pressure air to inject the NaCl injected into the container into the roll-type reverse osmosis membrane device. The NaCl concentration used was 20 g / L. The tracer outlet concentration value corresponding to every 0.1 second is collected at the outlet of the membrane device, and the residence time distribution test is carried out.

[0036] Adjust the inlet water pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com