Material detention period and distributing on-line measurement system and method

A residence time and measurement system technology, applied in the direction of measuring devices, material excitation analysis, material analysis through optical means, etc., can solve the problems of physical hazards for operators, easy to cause photosensitive dermatitis, high cost of test devices, etc., and achieve anti-interference The effect of strong ability, low test cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] This embodiment will be described in detail below in conjunction with the accompanying drawings.

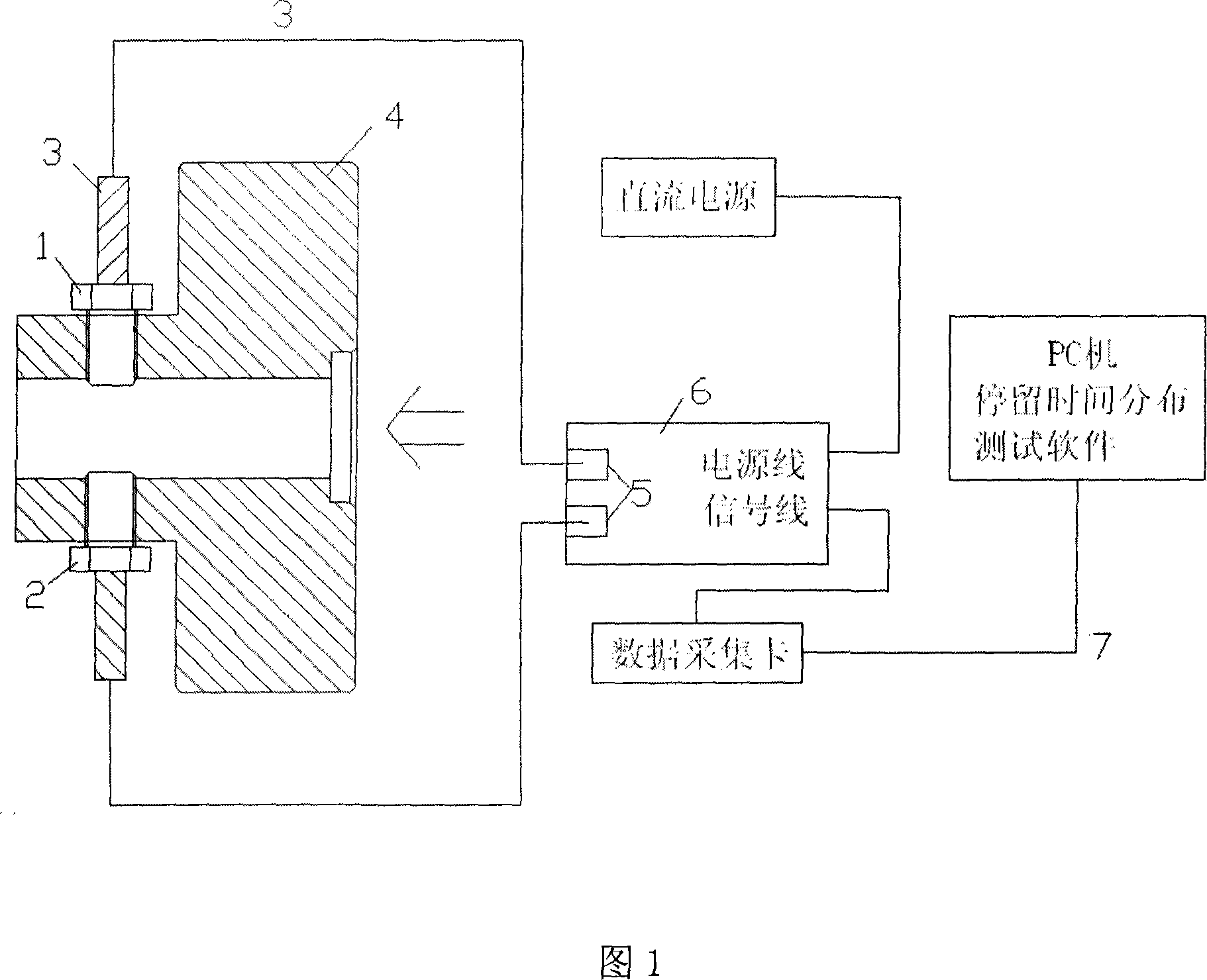

[0036] As shown in Figure 1, in the polymer residence time distribution online measurement system, the first optical fiber probe 1 and the second optical fiber probe 2 connected to the optical fiber sensor 6 are installed at the head position of the extruder, the first optical fiber probe 1, the second optical fiber probe Two optical fiber probes 2 directly contact the molten polymer to obtain color information in the molten polymer. The analog output of the fiber optic sensor 6 is connected to a PC equipped with residence time distribution test software through a data acquisition card, and the PC displays the output signal of the fiber optic sensor in real time, and then obtains a residence time distribution curve.

[0037] The light source emitted by the optical fiber sensor 6 can be visible light or infrared rays, as long as the optical fiber sensor with a monochromatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com