Device and method for online measurement of residence time distribution of rotating packed bed

A technology of rotating packed bed and residence time, which is applied in the direction of material resistance, etc., can solve the problems of short residence time, difficulty in RTD measurement, and inability to directly apply rotating packed bed, so as to achieve accurate data and fully reflect the effect of detailed characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

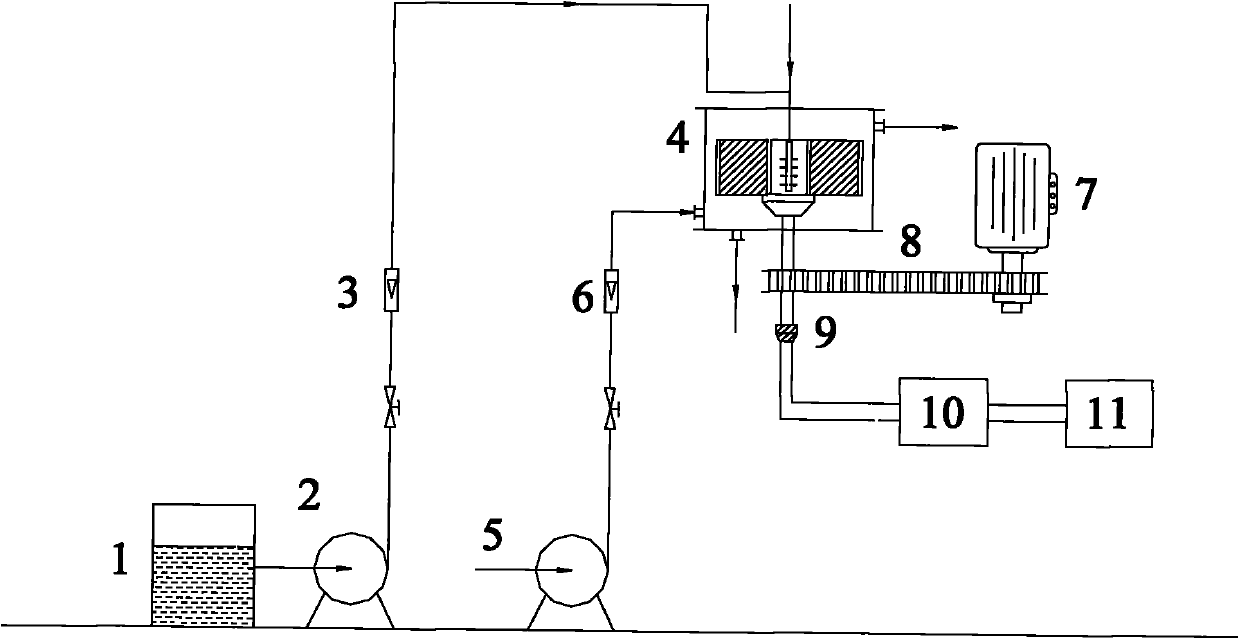

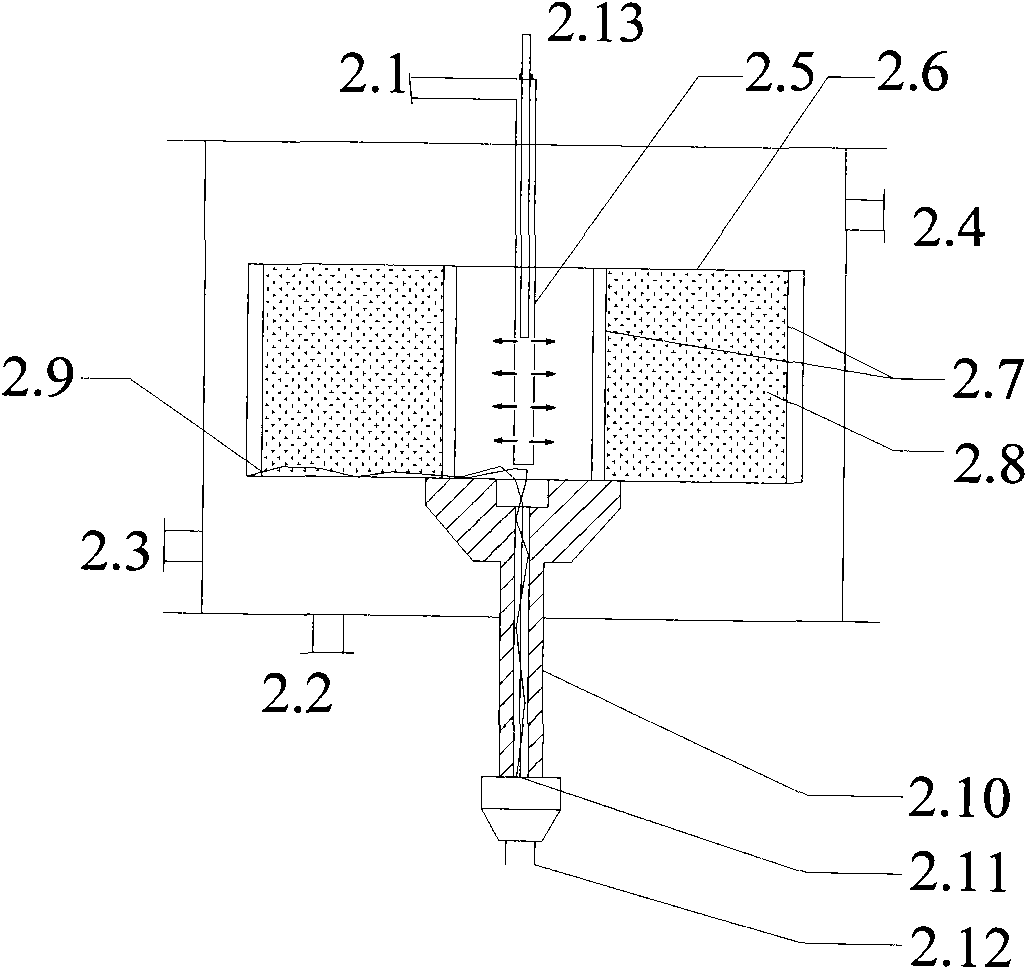

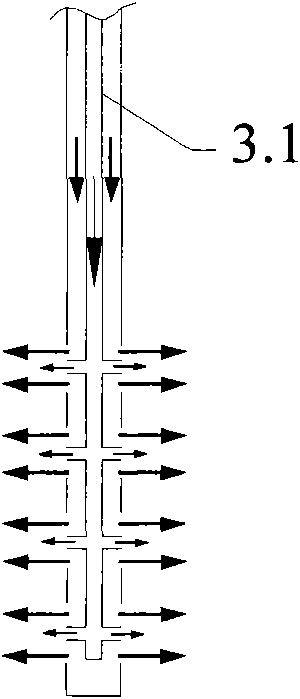

Method used

Image

Examples

Embodiment 1

[0035] The water flow rate is fixed at 50L / h, pumped into the rotating packing bed, sprayed evenly onto the inner surface of the packing through the liquid distributor, the rotor rotates at a speed of 100rpm, and the air flows at a gas flow rate of 1m 3 / h is sent into the rotary packing bed by the air compressor, and the inner and outer sides of the packing are equipped with cylindrical copper mesh electrodes. The average resistance value measured online by the data acquisition system is 13178.97Ω, the baseline conductance value obtained by taking the reciprocal is 0.000076S, and the average residence time of the rotating packed bed can be calculated as 0.56s.

Embodiment 2

[0037] The water flow rate is fixed at 250L / h, pumped into the rotating packing bed, sprayed evenly onto the inner surface of the packing through the liquid distributor, the rotor rotates at a speed of 2800rpm, and the air flows at a gas flow rate of 5m 3 / h is sent into the rotary packing bed by the air compressor, iron orifice plate electrodes are installed on the inside and outside of the packing, the electrodes are connected with electric wires, and the wires pass through the hollow shaft to transmit the electrical signal to the outside of the rotating packing bed through the mercury slip ring, and are collected by the data The online measurement of the system shows that the average current value obtained by the online measurement of the data acquisition system is 1.0828mA, and the average residence time of the rotating packed bed is calculated to be 0.01s.

Embodiment 3

[0039] The water flow rate is fixed at 150L / h, pumped into the rotating packing bed, sprayed evenly onto the inner surface of the packing through the liquid distributor, the rotor rotates at a speed of 840rpm, and the air flows at a gas flow rate of 10m 3 / h is sent into the rotating packing bed by the air compressor, and the inner and outer sides of the packing are equipped with silver mesh electrodes, which are connected with electric wires, and the wires pass through the hollow rotating shaft to transmit the electrical signal to the outside of the rotating packing bed through the mercury slip ring, and are collected by the data The average voltage value measured online by the system is 6.8201V, and the average residence time of the rotating packed bed is calculated to be 0.21s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average resistance value | aaaaa | aaaaa |

| Conductance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com