Random polishing track motion method for restraining track error

A trajectory movement and trajectory technology, which is applied in the field of optical manufacturing of lithography objective lenses, can solve the problems of high performance requirements of machine tools and difficult realization, and achieve the effect of improving precision and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

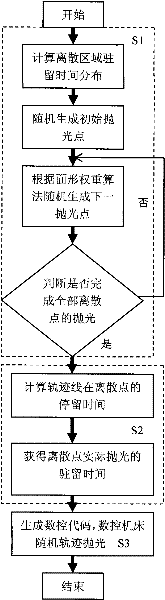

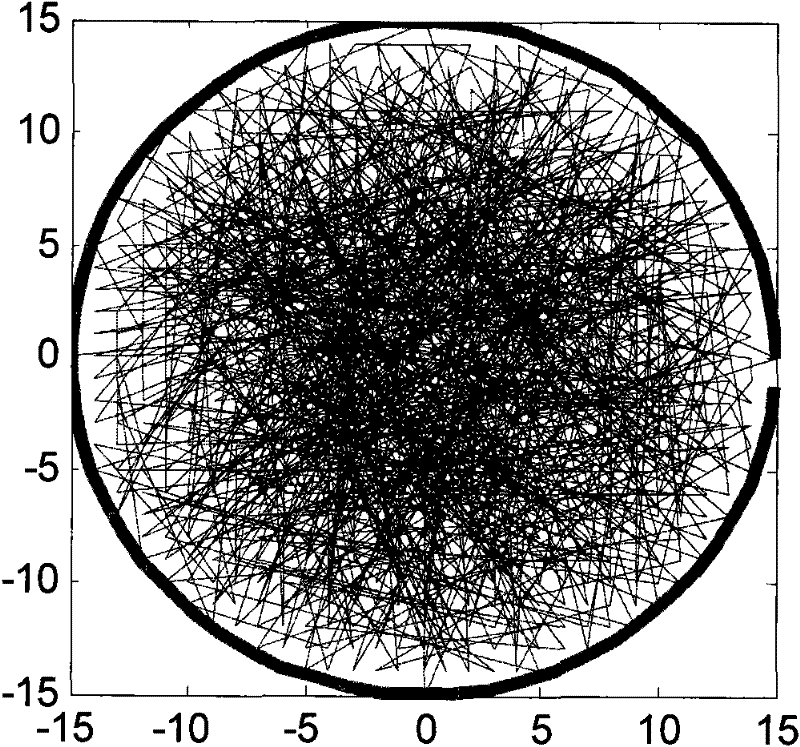

[0017] combine figure 1 Shown the flow chart of the inventive method, below only with a piece of optical element to be polished is the quartz plane glass of Φ 30mm as an example, this example is as follows to the specific implementation steps of realizing the inventive method:

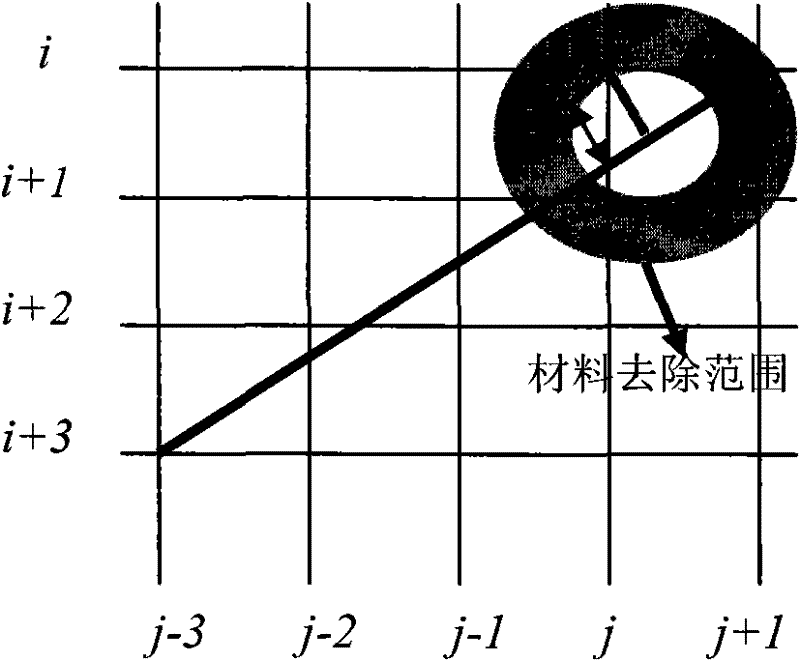

[0018] Step 1: Discretize the error distribution of the quartz flat glass surface to be polished with 30×30 grid data points. The discrete points are evenly distributed on the surface of the optical element to be polished. The discrete data points are the points to be polished by the polishing head.

[0019] Step 2: Calculate and determine the residence time distribution on the quartz glass surface according to the removal function distribution an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com