Patents

Literature

72results about How to "Optimize motion trajectory" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

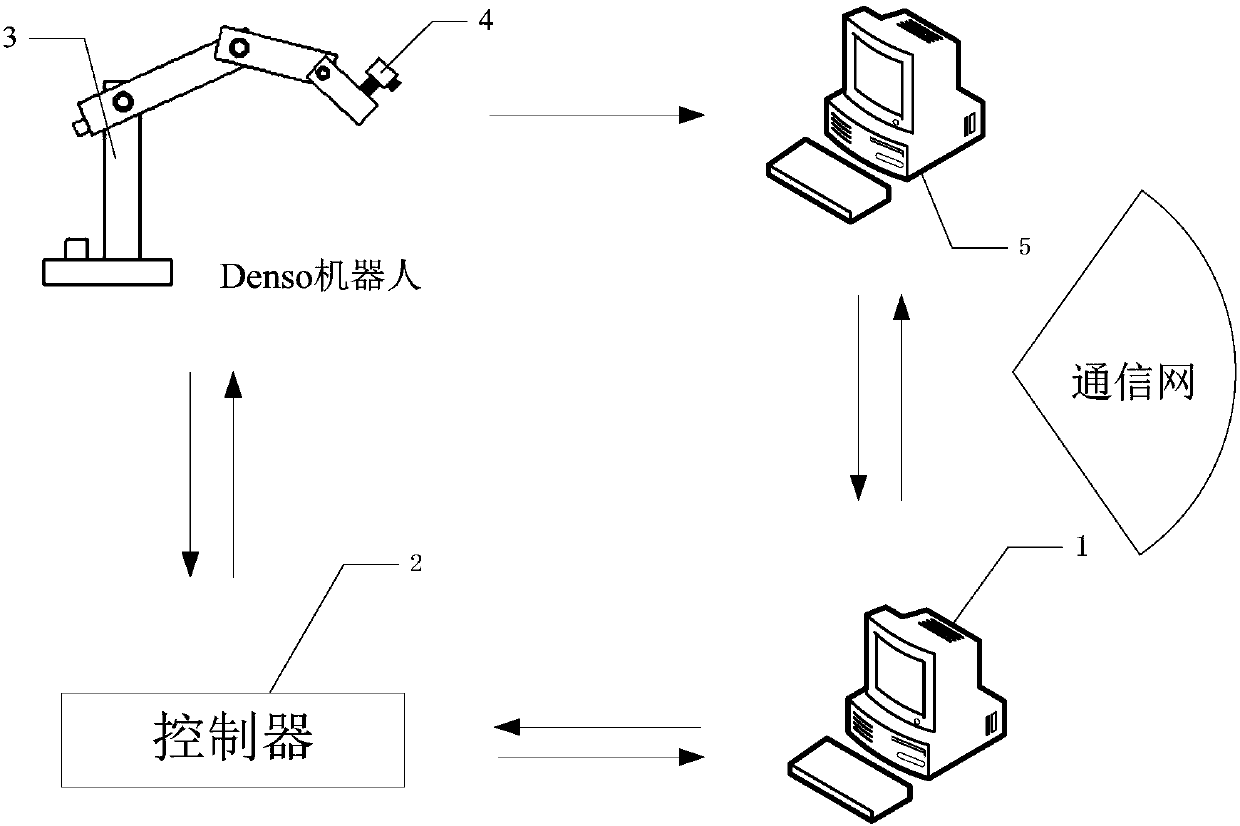

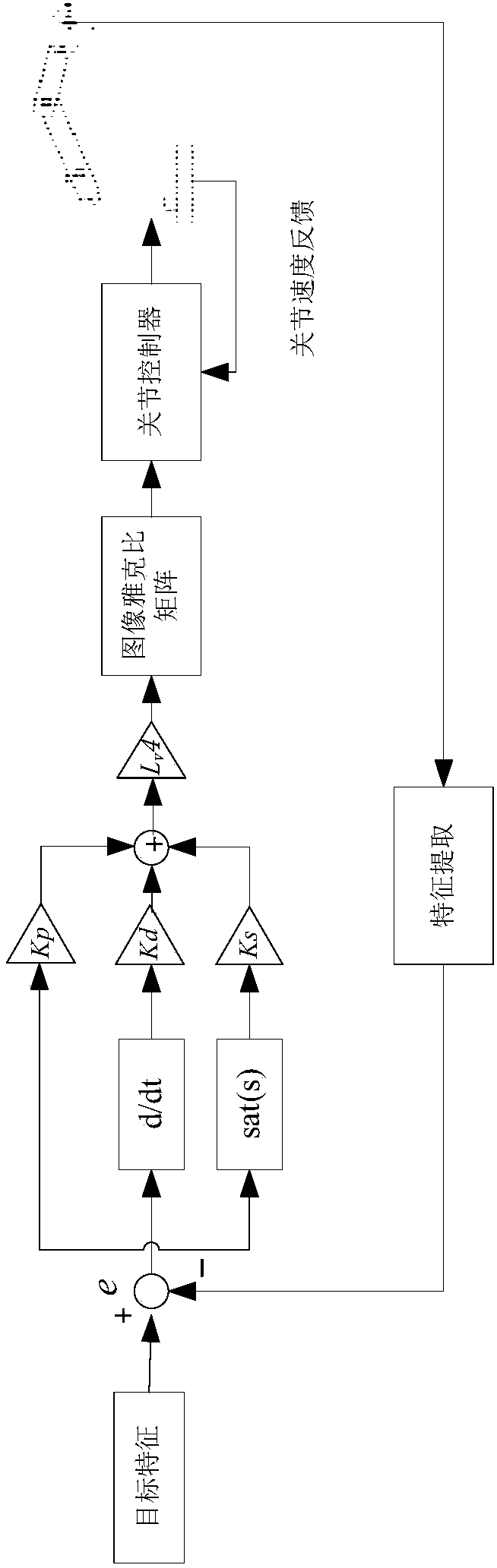

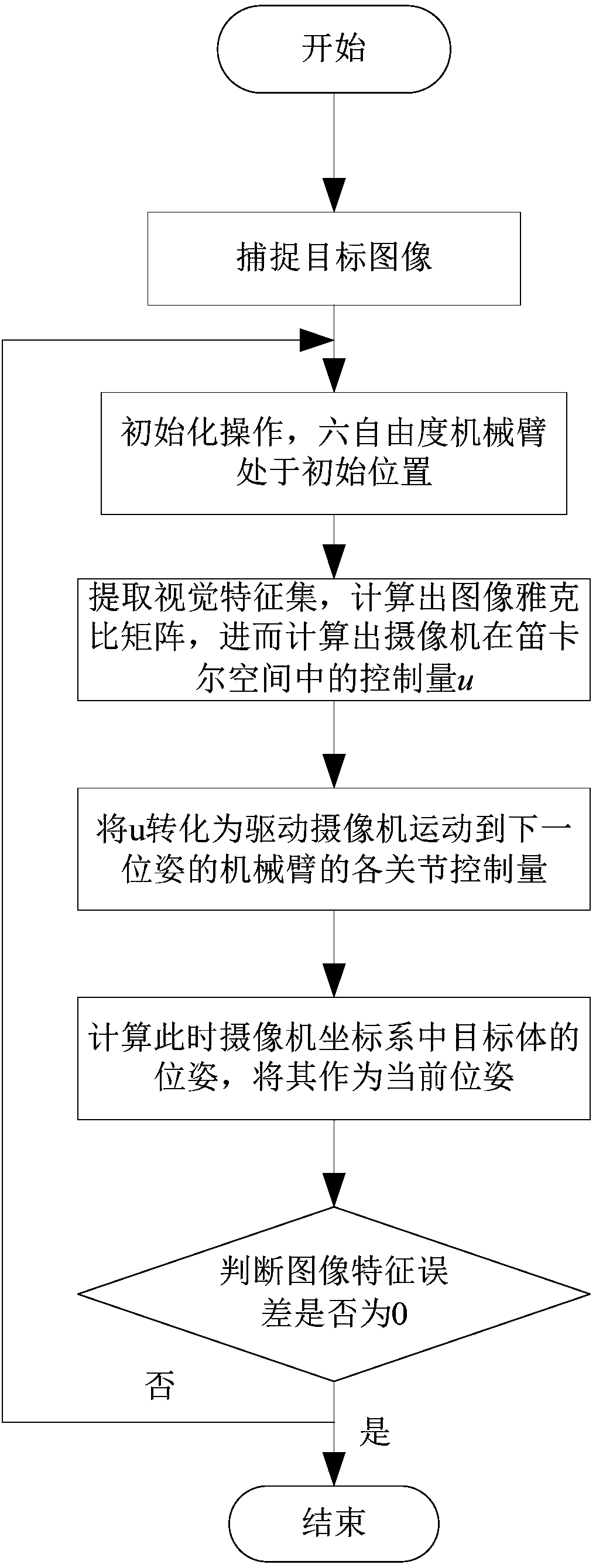

PD-SMC control method of visual servo system based on eye-on-hand structure

ActiveCN107627303AGuaranteed availabilityDealing with uncertaintyProgramme-controlled manipulatorAdaptive controlVisual servoing systemProportional control

The invention relates to the field of visual servo systems, in particular to a PD-SMC control method of a visual servo system based on an eye-on-hand structure so as to solve the problems of uncertainty and large computation amount existing in an existing visual servo system control method. The method comprises the steps of (1) setting an expected image and collecting feature points of the expected image as an expected visual feature set; (2) conducting projection transformation on a target expected image with the current state of the relative poses of a camera and a target body to obtain a current image of the camera; (3) adopting the PD-SMC method for a visual servo controller part and adopting a proportional control method for a joint controller part; (4) extracting a visual feature setfrom the current image, computing a jacobian matrix of the image and then computing the controlled quantity u of the camera in a Cartesian space; and (5) computing the pose of the target body in a camera coordinate system, and repeating the operations with the pose as the current pose until the error is zero. The PD-SMC control method can be applied to target grabbing equipment.

Owner:HARBIN ENG UNIV +3

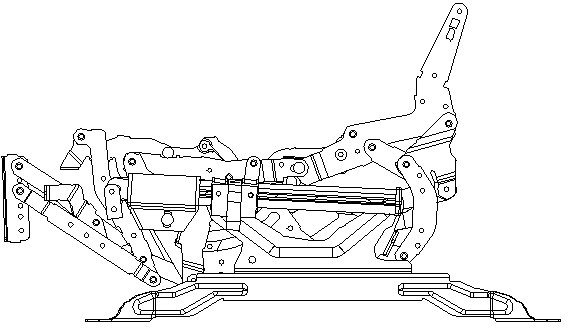

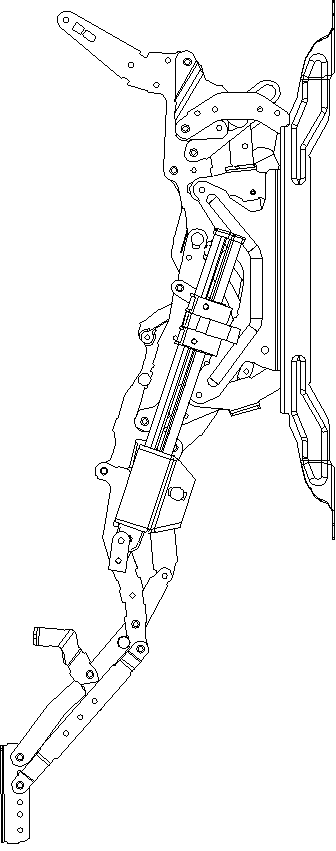

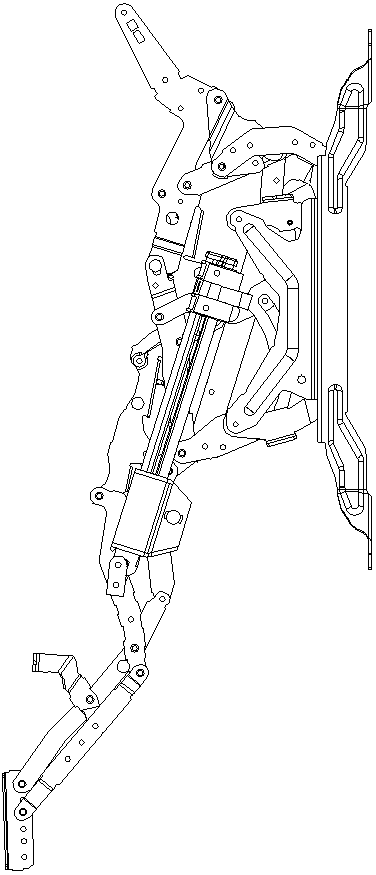

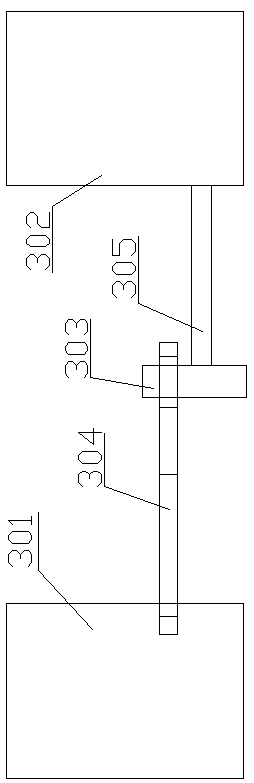

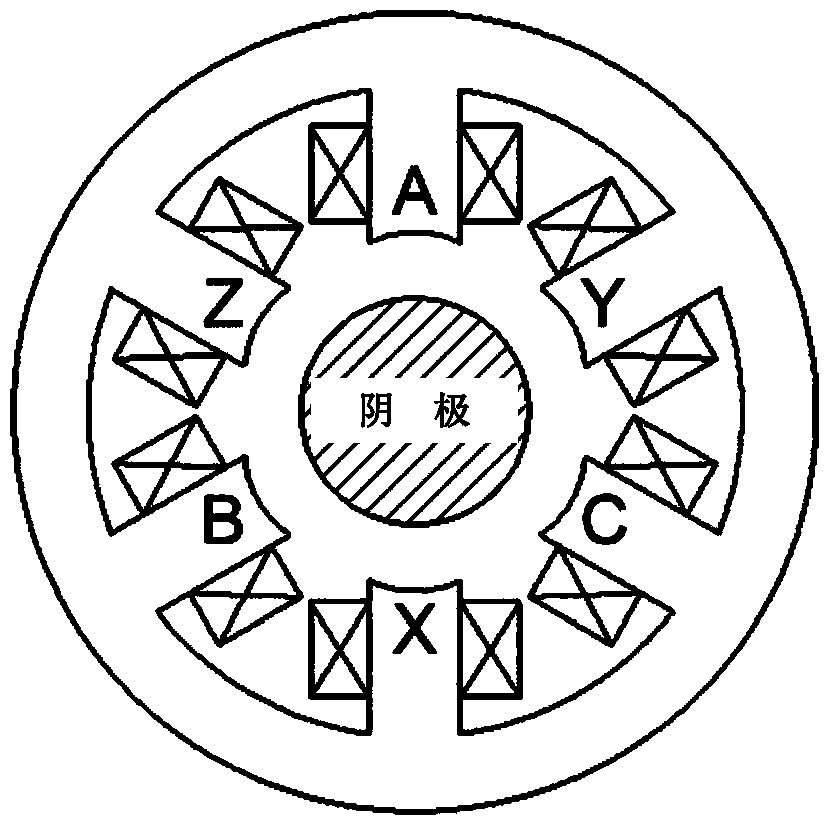

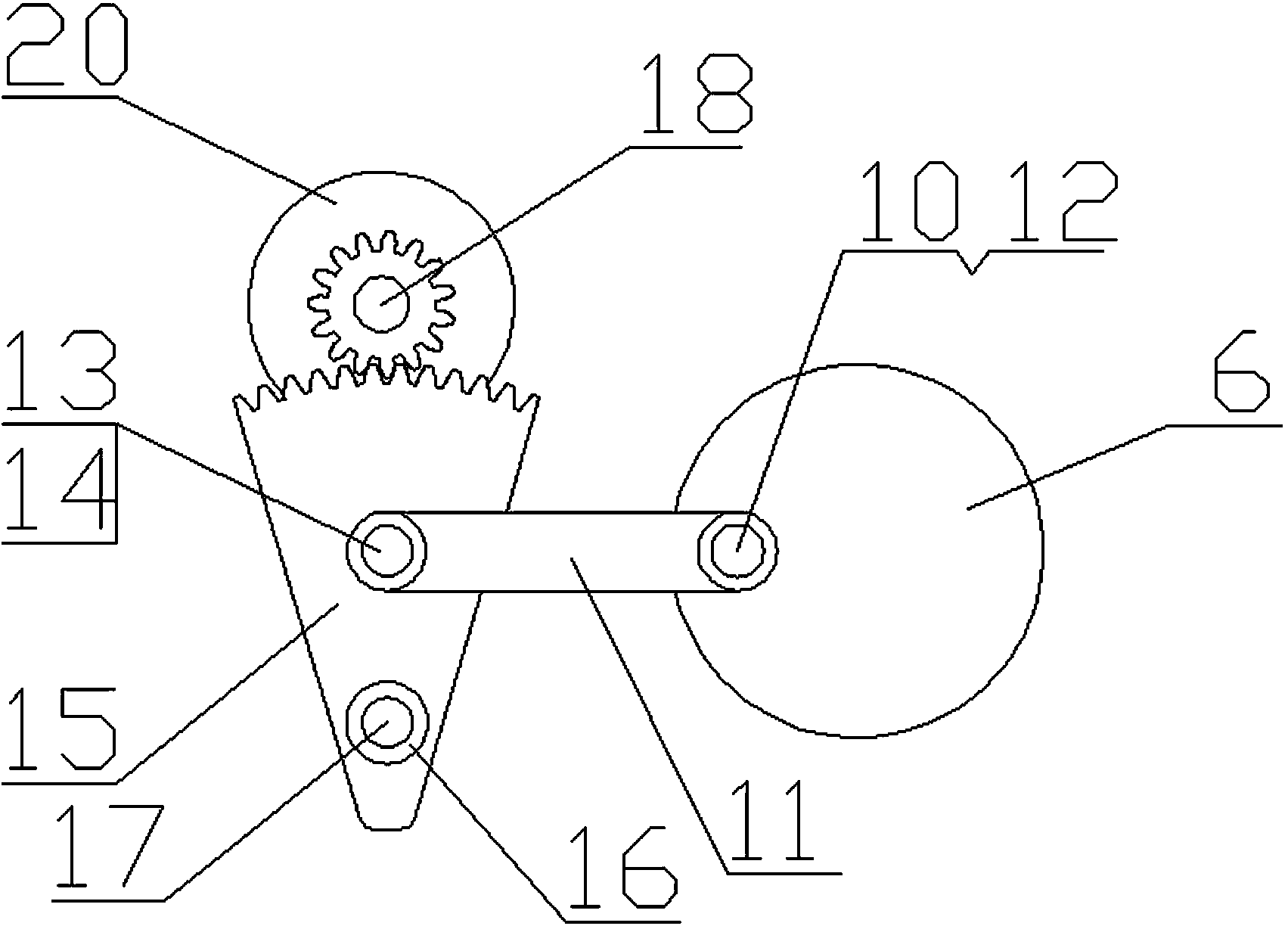

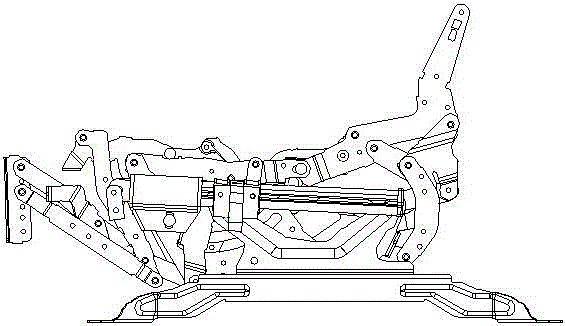

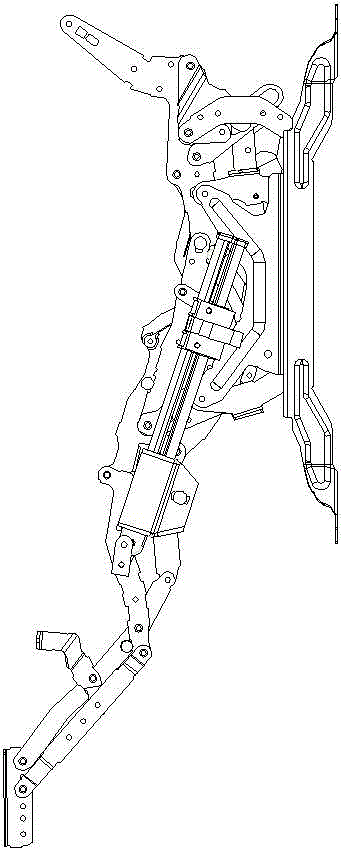

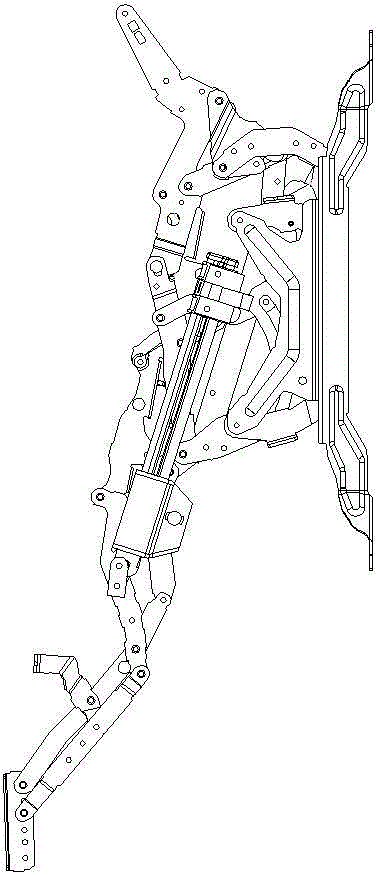

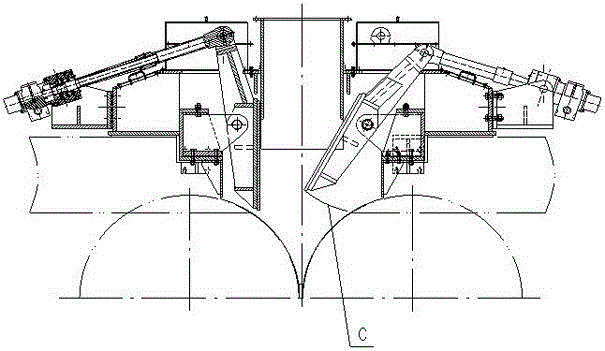

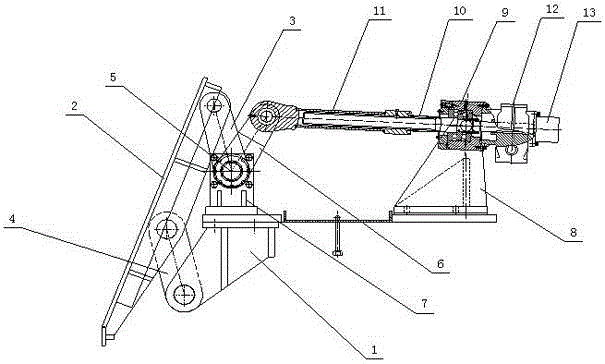

Mechanical stretching device for electric rocking chair of movable sofa

ActiveCN103445558ARealize electric functionImprove comfortSofasCouchesMechanical stretchingElectric machinery

The invention relates to a mechanical stretching device for an electric rocking chair of a movable sofa. The mechanical stretching device comprises a left-side member, a right-side member and an electric device, wherein the electric device comprises a motor, a motor fixing bracket, a guide rail bracket, a motor fixing tube, a motor moving sliding block and a motor guide rail, the motor fixing tube is mounted on the motor fixing bracket, the motor fixing bracket is rotatably connected with a transmission connecting member, and the transmission connecting member is rotatably connected with the guide rail bracket through a third rotating shaft; a first guide rail is arranged on the guide rail bracket and is in an circular arc shape; the third rotation shaft is arranged in the first guide rail; one end of the motor is connected with the motor moving sliding block, the other end of the motor is rotatably connected with a leg square tube, and the motor is mounted on the motor guide rail; the motor moving sliding block is fixed on the motor fixing tube and is in sliding connection with the motor guide rail. According to the mechanical stretching device, the motor fixing tube is provided with a sunken part, and the motor moving sliding block is fixed in the sunken part. As the electric rocking chair is endowed with an electric function, the automatic degree and the comfort of the sofa are improved.

Owner:REMACRO MASCH & TECH (WUJIANG) CO LTD

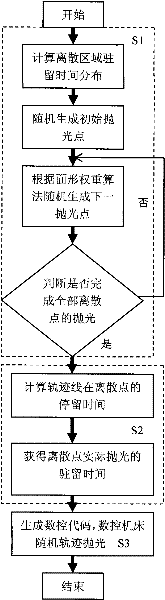

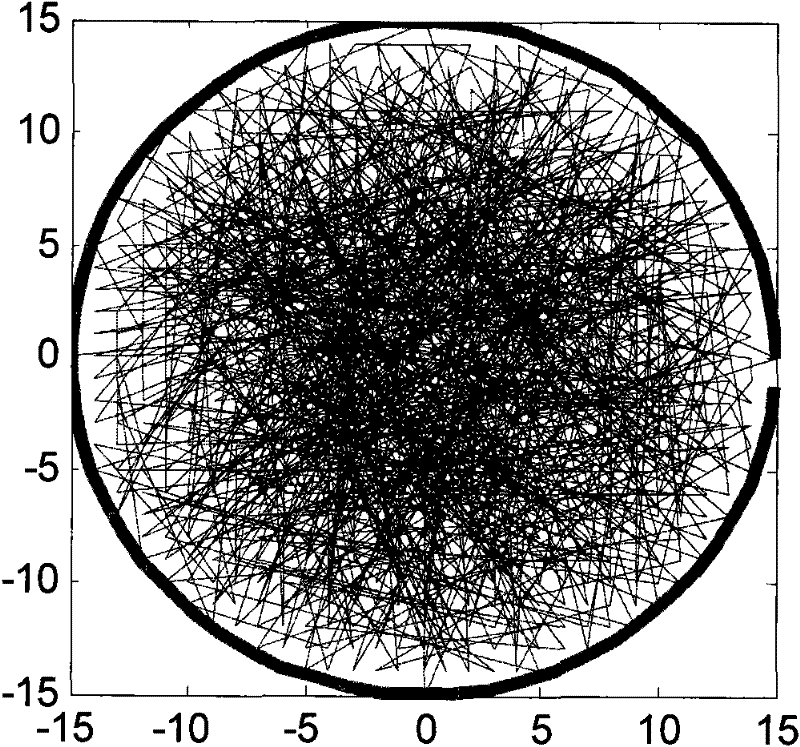

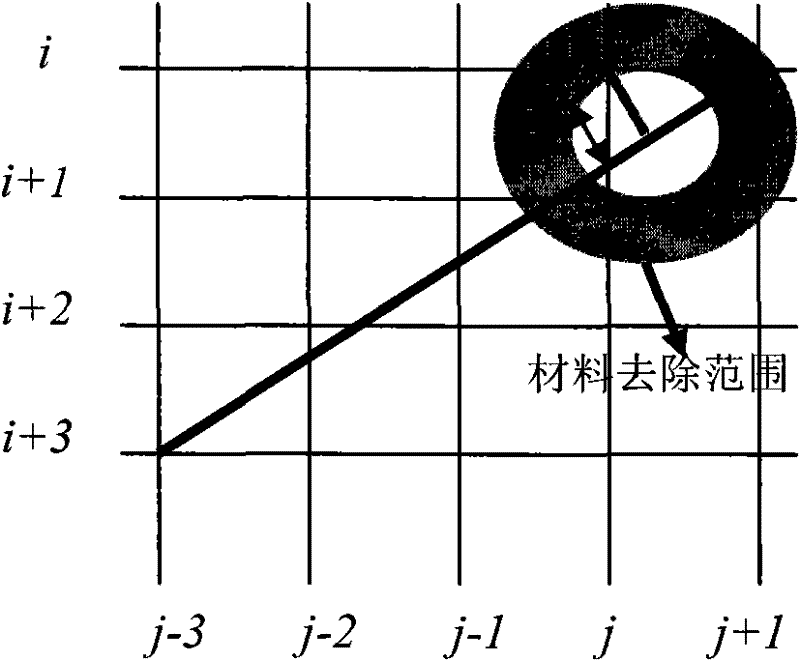

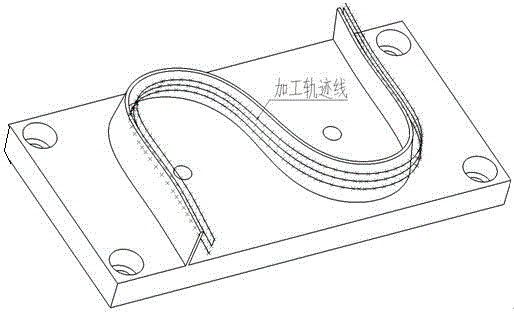

Random polishing track motion method for restraining track error

InactiveCN102248461AHigh precisionOptimize motion trajectoryOptical surface grinding machinesNumerical controlLitter

The invention relates to a random polishing track motion method for restraining a track error, which comprises the following steps: confirming to-be-polished points and residence time distribution on a surface of a to-be-polished optical element and utilizing a random track algorithm to generate a polishing sequence and a polishing track of dispersed points on the surface of the to-be-polished optical element; utilizing a residence time compensation method to calculate the residence time distribution for a polishing head motion track to pass through by the polishing points, thereby acquiring the accurate residence time of the dispersed points on the surface of the to-be-polished optical element; generating a random track numerical control polishing program code by a machine tool code conversion program according to the residence time distribution; and polishing all the points on the surface of the to-be-polished optical element by executing the random track numerical control polishingprogram code on a numerical control polishing machine tool. A random track polishing method is used for enabling the motion tracks of the polishing head and polishing grains to approach to random litter distribution according to surface figure distribution, thoroughly removing regular track scratches from the to-be-polished optical element, uniformly spreading the removal function iteration errors among regular tracks on the whole surface figure, and promoting the surface figure accuracy.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

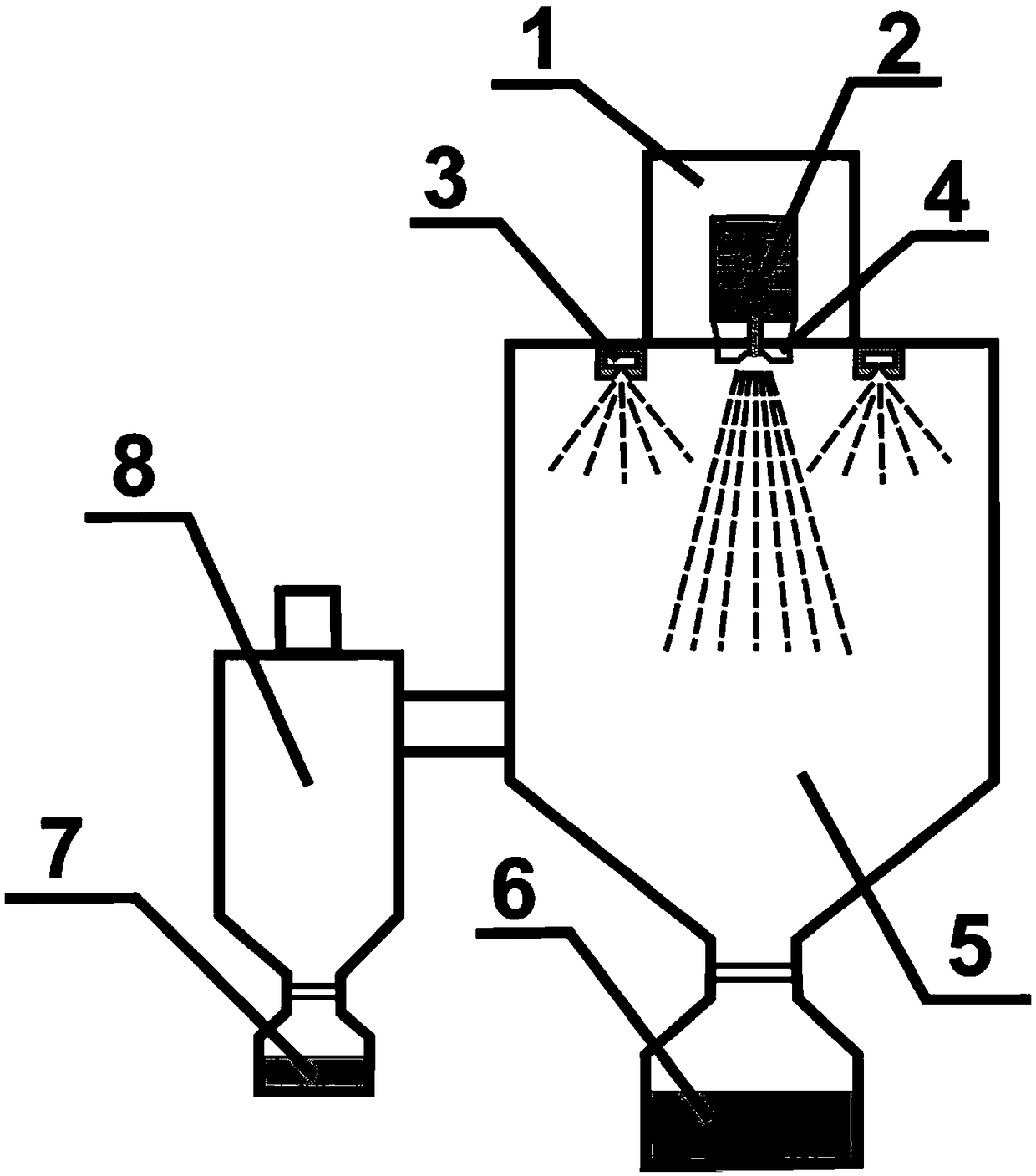

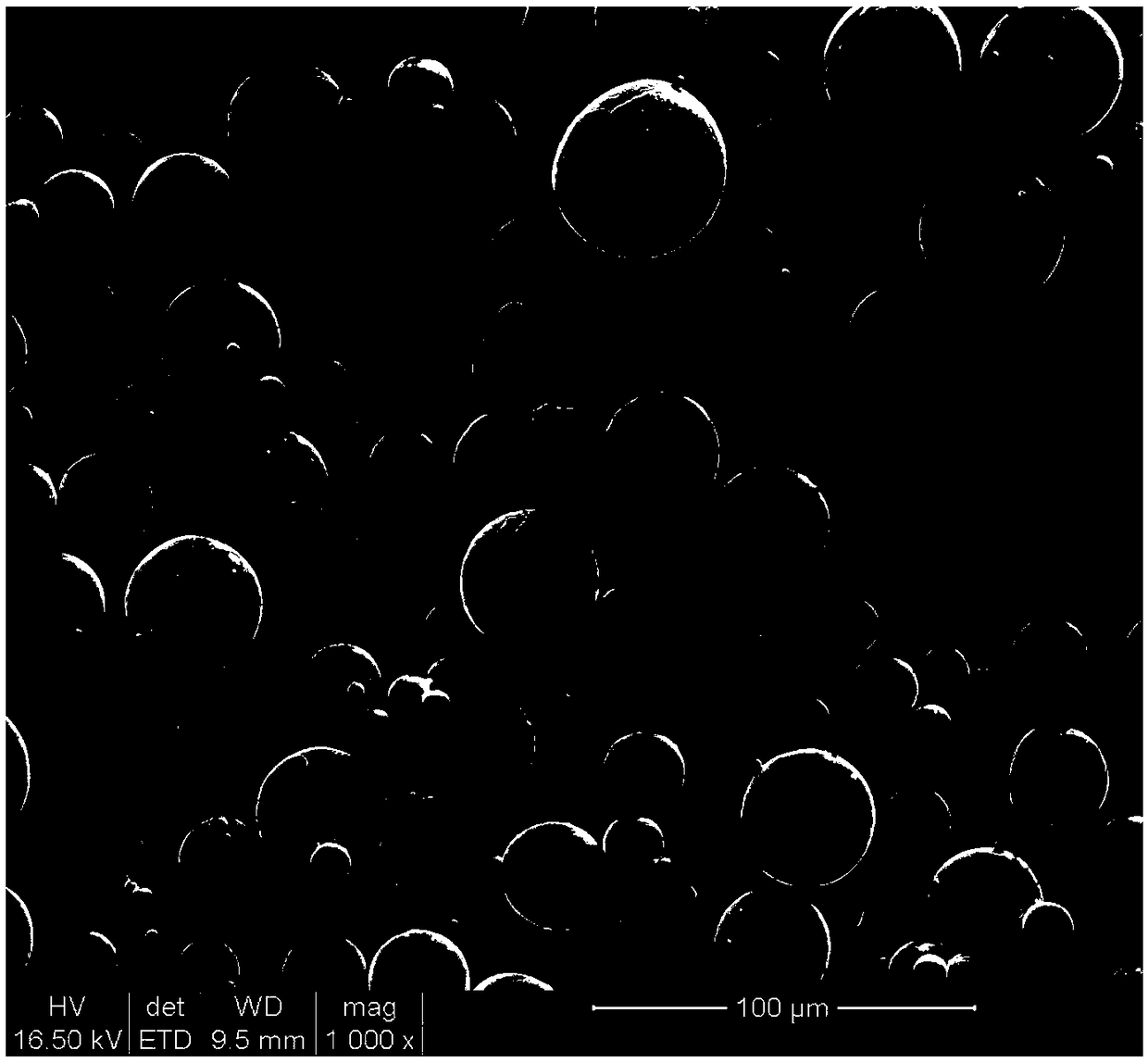

Gas atomization preparation method of metal power with low satellite ball rate and for 3D printing

The invention relates to a gas atomization preparation method of metal power with a low satellite ball rate and for 3D printing. The preparation method is characterized in that in a process of ultrasonic tight coupling vacuum gas atomization, an annular gas filling device is arranged at the upper end of an atomization chamber, an external airflow is introduced to improve a movement track of returngas in the atomization chamber, a probability of a condensed particle reentering an area to collide and bond with a high temperature particle in the gas atomization process is reduced so as to realize the preparation of the spherical metal powder for 3D printing with a low satellite ball rate and high mobility. Compared with the prior art, the preparation method innovatively introduces the external airflow to improve the movement track of the return gas in the atomization chamber, realizes the production of the metal powder with the low satellite ball rate and high mobility through the annular gas filling device on the basis of a traditional tight coupling atomization powder manufacturing technology, and can meet various demands of the industrial production for the high-quality sphericalmetal powder.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

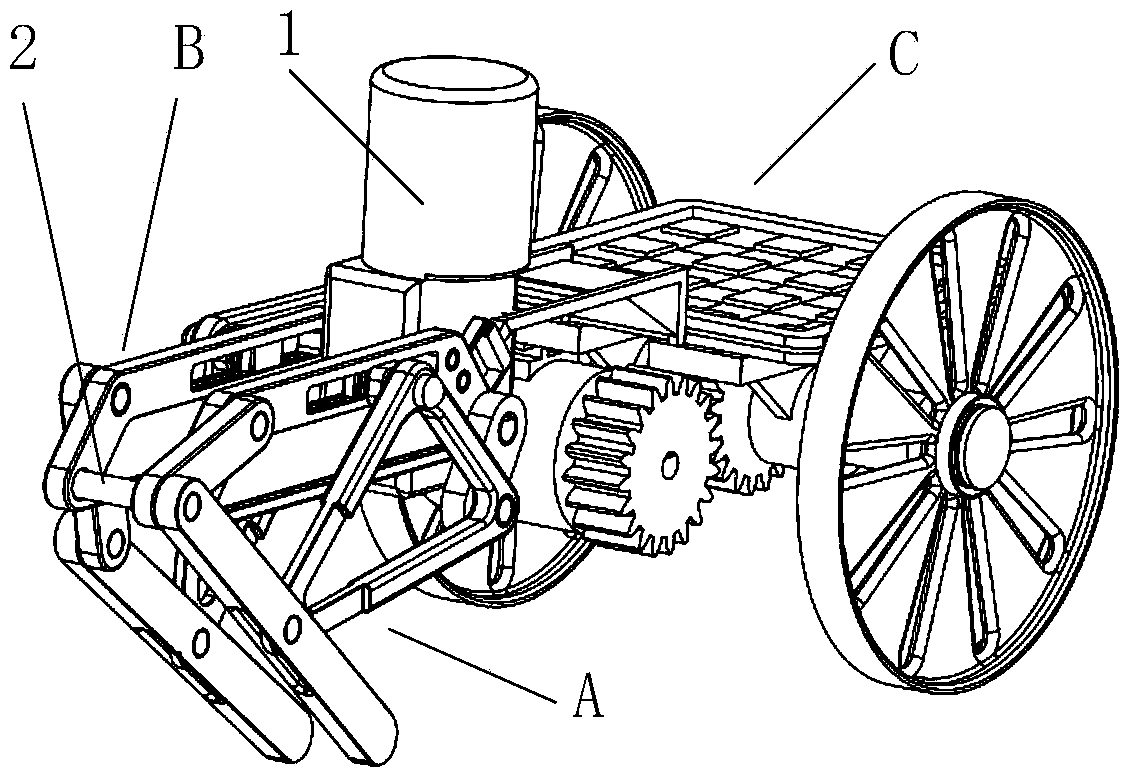

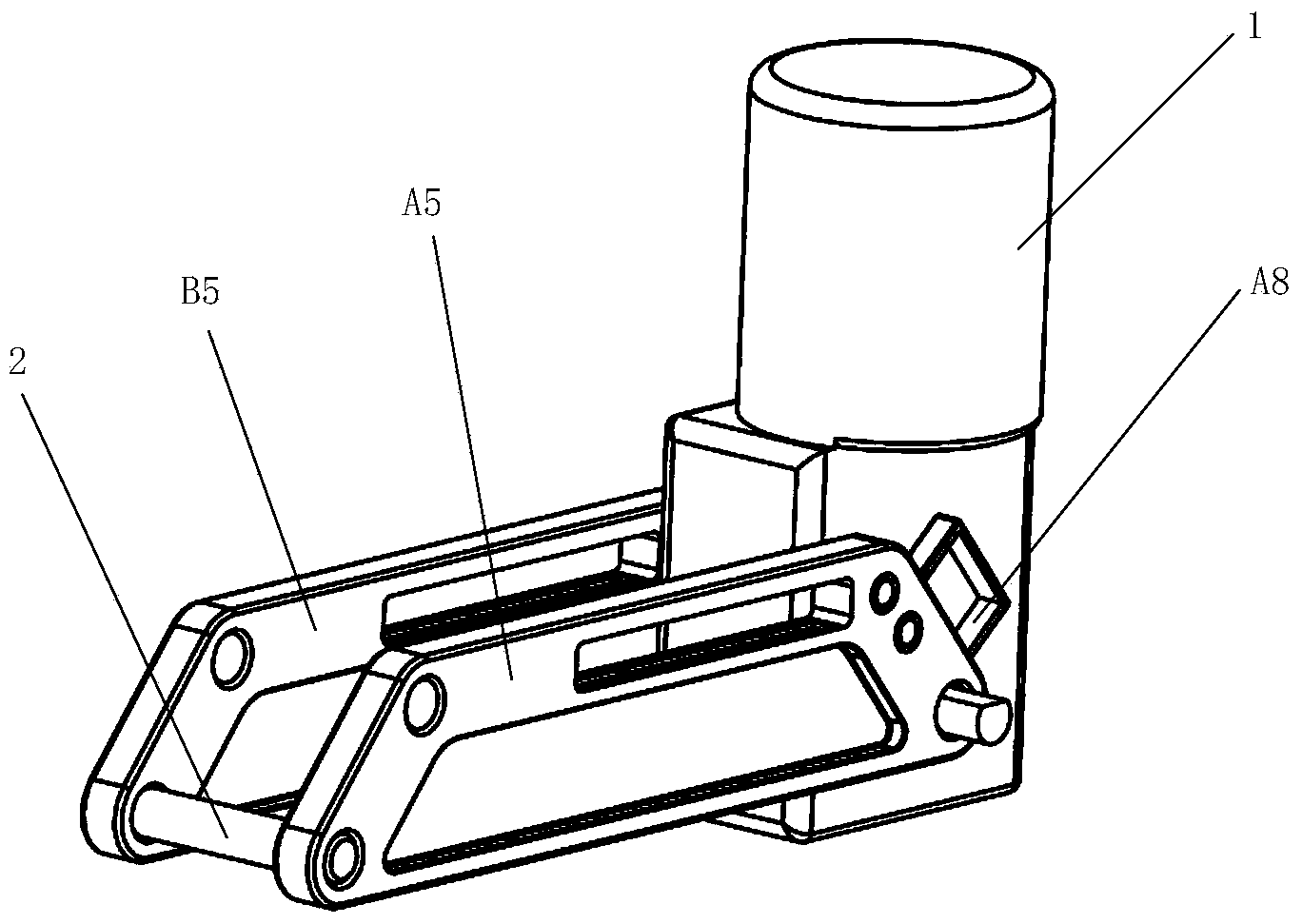

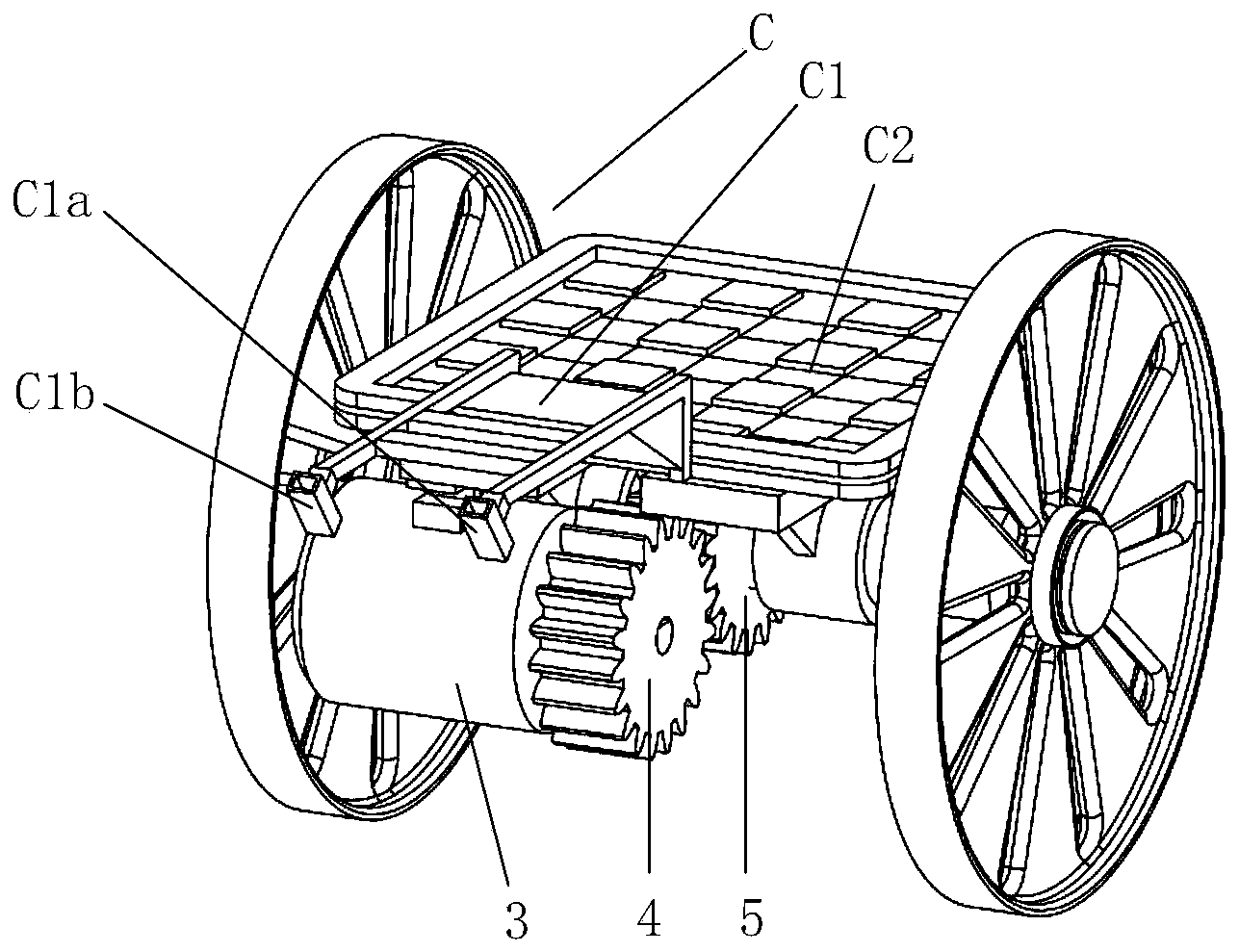

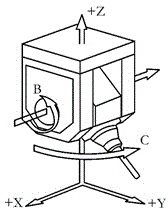

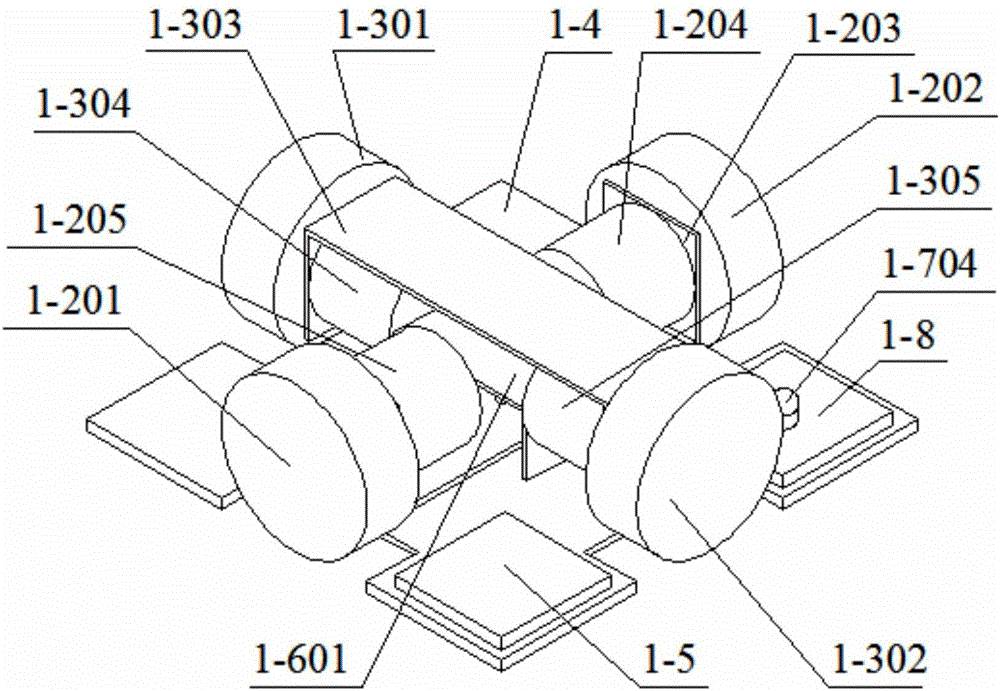

Wheel and leg composite carrying robot

ActiveCN103818492AOptimize motion trajectoryReduce internal frictionVehiclesEngineeringRobot locomotion

A wheel and leg composite carrying robot comprises a left side leg (A), a right side leg (B) and a trailer (C), wherein a clamping groove of a left first connecting rod (A1) of the left side leg (A) is matched and fixed with one output shaft of a double-output shaft motor (1), a clamping groove of a right first connecting rod (B1) of the right side leg (B) is matched and fixed with the other output shaft of the double-output shaft motor (1), a left rack (A5) of the left side leg (A) is fixedly connected with a right rack (B5) of the right side leg (B) through a connecting shaft (2), a left clamping sleeve (C1a) and a right clamping sleeve (C1b) of a connecting frame (C1) of the trailer (C) is respectively and fixedly connected with a left clamping ring (A8) and a right clamping ring (B8), and the double-output shaft motor (1) drives for the complete cycle for realizing motion of the robot. The wheel and leg composite carrying robot is simple in leg structure and is easy to process and assemble; a sliding pair is adopted at the joint, so that the foot end track is optimized, synergic movement of wheels and legs is realized, and the internal friction is reduced. The robot can be used in the fields of planet detection, cargo transportation, military reconnaissance and the like.

Owner:BEIJING JIAOTONG UNIV

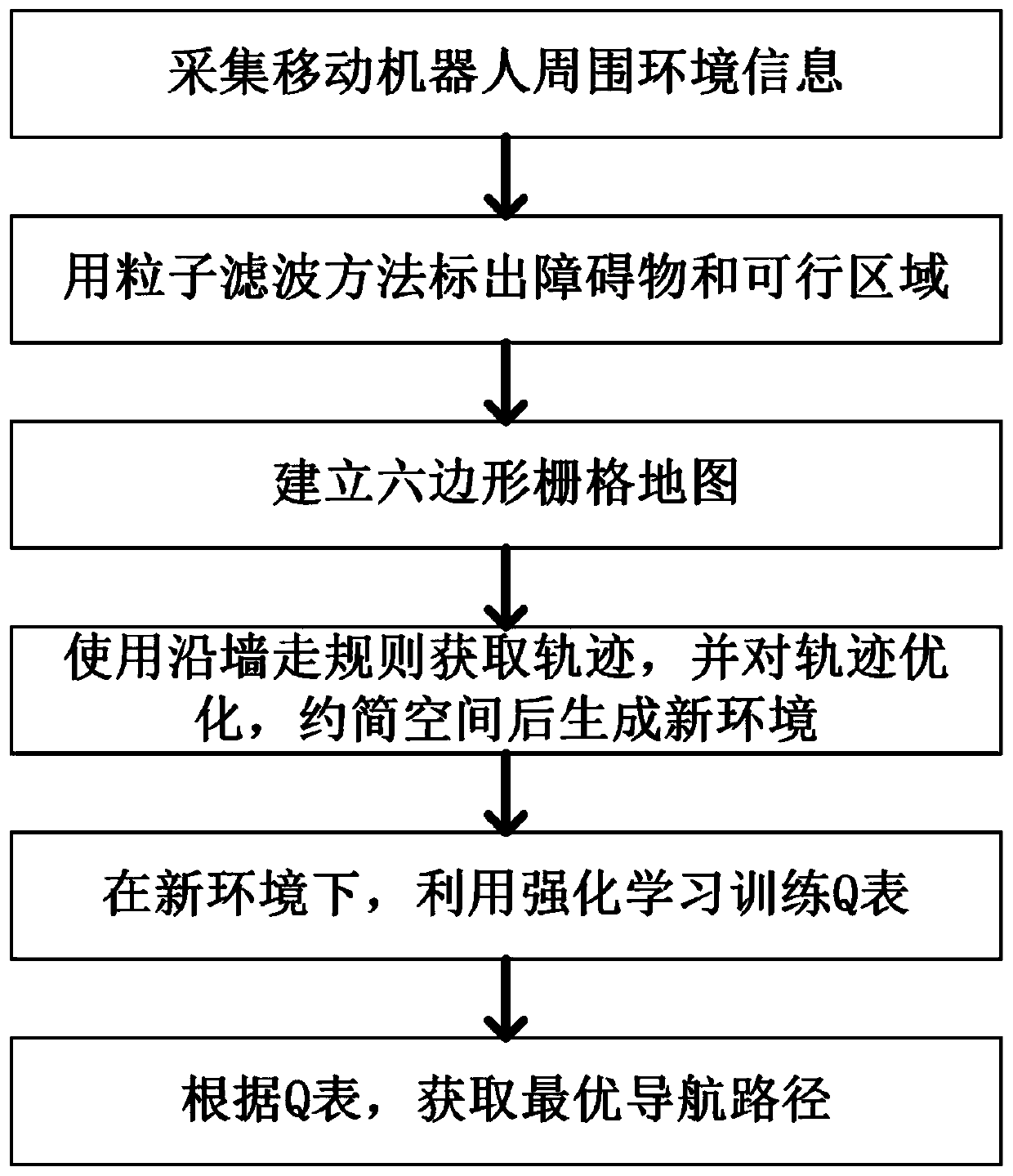

Robot navigation space reduction method

ActiveCN110908377AReduce computational complexityFast convergencePosition/course control in two dimensionsComputer visionMotion strategy

The invention discloses a robot navigation space reduction method which comprises the steps of enabling a robot to scan the surrounding environment through a sensor of the robot to obtain informationof surrounding environment; establishing a binary hexagonal grid map according to the surrounding environment information, marking a passable area and a non-passable area in a map, and forming an original environment map; according to the starting point position and the ending point position in the original environment map, acquiring two path tracks from the starting point to the ending point by using rules of walking along the left hand and the right hand; determining an optimization parameter K value, optimizing the two path trajectories, and joining the two optimized path trajectories to generate a reduced new navigation space; and according to the initial position of the robot and the new navigation space, updating the Q table through reinforcement learning, obtaining an optimal motionstrategy of the robot, and obtaining a motion path of the robot. The invalid exploration space of the robot in the navigation process is reduced, convergence is fast, and the learning efficiency is high.

Owner:NANJING UNIV

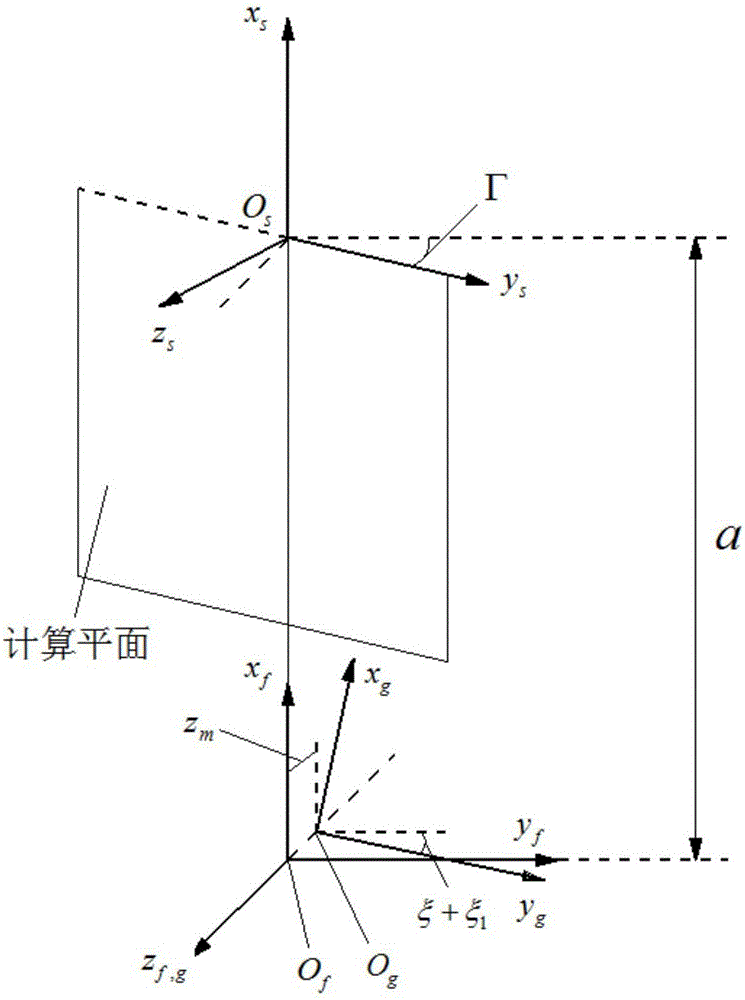

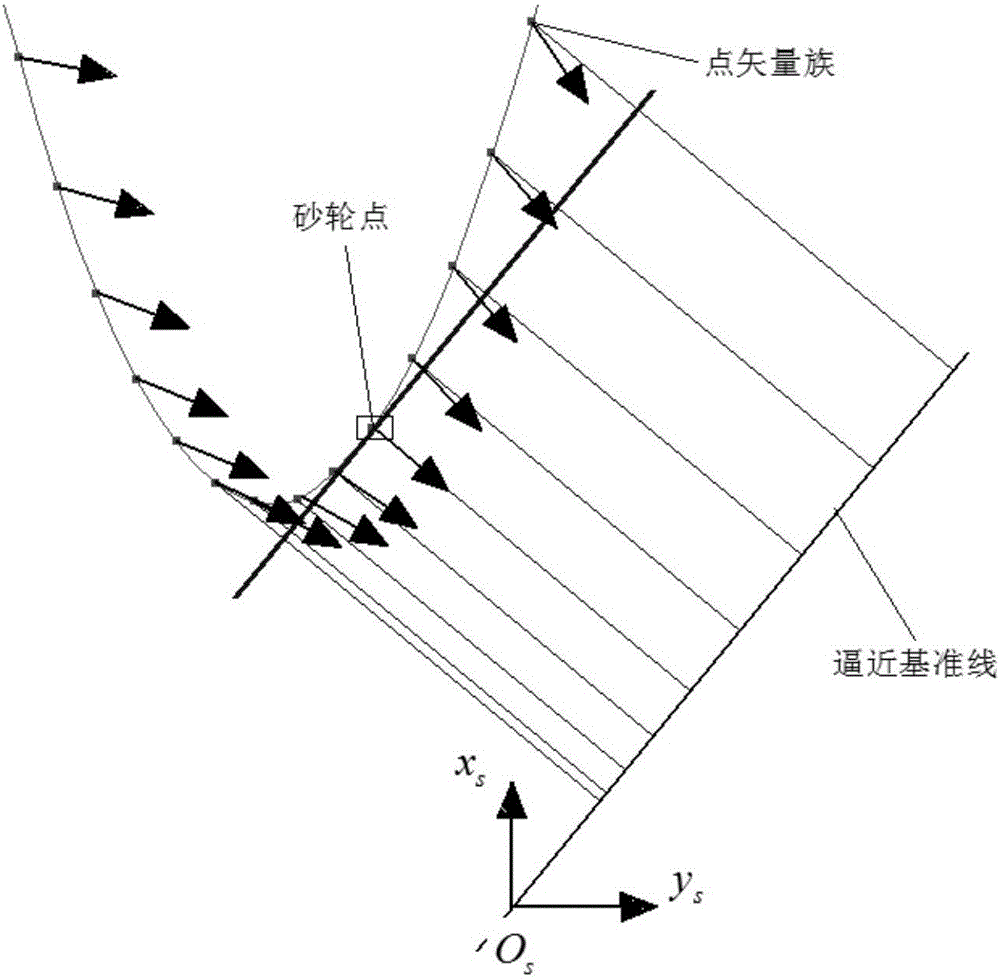

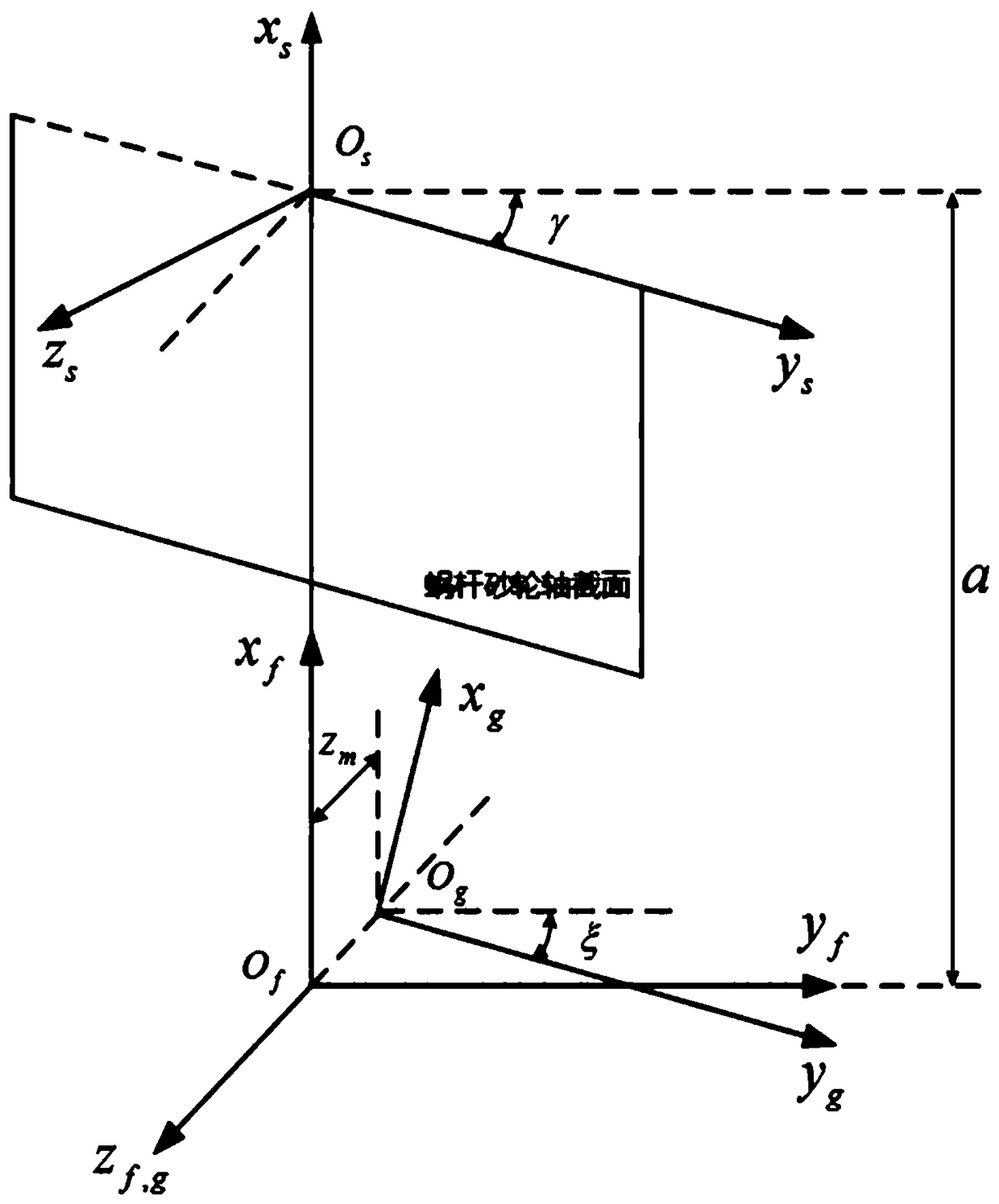

Point vector double-enveloping method for determining tool profile in helical surface generation processing

The invention relates to the field of helical surface manufacture and relates to a point vector double-enveloping method for determining a tool profile in helical surface generation processing. A profile of a gear end section is subjected to point discrete processing according to an averaging criterion, and space vectors of discrete points on a gear surface are added to constitute point vectors; meanwhile, helical motion tracks of the point vectors along the gear surface and rotation generation motion tracks along a gear axis are subjected to discrete processing, the planar point vector double-enveloping method is established, the points, having the shortest directed distance with a grinding wheel, in a two-dimensional point vector group are determined to be enveloping points, and finally, the generation tool profile is formed by all the enveloping points in a fitting manner.

Owner:CHONGQING UNIV

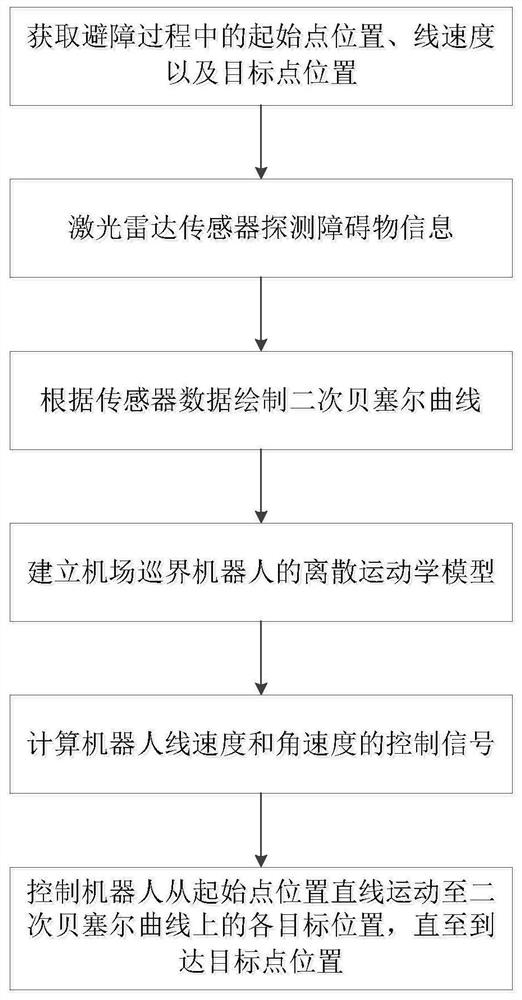

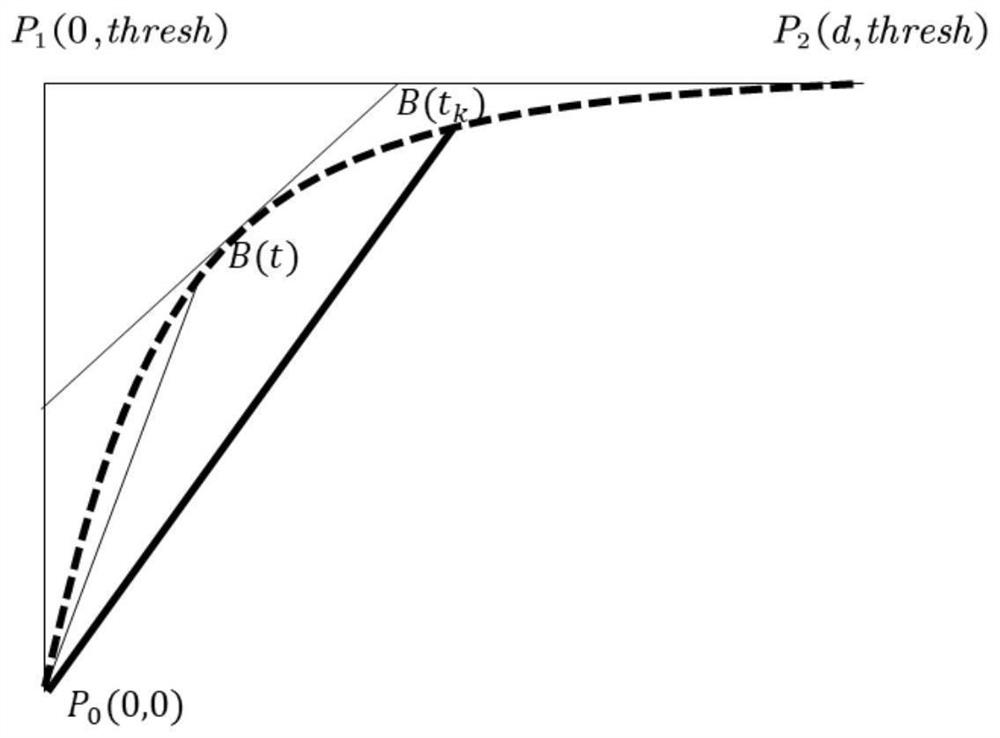

Airport boundary patrol robot local path planning method and system based on Bezier curve

ActiveCN112256023AEasy to control poseOptimize motion trajectoryPosition/course control in two dimensionsControl signalSimulation

The invention discloses an airport boundary patrol robot local path planning method and system based on a Bezier curve. The method comprises the steps: acquiring the starting point position, the linear speed and the target point position in an obstacle avoidance process of an airport boundary patrol robot; detecting obstacle information by using a laser radar sensor carried by the airport boundarypatrol robot, and drawing a quadratic Bezier curve according to sensor measurement data; and establishing the discrete kinematics model of the airport boundary patrol robot, calculating the control signals of the linear speed and the angular speed of the robot, and controlling the robot to linearly move from the starting point position to each target position on the quadratic Bezier curve by thesignals until the robot reaches the target point position. According to the invention, the influence of the target point direction and the local obstacle position is comprehensively considered, path planning parameters are adjusted, and the robot motion trail is optimized; and a quadratic Bezier curve algorithm is adopted, speed planning is efficiently carried out, real-time calculation is guaranteed, and the pose of the robot during movement is easy to control.

Owner:NANJING UNIV OF SCI & TECH

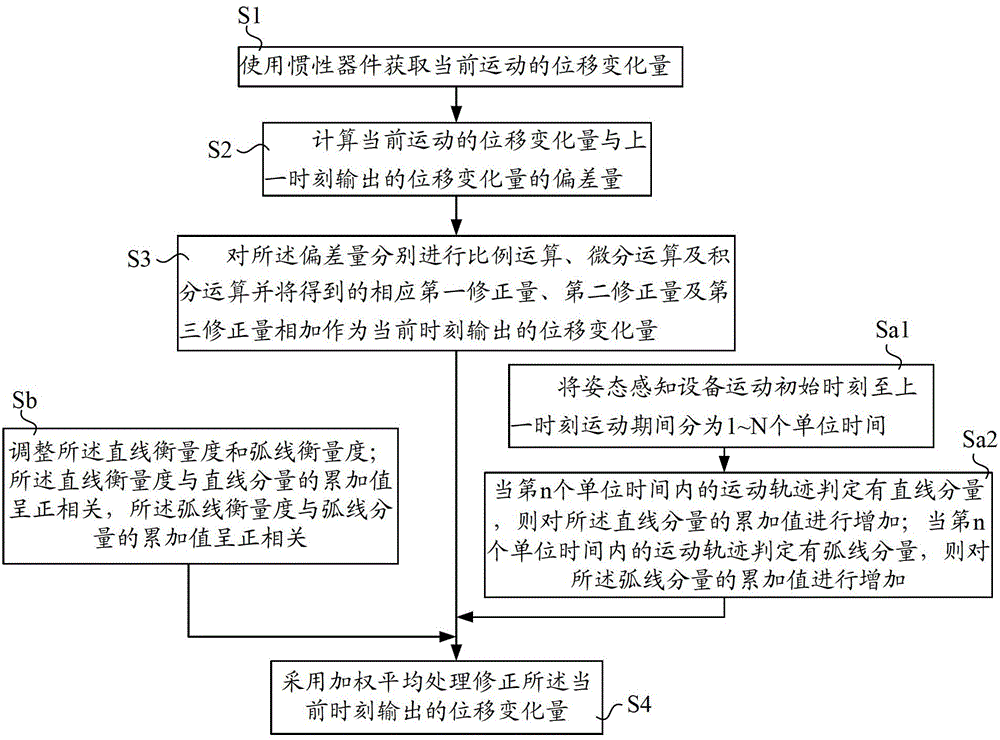

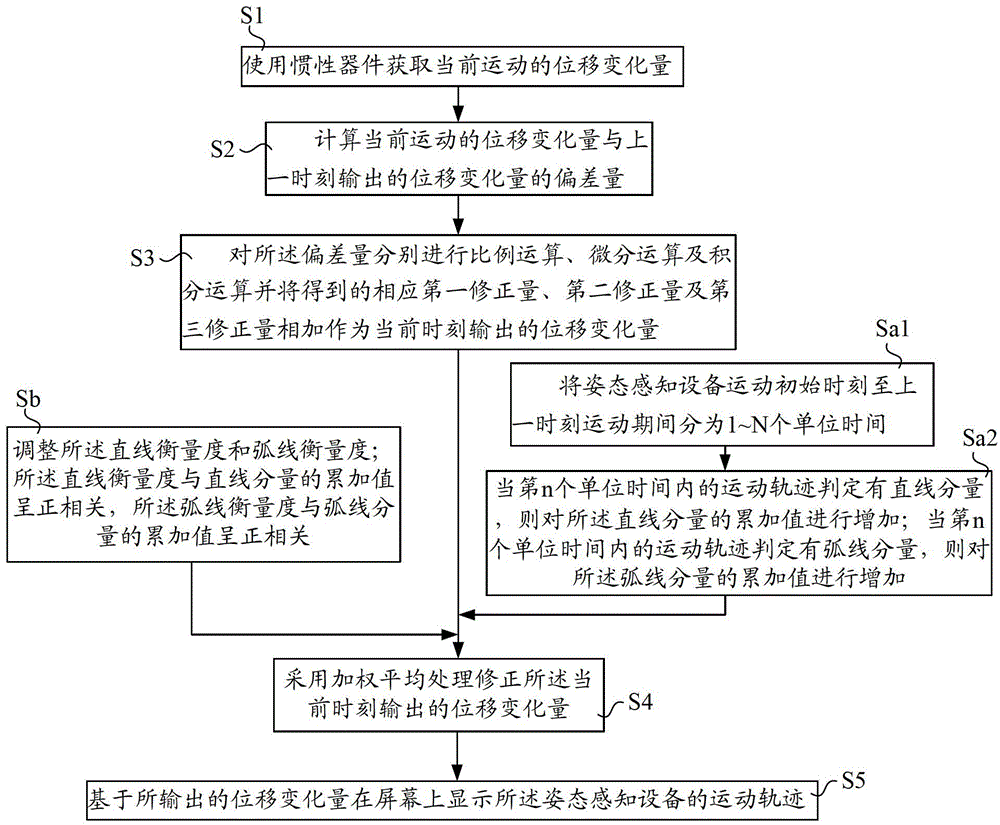

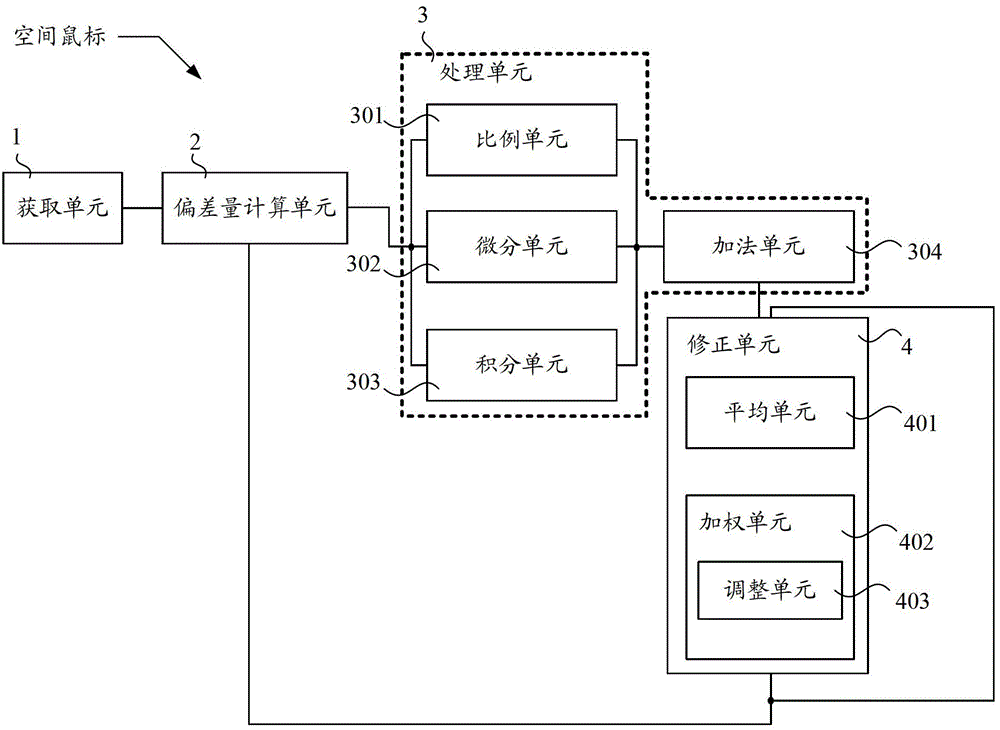

Output control method and device of gesture sensing equipment, and display control method and system

ActiveCN102981646AEliminate the deviation of the output displacement variationOptimize motion trajectoryInput/output processes for data processingControl theoryInertia

The invention relates to an output control method and device of gesture sensing equipment, and a display control method and system. The output control method comprises the following steps of: obtaining a displacement variation of the current movement by using an inertial device; calculating a deviation amount of the displacement variation of the current movement and a displacement variation output in the former moment; respectively carrying out proportional operation, differential operation and integral operation on the deviation amount and adding an obtained corresponding first correction, an obtained corresponding second correction and an obtained corresponding third correction to be used as a displacement variation output in the current moment; and the output control device comprises an obtaining unit used for obtaining the displacement variation of the current movement, a deviation amount calculating unit used for calculating the deviation amount of the displacement amount, and a processing unit used for respectively carrying out proportional operation, differential operation and integral operation on the deviation amount and adding results to be used as the displacement variation output in the current moment. According to the invention, the deviation in the displacement variation output by the gesture sensing equipment can be eliminated.

Owner:JIANGSU HUITONG GRP

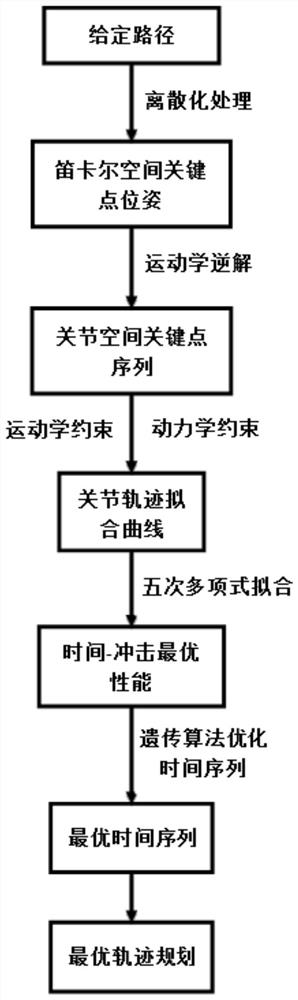

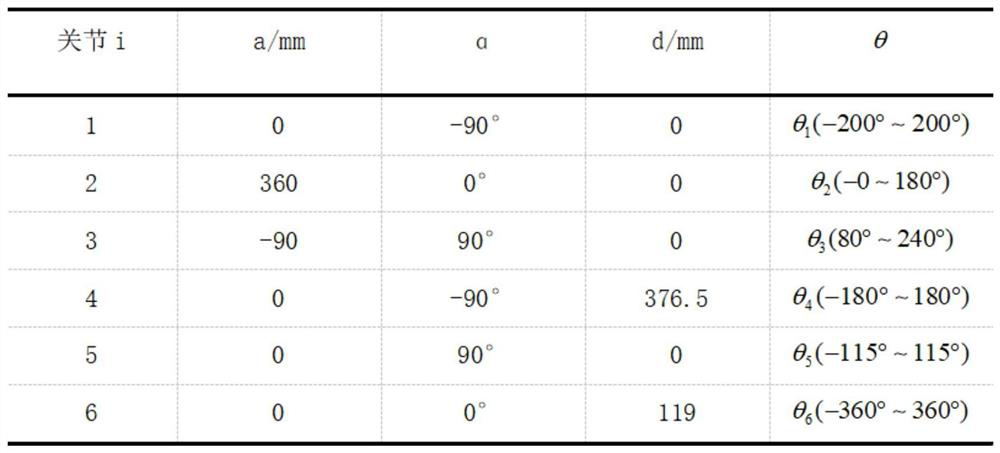

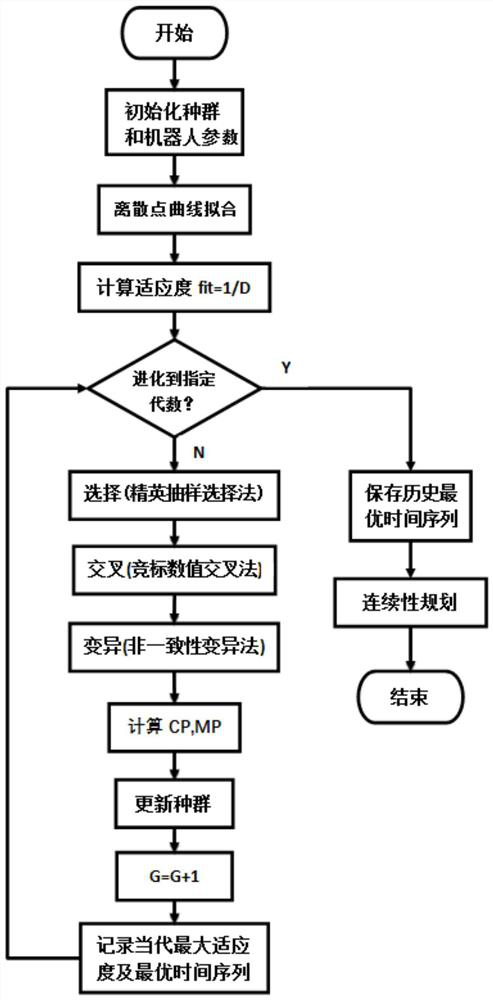

Industrial robot trajectory optimization method based on improved genetic algorithm

ActiveCN112692826AOptimize motion trajectoryMotion track stabilityProgramme-controlled manipulatorAlgorithmGene selection

The invention discloses an industrial robot trajectory optimization method based on an improved genetic algorithm, and aims to provide a trajectory through which an industrial robot completes a given route with the shortest time and the minimum impact based on the given path and a certain constraint condition. Based on a traditional genetic algorithm, the industrial robot trajectory optimization method disclosed by the invention improves a gene selection formula, a crossover formula and a mutation formula, improves crossover and mutation probabilities on the basis of self-adaption PRGA, optimizes the action time of a mechanical arm under the condition that the motion trail of the robot is stable, reduces resonance and shaking, caused by overlarge impact, of the robot, and enables the robot to run stably and smoothly, thereby greatly improving the working efficiency and prolonging the service life of the robot.

Owner:FOSHAN UNIVERSITY

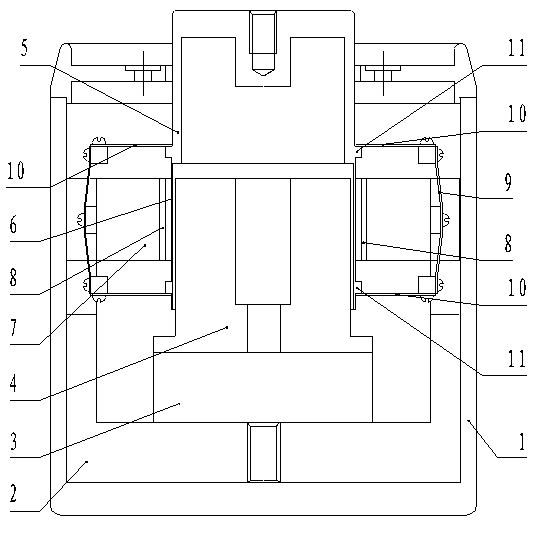

Hydraulic support device and supporting method based on extending in roadway

Owner:山东塔高矿业机械装备制造有限公司

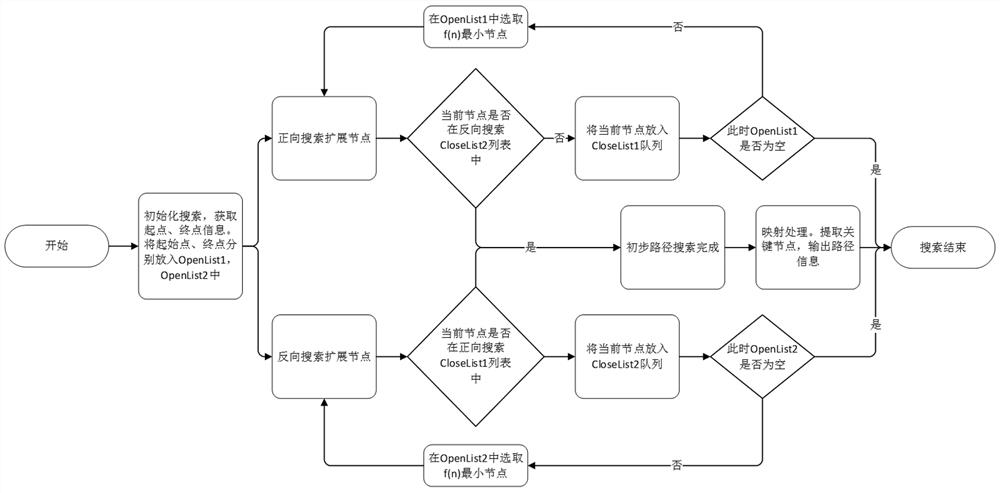

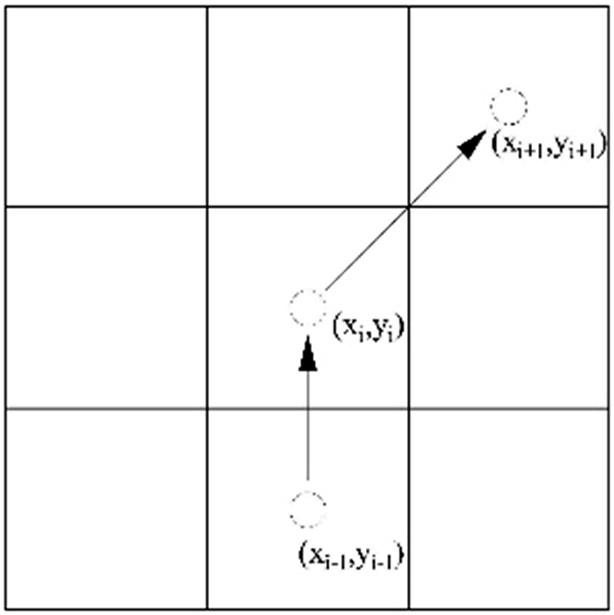

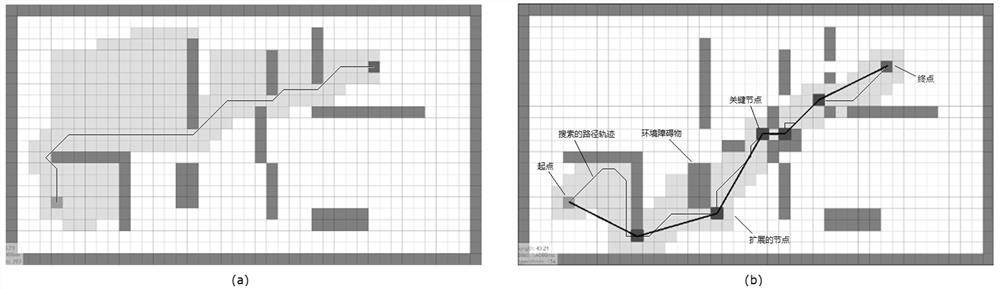

AGV robot path planning method and system based on improved search algorithm

ActiveCN113485360AImprove the efficiency of route searchOptimize motion trajectoryPosition/course control in two dimensionsVehiclesIterative searchBidirectional search

The invention relates to an AGV robot path planning method and system based on an improved search algorithm, wherein the method carries out path search based on the search algorithm by adopting a bidirectional iteration mode, that is., the iterative search is started from a starting point and an end point until the bidirectional search converges, wherein the bidirectional search adopts different heuristic functions, and bidirectional search is prevented from being interfered by a same environmental factor; and key node extraction is carried out on the obtained series of path track nodes, and path information is formed and output. The method and the system are favorable for improving the path searching efficiency.

Owner:FUZHOU UNIV

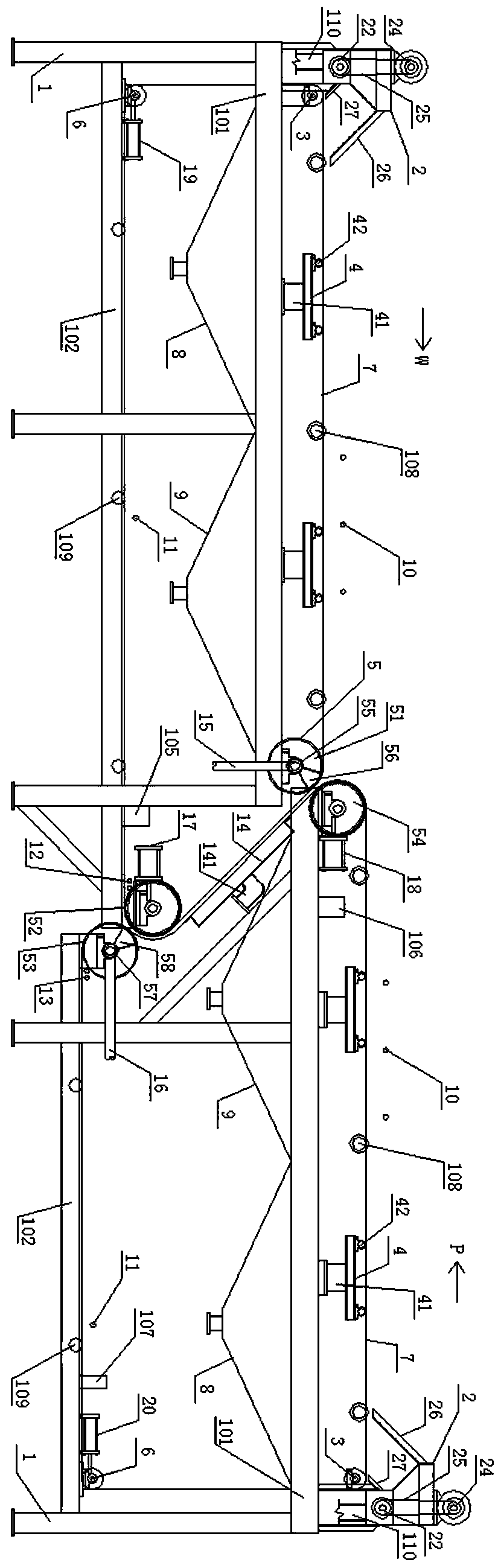

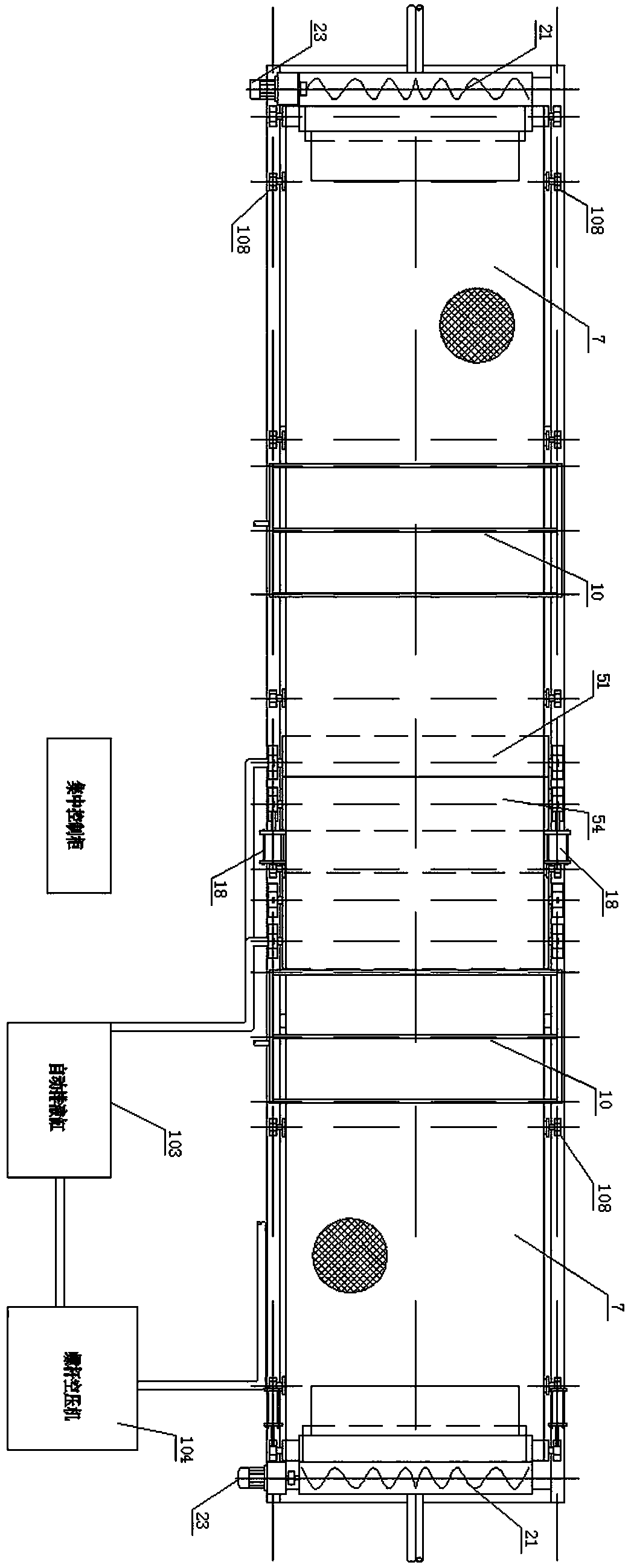

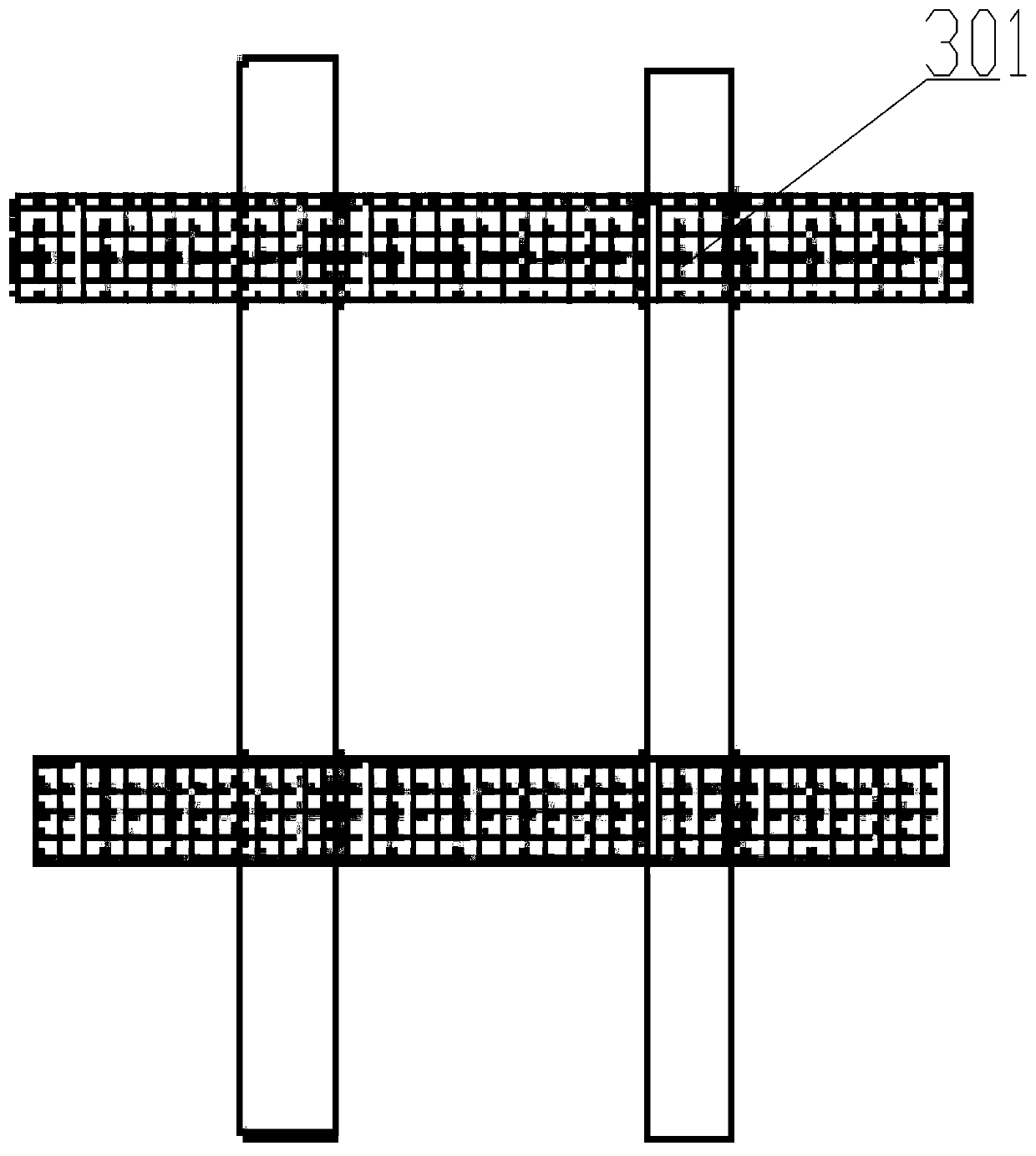

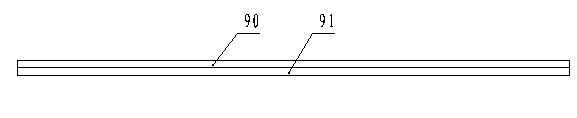

Novel belt type vibratory rolling filtering device

ActiveCN108211478AExtended service lifePrevent extrusionMoving filtering element filtersMechanical engineeringLiquid content

The invention provides a novel belt type vibratory rolling filtering device. The novel belt type vibratory rolling filtering device comprises belt type vibratory rolling filtering machines which are oppositely arranged, wherein each filtering machine comprises a rack; the rack comprises an upper supporting frame and a lower supporting frame; a layering distribution device is arranged at the upstream end of the upper supporting frame; in the material flowing direction, the rack is provided with a guiding roll, a vibrating part, a driving rolling part and a tensioning roll in sequence; a ring-shaped filtering belt is arranged around the guiding roll, the vibrating part, the driving rolling part and the tensioning roll; the left driving rolling part comprises a first extruding and dewateringroller positioned on the upper supporting frame and a second driving electric roller positioned on the lower supporting frame; the right driving rolling part comprises a second extruding and dewatering roller positioned on the lower supporting frame and a first driving electric roller positioned on the upper supporting frame; extruding gaps are respectively formed between the first extruding and dewatering roller and the first driving electric roller, between the two filtering belts surrounding the left driving rolling part and the right driving rolling part and between the second extruding and dewatering roller and the second driving electric roller. The novel belt type vibratory rolling filtering device provided by the invention has the advantages that the liquid content of filter cakesis low and the productivity is improved.

Owner:贾守民 +1

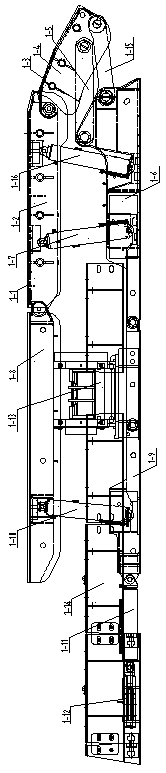

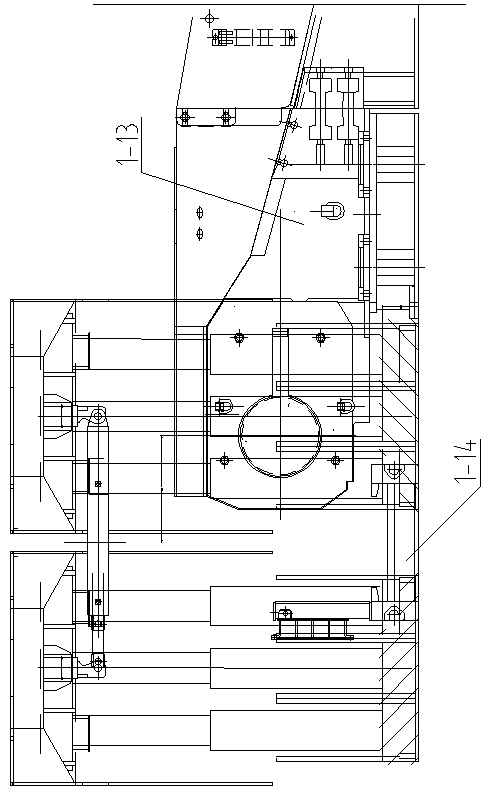

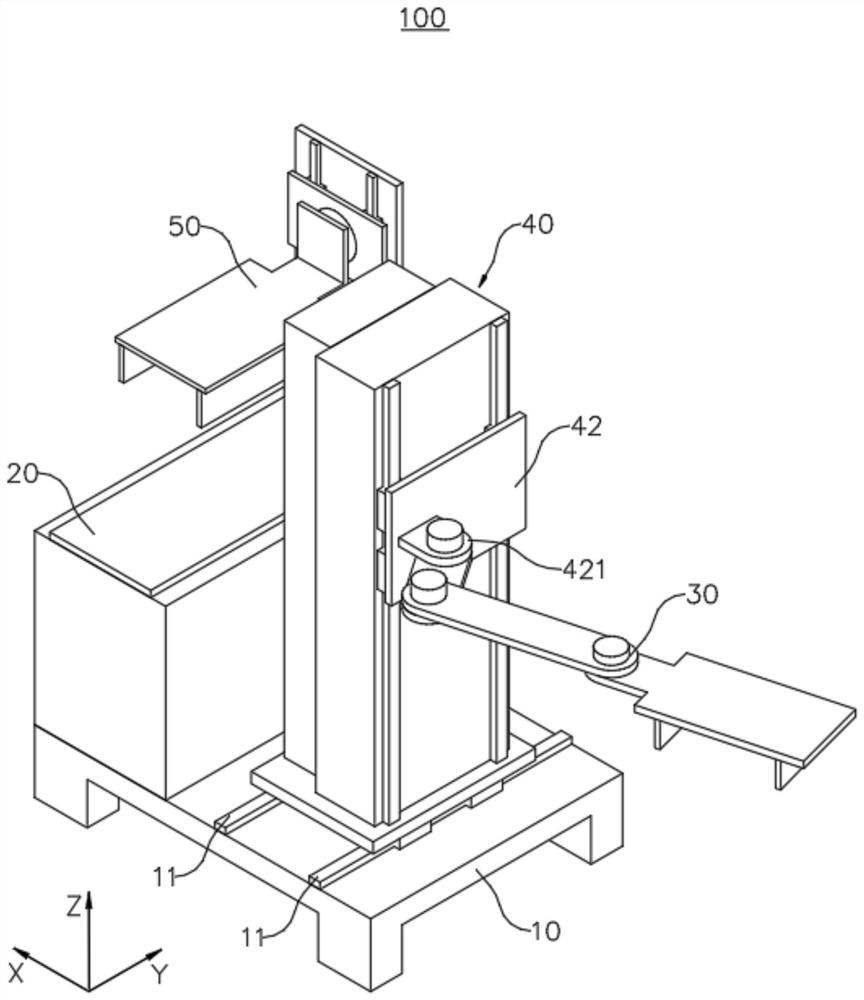

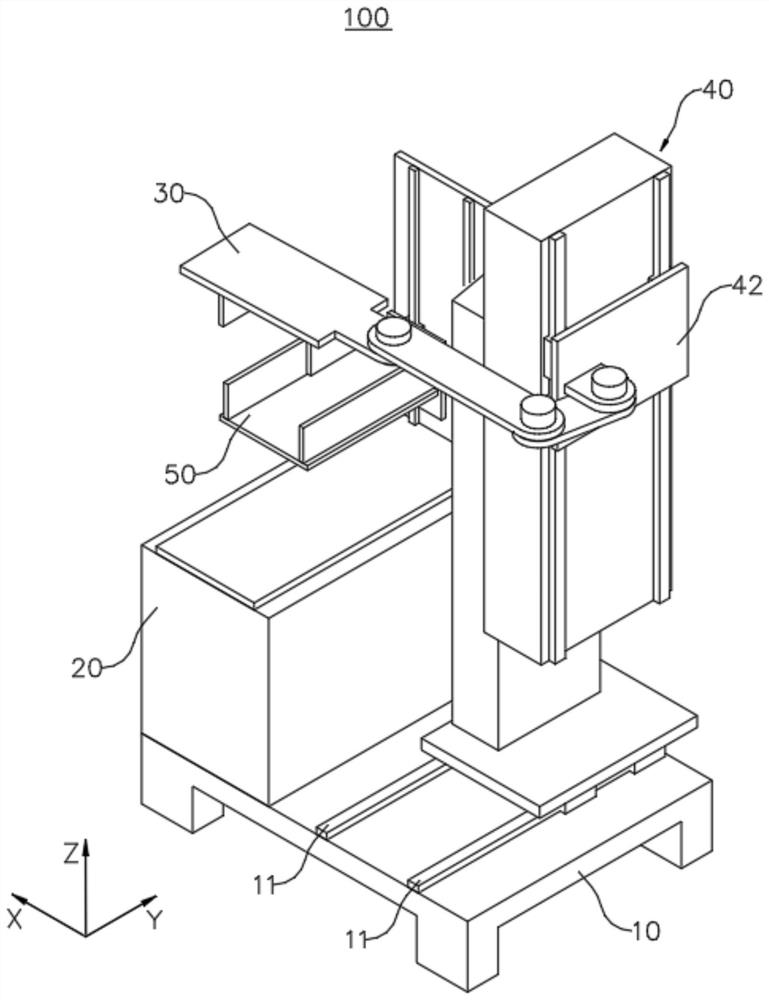

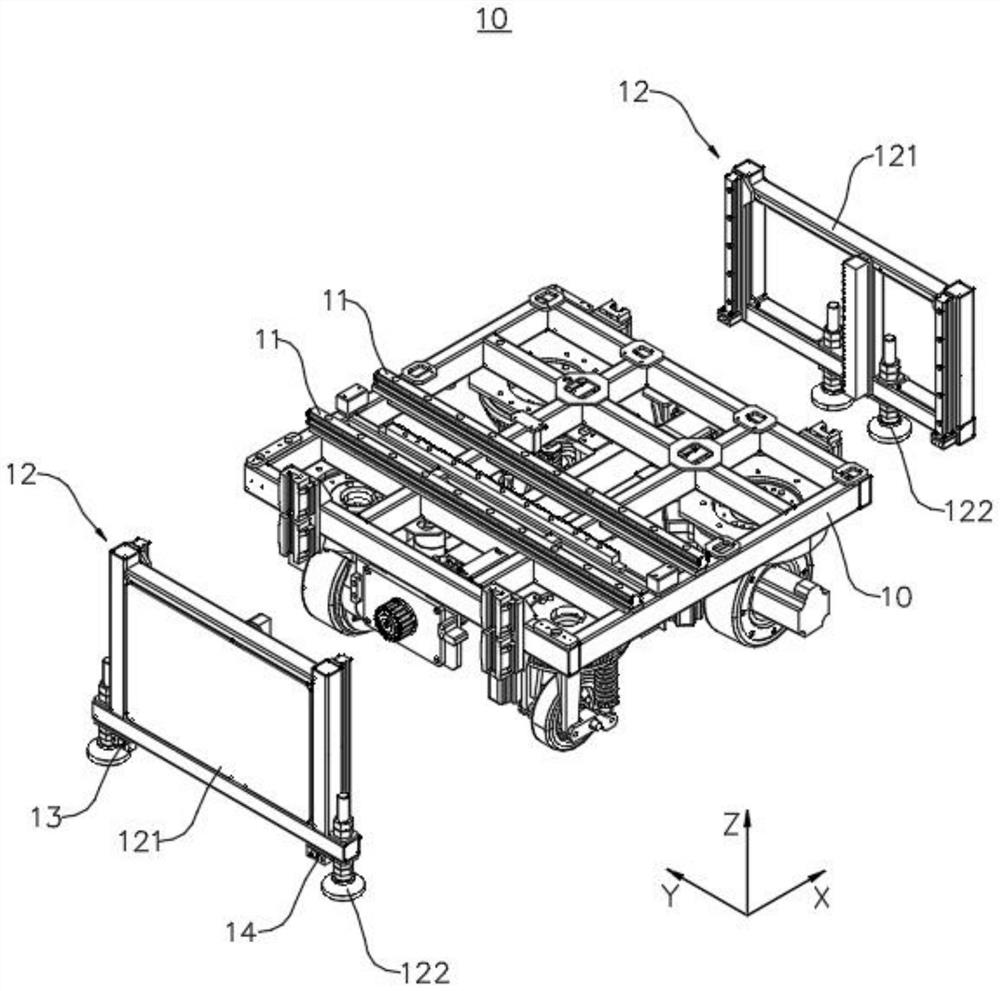

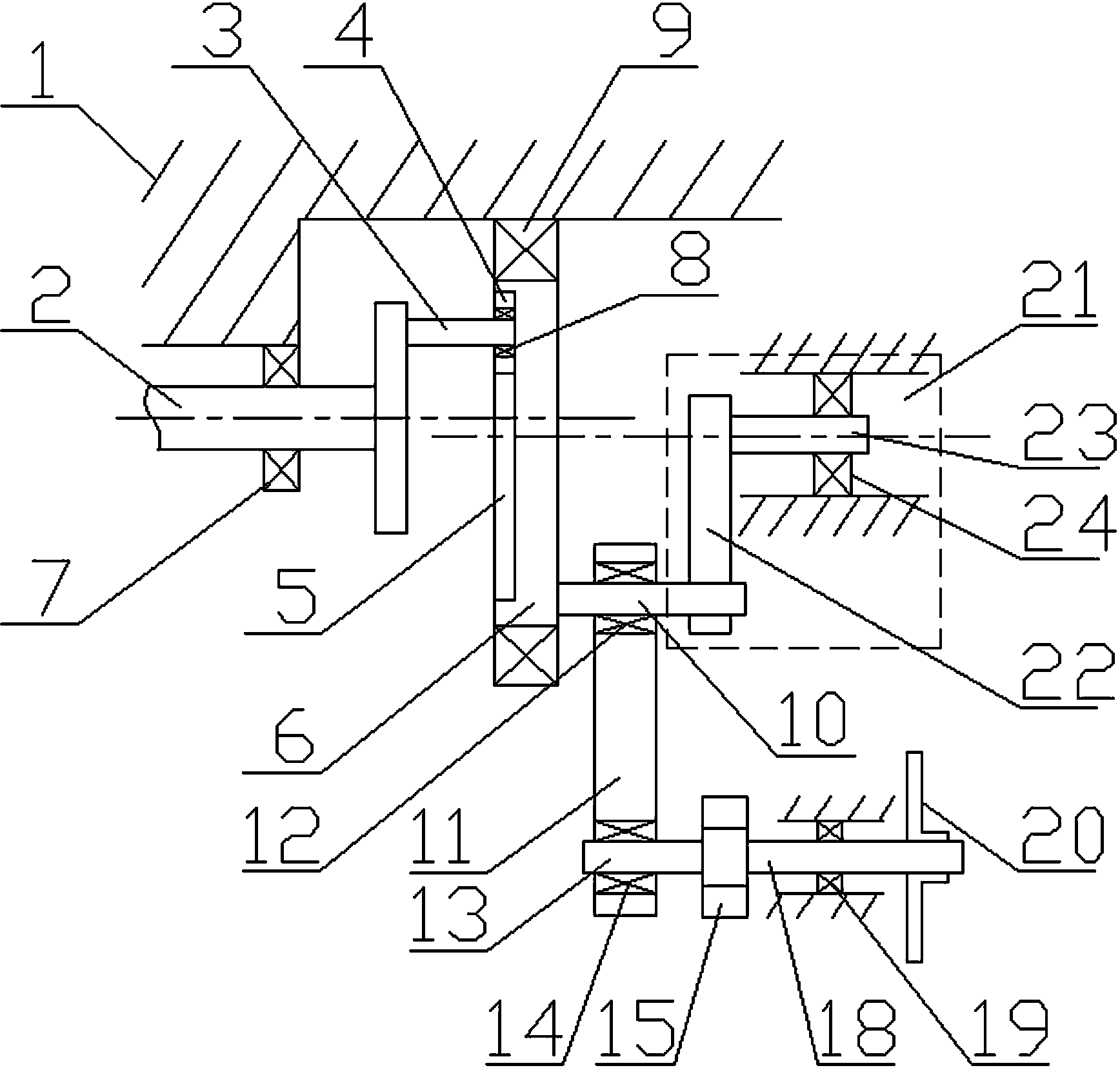

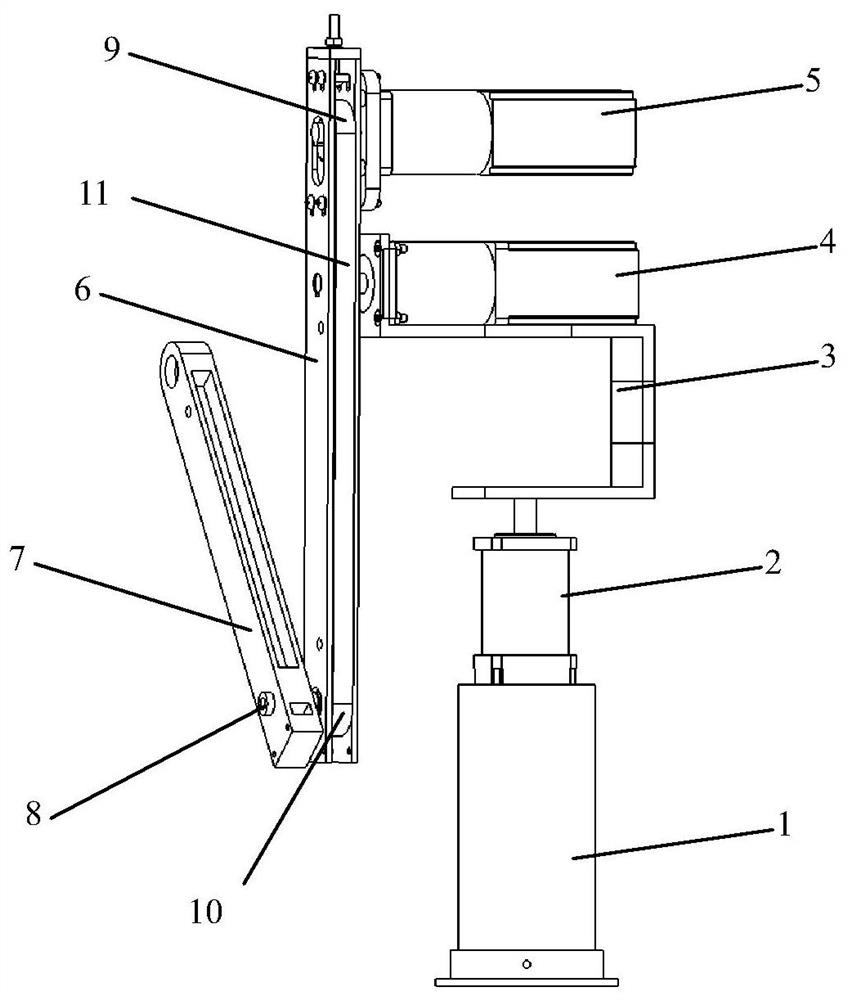

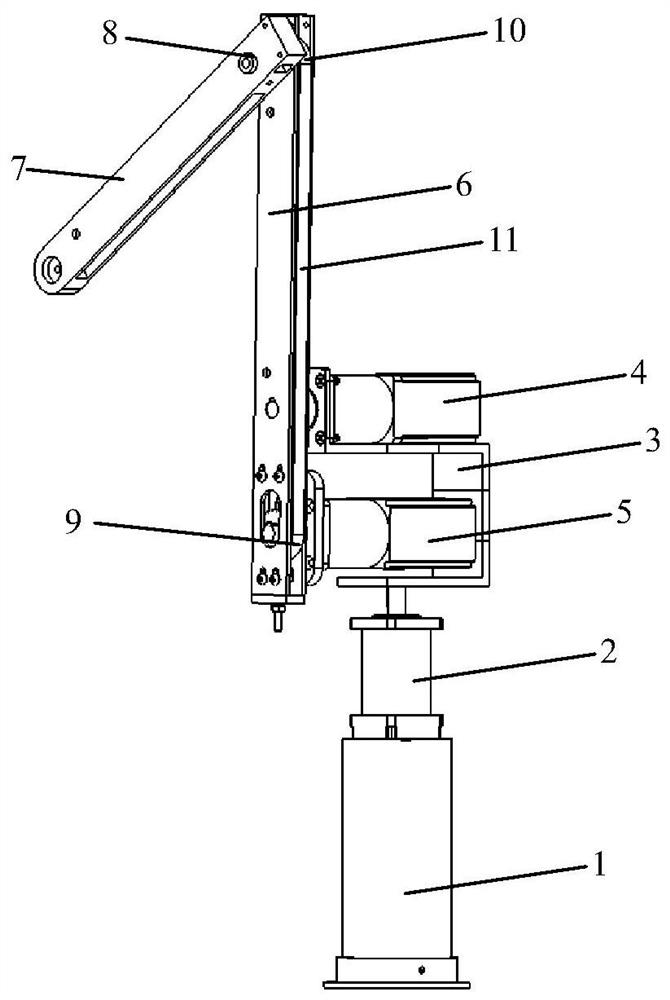

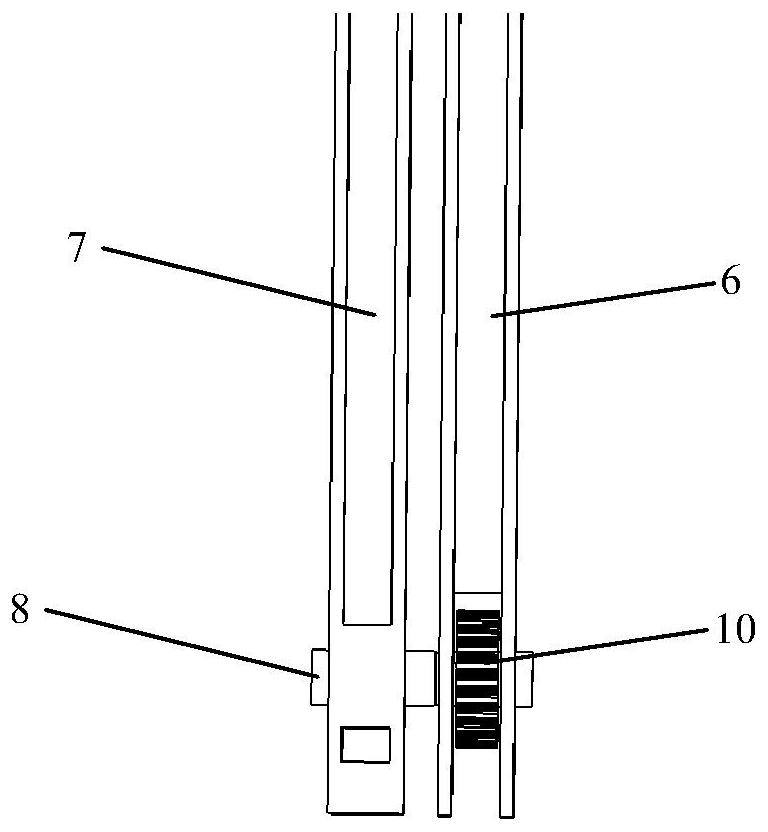

Lifting mechanism and bricklaying robot

ActiveCN113389394AOptimize motion trajectoryShorten the lengthBuilding material handlingControl engineeringStructural engineering

The invention provides a lifting mechanism and a bricklaying robot, and belongs to the technical field of building machinery. The lifting mechanism comprises a first mounting base, a lifting base, a first driving piece and a first transmission assembly, wherein the lifting base is movably arranged on the first mounting base in the vertical direction, a base used for mounting an executing mechanism is arranged on the lifting base, the first driving piece is installed on the lifting base, the first driving piece and the base are located in the same installation face, the first driving piece and the base are arranged in a spaced mode in the left-right direction, the first driving part is in transmission connection with the first mounting base through the first transmission assembly, the first driving part is used for driving the lifting base to move up and down through the first transmission assembly, the first transmission assembly is located on the side, in the left-right direction, of the lifting base, and the first transmission assembly is farther away from the base than the first driving piece. The lifting mechanism of the structure is small in occupied space and can be suitable for more operation environments, the descending position of the base is not limited, and therefore the operation requirements of different heights can be met.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

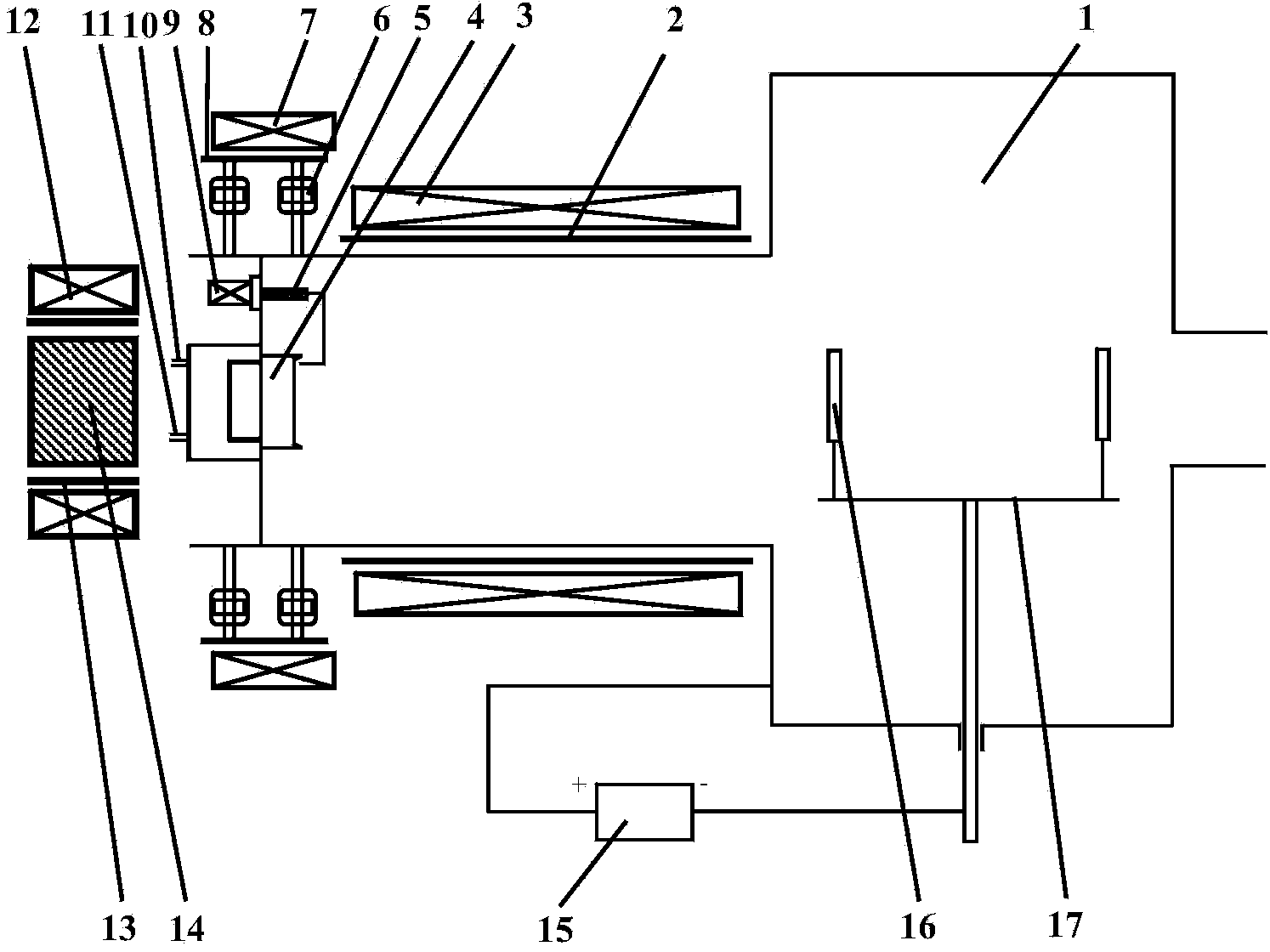

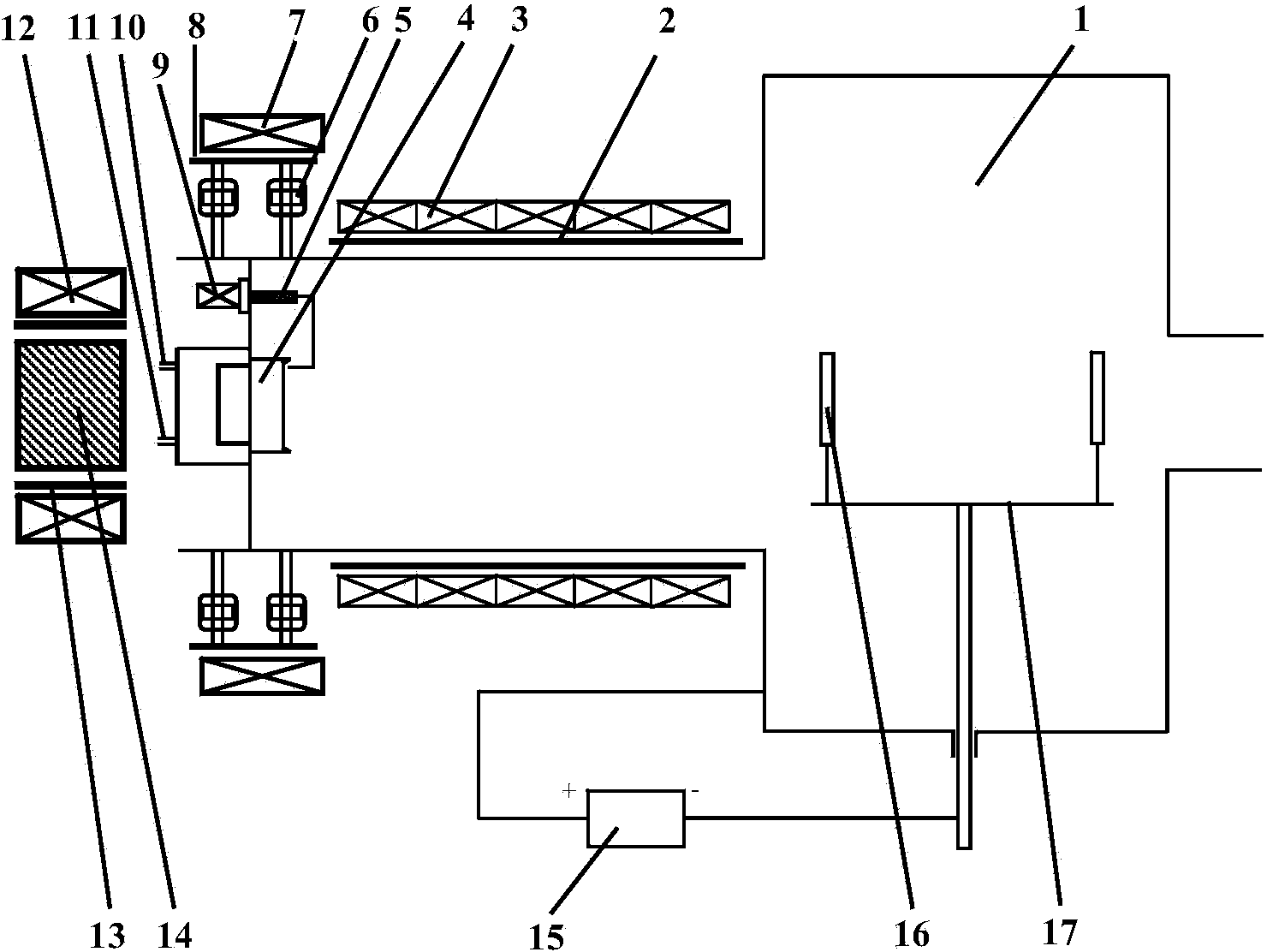

Auxiliary electric arc ion plating device for coupling rotary transverse magnetic field with axial magnetic field

ActiveCN103643213AEmission reductionReduce in quantityVacuum evaporation coatingSputtering coatingVolumetric Mass DensityTransverse magnetic field

The invention belongs to the field of material surface modification and in particular relates to an auxiliary electric arc ion plating device for coupling a rotary transverse magnetic field with an axial magnetic field, wherein a work table and a target are arranged in a vacuum chamber of the device; the front side of the target is opposite to the work table; an axial magnetic field generation device which is arranged behind the target is sleeved on a flange or a support cylinder and insulating protection is arranged between the axial magnetic field generation device and the flange or the support cylinder; a rotary transverse magnetic field generation device which is arranged outside the vacuum chamber is sleeved on a flange or a support cylinder at the outer side of the target and insulation protection is arranged between the rotary transverse magnetic field generation device and the flange or the support cylinder; an axial magnetic field generation device which is arranged in a plasma transmission channel is sleeved on a flange or a support cylinder on the outer side of the vacuum chamber and insulation protection is arranged between the axial magnetic field generation device and the flange or the support cylinder. The movement of an arc spot is controlled by the rotary transverse magnetic field, so that the discharging manner of the arc spot is improved; the movement speed of the arc spot and the emission of large particles on the surface of the target are improved; meanwhile, the plasma transmission is restrained by the axial magnetic field; and the density and the utilization rate of the plasma are improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Horizontal rotating weft-guiding transmission mechanism for weaving machine

The invention relates to a horizontal rotating weft-guiding transmission mechanism for a weaving machine. A driving shaft and a driven plate are rotatably arranged on a rack; a primary core shifting shaft is fixed on an end surface of the driving shaft, and is connected with a driving roller through a primary core shifting shaft bearing in a sleeving manner; the driving roller extends in a chute in an end surface of the driven plate and applies force on a side wall of the chute; and when the driving shaft rotates by a circle, the driven plate can be driven by the primary core shifting shaft, the driving roller and the chute to rotate by a circle relative to the driving shaft under the condition that the speed ratio is changed. The transmission mechanism is simple and stable in structure; requirements on distribution of time and angles of a sword tape and a sword head inside and outside a weaving opening during weaving of the weaving machine can be met; the rigidity is high; connection transmission is soft; impact force is small; the movement trails of the sword tape and the sword head are effectively optimized; parts are machined simply; the cost and the inertia are low; the transmission mechanism is easy to repair; the production cost is saved; the running efficiency of the weaving machine is improved; and the number of reciprocating motion parts is small, so that high-speed running is facilitated.

Owner:JIANGSU YOUCHENG CNC TECH CO LTD

Device and method for obtaining position of liquid displacement surface in rock fracture

ActiveCN111595550AAddresses issues where direct knowledge of the displacement process is not possibleInnovativeHydrodynamic testingSurface/boundary effectVertical planeClassical mechanics

The invention provides a device and method for obtaining the position of a liquid displacement surface in a rock fracture. The top end of a water tank communicates with a gas pressurizing device usedfor providing a stable pressure. The device comprises normal stress frames, a rock crack simulation sample used for a simulation experiment is installed between the normal stress frames through a supporting plate assembly, and a plurality of high-speed cameras used for monitoring the experiment process are arranged on the periphery of the rock crack simulation sample; and a water outlet in the bottom end of a water tank is communicated with a crack communicated with the rock crack simulation sample through a high-pressure water pipe. Therefore, the motion loss rule of the filler can be directly observed, researchers can conveniently observe the displacement operation rule from the plane and the vertical plane, and the device has the advantages of being visual in observation, easy to operate and convenient to collect data.

Owner:CHINA THREE GORGES UNIV

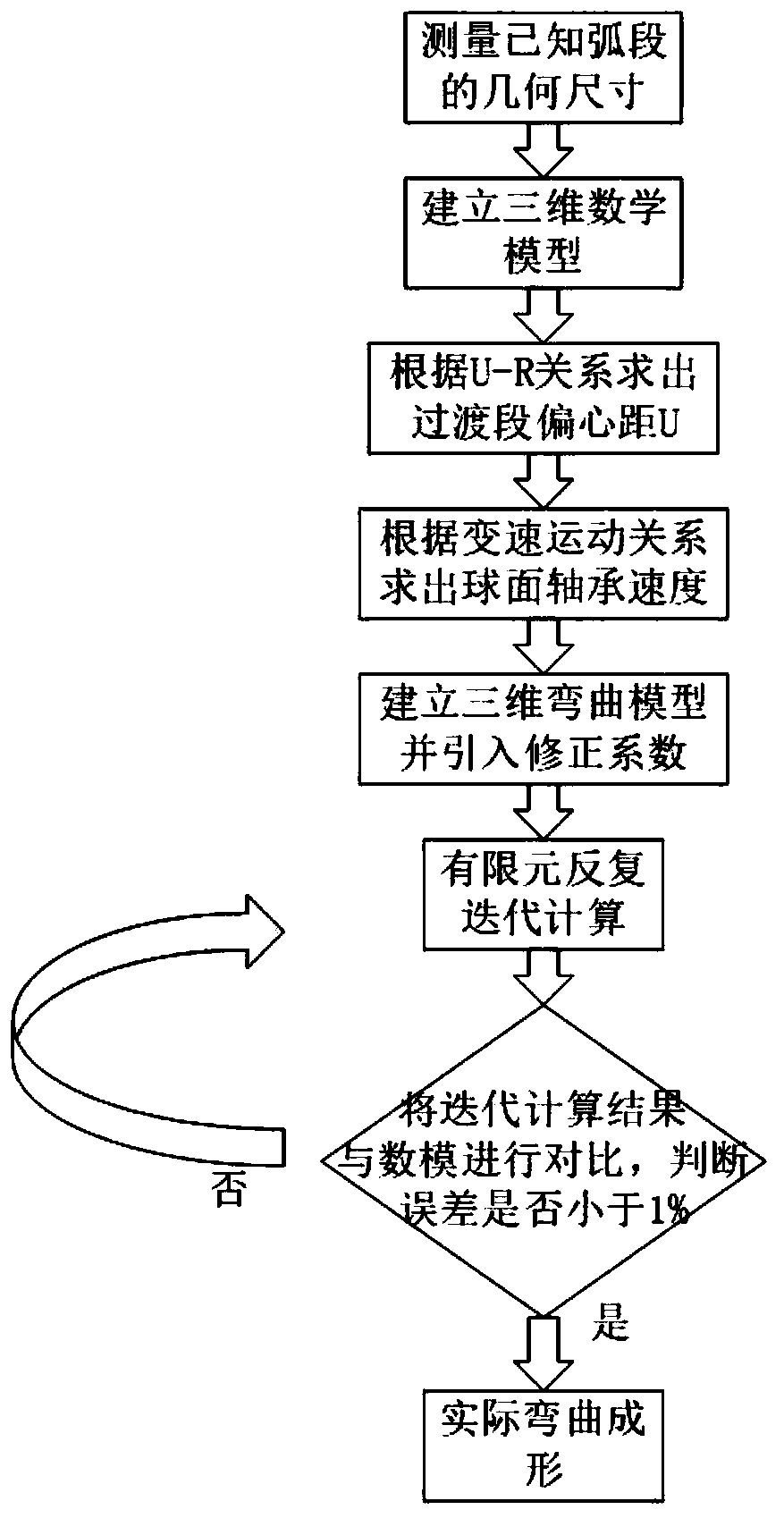

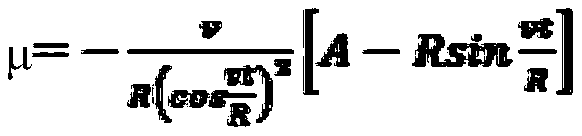

Transition section optimization method based on three-dimensional free bending technology

InactiveCN110837711ASmooth motionReduced cross-section ovalityGeometric CADDesign optimisation/simulationEngineeringOvality

The invention discloses a transition section optimization method based on a three-dimensional free bending technology. Uniform motion of an original transition section bending die is optimized into variable motion; therefore, a corresponding bending die speed can be obtained at each time node, meanwhile, the optimized transition section bending die moves more stably, the ovality of the section ofthe bending component is reduced, in addition, the optimized bending die movement track is smoother, and the transition section and the bending section are basically tangent. The method specifically comprises the steps that the geometric dimension of a known arc section is measured, the eccentric distance U of a transition section is obtained according to the U-R relation, and then the bending diespeed corresponding to each time node is worked out through the variable-speed motion rule. meanwhile, a correction coefficient k is introduced, after each forming result is compared with the targetcomponent, if the error is not within the allowable range, correction parameters are adjusted to achieve iterative correction till the error reaches the allowable range, and it is regarded that the process is completed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

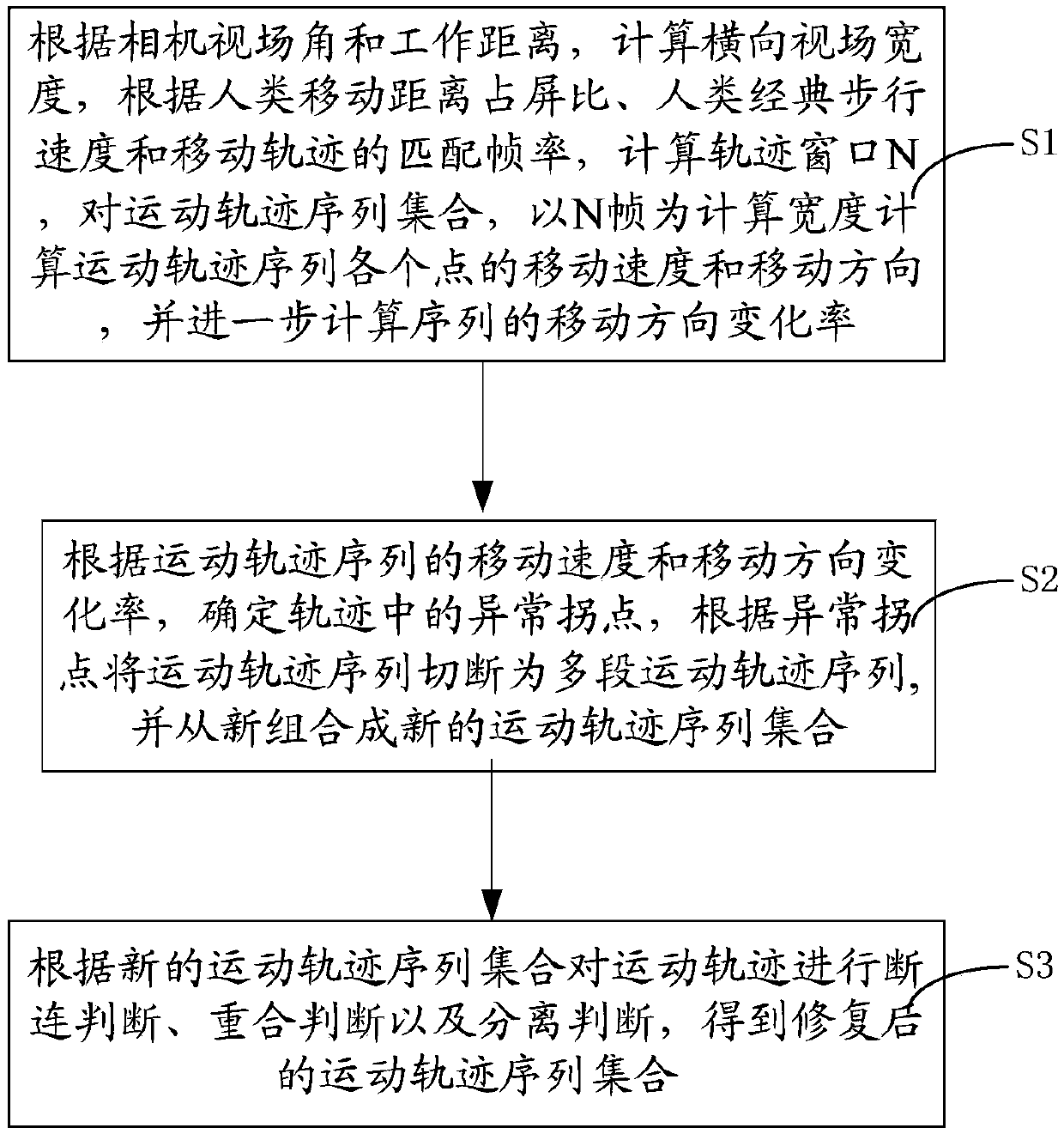

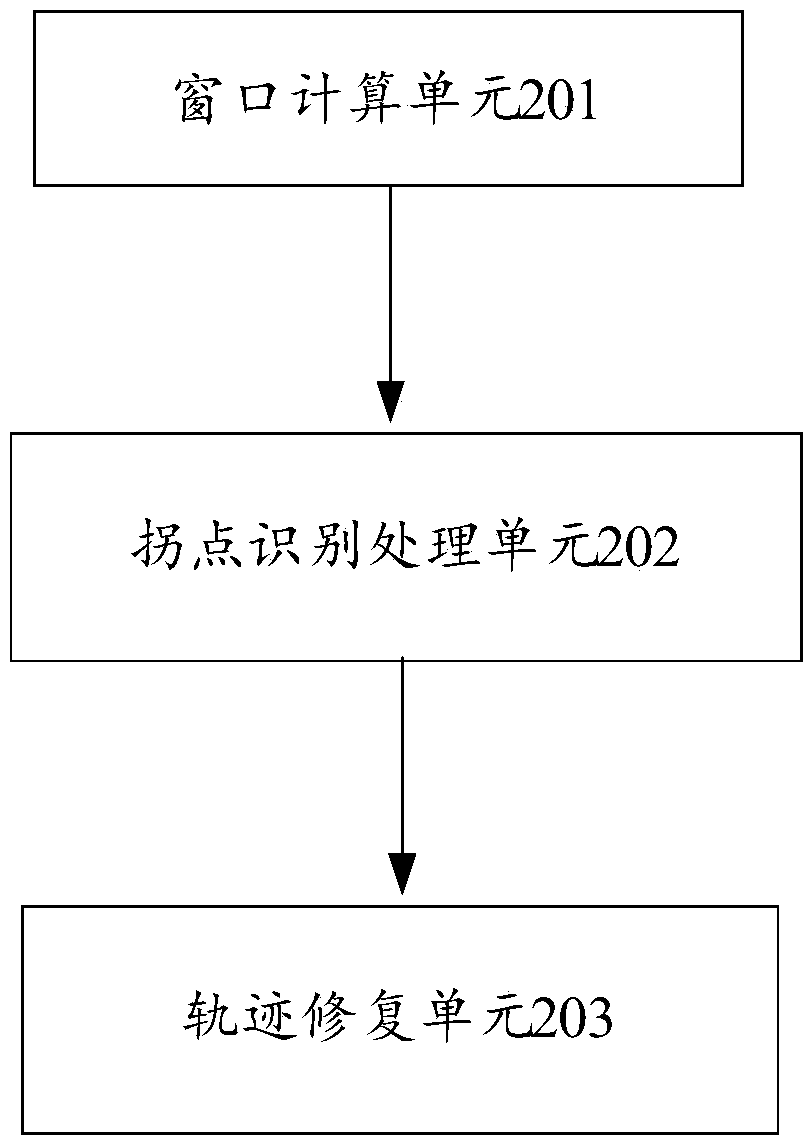

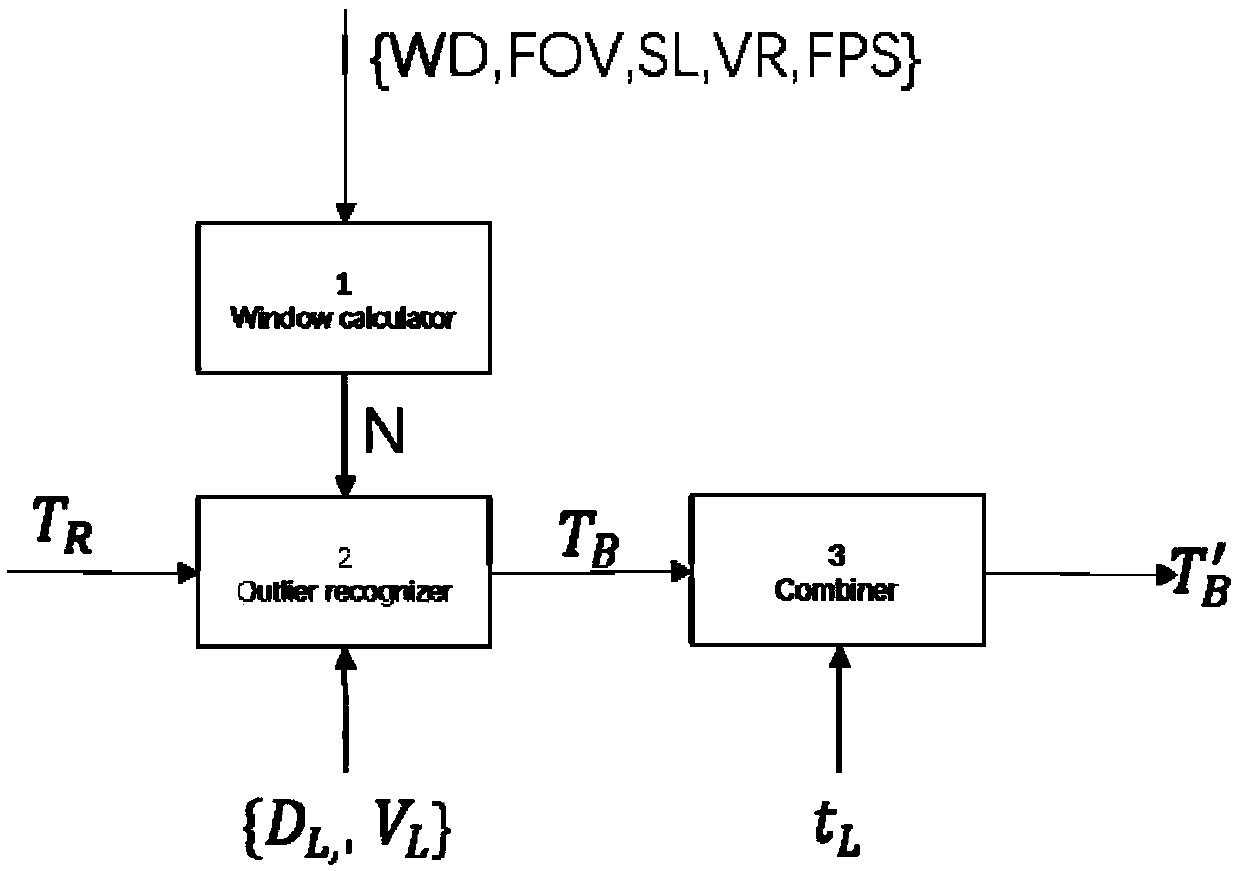

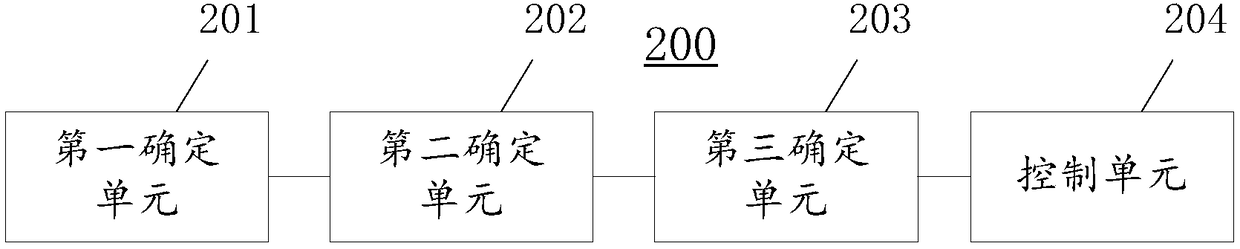

A non-feature matching motion trajectory optimization method and system

ActiveCN109523571AOptimize motion trajectoryImage enhancementImage analysisTrajectory optimizationComputer science

The invention discloses a non-feature matching motion trajectory optimization method and system, The method comprises the steps of: step S1, Depending on the angle of view and the working distance ofthe camera, calculating a lateral field of view width, calculating a trajectory window N according to the ratio of the human moving distance to the screen, the matching frame rate of the classic walking speed and the moving trajectory, calculating the moving speed and the moving direction of each point of the moving trajectory sequence with N frames as the calculating width, and further calculating the changing rate of the moving direction of the sequence; Step S2, determining abnormal inflection points in the trajectory according to the moving speed and the changing rate of the moving direction of the moving trajectory sequence, cutting the moving trajectory sequence into a plurality of pieces of moving trajectory sequences according to the abnormal inflection points, and re-combining themoving trajectory sequences into a new set of moving trajectory sequences; Step S3, judging the disconnection, coincidence and separation of the motion trajectory according to the new motion trajectory sequence set to obtain the repaired motion trajectory sequence set.

Owner:GUANGZHOU PANYU POLYTECHNIC

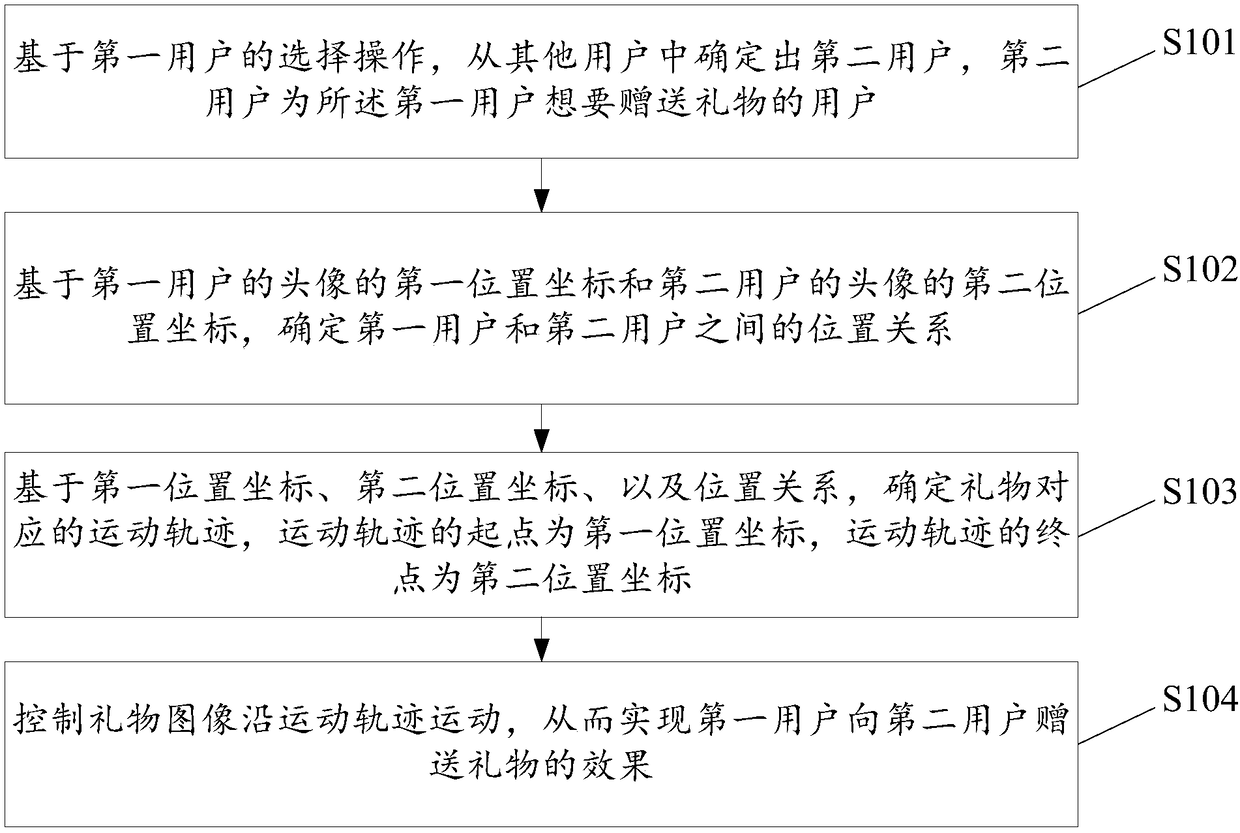

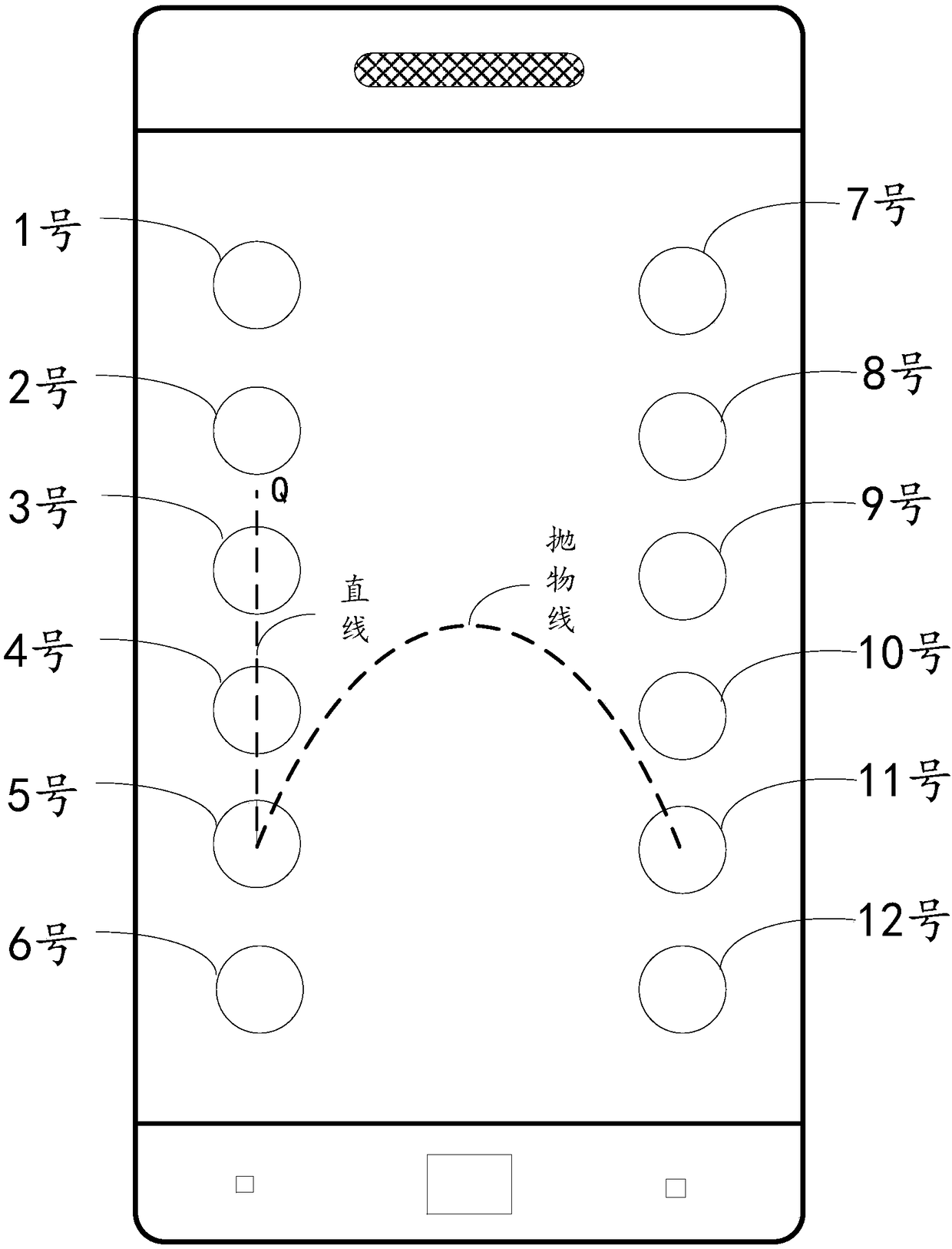

Method and device for implementing special effect of gift

InactiveCN108537863AIncrease motivationOptimize motion trajectoryAnimationGift givingHuman–computer interaction

The present invention discloses a method for implementing a special effect of a gift, and the method comprises the steps: determining a second user from other users based on a selection operation of afirst user, wherein the second user is a user, to whom the first user wants to give a gift; determining a positional relationship between the first user and the second user by the first position coordinates of a head portrait of the first user and the second position coordinates of the head portrait of the second user; determining a motion trajectory based on the first position coordinates, the second position coordinates, and the position relationship; controlling a gift image to move along the motion trajectory, thereby achieving the effect that the first user gives the gift to the second user. The method achieves the improvement of the gift display effect, improves the enthusiasm of a user in using a gift giving function, and is not liable to affect other users. Meanwhile, the invention also discloses a device for implementing the special effect of the gift.

Owner:WUHAN DOUYU NETWORK TECH CO LTD

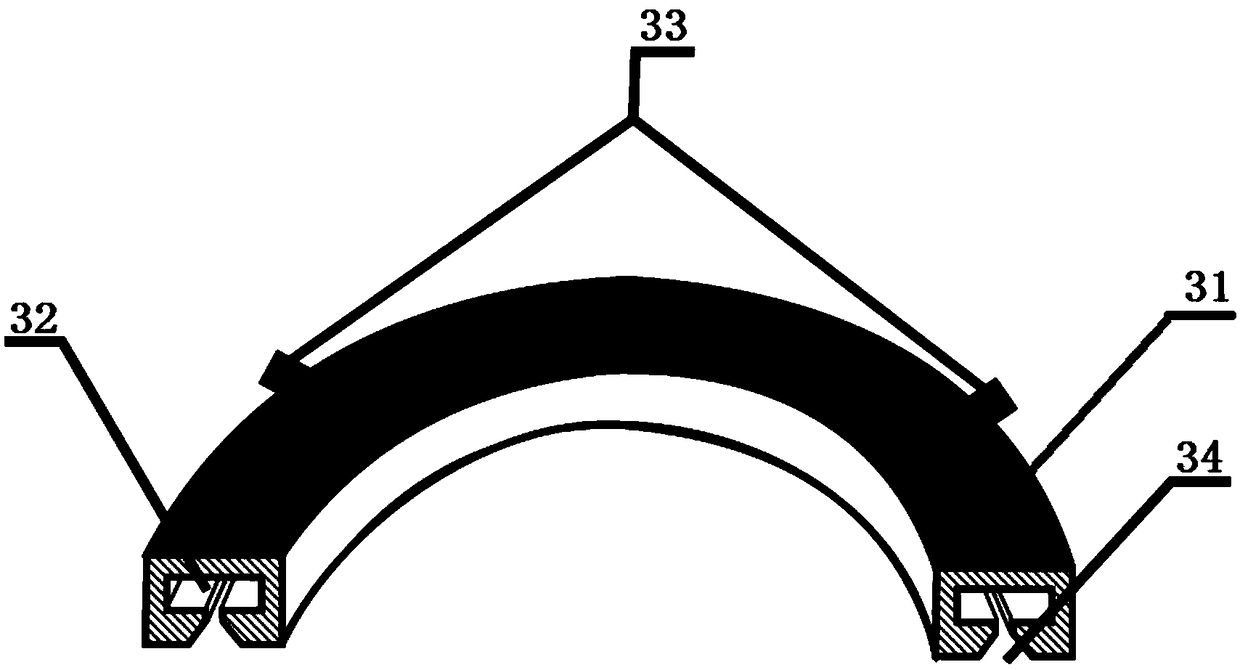

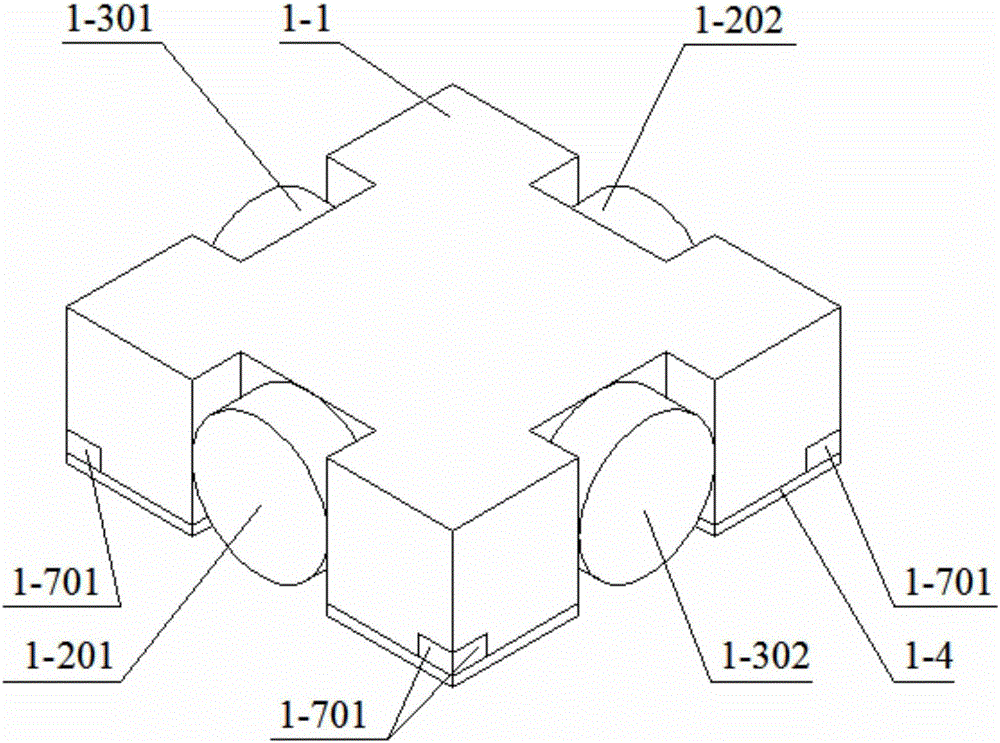

Multi-joint tabletop mechanical arm

PendingCN111993396AImprove athletic abilityIncrease payloadProgramme-controlled manipulatorCentre of rotationEngineering

The invention belongs to the technical field of industrial mechanical arms. The two-degree-of-freedom light tabletop mechanical arm is provided, two joints of the mechanical arm can rotate by 360 degrees without limitation, two rotating power parts are close to the rotating center, the rotational inertia of each arm is greatly reduced, and the effective load of the mechanical arm is increased. According to the technical solution, the multi-joint tabletop mechanical arm comprises a base and a base power part installed on the base, and the mechanical arm is characterized by further comprising anarch-shaped frame driven by the base power part, a large arm rotating power part installed on the arch-shaped frame and of which the shaft axis is perpendicular to that of the base power part, a large arm body driven by the large arm rotating power part, a small arm body rotatably positioned at one end of the large arm body through a large-small arm connecting shaft, a small arm rotating power part installed at the other end of the large arm body, and a transmission assembly rotatably positioned on the small arm body and transmitting power of the small arm rotating power part to the small armbody.

Owner:杭州捷铭智能装备有限公司

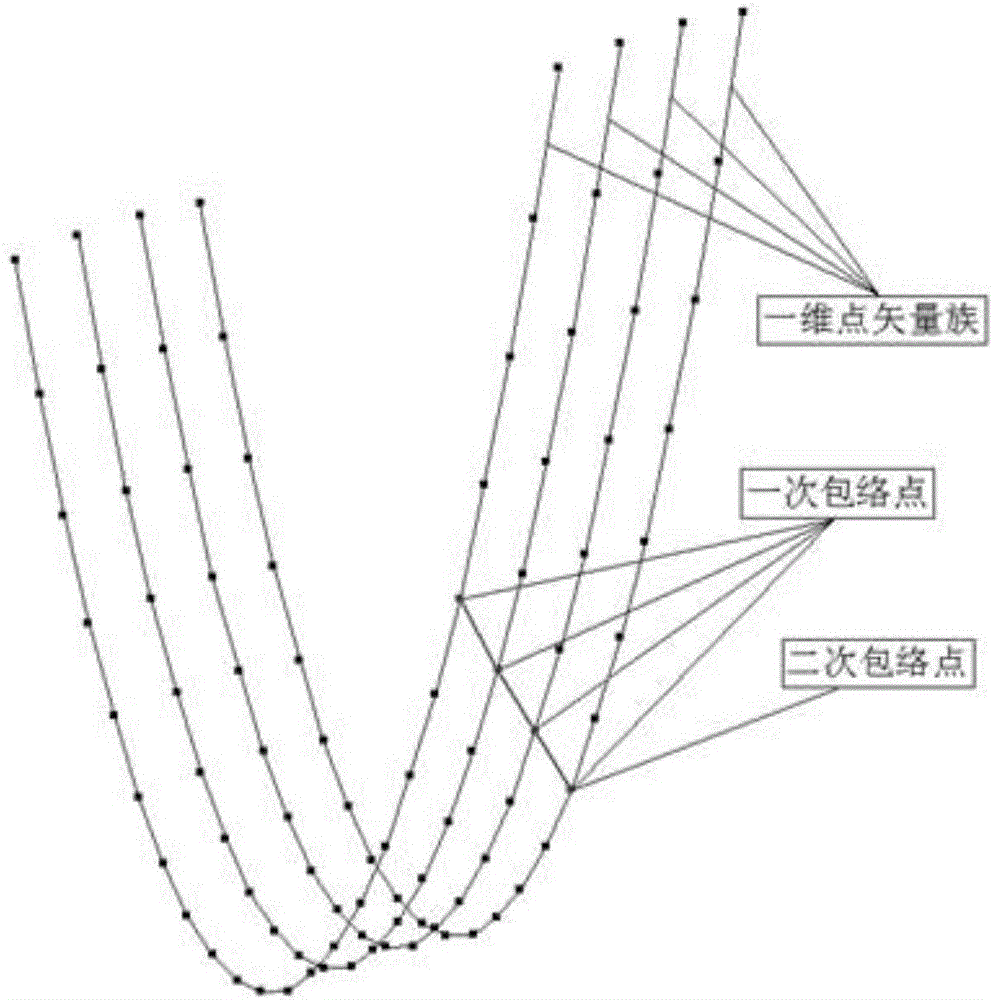

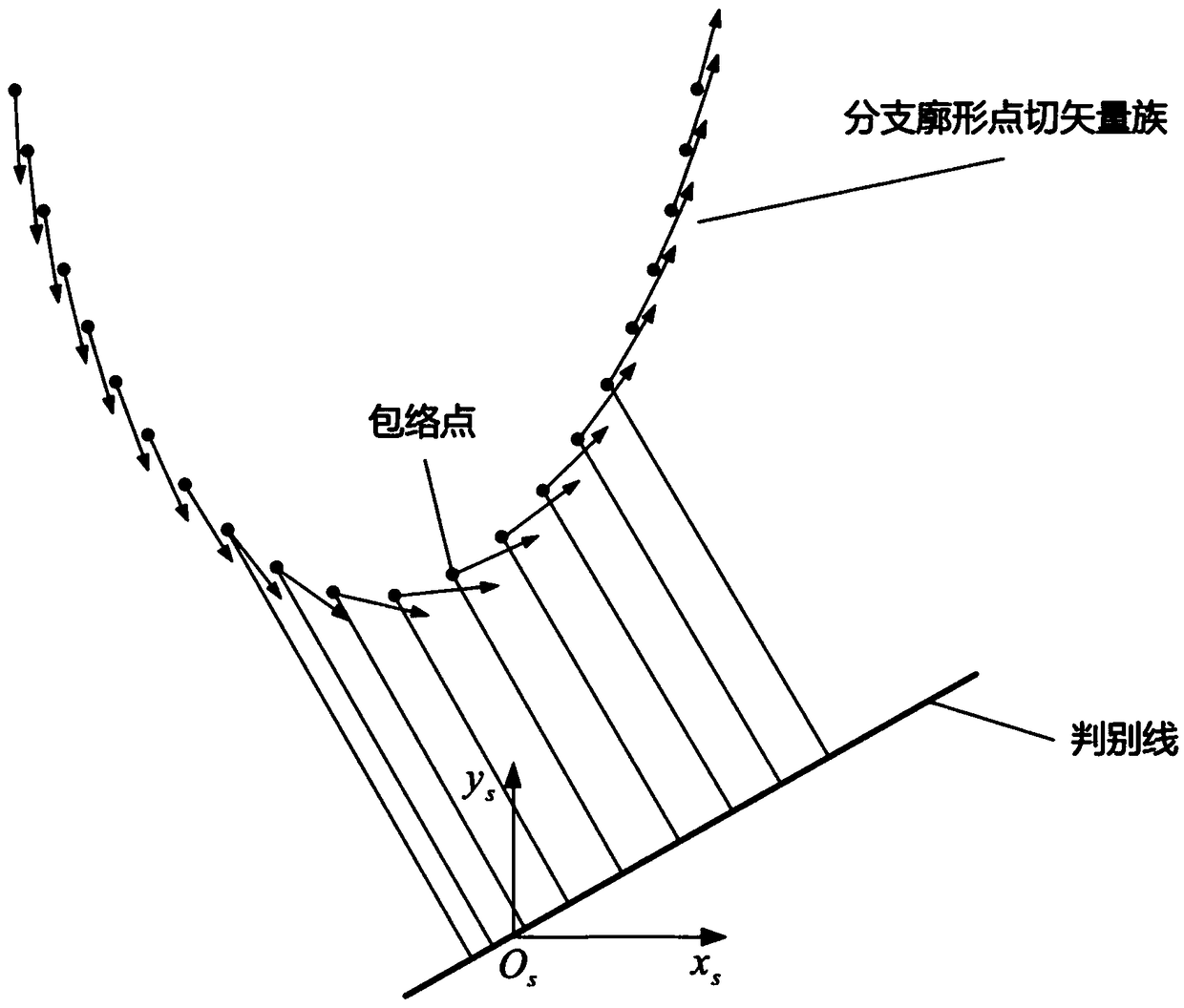

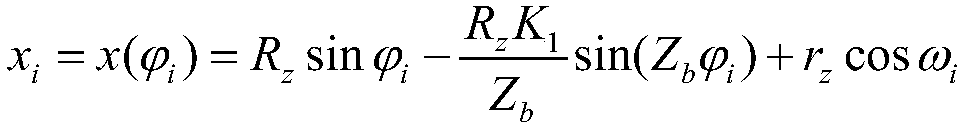

Digital enveloping method for determining profile of worm grinding wheel in grinding of modified cycloidal gear

The invention discloses a digital enveloping method for determining a profile of a worm grinding wheel in grinding of a modified cycloidal gear. The digital enveloping method for determining the profile of the worm grinding wheel in grinding of the modified cycloidal gear comprises the steps that the profile of a standard cycloidal gear is dispersed into a series of points and forms a profile point tangent vector with a tangent vector at a profile, and the profile point tangent vector of the profile of the modified cycloidal gear is calculated according to a modified curve; meanwhile, a forming enveloping track and a generating enveloping track are dispersed into a series of points, the profile point tangent vector is used as a profile point tangent vector family of a forming space of forming enveloping motion and generating enveloping motion, and then, the profile point tangent vector family is switched through coordinate transformation and projection; and the digital enveloping method of a plane profile point tangent vector family is established, the dimensionality of a secondary enveloping profile point tangent vector family is reduced to a first enveloping profile point tangentvector family, worm grinding wheel profile points are obtained by using the digital enveloping method, and a worm grinding wheel profile is obtained through fitting. The method is simple and convenient to calculate, the worm grinding wheel profile can be rapidly obtained, and cycloidal gear profile points correspond to the worm grinding wheel profile points in a one-to-one mode.

Owner:CHONGQING UNIV

A mechanical stretching device for a movable sofa electric rocking chair

ActiveCN103445558BRealize electric functionImprove comfortSofasCouchesMechanical stretchingElectric machinery

The invention relates to a mechanical stretching device for an electric rocking chair of a movable sofa. The mechanical stretching device comprises a left-side member, a right-side member and an electric device, wherein the electric device comprises a motor, a motor fixing bracket, a guide rail bracket, a motor fixing tube, a motor moving sliding block and a motor guide rail, the motor fixing tube is mounted on the motor fixing bracket, the motor fixing bracket is rotatably connected with a transmission connecting member, and the transmission connecting member is rotatably connected with the guide rail bracket through a third rotating shaft; a first guide rail is arranged on the guide rail bracket and is in an circular arc shape; the third rotation shaft is arranged in the first guide rail; one end of the motor is connected with the motor moving sliding block, the other end of the motor is rotatably connected with a leg square tube, and the motor is mounted on the motor guide rail; the motor moving sliding block is fixed on the motor fixing tube and is in sliding connection with the motor guide rail. According to the mechanical stretching device, the motor fixing tube is provided with a sunken part, and the motor moving sliding block is fixed in the sunken part. As the electric rocking chair is endowed with an electric function, the automatic degree and the comfort of the sofa are improved.

Owner:REMACRO MASCH & TECH (WUJIANG) CO LTD

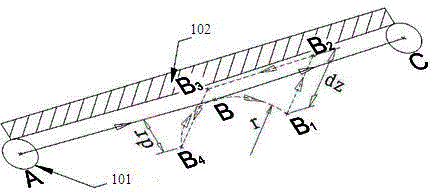

Numerical control program cutter path optimization method

InactiveCN104932422AAvoid collisionOptimize motion trajectoryNumerical controlNumerical controlComputer science

The invention provides a numerical control program cutter path optimization method. A line segment ABC is a line taken from contour processing, a cutter moves from an A point to a C point via a B point, and the C point is the super-path point location. The method is characterized in that an arc path B-B1 is added at the B point along the tangent direction of an AB line segment, the cutter moves to a B1 point, the B1 point is far away from a part, and the cutter is withdrawn at the point; after the cutter is withdrawn at the B1 point, the cutter continues to move to a B2 point, the angle of the C axis is rotated, the cutter then moves to a B3 point, the cutter cuts at a B4 point, and the cutter-moving path employing arc cutting moves to the B point and finally to the C point. According to the method, the movement track after super-path is optimized, and the problem of part overcutting in the processes of cutter lifting and cutting is solved.

Owner:JIANGXI HONGDU AVIATION IND GRP

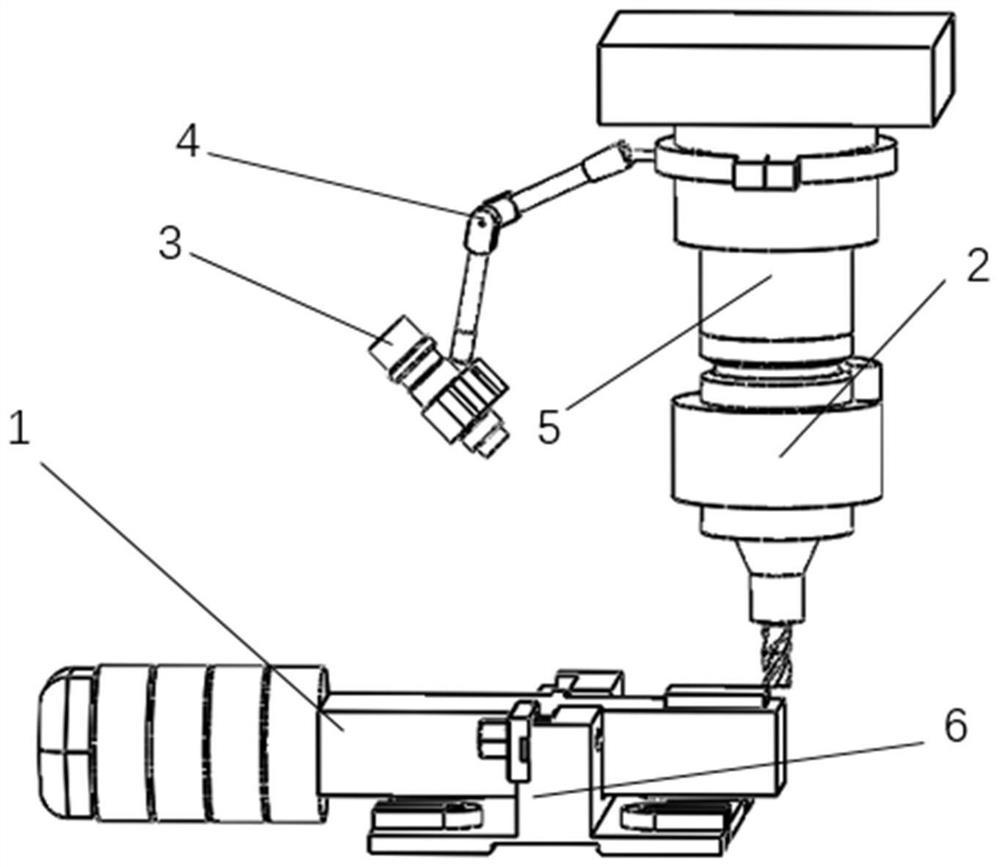

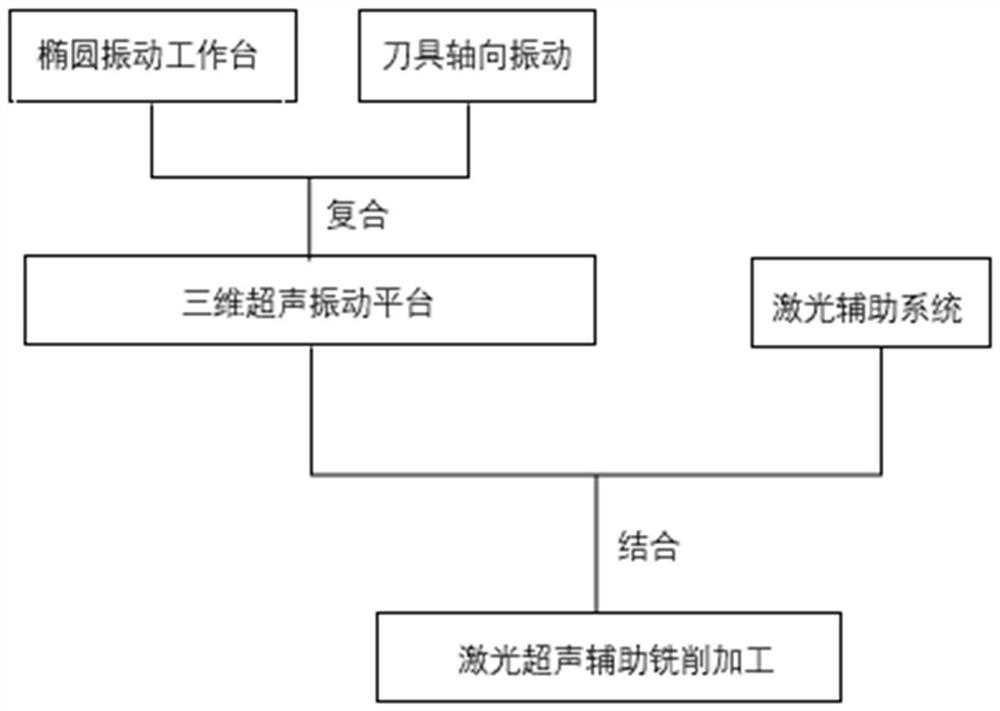

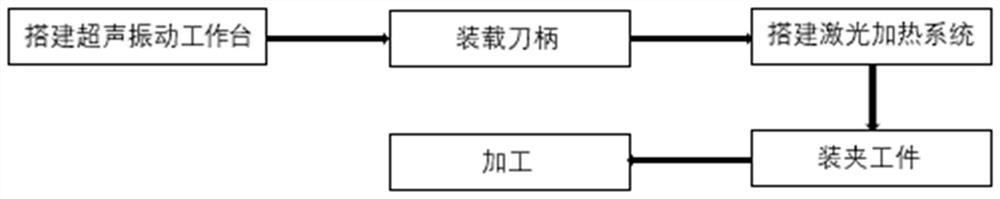

Double auxiliary milling device and method for crisp and hard material machining

InactiveCN112643099ASolve the problem of high-efficiency precision machiningImprove machinabilityMilling equipment detailsMetal working apparatusMaterial removalCutting force

The invention provides a double auxiliary milling device and method for crisp and hard material machining and relates to the technical field of crisp and hard material milling. The machining method comprises heating and softening a to-be-machined region of a workpiece by using a laser heat source first to reduce the hardness of the material and improve the cutting machinability of the material; and then carrying out ultrasonic auxiliary milling on the crisp and hard material by using a three-dimensional ultrasonic vibrating system formed by compounding elliptical vibration of a worktable and axial vibration of a cutter. Through laser heating and softening and ultrasonic vibration assisting, the method can improve the machinability of the material and improve the moving track between the cutter and the workpiece, so that a cutting force and cutter wear are reduced, the material removal rate and the surface intactness are improved and finally, an efficient precise machining problem of the crisp and hard material is solved. The invention further provides a double auxiliary milling method for crisp and hard material machining.

Owner:HUAQIAO UNIVERSITY

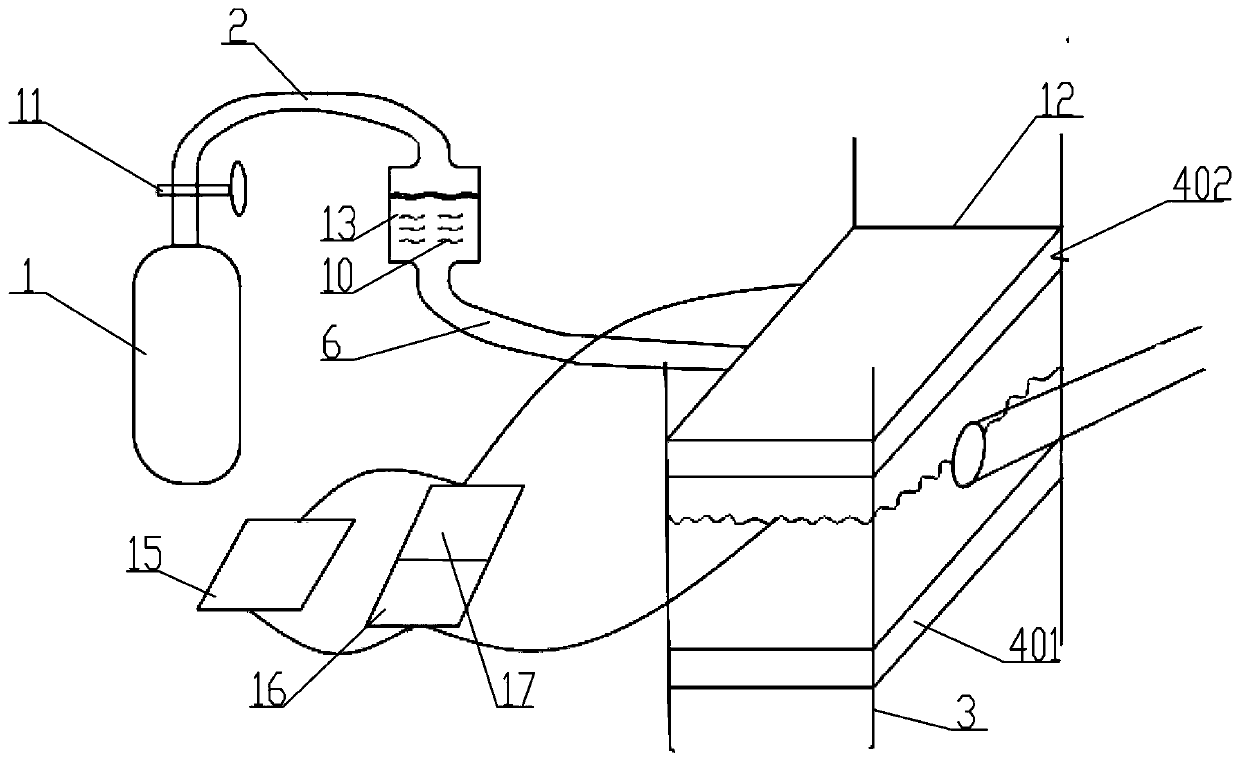

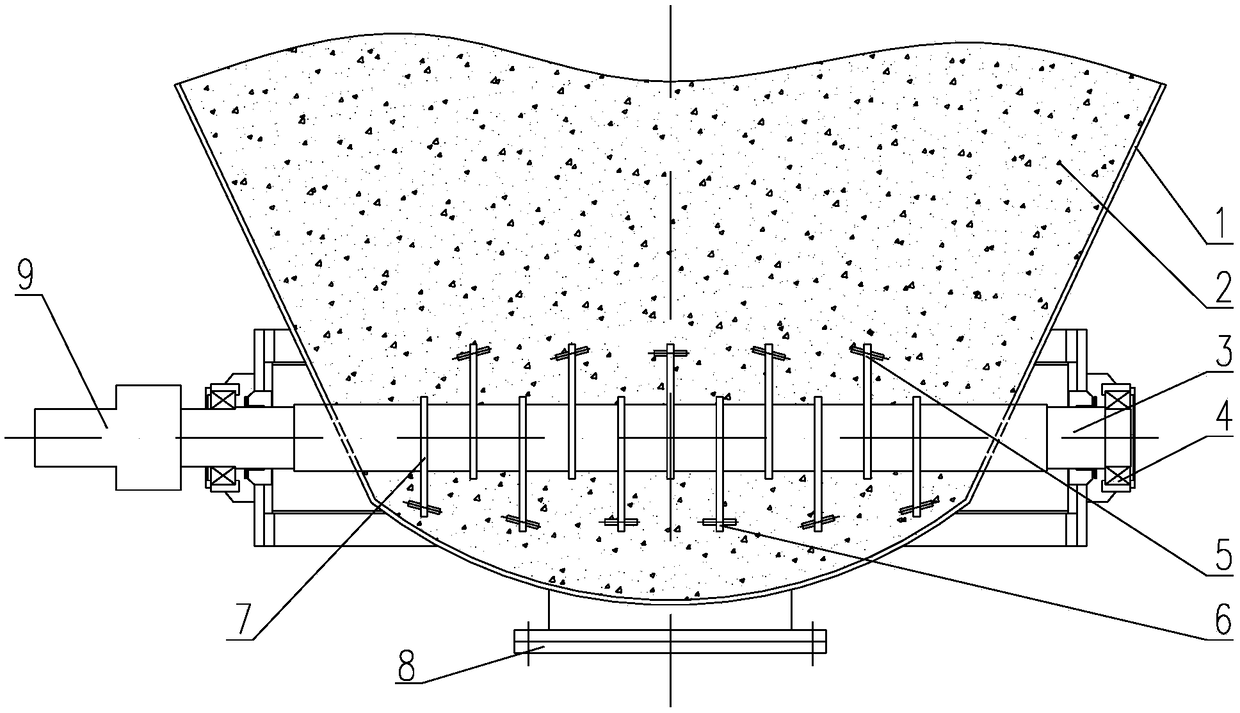

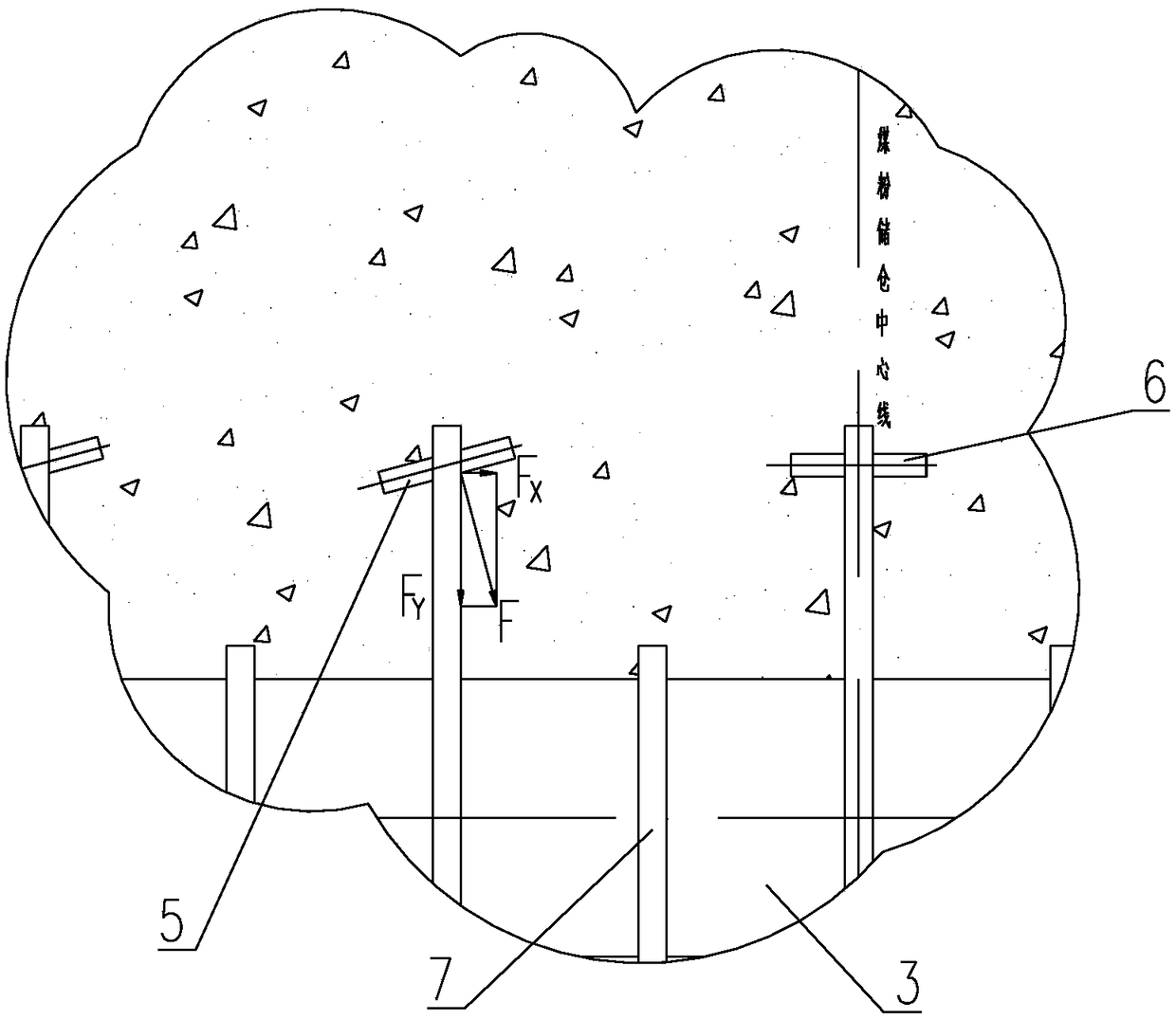

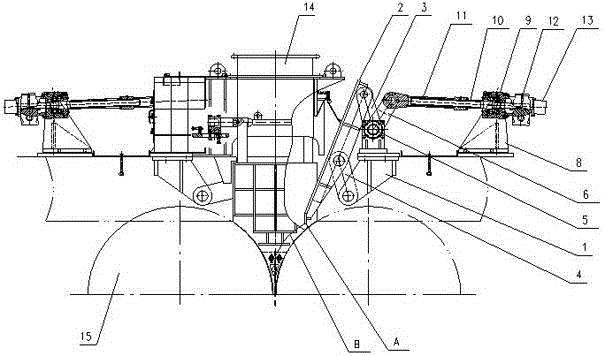

Anti-stacking mechanical fluidization device for coal powder storage bin

PendingCN109398977AOptimize motion trajectoryGood material distributionLarge containersDistribution characteristicEngineering

The invention relates to an anti-stacking mechanical fluidization device for a coal powder storage bin. The mechanical fluidization device is arranged at the bottom of the coal powder storage bin andthe upper portion of a feeding opening, and comprises a driving device, a horizontal rotating shaft, first arch breaking components, and second arch breaking components. The driving device is locatedoutside the coal powder storage bin, and the power output end of the driving device is connected with one end of the horizontal rotating shaft crossing the bottom of the coal powder storage bin and drives the horizontal rotating shaft to rotate. The middle of the horizontal rotating shaft is provided with a plurality of the first breaking arch components, and the two sides of the horizontal rotating shaft are provided with a plurality of the second breaking arch components, wherein each first breaking arch component is composed of a vertical pole and horizontal blades, each second breaking arch component is composed of a vertical pole and inclined blades. The vertical poles are fixedly arranged on the horizontal rotating shaft in the radial direction. The horizontal blades or the inclinedblades are fixedly arranged at the extension end of the vertical poles. According to the coal powder distribution characteristics at the bottom of the coal powder storage bin, the mechanical fluidization device is provided with the multiple first arch breaking components with the horizontal blades in the middle and the multiple second arch breaking components with the inclined blades on both sides. The mechanical fluidization device has simple structure and good arch breaking effect, and is convenient to use.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Flow regulation mechanism

The invention discloses a flow regulation mechanism which comprises a bracket, a flow regulation plate, a first side link, a second side link, a rotating shaft and a driving mechanism, wherein the rotating shaft is mounted on the bracket via a support; the driving mechanism drives the rotating shaft to rotate; one end of the first side link is fixedly connected with the rotating shaft; the other end of the first side link is articulated with the top end of the flow regulation plate; one end of the second side link is articulated with the bracket; and the other end of the second side link is articulated with the middle lower part of the flow regulation plate. The flow regulation mechanism has the benefits that a material collapse phenomenon of a stock column can be greatly reduced, and the impact of materials on a roller surface is reduced when the flow regulation mechanism is used in a roller press, so that the service life of the roller surface is prolonged.

Owner:CHENGDU LEEJUN TECH CO LTD

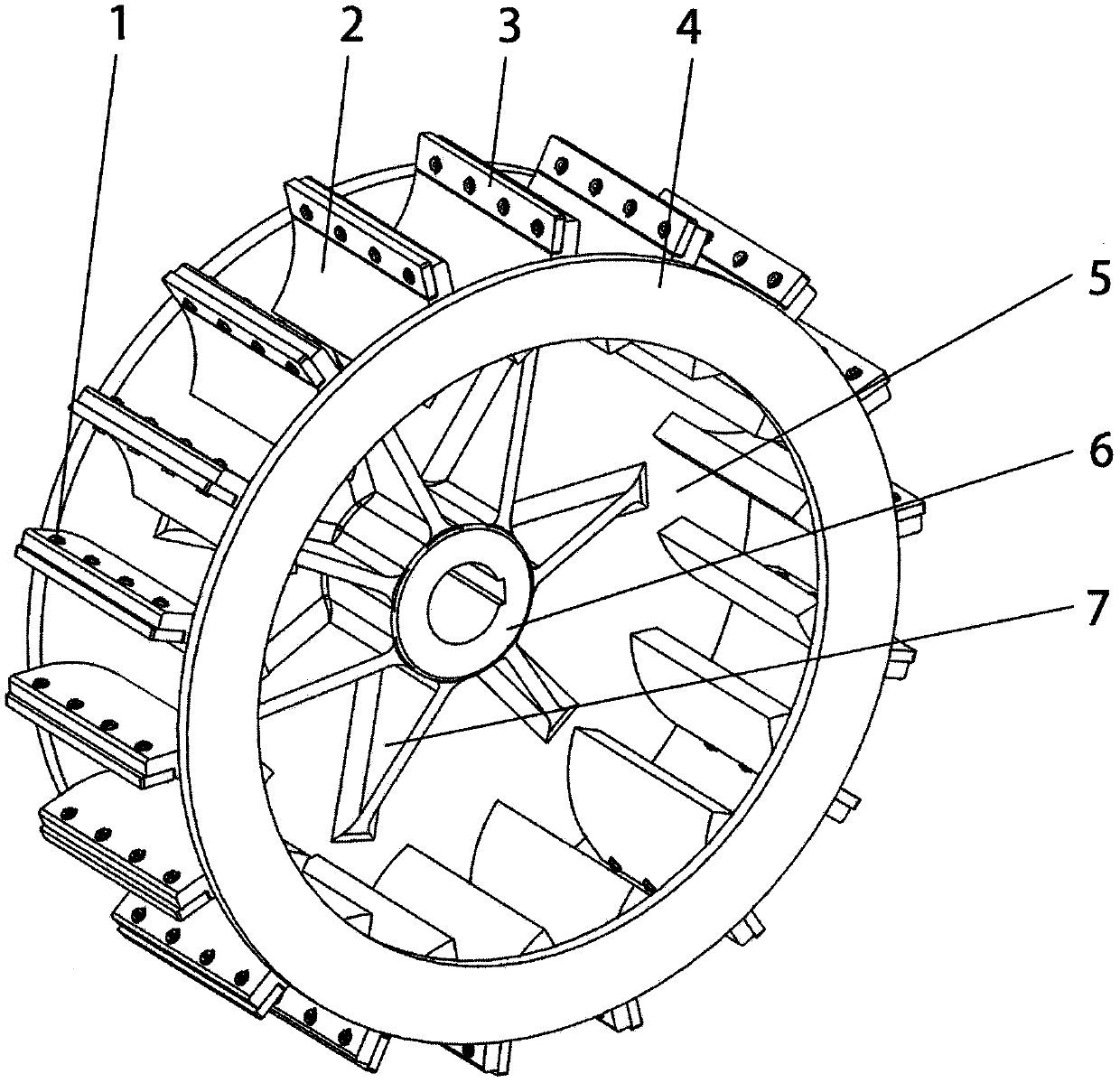

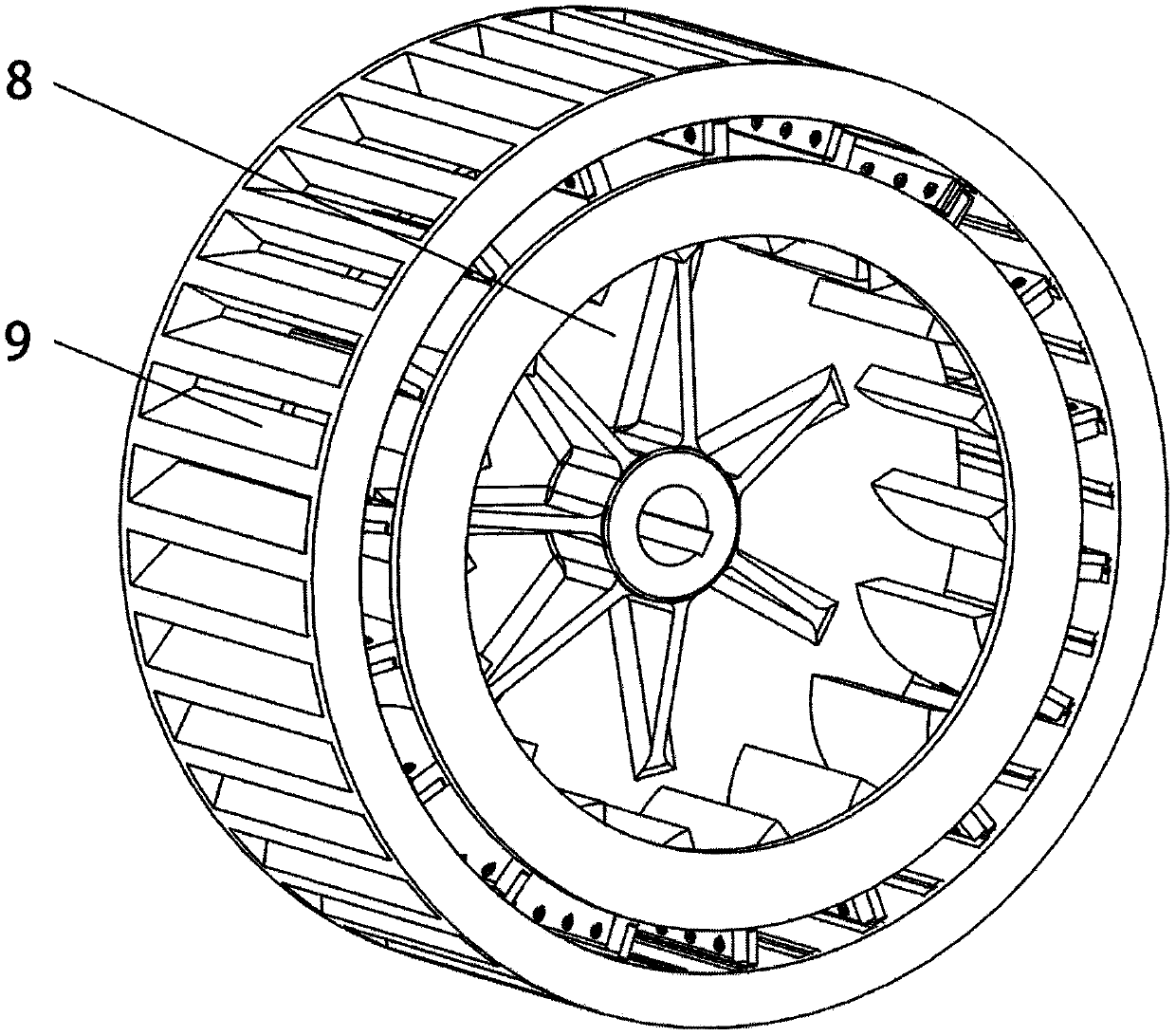

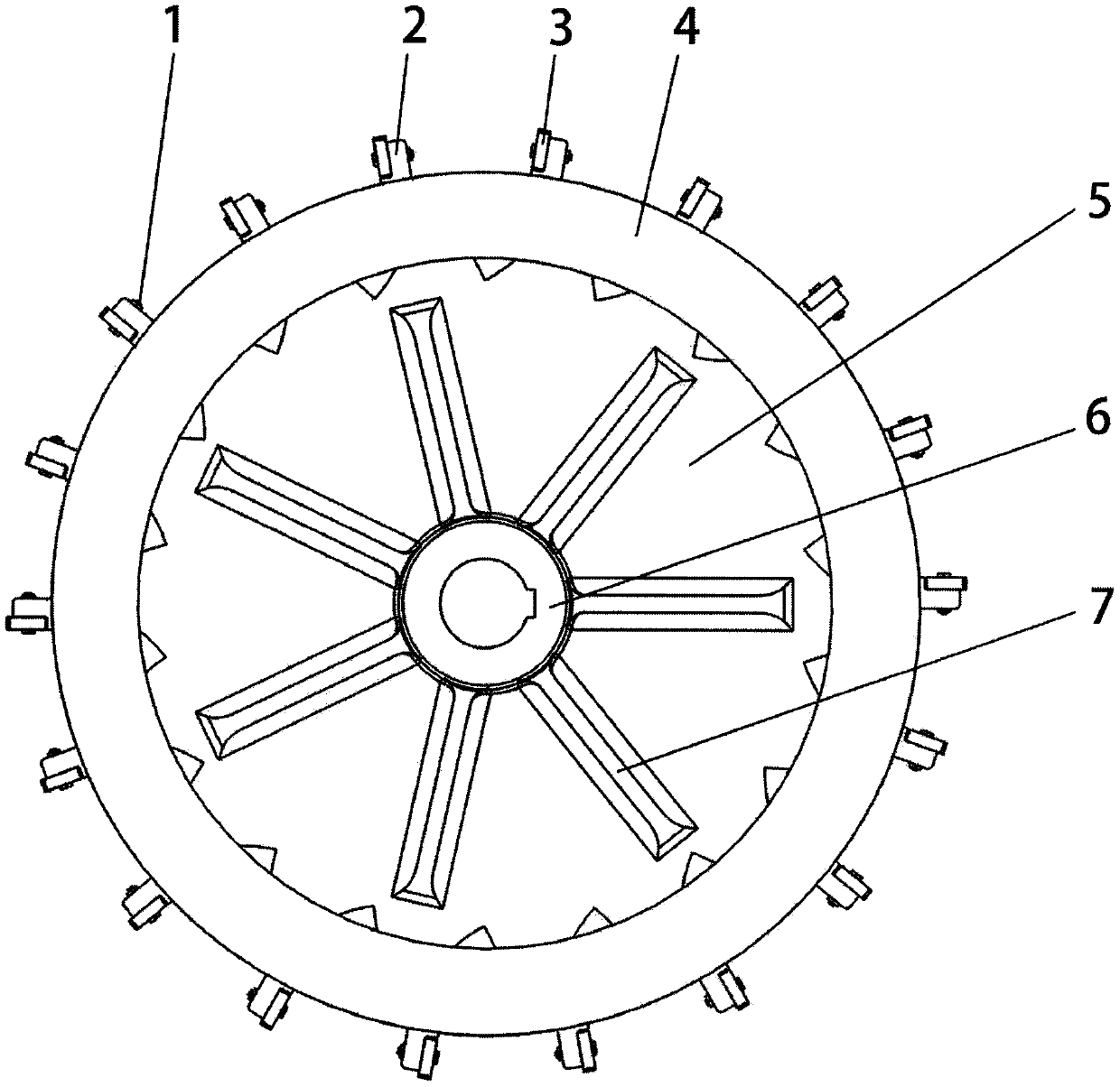

Impeller of ring flaker

The invention discloses an impeller of a ring flaker. The impeller comprises an impeller shell, blades and bolts; the impeller shell is formed by welding an impeller ring, an impeller plate, a shaft sleeve, conical linings and a plurality of blade plates; the blade plates are uniformly distributed in the circumferential direction of the impeller ring, the two sides of each blade plate are welded to the impeller ring and the impeller plate, and the projection of any blade plate in the axial direction of the impeller is in a bent shape; each blade plate is formed by combining an arc plate with astraight plate, wherein the straight plate portions of the blade plates are arranged in a radial radiation shape, and the inner sides of arcs of the arc plate portions are arranged in the rotation direction of the impeller. The structure has the beneficial effects that the aerodynamic characteristics of the impeller are optimized, the stirring effect on airflow during high speed rotation of the impeller is reduced, aerodynamics noise of air in the high-speed rotation impeller is lowered, and the operation energy consumption is reduced; and the motion tail of a fed wood chip in the impeller isoptimized, friction when the wood chip is attached to the blade plates to slide is reduced, abrasion of the blade plates is reduced, the situation that the wood chip is broken by the blade plates isreduced, and the wood chip feeding efficiency of the impeller is improved.

Owner:NANJING FORESTRY UNIV

Anti-fatigue permanent magnetic vibration table

ActiveCN103831226AReduce resistanceReduce heat generationMechanical vibrations separationPhysicsLap joint

The invention discloses an anti-fatigue permanent magnetic vibration table which comprises an outer cover. A permanent magnet is arranged at the bottom of the outer cover and provided with a magnet core. A vibration column is connected with a gap outside the magnet core in a sleeved mode and extends out of the outer cover. An electromagnetic coil is arranged outside the position, coinciding with the magnet core, of the bottom of the vibration column. A support fixed to the outer cover is connected with a gap outside the vibration column in a sleeved mode. Vertical spring pieces which are vertically arranged are evenly distributed on the periphery of the support. The two ends of the vertical spring pieces are connected with horizontal spring pieces. The two layers of horizontal spring pieces are connected with an upper step arranged outside the vibration column and a lower step arranged outside the vibration column in a lap joint mode. The spring pieces are connected with the vibration column in a lap joint mode, and therefore resistance of the spring pieces to the vibration column is reduced, generated heat is reduced, limitation on the freedom degree of the spring pieces is reduced as well, and the service life of the spring pieces is prolonged; the two layers of horizontal spring pieces well guide the vibration column, and therefore the moving track of the vibration column is stable, and the service life of the vibration table is prolonged.

Owner:YMC PIEZOTRONICS

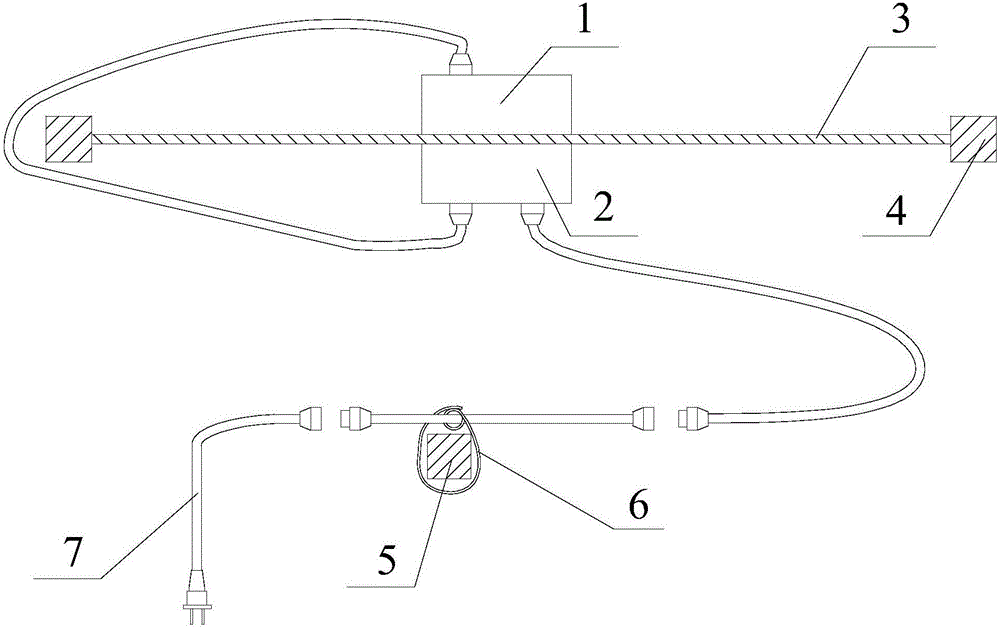

Glass wiping robot with lifting type walking mechanism and glass wiping method of glass wiping robot

ActiveCN106108768AInnovative designSimple structureProgramme controlComputer controlMagnetic tension forceDrive wheel

The invention discloses a glass wiping robot with a lifting type walking mechanism. The glass wiping robot comprises a driving part, a driven part and a safety power dual-purpose wire. The driving part comprises a driving part bottom plate, a driving part shell connected to the top of driving part bottom plate, a first driving wheel set, a second driving wheel set, a driving part lifting unit, a driving part sensing unit, a driving part controller and a driving part energy source, and driving part cleaning cloth and a driving part magnet are connected to the bottom surface of the driving part bottom plate. The driven part comprises a driven part bottom plate, a driven part shell connected to the top of the driven part bottom plate, a first driven wheel set, a second driven wheel set, a driven part lifting unit, a driven part sensing unit, a driven part controller, a driven part energy source and a magnetic force adjusting device, and driven part cleaning cloth is connected to the bottom surface of the driven part bottom plate. The invention further discloses a glass wiping method of the glass wiping robot with the lifting type walking mechanism. The glass wiping robot is novel and reasonable in design, high in glass wiping efficiency and safe and convenient to use.

Owner:XIAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com