Digital enveloping method for determining profile of worm grinding wheel in grinding of modified cycloidal gear

A worm grinding wheel, cycloid gear technology, applied in the direction of elements with teeth, belts/chains/gears, gear teeth, etc., can solve problems such as difficulty in solving, complex profile representation, etc., to achieve motion trajectory optimization, geometric versatility Good, easy to model effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

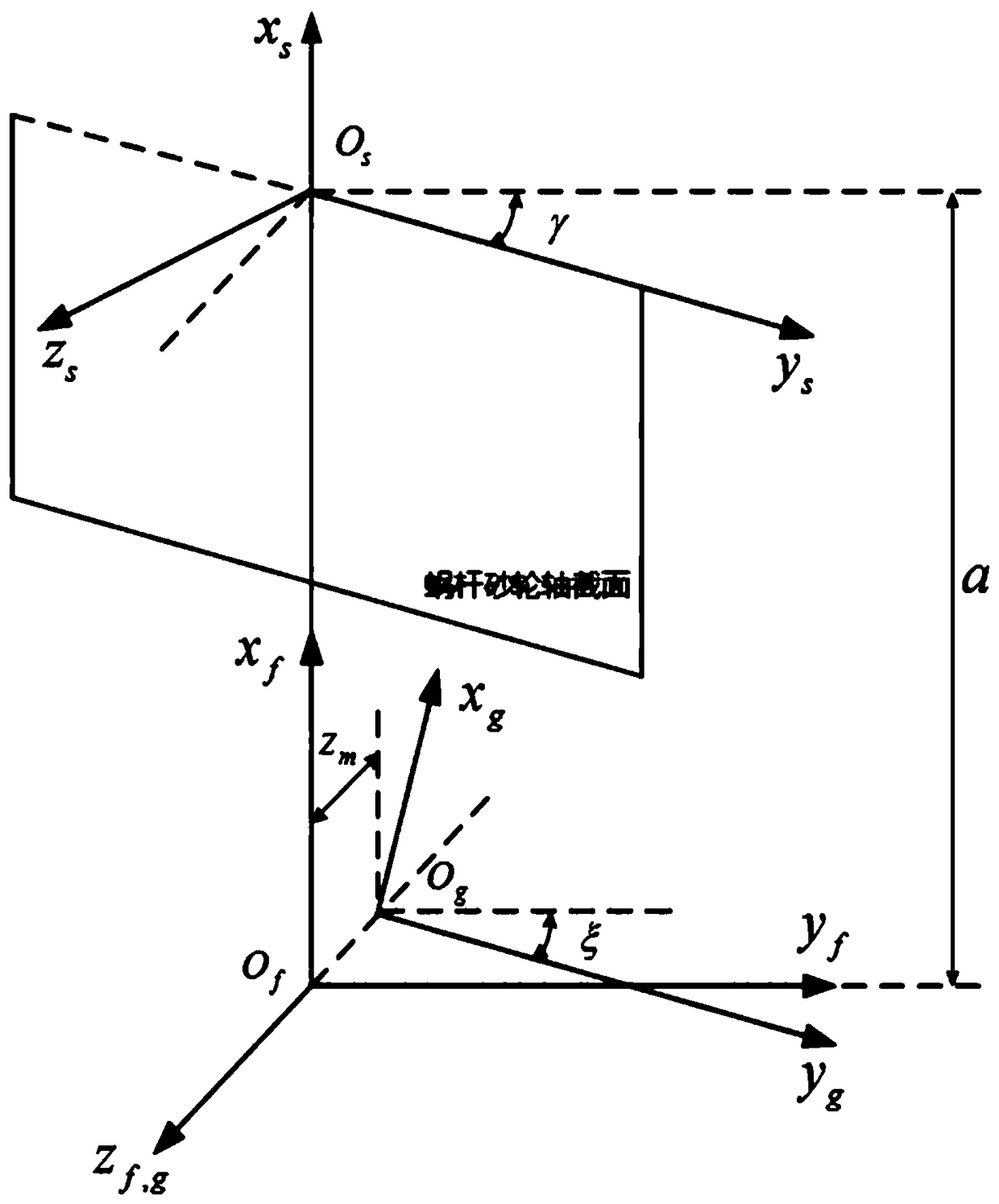

[0024] Below in conjunction with the accompanying drawings, the present invention will be further explained by taking the worm grinding wheel generating and grinding cycloidal gear as an example.

[0025] In this embodiment, the digital envelope method for determining the contour shape of the worm sand in the generative grinding of the modified cycloidal gear includes the following steps:

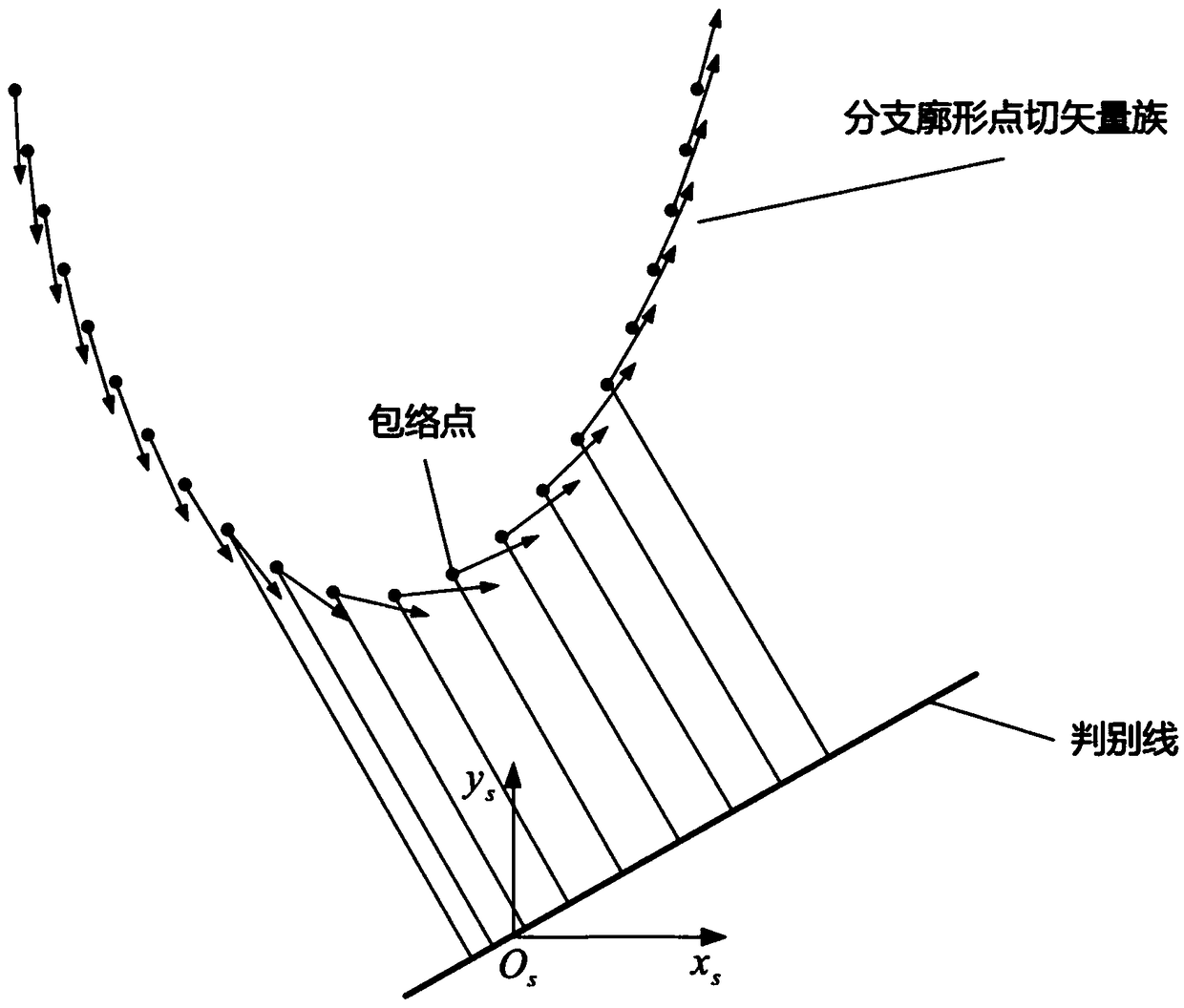

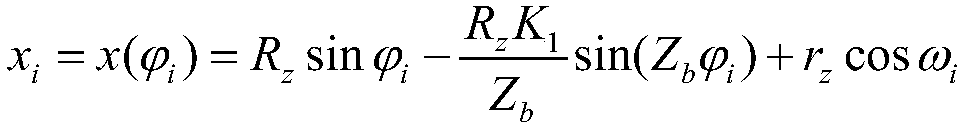

[0026] Step 1: Discretize the standard cycloid tooth profile according to the average discretization criterion to obtain the standard profile point, and obtain the corresponding tangent vector and normal vector at the standard profile point, and the profile point and its corresponding tangent vector constitute the profile point cut vector. The standard cycloidal tooth profile is composed of a section of equidistant curves of a short epicycloid, and the standard cycloidal tooth profile is discretized into a series of points according to the average angle dispersion criterion (of course, in d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com