Auxiliary electric arc ion plating device for coupling rotary transverse magnetic field with axial magnetic field

An arc ion plating and axial magnetic field technology, applied in ion implantation plating, sputtering plating, vacuum evaporation plating, etc. The effect of target utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] An important feature of arc ion plating is that the arc spot discharge forms a high temperature area near it, and it will radiate to other positions in the vacuum chamber at the same time, and is limited by the space of the vacuum chamber, the space around the target is also limited, so the arc source When designing, it will be difficult to make a breakthrough if the thinking is limited to the limited space in the vacuum chamber. Especially for the rotating transverse magnetic field design to control arc spot movement, if the rotating transverse magnetic field generator is placed around the target in the vacuum chamber, it will be limited by size and material, although better results can be achieved if conditions permit , but for the large-area deposition required for industrial production, it will be limited in long-term work. Therefore, in the face of wider applications, innovations and breakthroughs are required.

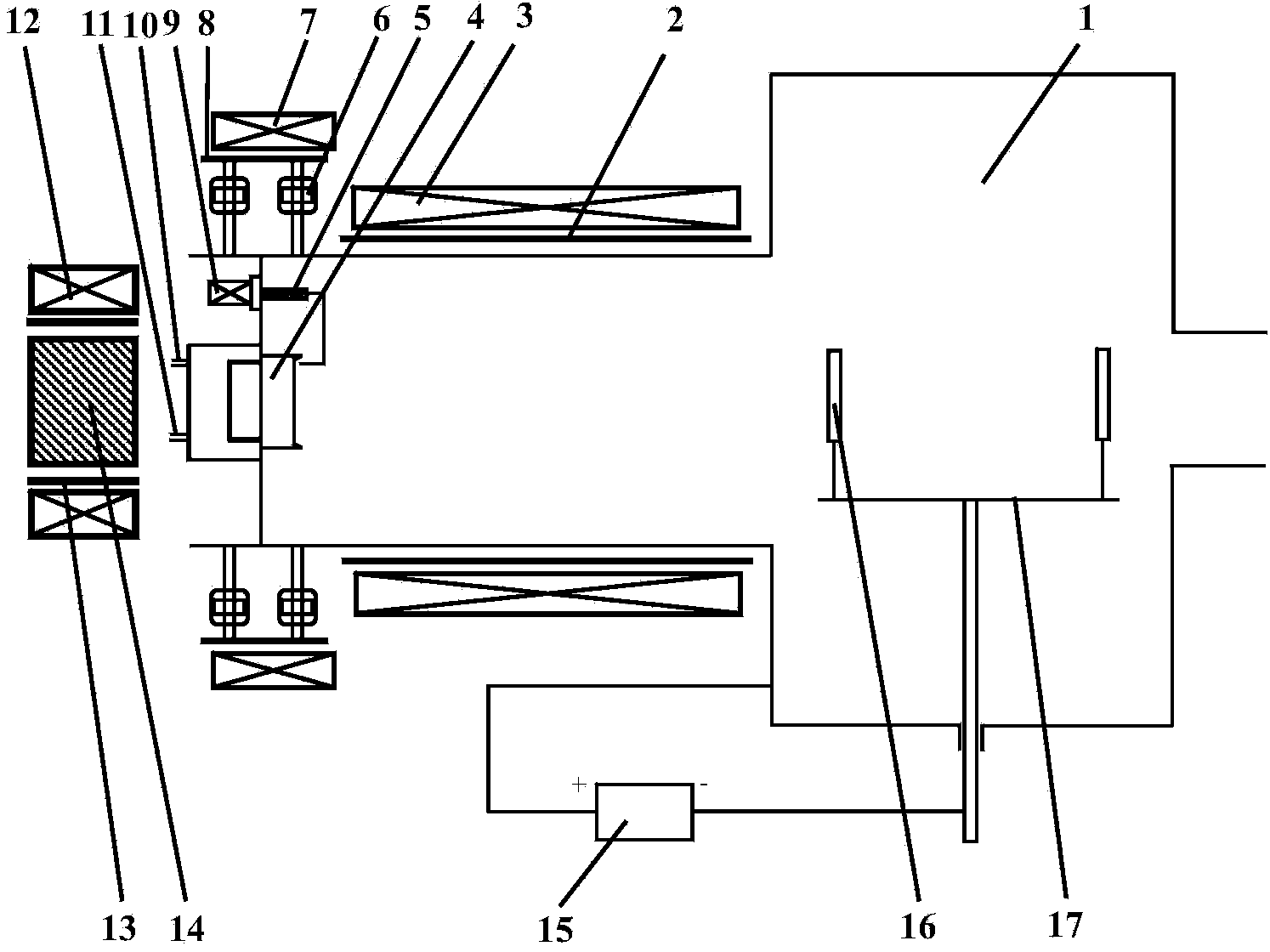

[0034] figure 1 It is a schematic structural diagr...

Embodiment 2

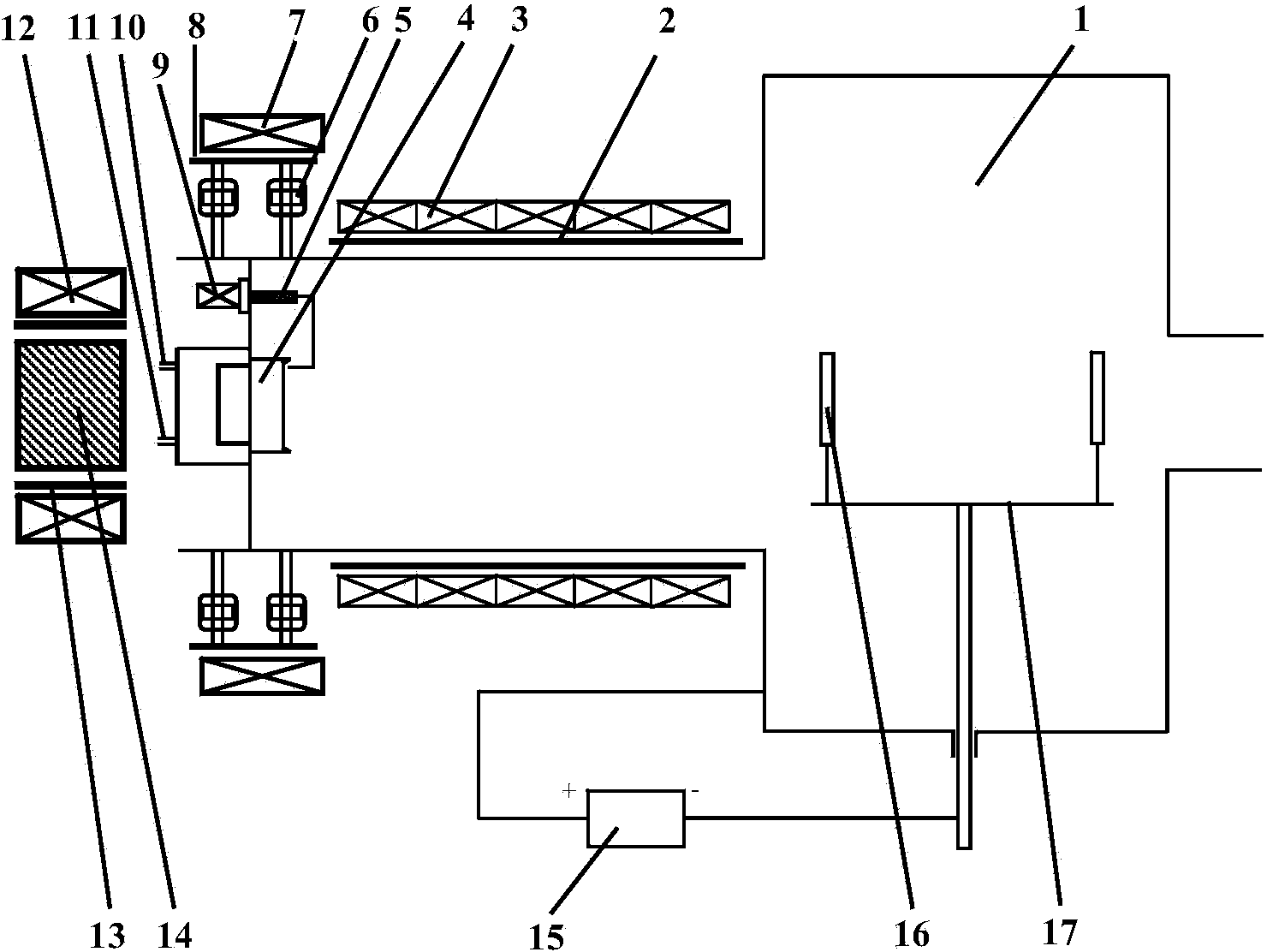

[0040] figure 2 It is an arc ion plating device assisted by a rotating transverse magnetic field coupled with a gradient axial magnetic field invented in Embodiment 2 for small-sized targets, in which the gradient magnetic field is composed of more than two electromagnetic coils, and the magnetic field strength is adjusted separately, and its size is along the direction of the plasma beam. The flow direction gradually decreases. The difference between this embodiment and Embodiment 1 is that the plasma confinement axial magnetic field generator uses a gradient magnetic field, which is composed of more than two electromagnetic coils, and the number of turns of the electromagnetic coil increases with the distance from the target. Decreases in a gradient. Under this condition, each electromagnetic coil can be connected in series to form a large coil. When the coil is energized, the current in each electromagnetic coil is the same, but because the number of turns of different co...

Embodiment 3

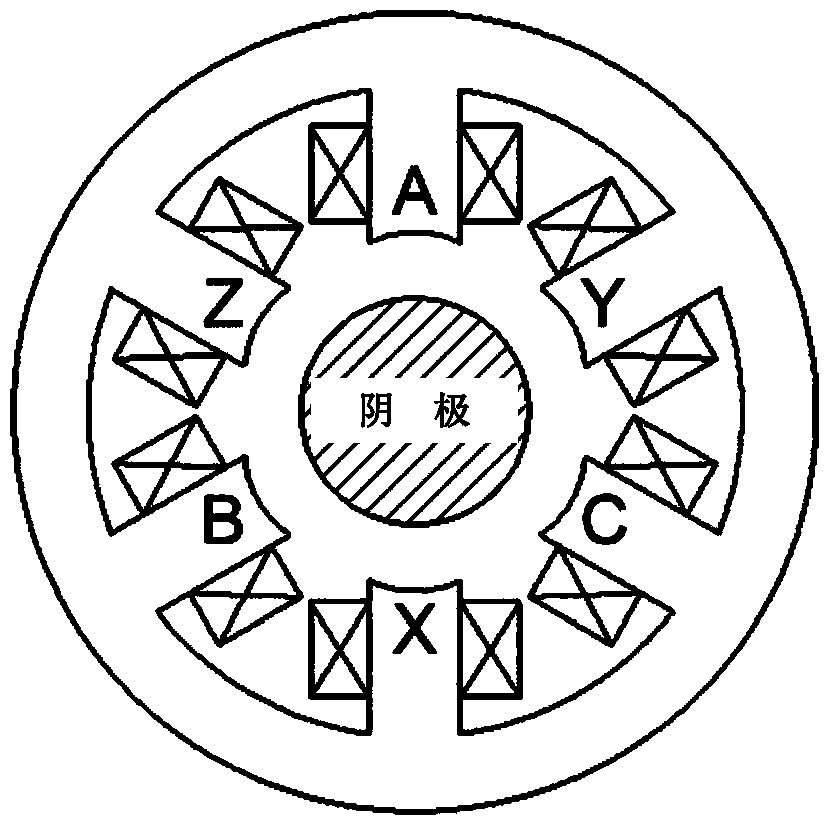

[0042] Different from Embodiment 1, the rotating transverse magnetic field generating device in this embodiment adopts a rotating transverse magnetic field generating device with three phases and six magnetic poles, image 3 It is a schematic diagram of the structure of the three-phase six-pole rotating transverse magnetic field generator used in this embodiment. There are six magnetic poles (A, Y, C, X, B, Z) evenly distributed on the circular closed main magnetic passage. A whole electromagnetic loop skeleton is formed, and the center of the electromagnetic loop skeleton is the cathode. The rotating transverse magnetic field generating device and the target are also coaxially placed, and the position can be adjusted. It is advisable to form an effective rotating magnetic field area on the target surface. The top end of each magnetic pole is straight or arc-shaped, symmetrically pointing to the center of the target surface. In the rotating transverse magnetic field generatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com