Industrial robot trajectory optimization method based on improved genetic algorithm

A technology for improving genetic algorithms and industrial robots, applied in the field of trajectory optimization of industrial robots based on improved genetic algorithms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079]The concepts, specific structures, and technical effects of the present invention will be described below in conjunction with examples and drawings to fully understand the objects, programs and effects of the present invention. It should be noted that the features in the embodiments and embodiments in the present application may be combined with each other in the case of an unable conflict.

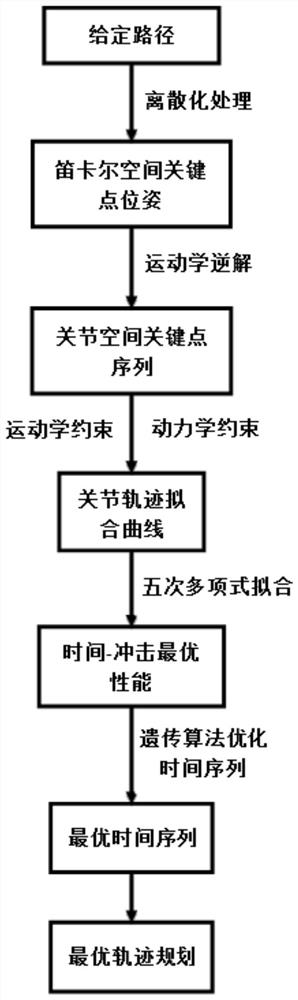

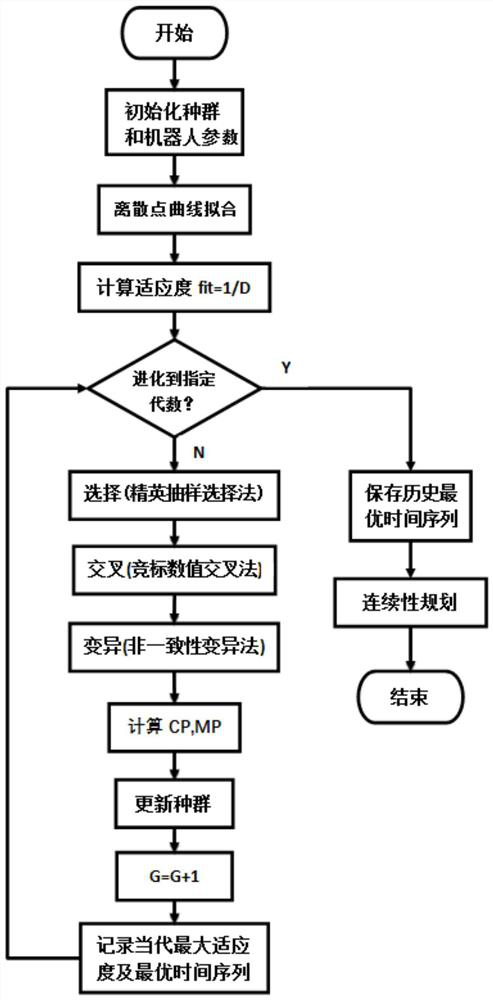

[0080]figure 1 Down to time - impact optimal trajectory planning flow chart, combined belowfigure 1 To explain an industrial robot trajectory optimization method based on improved genetic algorithm, in accordance with the present invention.

[0081]The present invention proposes an industrial robot trajectory optimization method based on improved genetic algorithm, including the following steps:

[0082]Step 1. The complete path is used in the Cartesian space using an arc interpolation and a linear interpolation combination method to obtain a series of key designs;

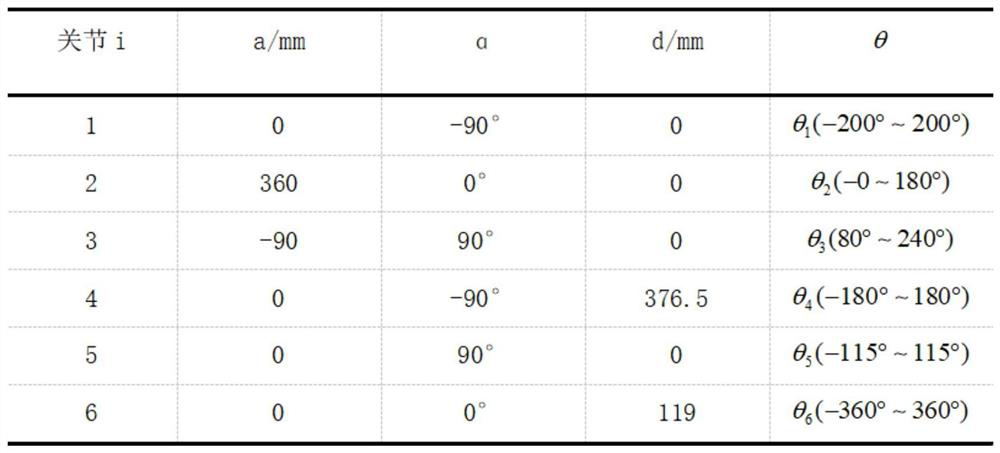

[0083]Step II. Establish a D-H pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com