Patents

Literature

38results about How to "Reduce heat generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

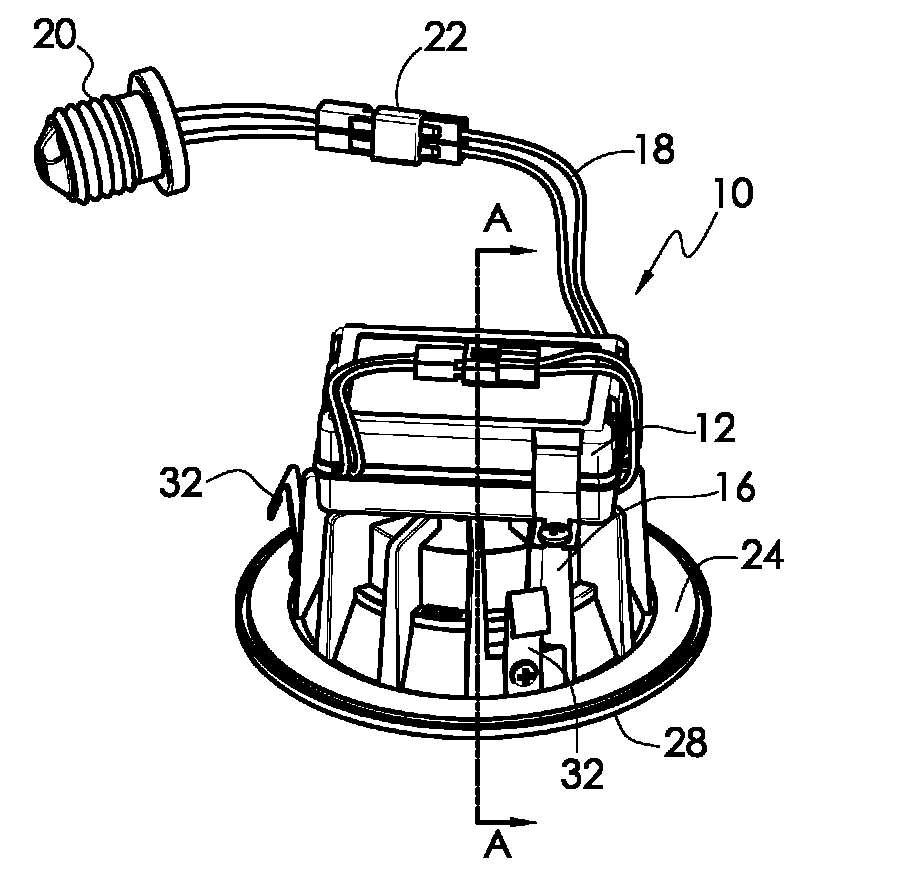

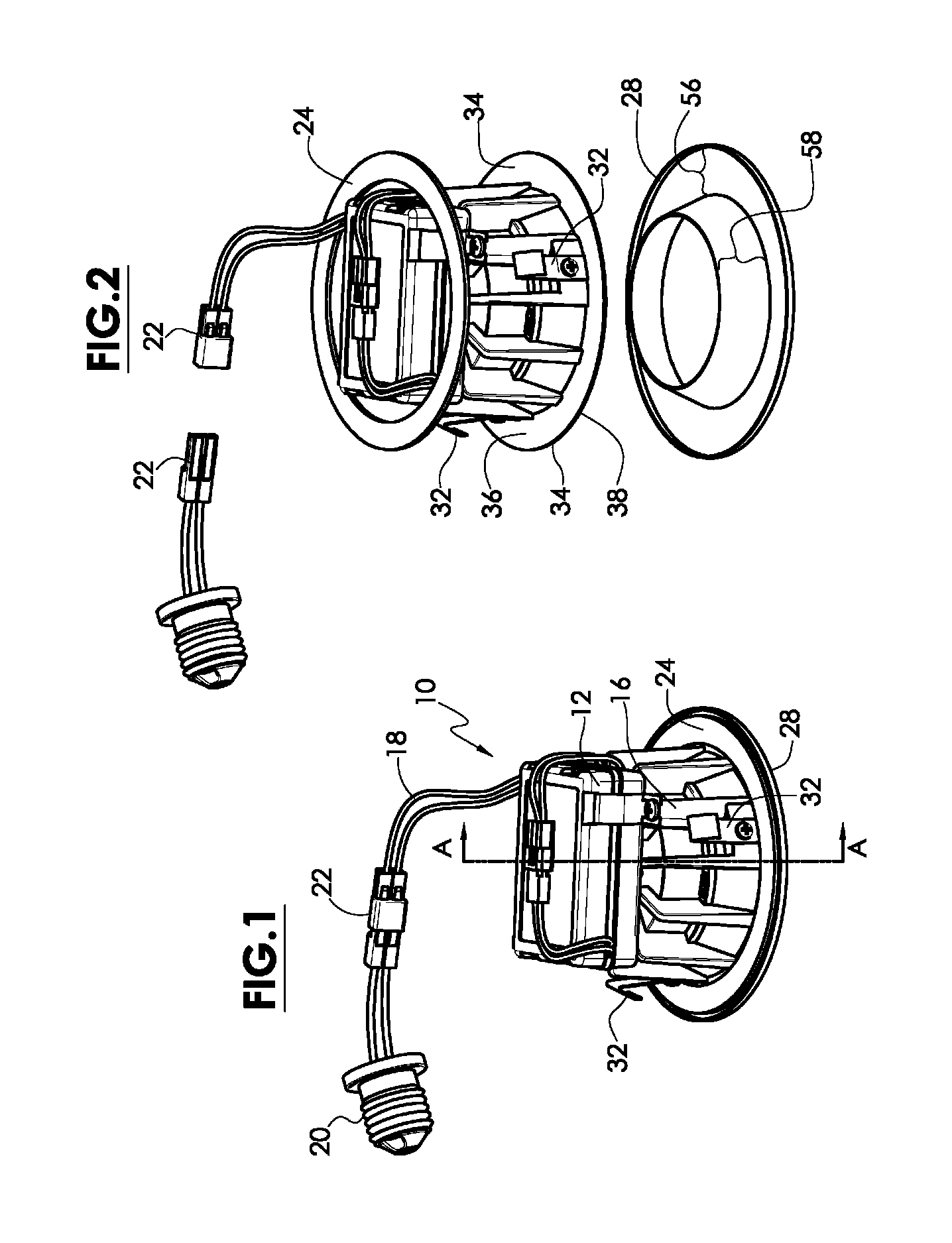

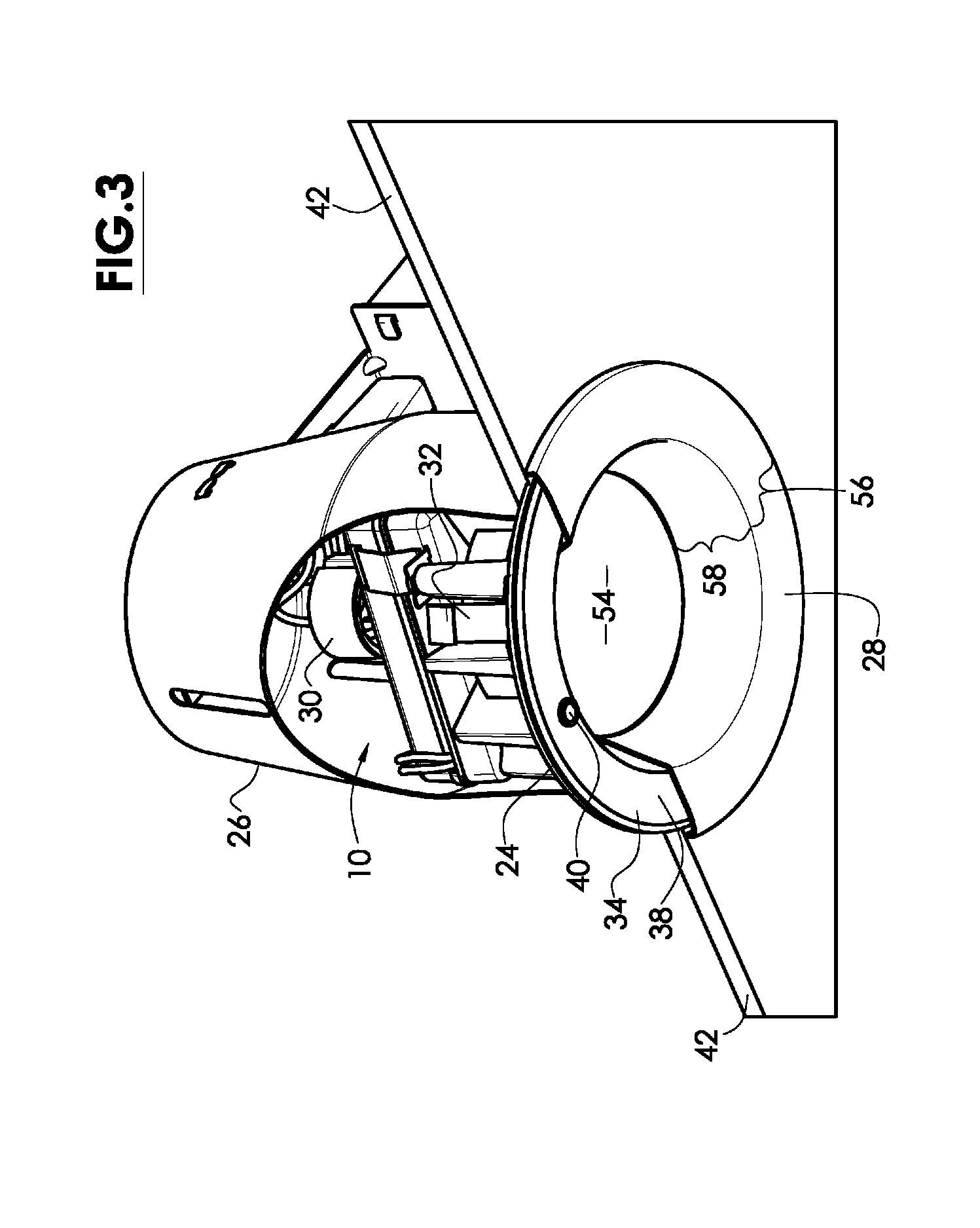

Recessed LED lighting fixture

ActiveUS8454204B1Reduce heat generationLow heat generationPlanar light sourcesFurnace componentsAspect ratioMagnet

A recessed lighting fixture providing illumination from a light source including a plurality of light emitting diodes (LEDs) wherein the fixture is placed within the ceiling space above a ceiling panel or wall. The fixture has a low aspect ratio heat sink. An interchangeable trim ring has an integrated light reflector and attaches to the bottom of the heat sink via rare earth or super magnets. A flange of the heat sink and a flat annular surface of the trim ring engage each other, providing a large contact surface to enable conductive heat transfer. The flange and flat annular surface are located below the ceiling panel, which is at room temperature to help cool the recessed LED lighting fixture through radiation and air convection.

Owner:CORDELIA LIGHTING

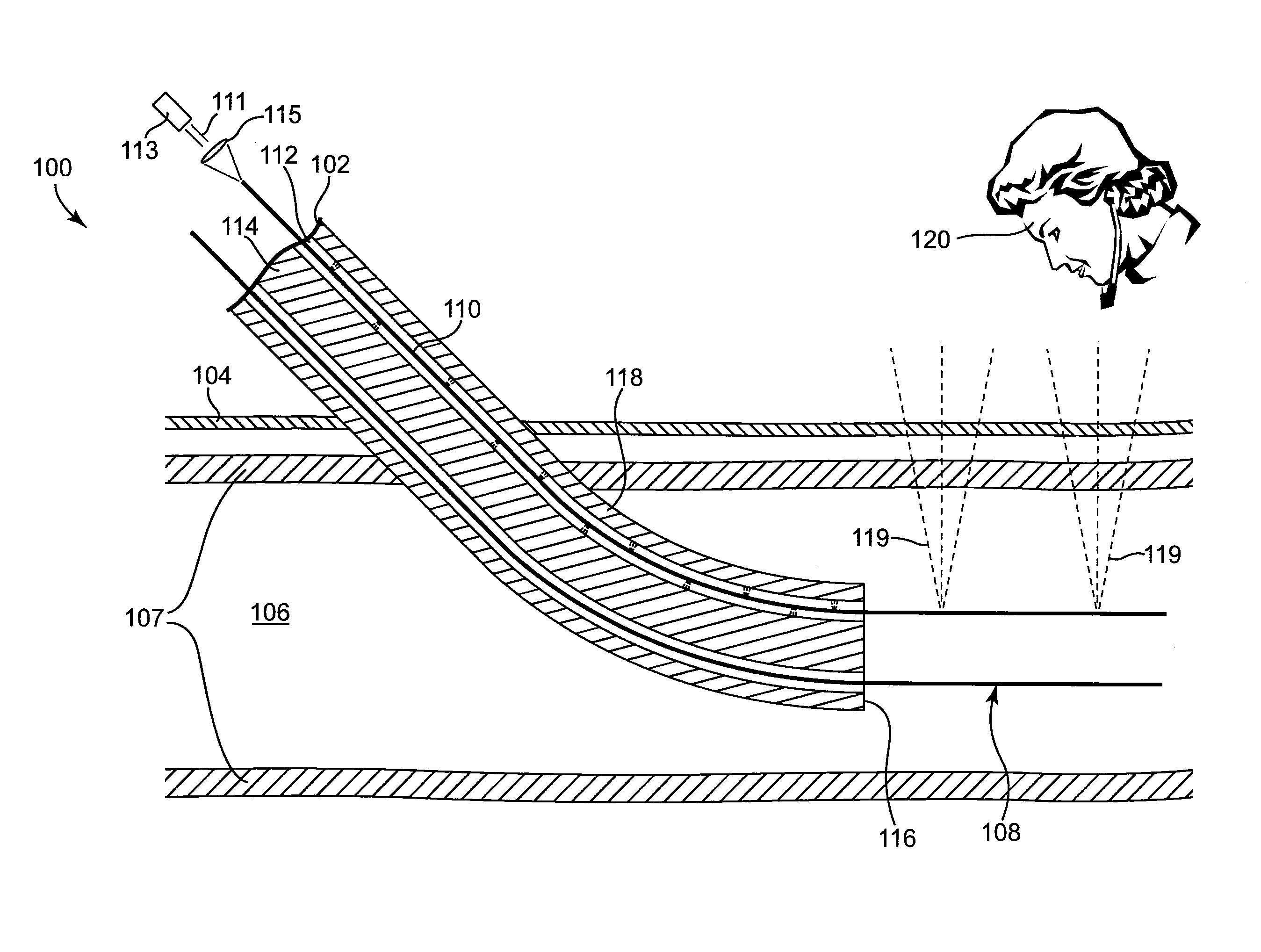

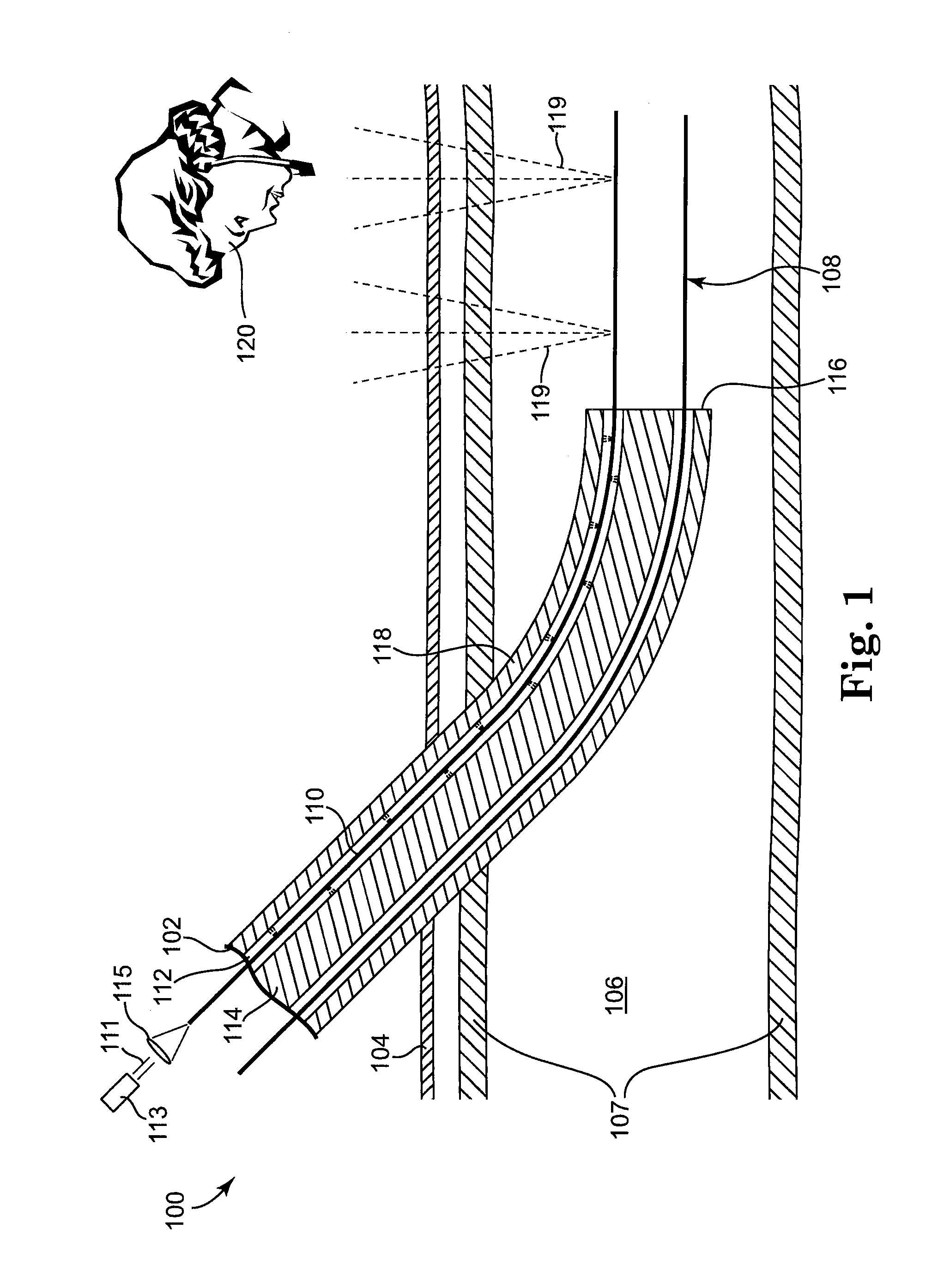

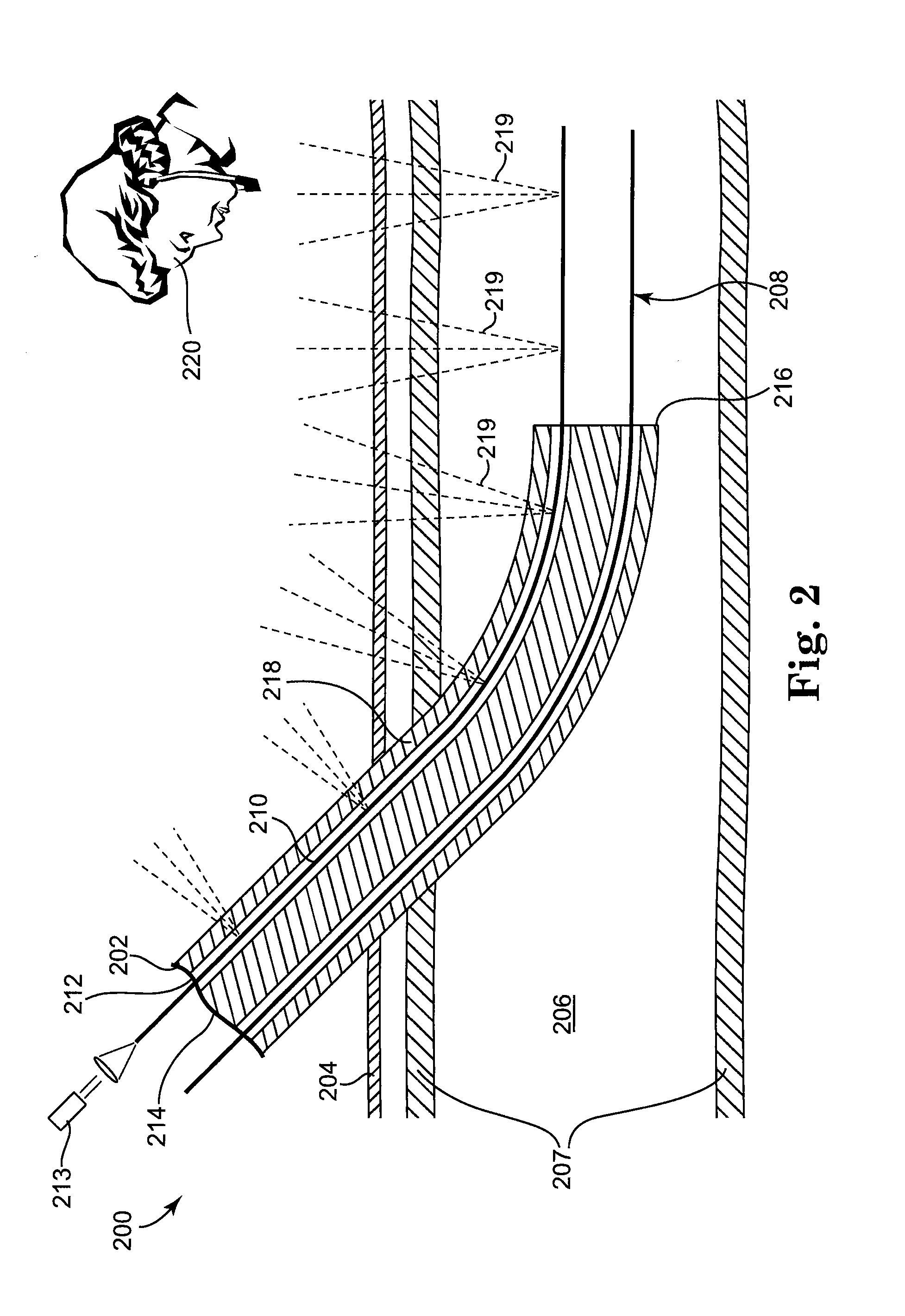

Light-guided transluminal catheter

InactiveUS20080194973A1Reduce heat generationEasily identifiableSurgeryMedical devicesCatheter insertionBlood stream

Generally, the present invention is directed to a light-guided catheter for direct visualization of placement through the skin. An embodiment of the invention includes a method for transcutaneous viewing and guiding of intracorporeal catheters into a body that comprises inserting a catheter into the body having at least one lumen and internally illuminating the catheter with light capable of propagating through the blood and tissue to an external viewer outside of the body. The illumination may be point source, continuous, single or multi wavelength. A method of treatment of blood conditions is also disclosed using direct placement of a photo treatment source in the blood stream.

Owner:CHILDRENS MEDICAL CENT CORP

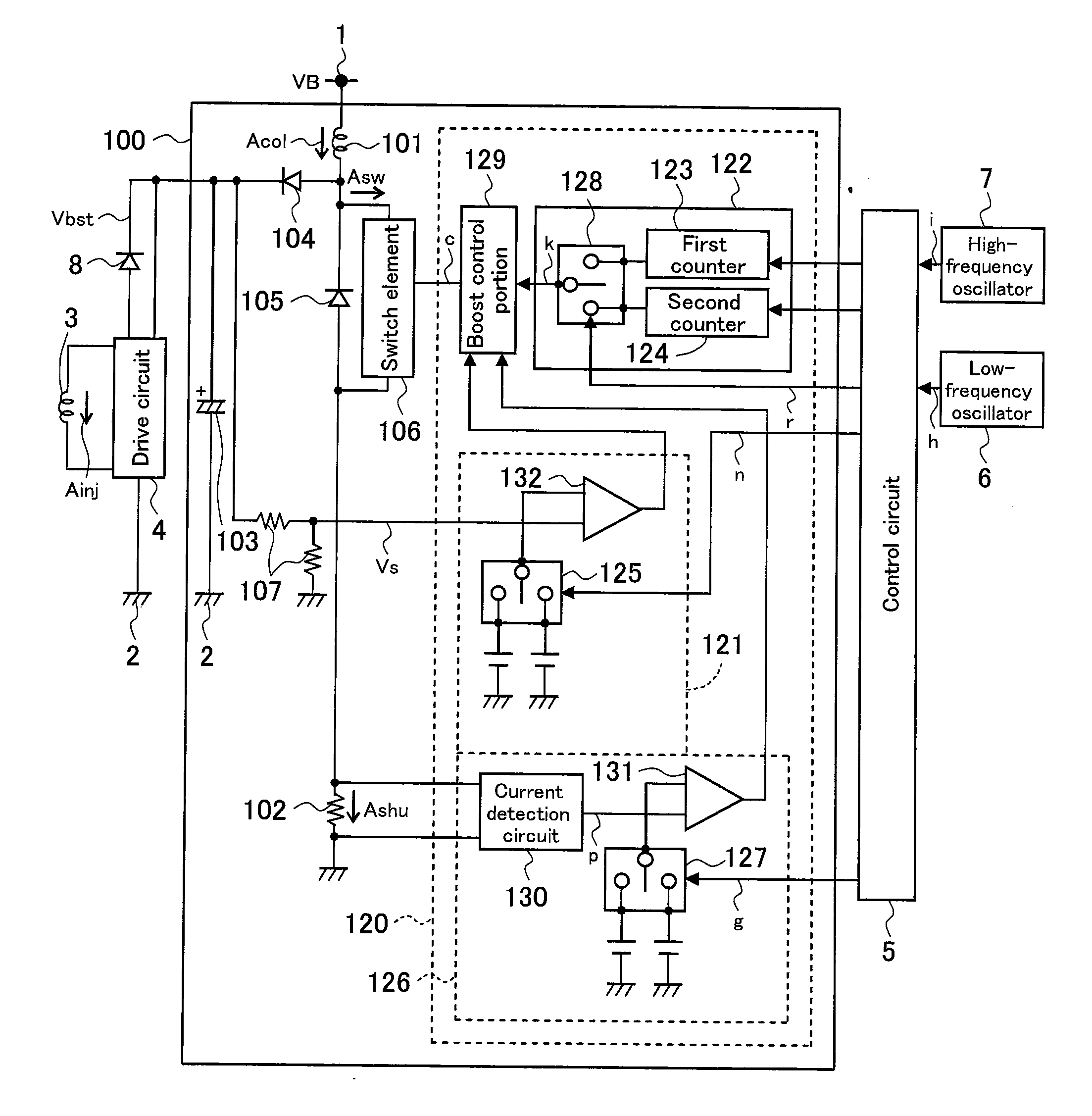

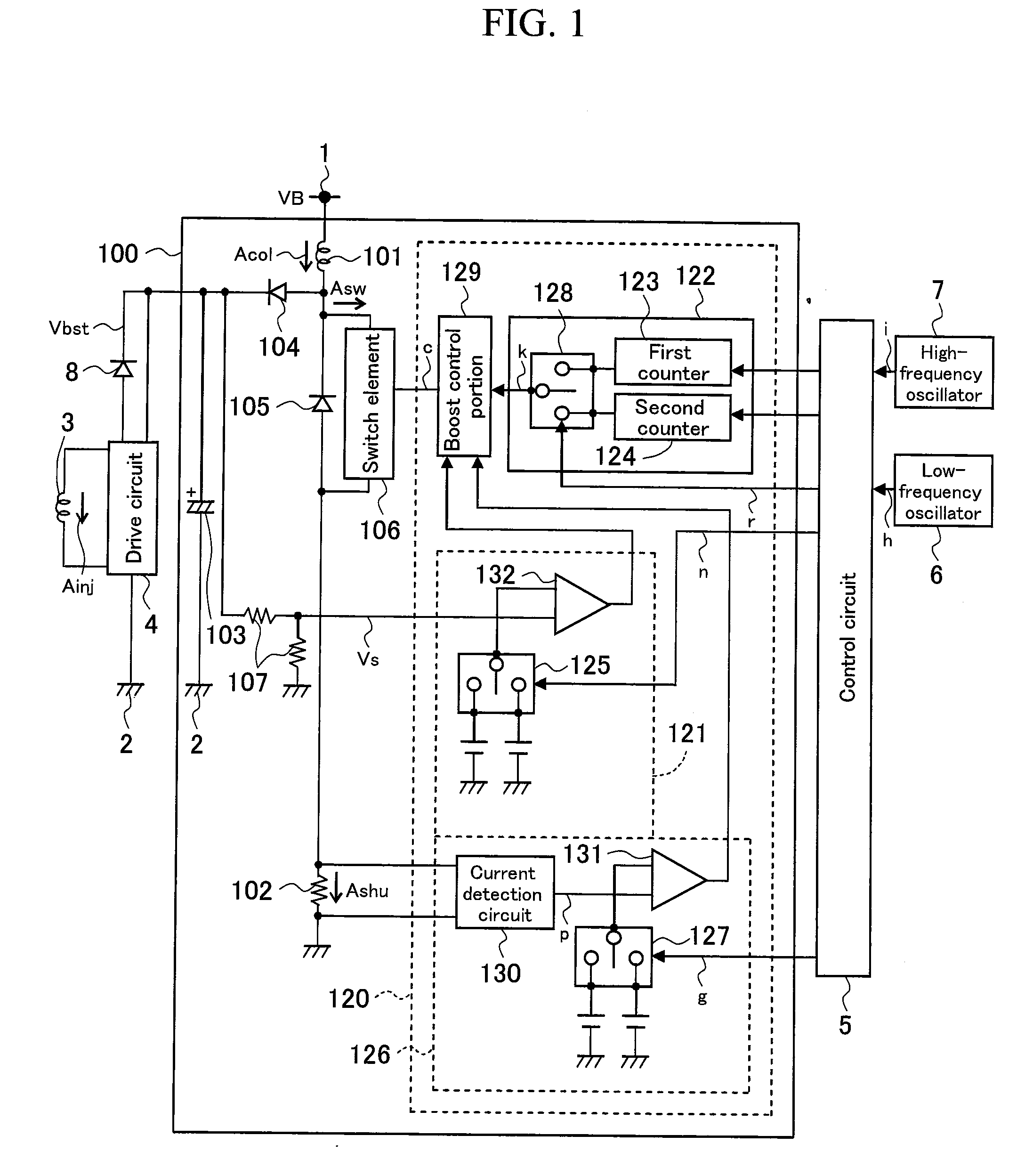

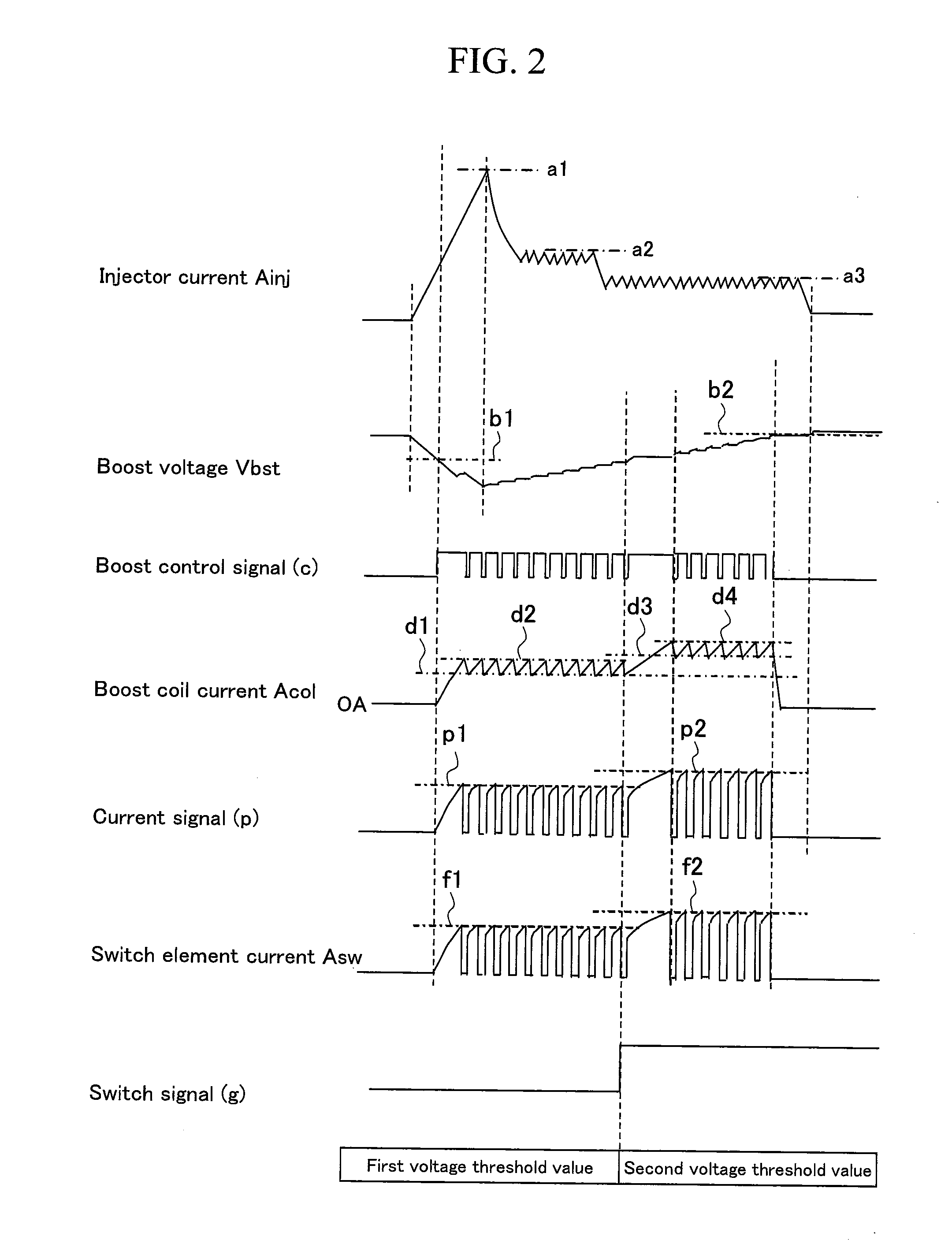

Internal Combustion Engine Controller

ActiveUS20100242920A1Reduce heat generationSuppress frequencyInternal-combustion engine testingElectrical controlCurrent regulationEngineering

There is provided an internal combustion engine controller that realizes a reduction in maximum current value and current regulation without sacrificing boost performance. An internal combustion engine controller 100 comprises: a boost coil 101 configured to boost a voltage VB of a battery power source; a boost switch element 106 configured to switch between causing a current to flow and stopping a current from flowing through the boost coil 101; and a current detection portion 126 configured to detect a current flowing through the boost switch element 106, wherein boost control is effected by repeating the switching of the switch element, the voltage boosted at the boost coil 101 is charged to a boost capacitor 103 via a diode 104, and, during the boost control, the internal combustion engine controller 100 makes the boost switch element 106 stop the current flowing through the boost coil 101 when the detected current reaches a switching stop current value and, after a predetermined set time Tdown has elapsed from the point at which current flow is stopped, makes the boost switch element 106 cause a current to flow through the boost coil 101.

Owner:HITACHI ASTEMO LTD

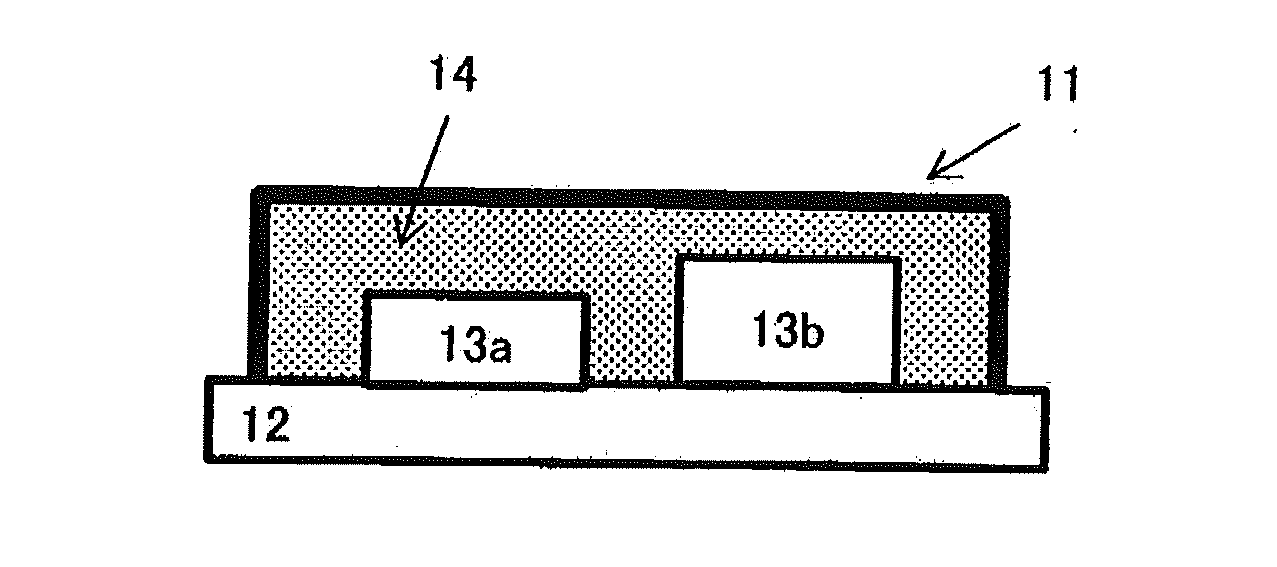

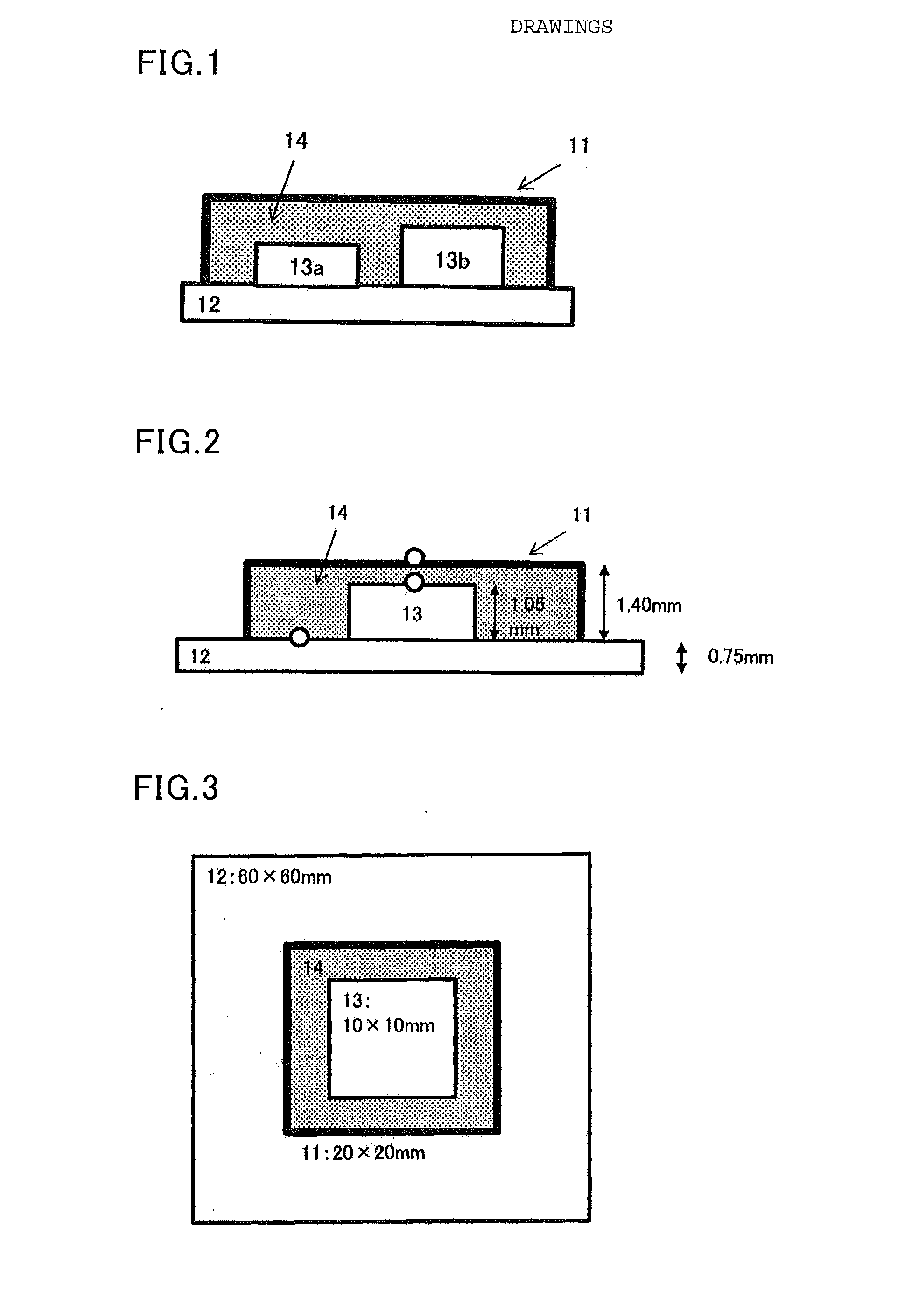

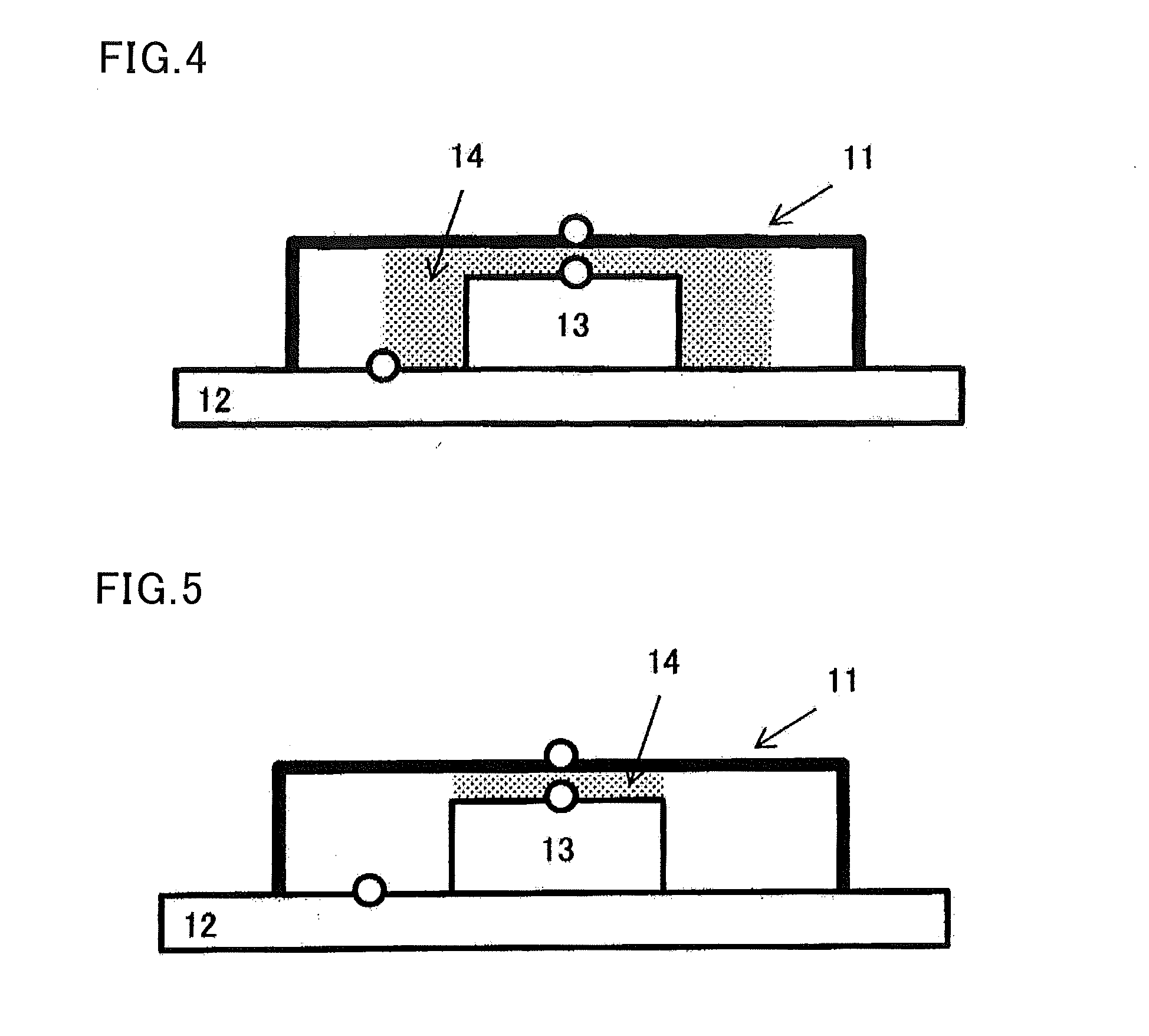

Heat dissipation structure

ActiveUS20150163958A1Reduce heat generationDeterioration of propertyMagnetic/electric field screeningLayered productsLiquid resinMoisture

The present invention provides a heat dissipation structure that does not cause problems such as contact failures in electronic components and that is applicable to electronic components with high heat densities. The present invention also provides a method for easily repairing an electronic device. The heat dissipation structure is obtained by filling and curing a thermally conductive curable resin composition in an electromagnetic shielding case on a substrate on which an electronic component with a heat density of 0.2 W / cm2 to 500 W / cm2 is mounted, the thermally conductive curable resin composition containing a curable liquid resin (I) and a thermally conductive filler (II), having a viscosity at 23° C. of 30 Pa·s to 3000 Pa·s and a thermal conductivity of 0.5 W / (m·K) or more, and being curable by moisture or heat.

Owner:KANEKA CORP

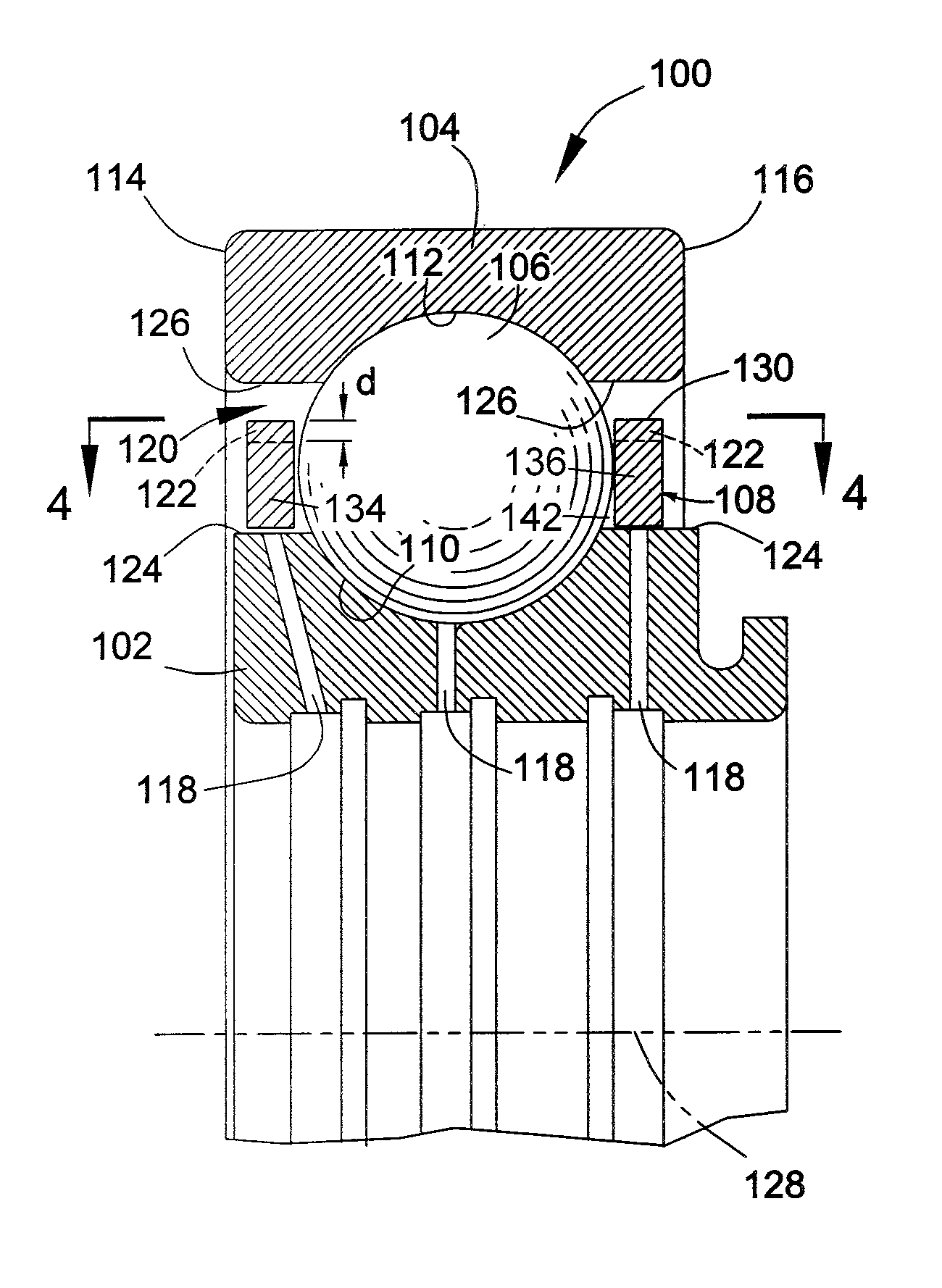

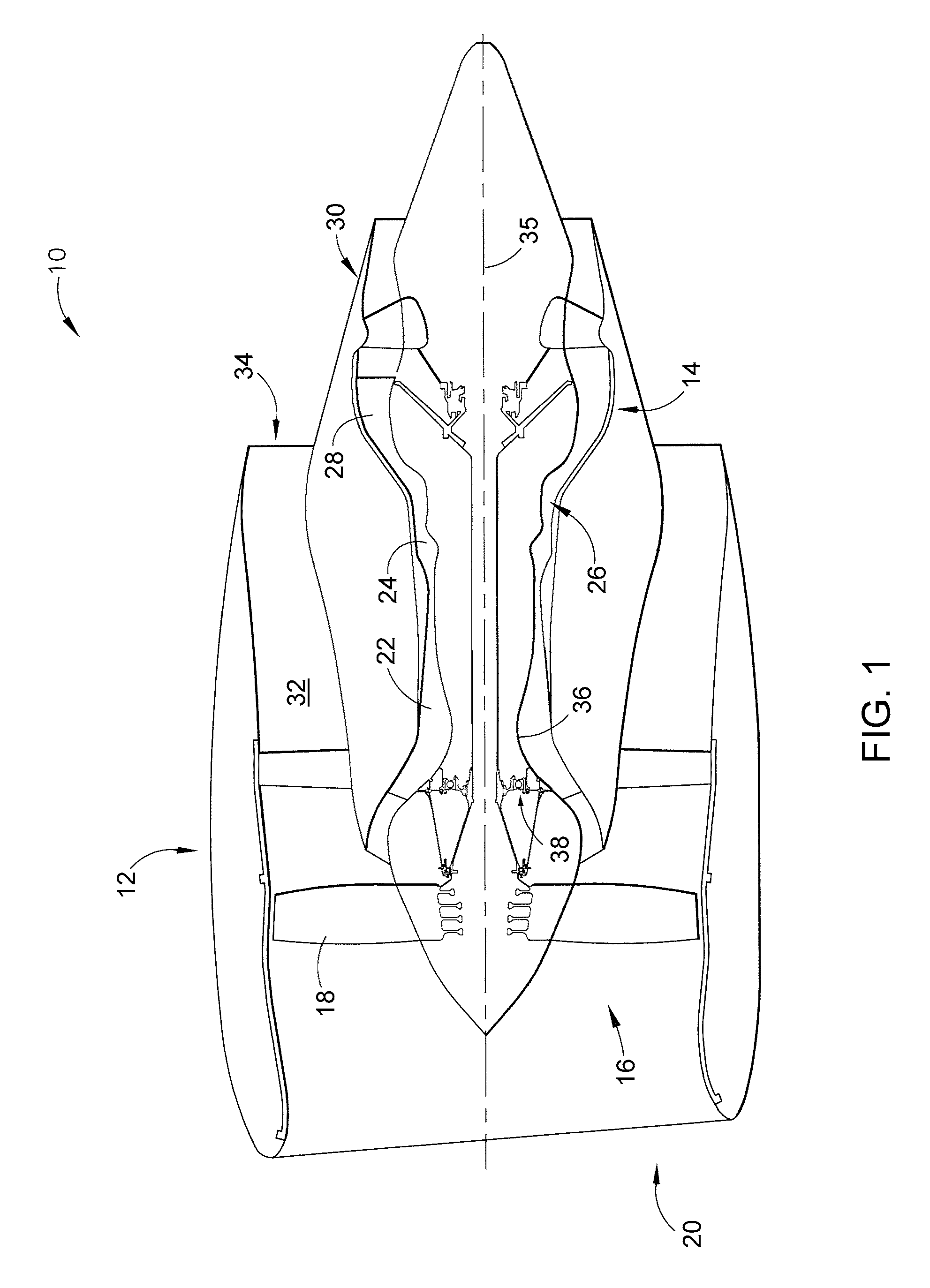

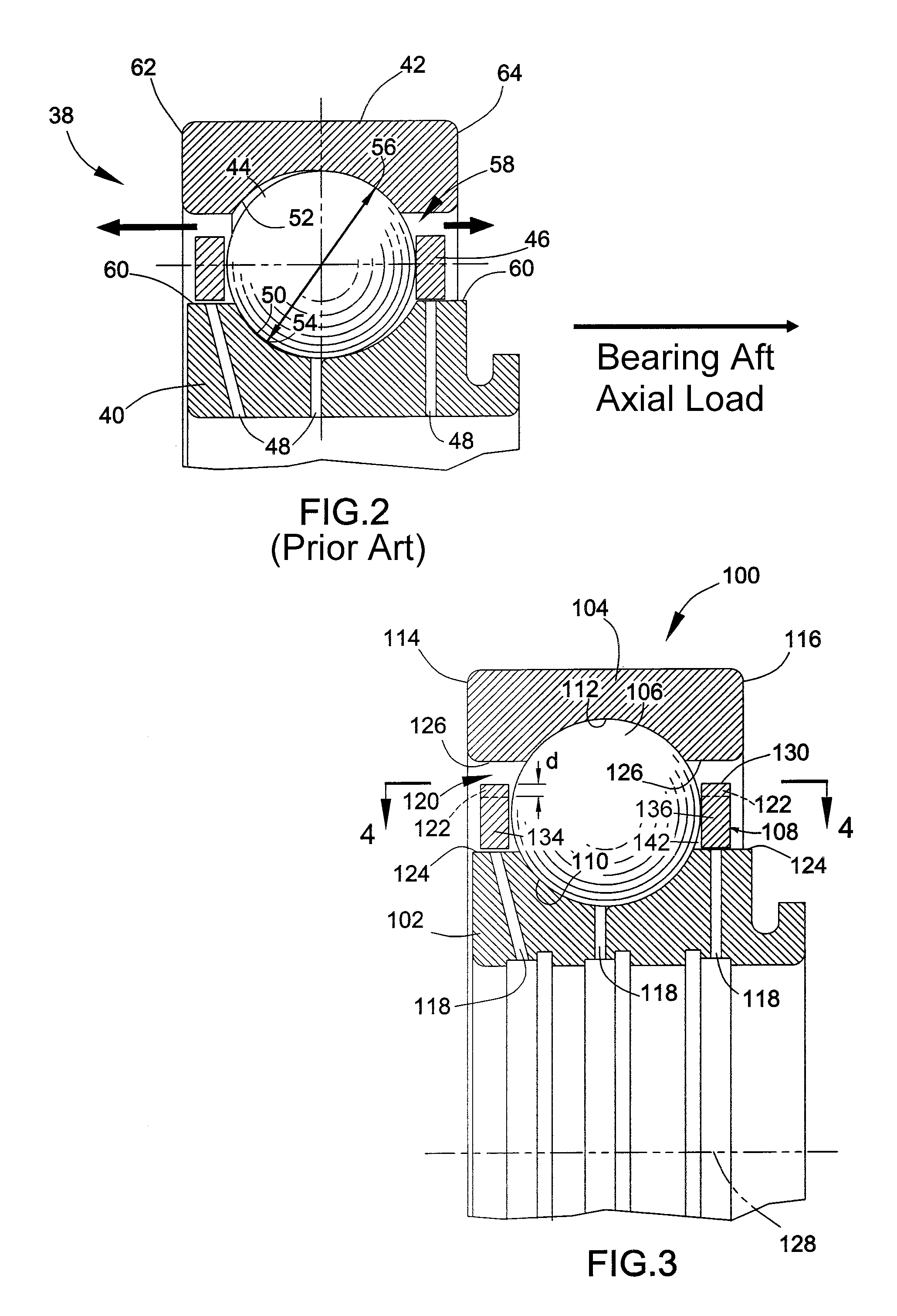

Dynamically-lubricated bearing and method of dynamically lubricating a bearing

ActiveUS20130087413A1Reduce heat generationHigh rotational speedShaftsBall bearingsGas turbinesEngineering

Dynamically-lubricated bearings and methods of dynamically lubricating bearings, including bearings used in gas turbine engines. Such a bearing includes an inner race having an inner race groove, an outer race having an outer race groove that opposes the inner race groove, rolling elements disposed between the inner and outer races and in rolling contact with the inner and outer race grooves, and a cage disposed between the inner and outer races to maintain separation between the rolling elements. A lubricant is introduced into a cavity between the inner and outer races, and rotation of the inner race relative to the outer race causes air to enter pockets of the cage that contain the rolling elements, which in turn causes the lubricant to exit the cavity of the bearing.

Owner:GENERAL ELECTRIC CO

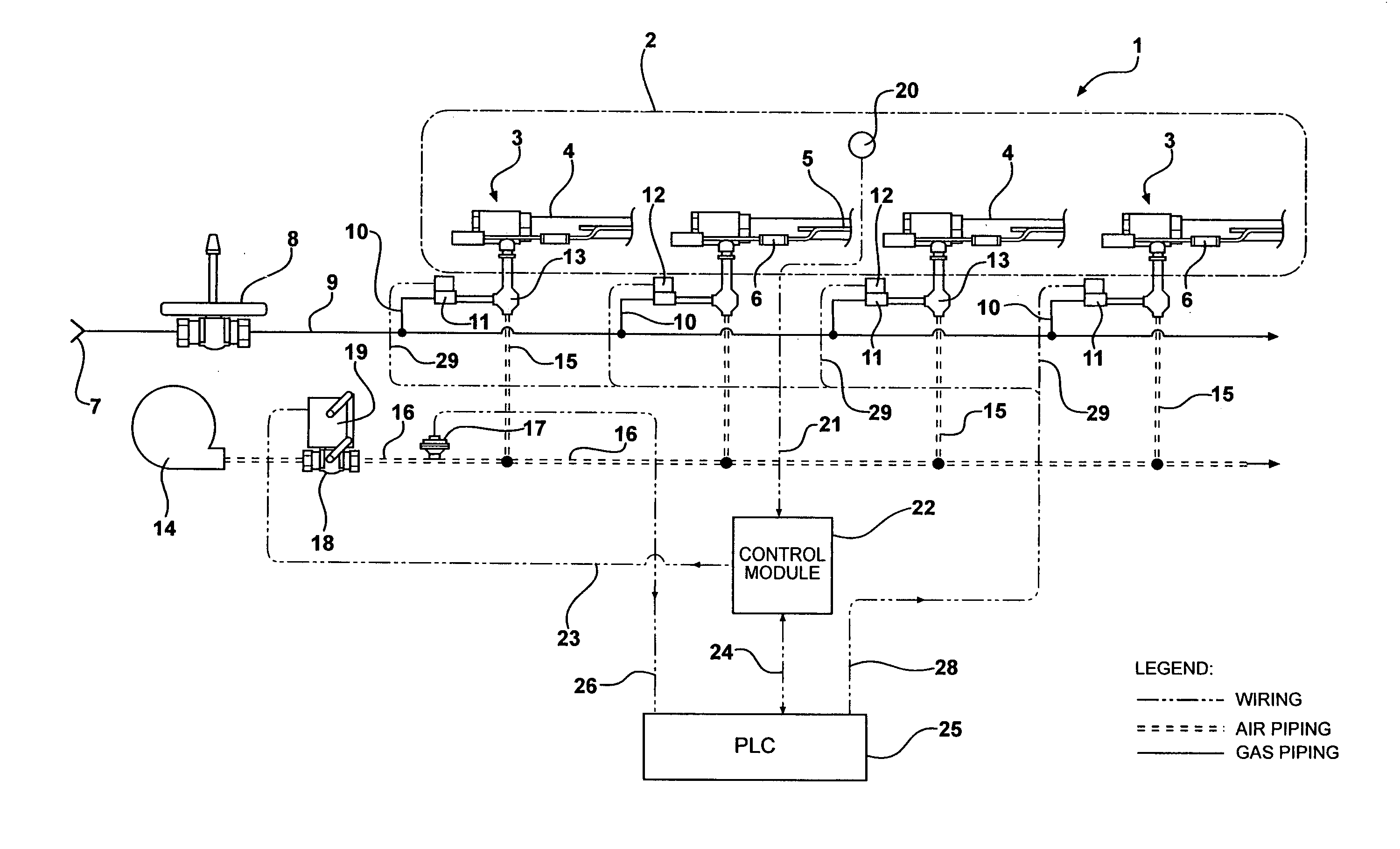

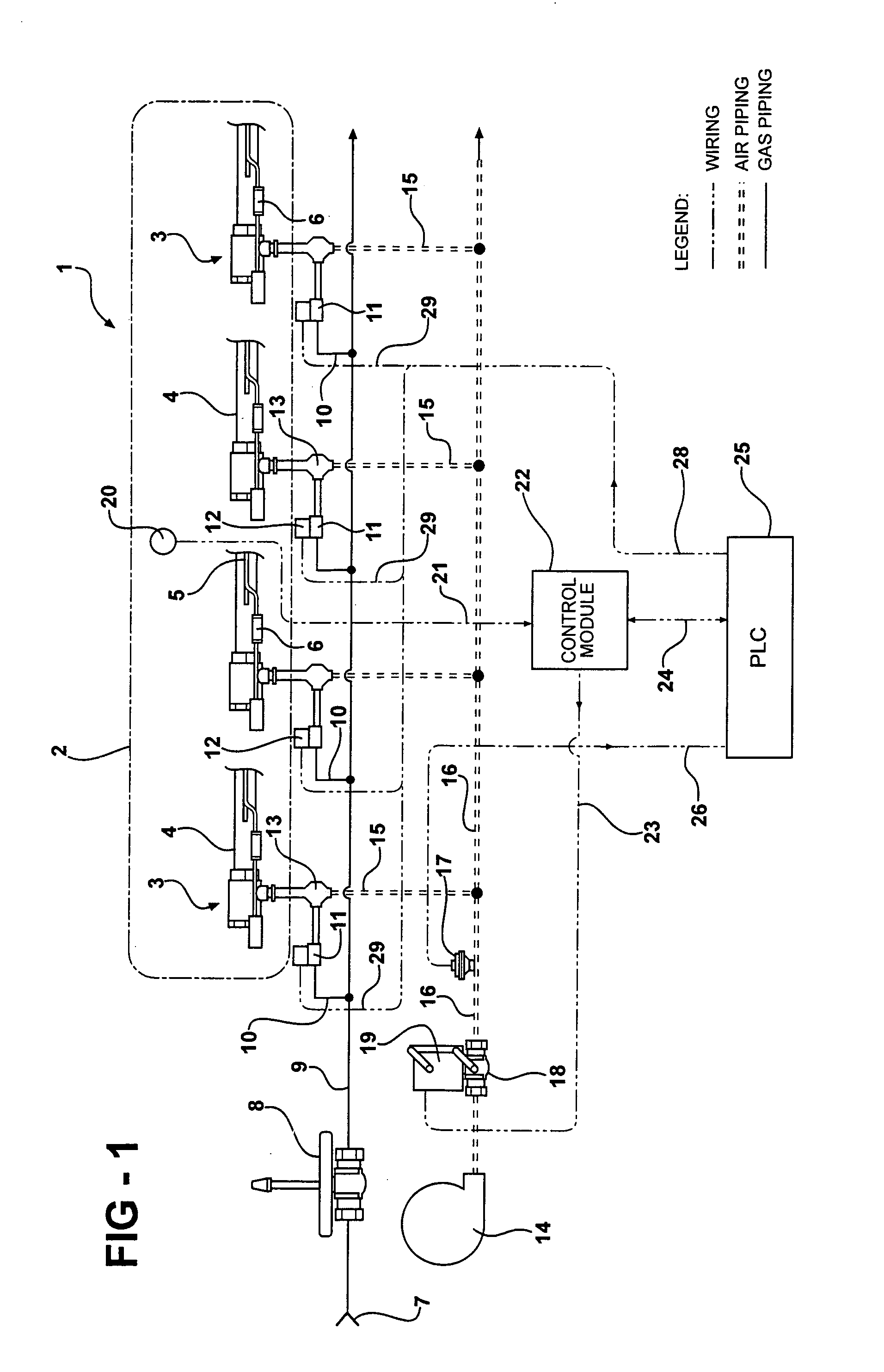

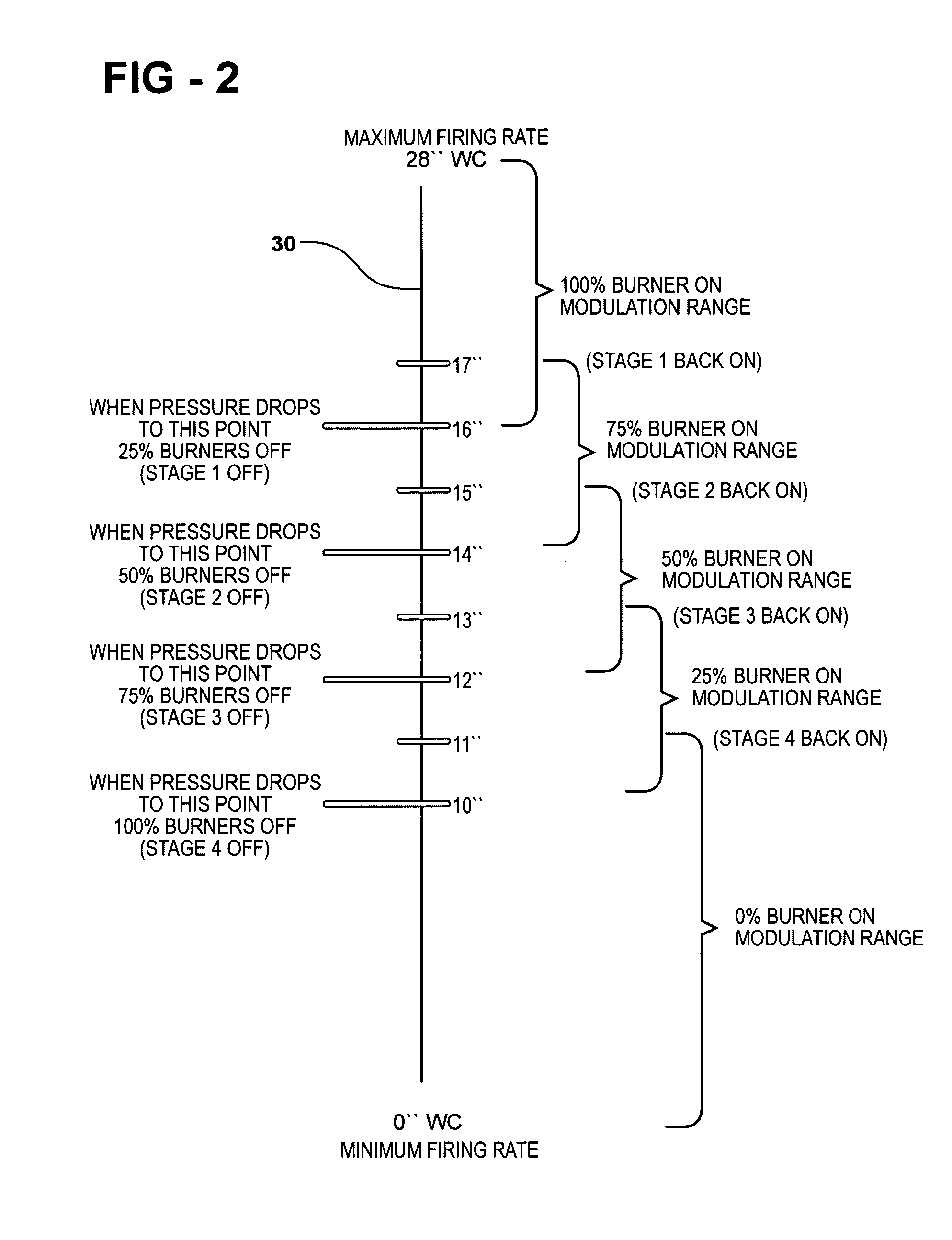

Methods and apparatus for controlling baking oven zone temperature

InactiveUS20060032930A1Reduce heat generationGreat heatTemperature control without auxillary powerFuel supply regulationFuel supplyCombustor

Owner:BANNER ENG & SALES

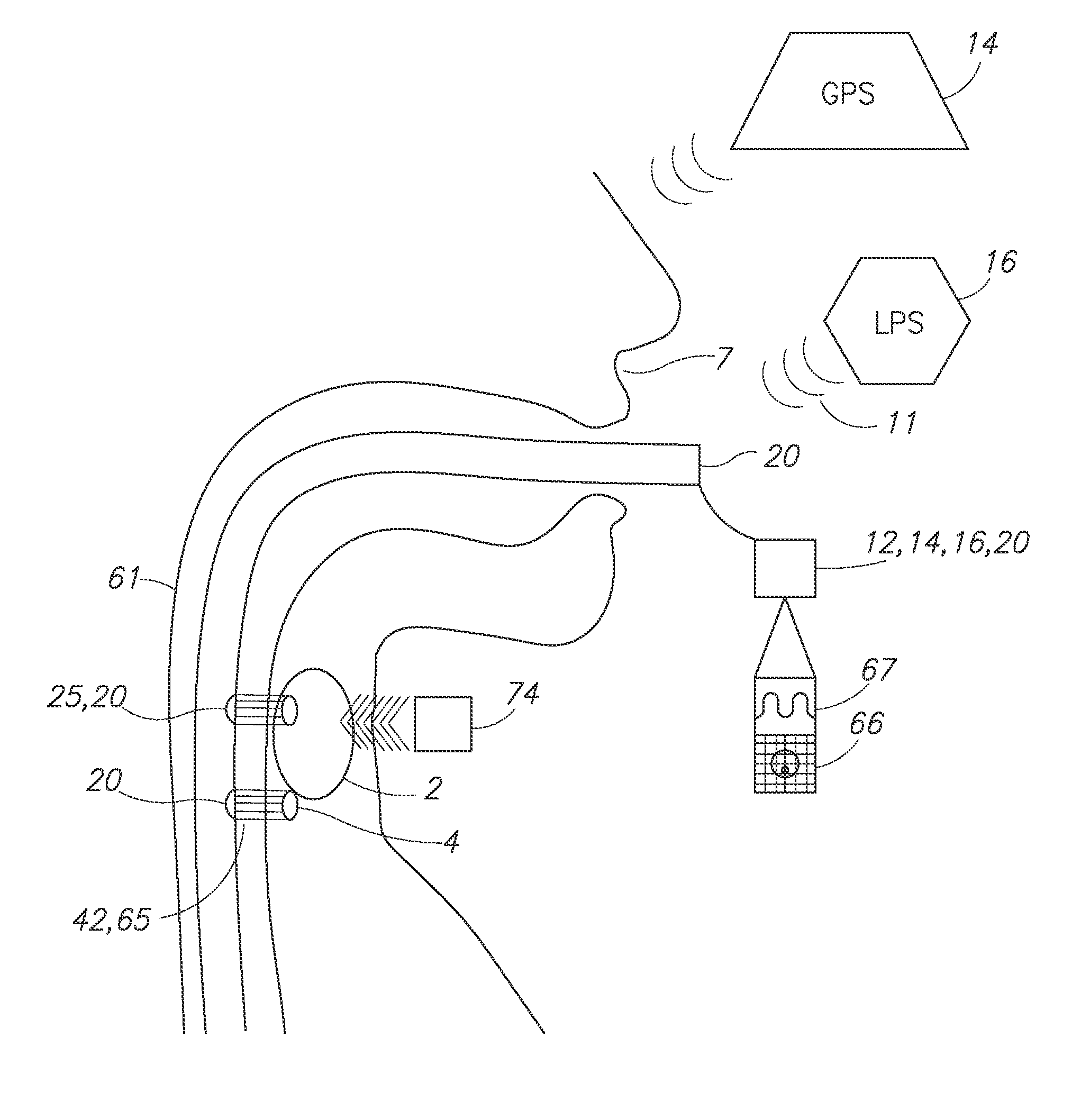

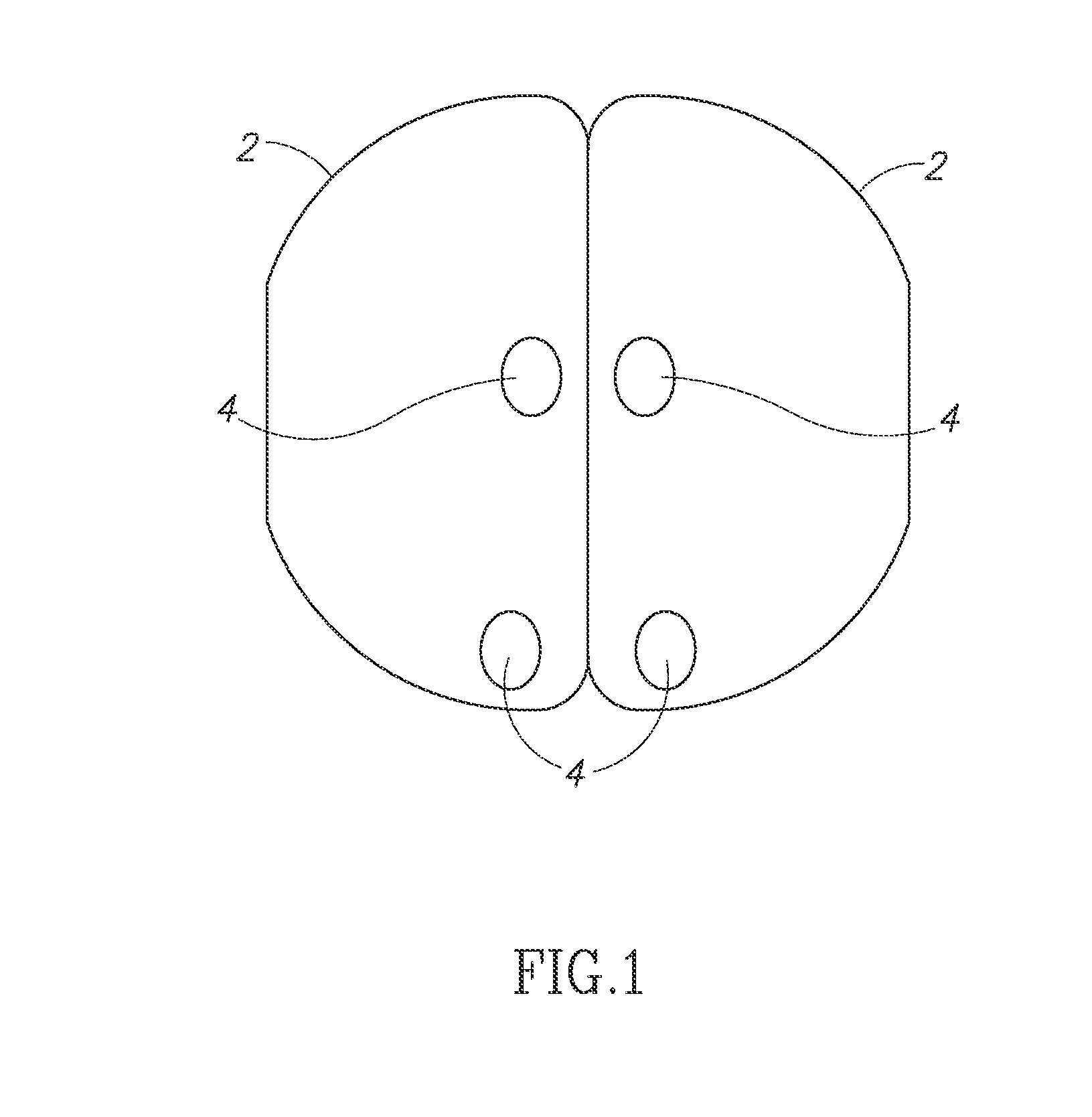

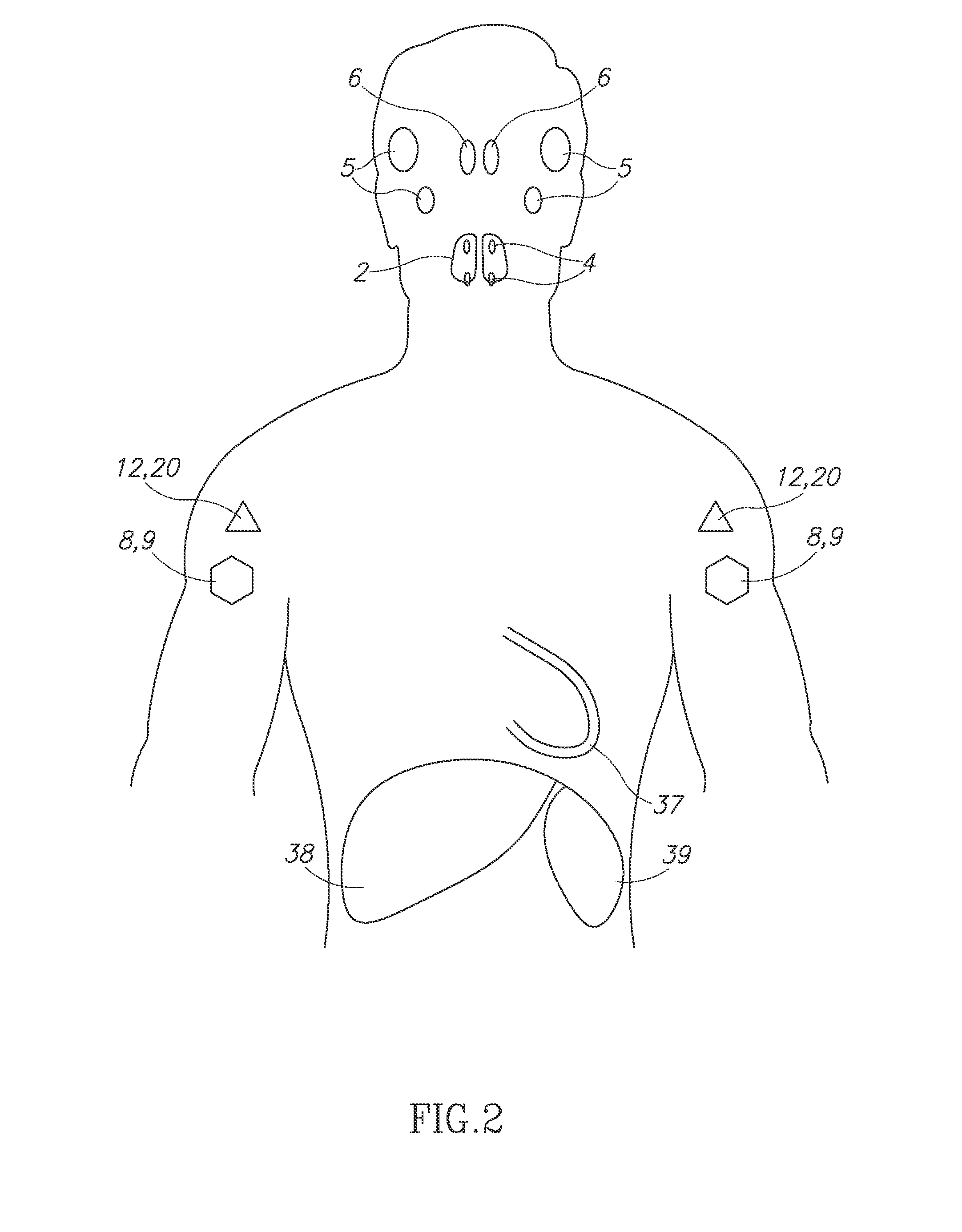

Localization of the parathyroid

ActiveUS20140288412A1Reduce heat generationReduce thyroid activitySurgical navigation systemsDiagnostic markersComputer visionLiving body

Systems and methods are disclosed for locating the parathyroid. In one aspect, temporal variation among a plurality of images is evaluated and at least one image is enhanced according to the temporal variation. The image may be enhanced to one or both of reduce conspicuity of the thyroid gland and enhance conspicuity of the parathyroid gland. Some of the plurality of images may be adjusted in order to align representations of a target portions. Adjustments may be based locations of one or more organs or one or more artificial markers affixed to a living body in the plurality of images. A local positioning system (LPS), GPS, or other locating system may be used to position a living body, align the plurality of images, or to guide the positioning of objects relative to the living body. An elastomeric gel marker for imaging applications is also disclosed.

Owner:SCHWARTZ ALAN N

Pad for thermotheraphy

InactiveUS20130041434A1Stable output and wavelengthReduce heat generationLight therapyExternal electrodesOptoelectronicsLight source

A pad for thermotherapy includes: a stretchable and flexible substrate; an electrode pattern positioned over the stretchable and flexible substrate, and including a plurality of light source electrodes and a linear electrode connecting the light source electrodes; light sources positioned over the electrode pattern; and a power supply unit for supplying power to the light source, wherein the linear electrode is formed longer than intervals between neighboring light source electrodes and separated from the substrate.

Owner:ELECTRONICS & TELECOMM RES INST

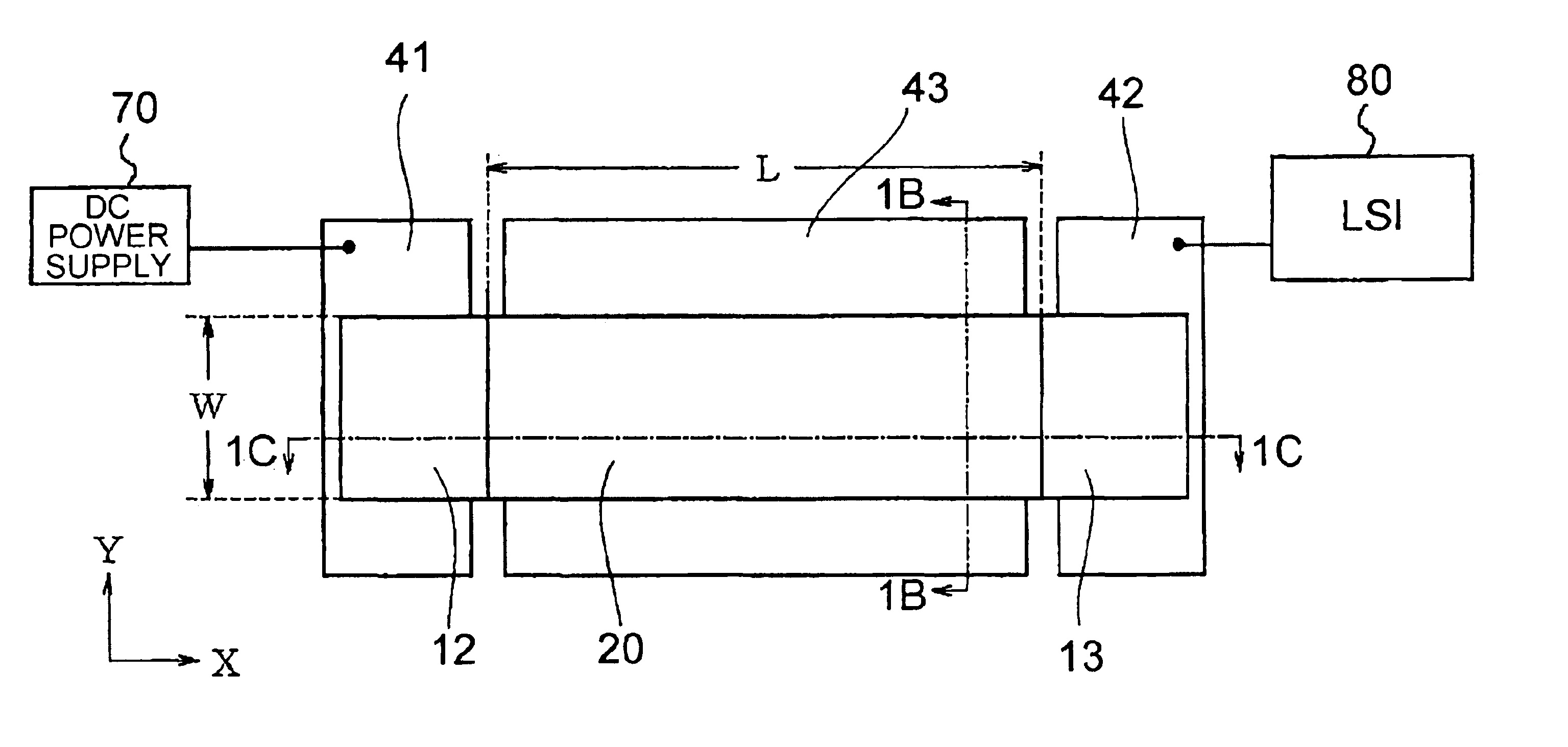

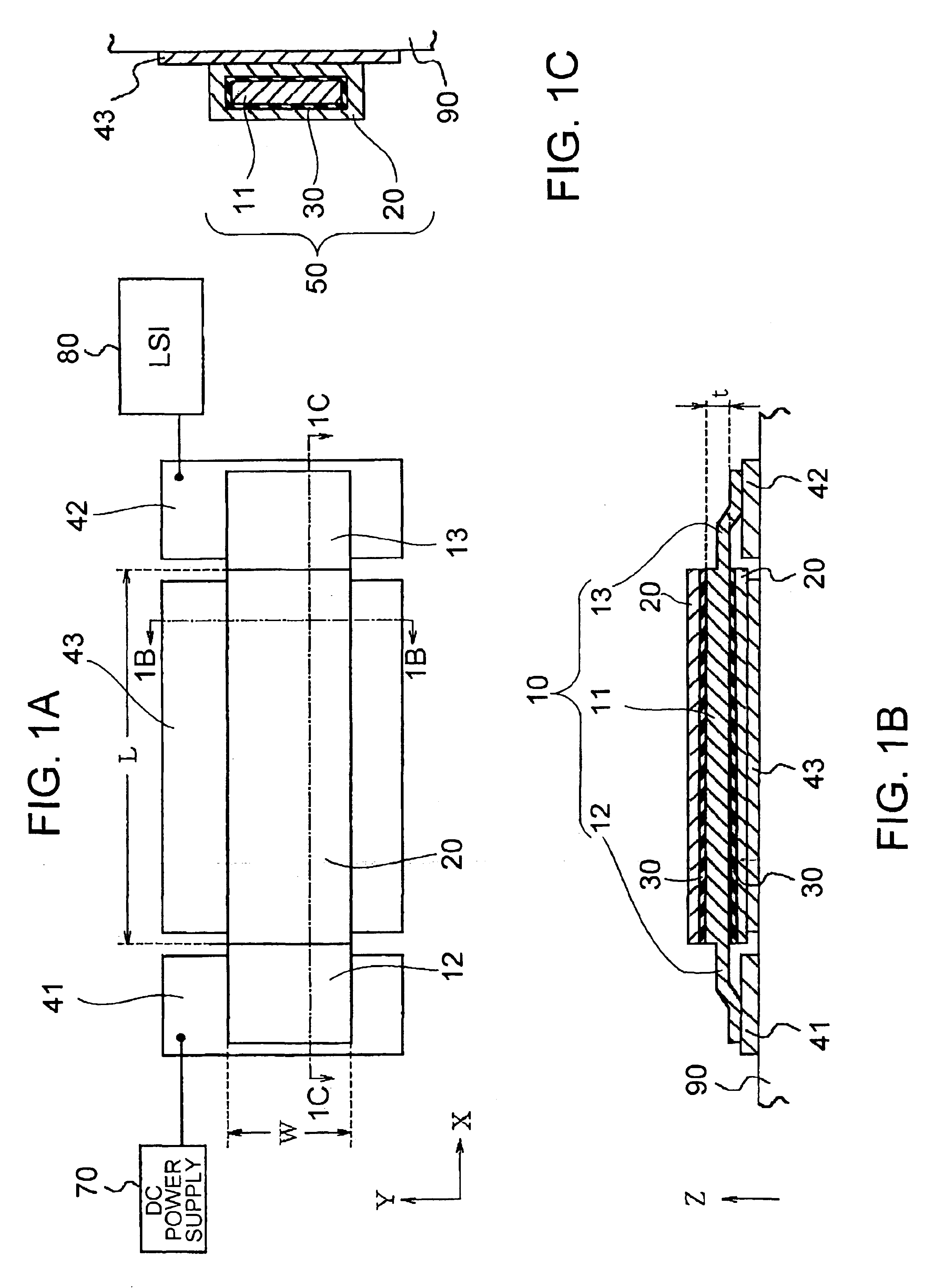

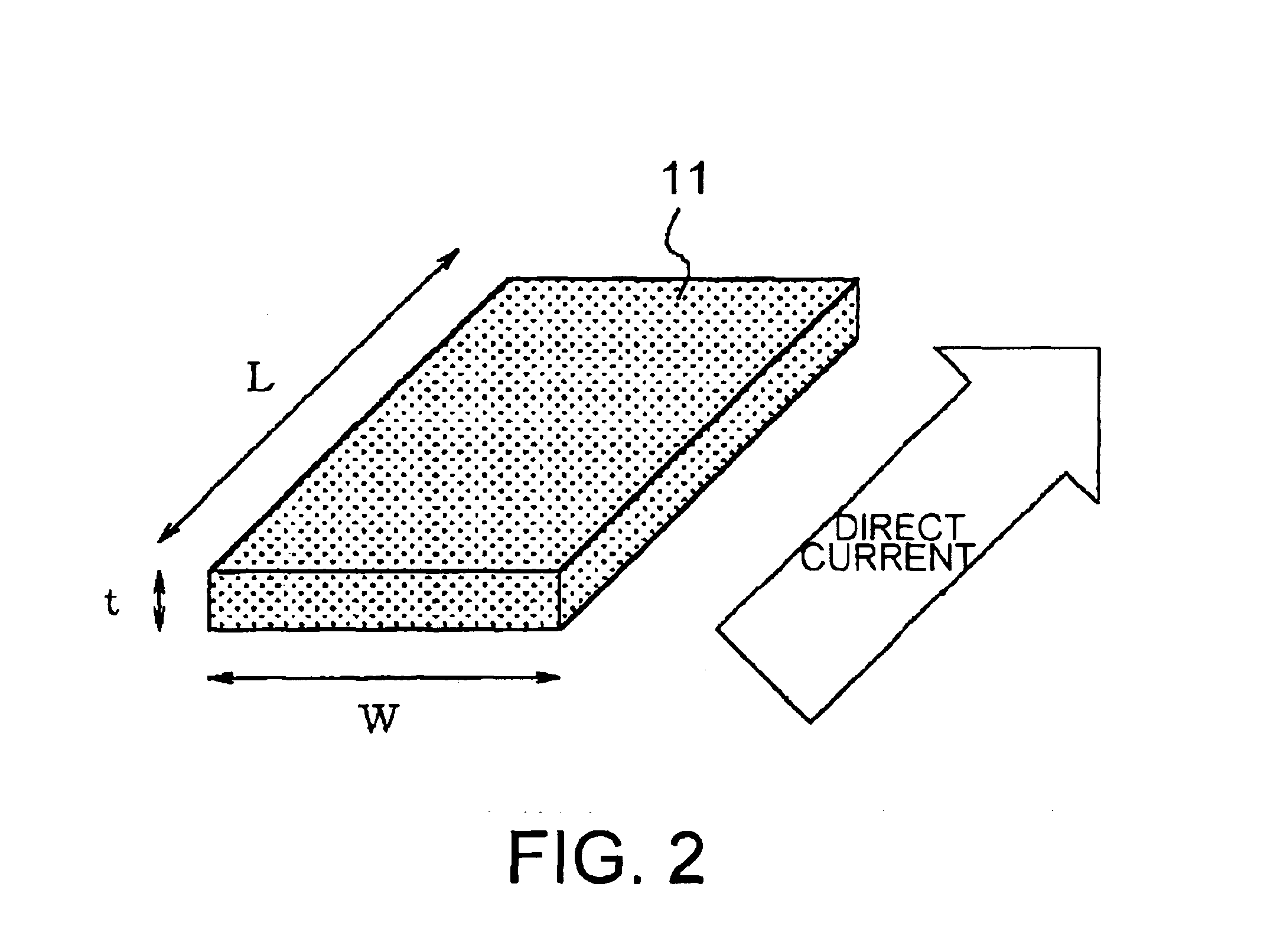

Transmission line type noise filter with reduced heat generation even when large DC current flows therein

ActiveUS7005944B2Reduce heat generationLow heat generationMultiple-port networksWaveguide type devicesCapacitanceTransmission line

A transmission line type noise filter, which is connectable between a direct current power supply and an electrical load component to pass a coming DC current while attenuating a coming AC current, includes a first conductor, a dielectric layer, a second conductor as a cathode, a first anode (12), and a second anode. The first and the second conductors and the dielectric layer serve as a capacitance forming portion. The thickness of the first conductor is selected to substantially restrict temperature elevation of the first conductor, which is caused by DC direct current flowing in the first conductor.

Owner:TOKIN CORP

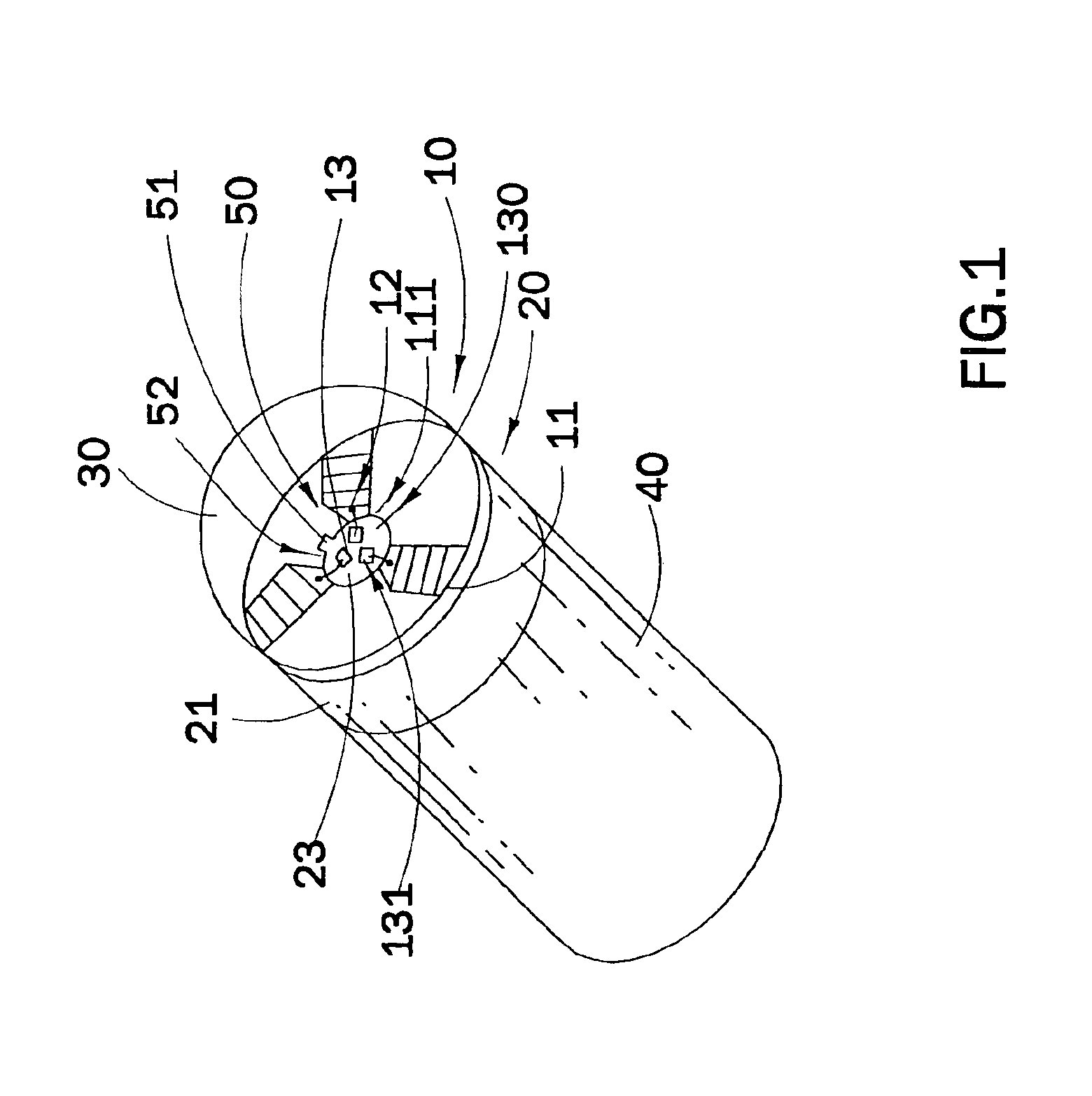

High intensity light source arrangement

InactiveUS6922018B2Prolong service life spanReduce heat generationLight source combinationsPoint-like light sourceElectricityHigh intensity light

A high intensity light source arrangement, which can prolong the service life span of the high intensity light source arrangement by better dissipating and reducing the heat generated, includes a luminary unit comprising a luminary circuit, at least a terminal electrically connected to the luminary circuit, and at least a luminary element adapted for electrifying with the terminal to emit light; a heat dissipation unit supporting the luminary unit and dissipating heat generated from the luminary unit; and a base housing for supporting the heat dissipation unit thereon including an electric input connector electrically connecting to the luminary unit.

Owner:CHEN AMY YUN

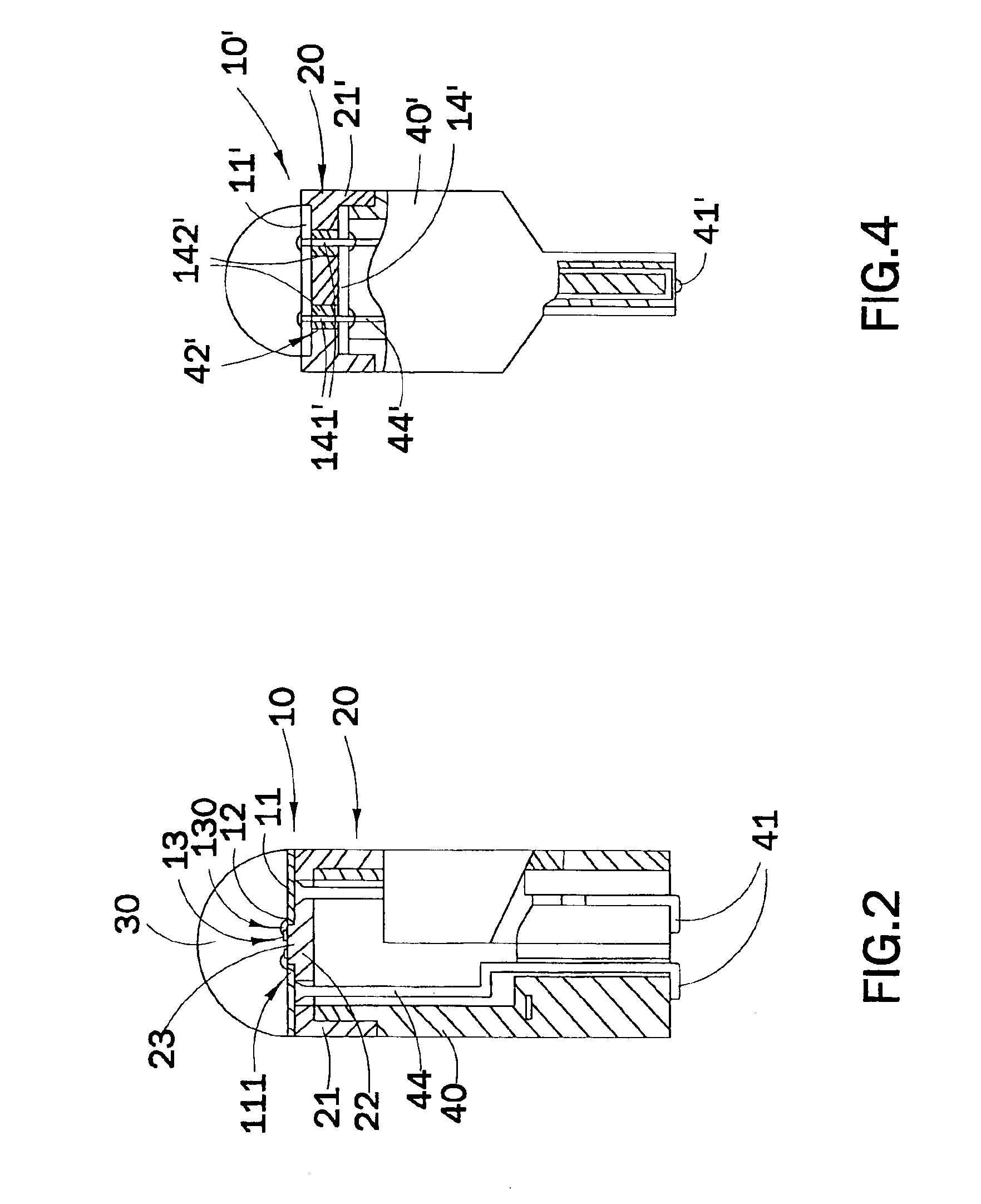

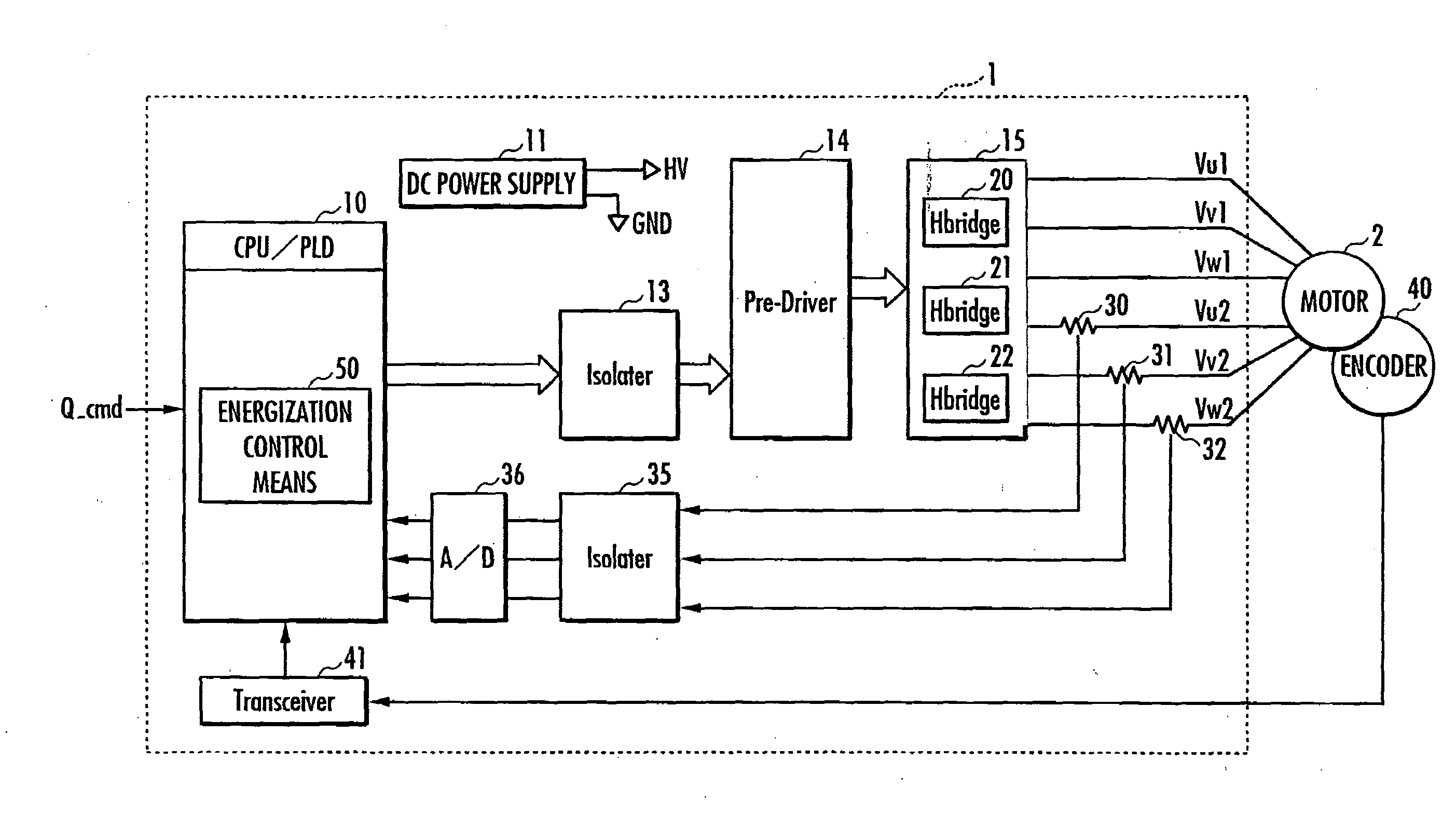

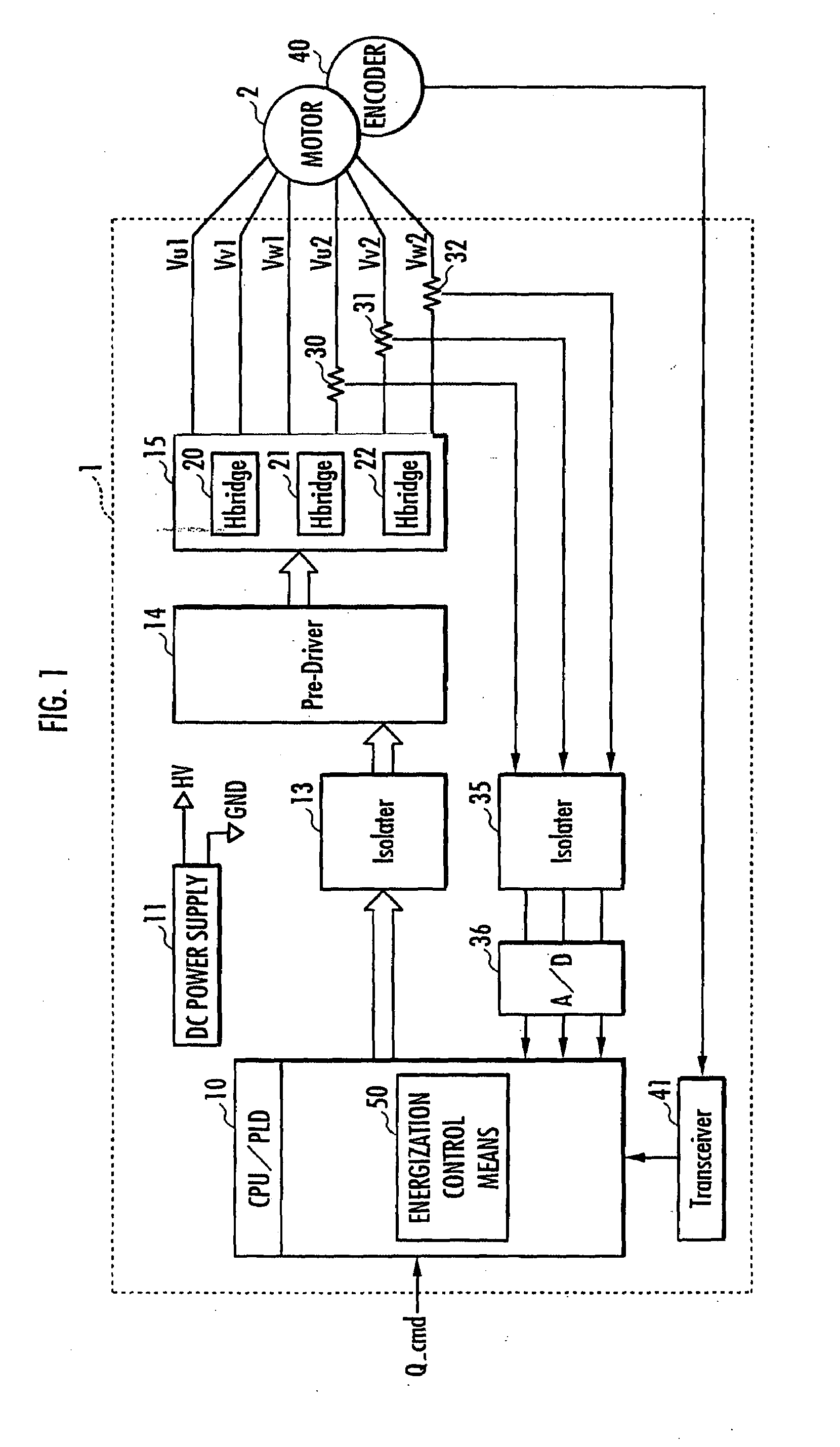

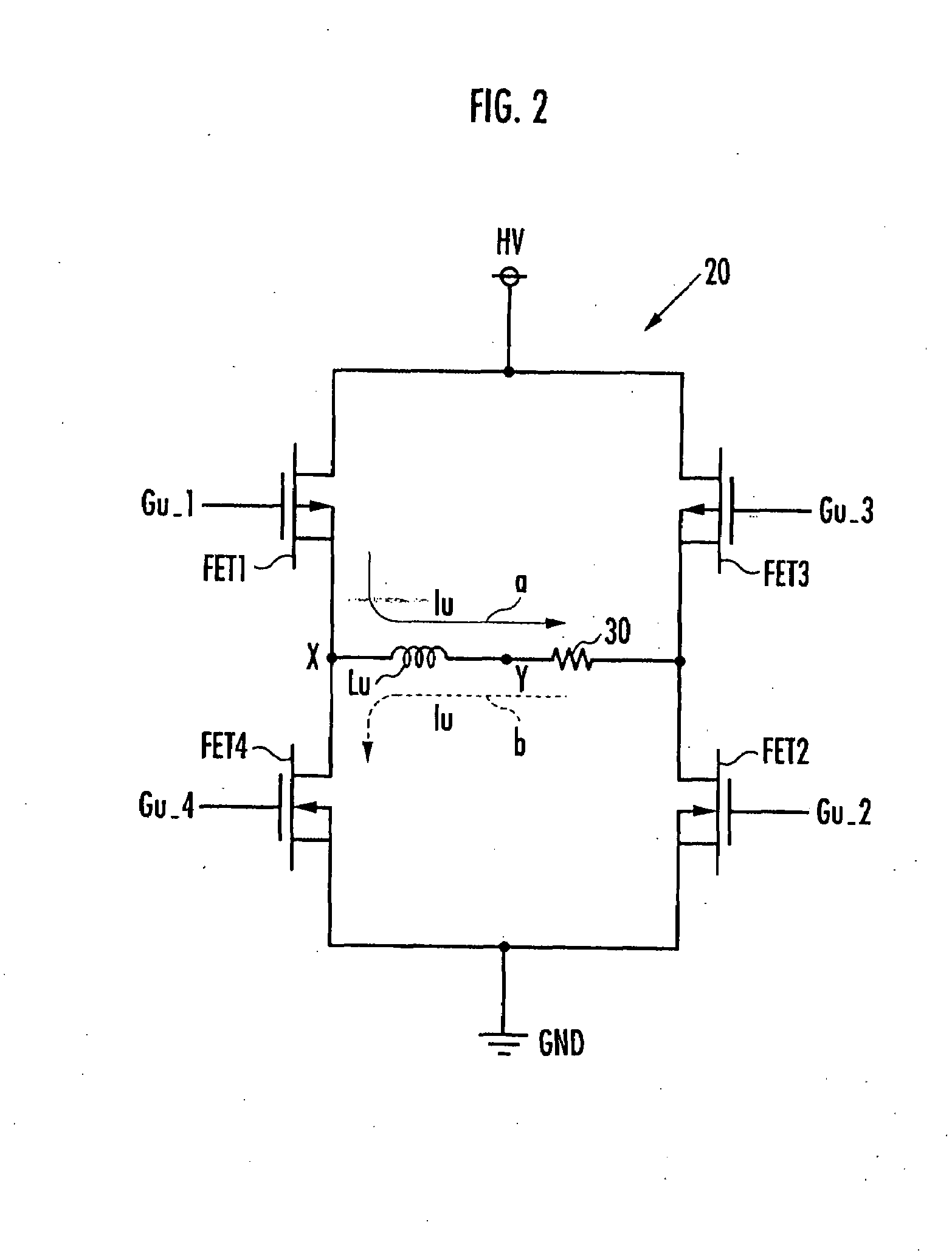

Motor controlling device

InactiveUS20070200515A1Reduce heat generationPrevent degradation of performanceSynchronous motors startersAC motor controlHigh potentialControl unit

To provide a motor controlling device that reduces heat generated by an armature and switching elements when an alternating motor is activated. A motor controlling device includes: an H bridge circuit 20 that has FET1 to FET4 that connect and disconnect a high potential end HV and a low potential end GND of a direct-current power supply to and from an armature Lu; and an energization control unit for controlling the amount of energization of the armature Lu by the PWM control that involves changing the ratio, in a predetermined control cycle, between an energization control period, in which the FET1 and the FET2 are turned on and the FET3 and the FET4 are turned off, or the FET3 and the FET4 are turned on and the FET1 and the FET2 are turned off, and a non-energization control period, in which the FET1 and the FET3 are turned on and the FET2 and the FET4 are turned off, or the FET2 and the FET4 are turned on and the FET1 and the FET3 are turned off.

Owner:HONDA MOTOR CO LTD

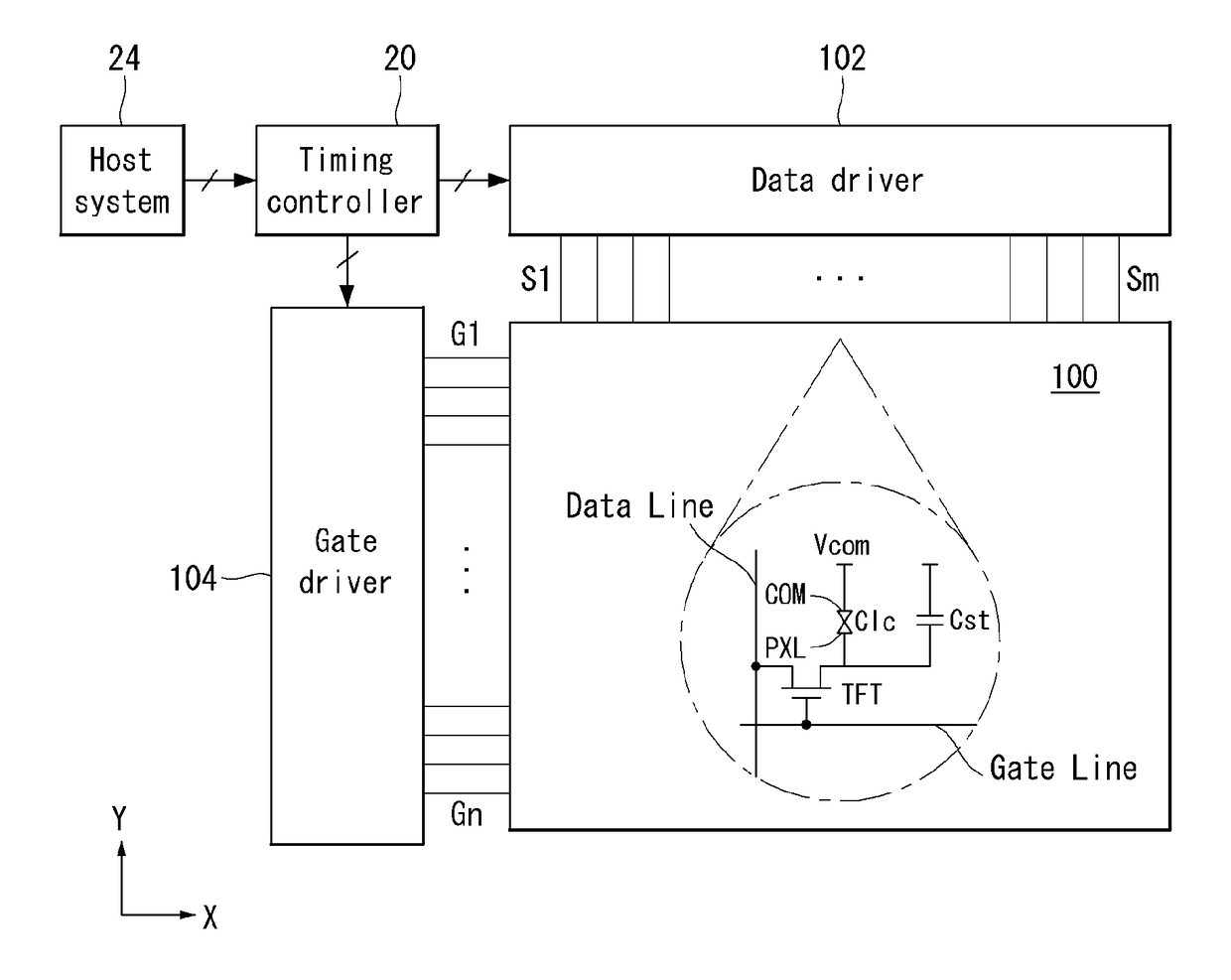

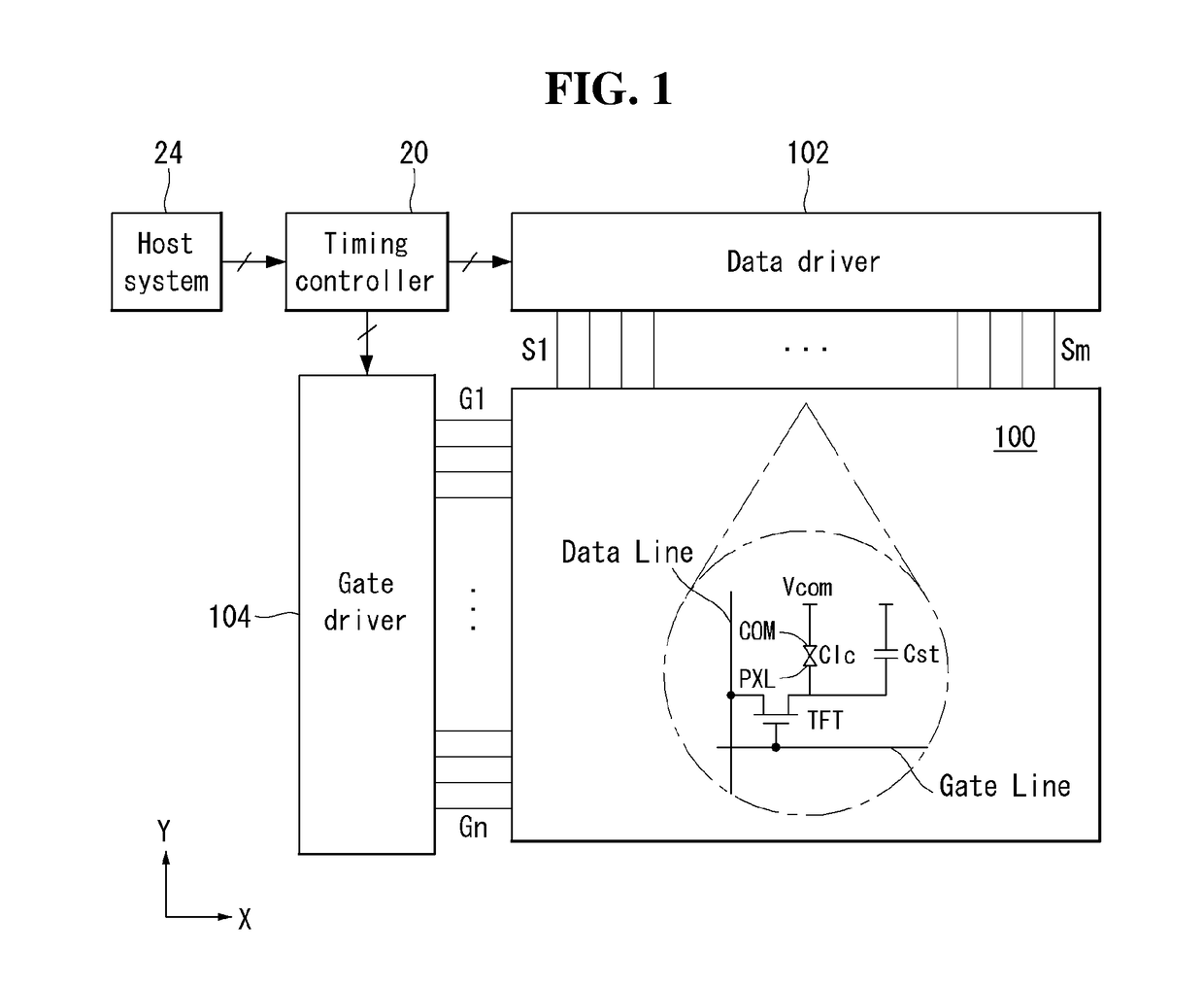

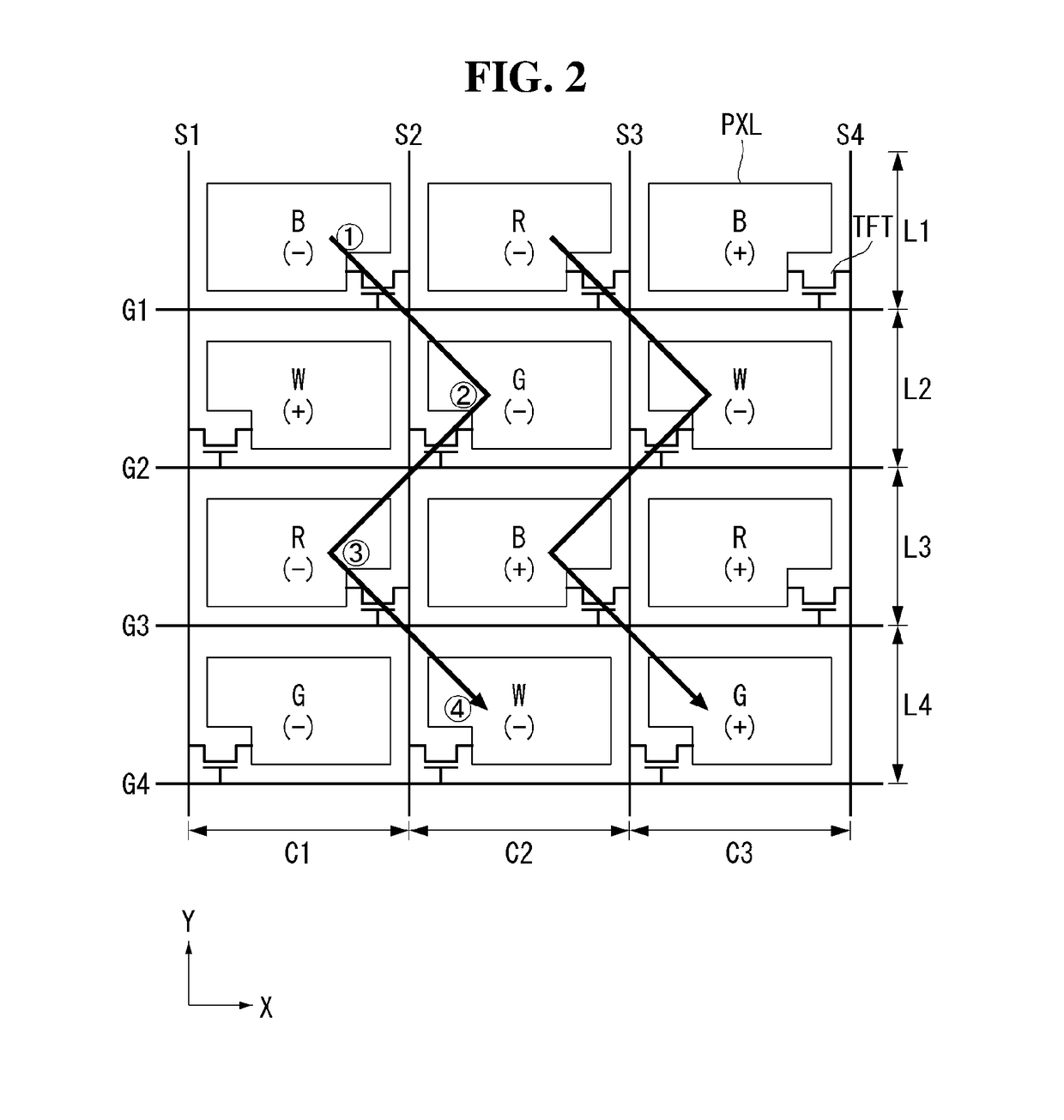

Liquid crystal display device

ActiveUS20170345382A1Reduce heat generationImprove qualityStatic indicating devicesNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal display device includes a plurality of data lines; a plurality of gate lines and a pixel array including a plurality of subpixels formed of first-color to fourth-color subpixels. The plurality of subpixels has a first arrangement or a second arrangement. The first arrangement is an arrangement in which in each row of the pixel array two of the first-color to fourth-color subpixels is interleaved. The second arrangement is a different arrangement than the first arrangement in which in each row of the pixel array two of the first-color to fourth-color subpixels are interleaved. A data driver is configured to drive the pixel array according to a first driving method when the pixel array has the first arrangement and drive the pixel array according to at least one second driving method that is different from the first driving method when the pixel array has the second arrangement.

Owner:LG DISPLAY CO LTD

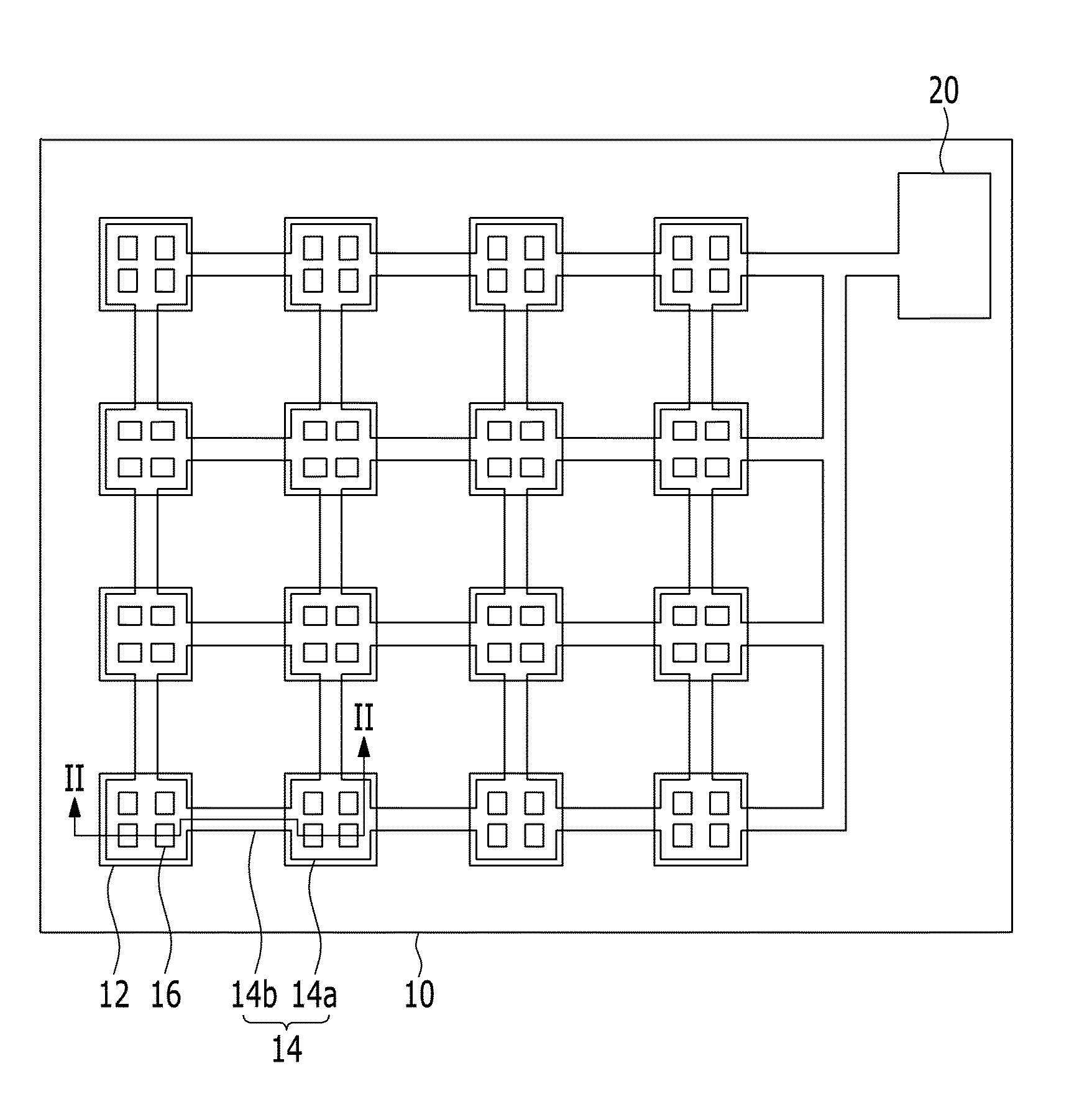

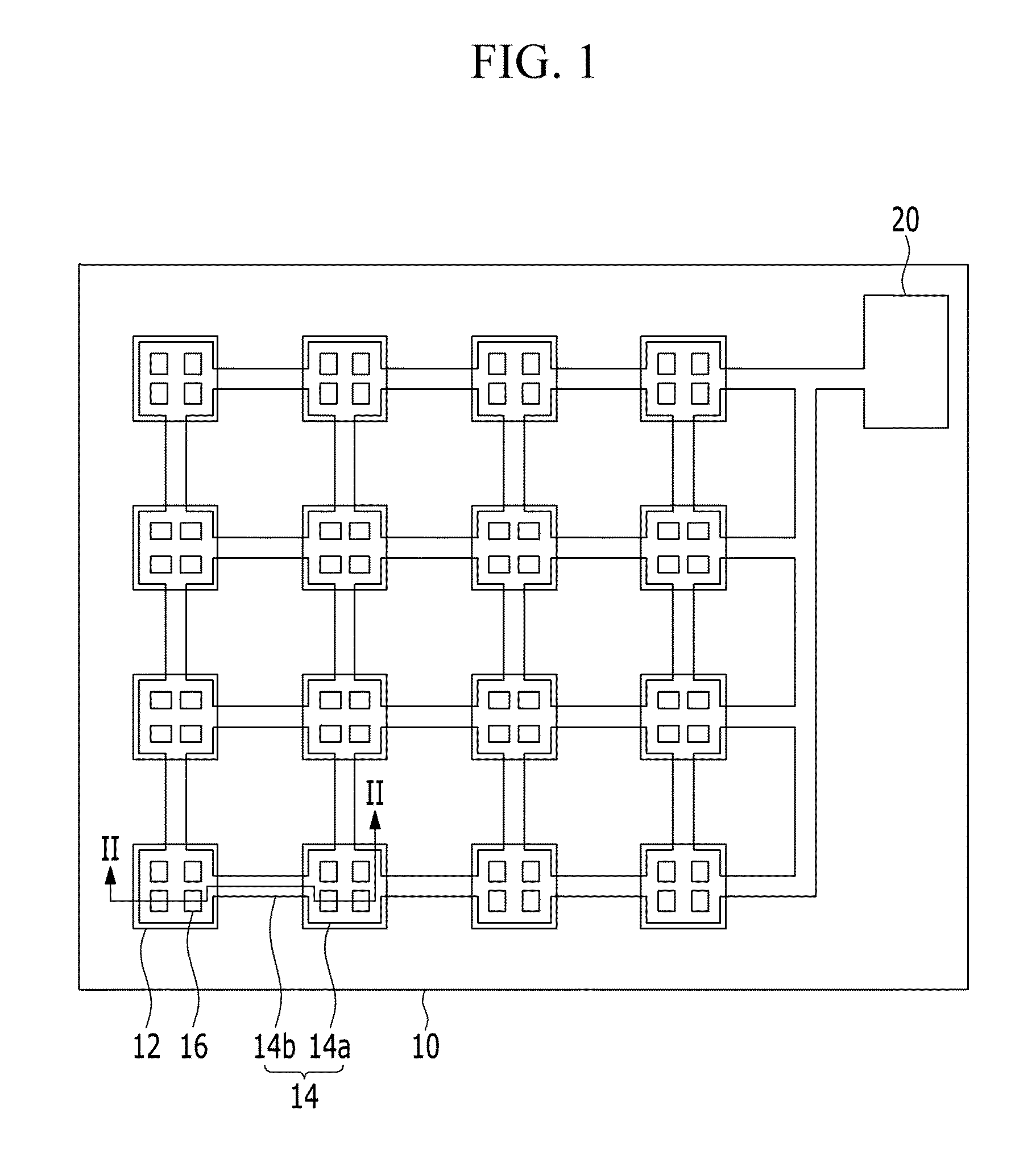

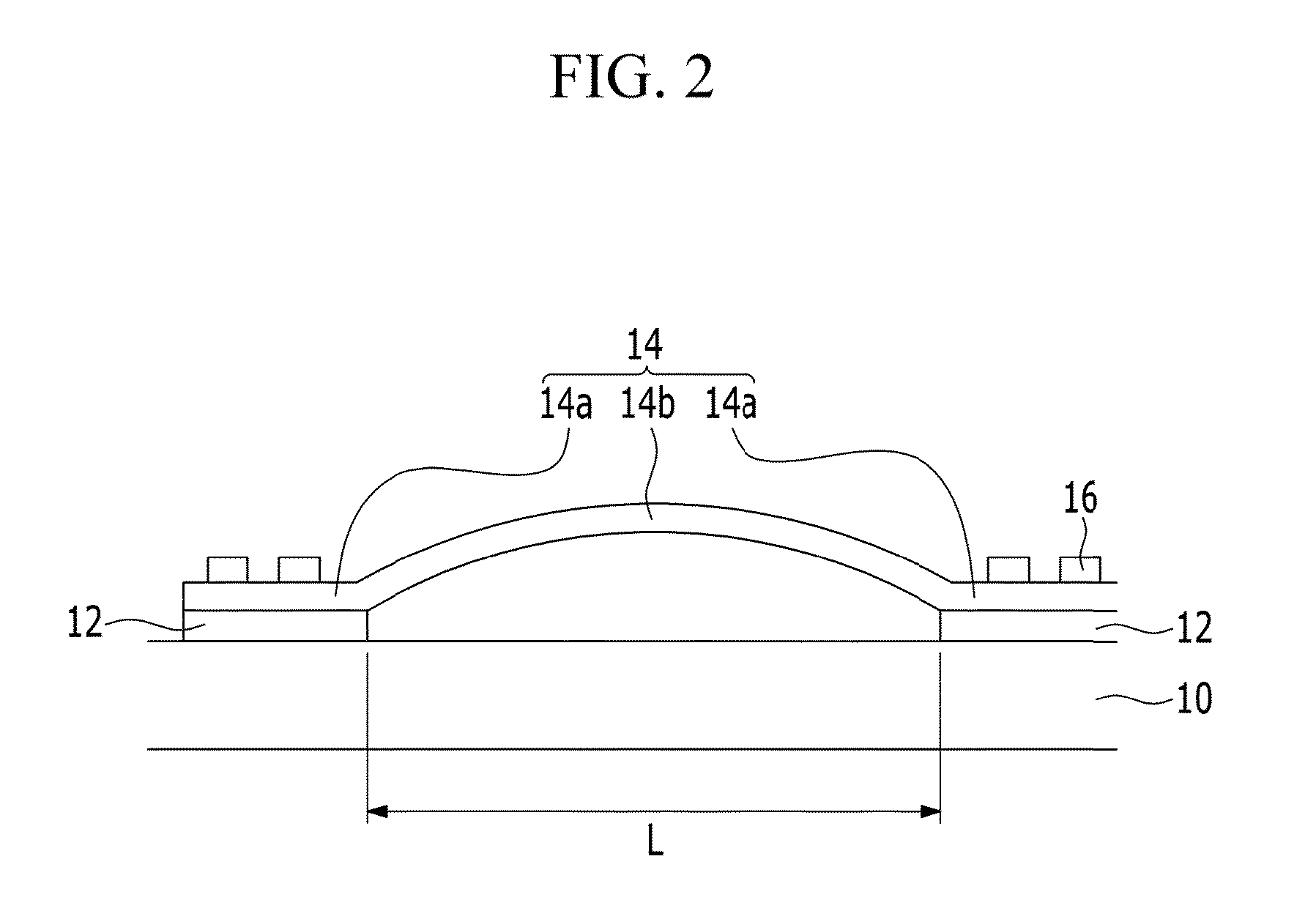

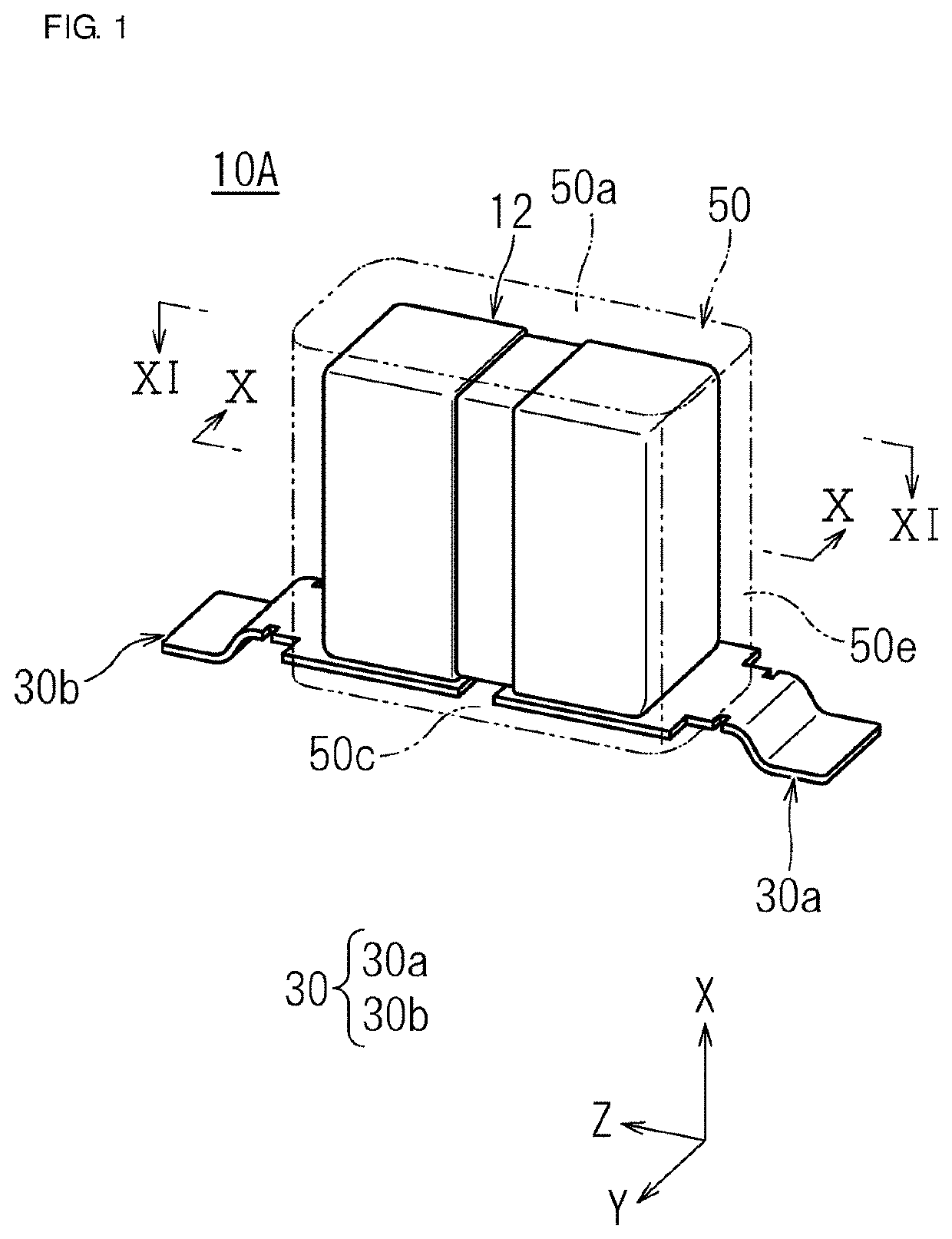

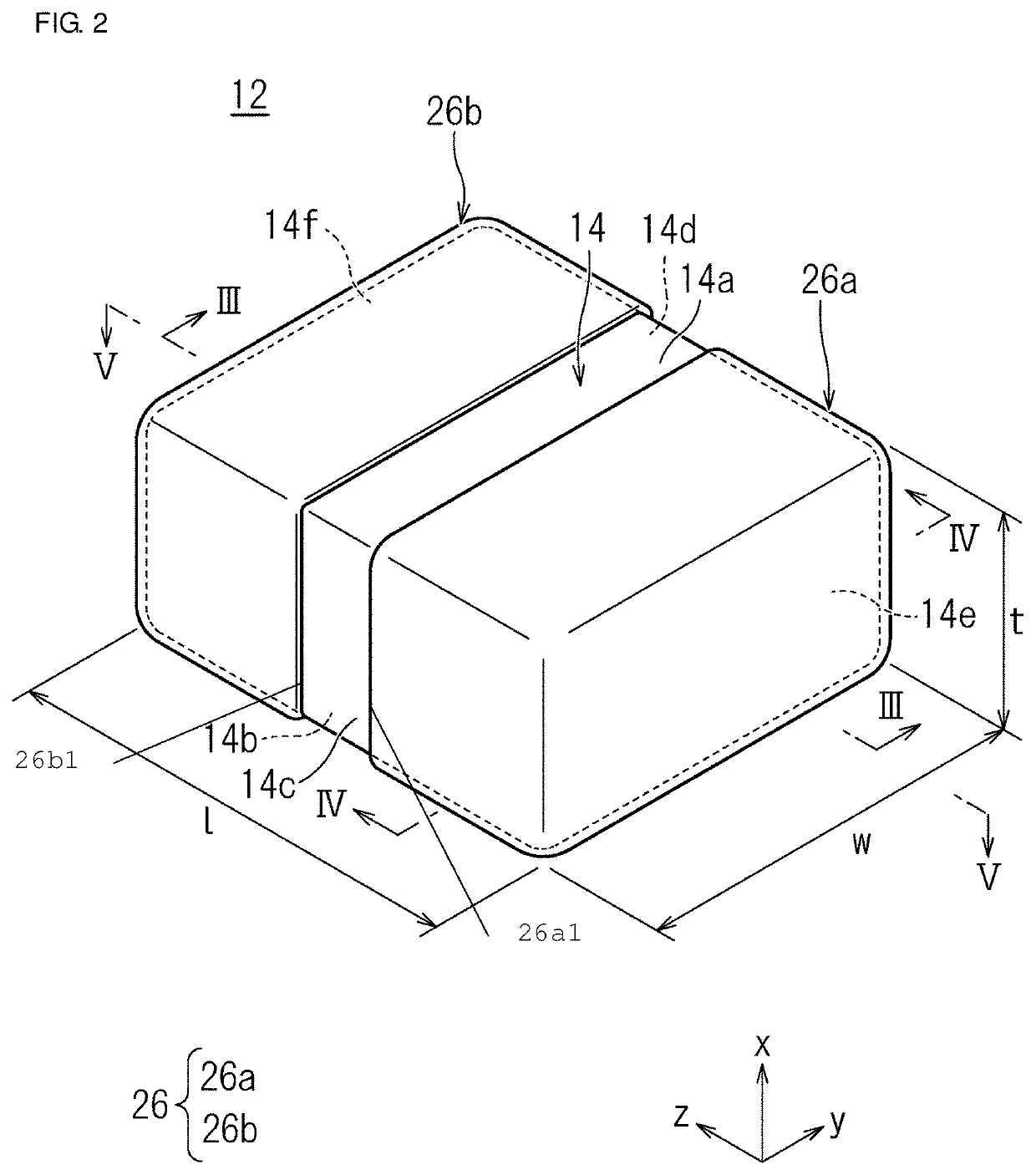

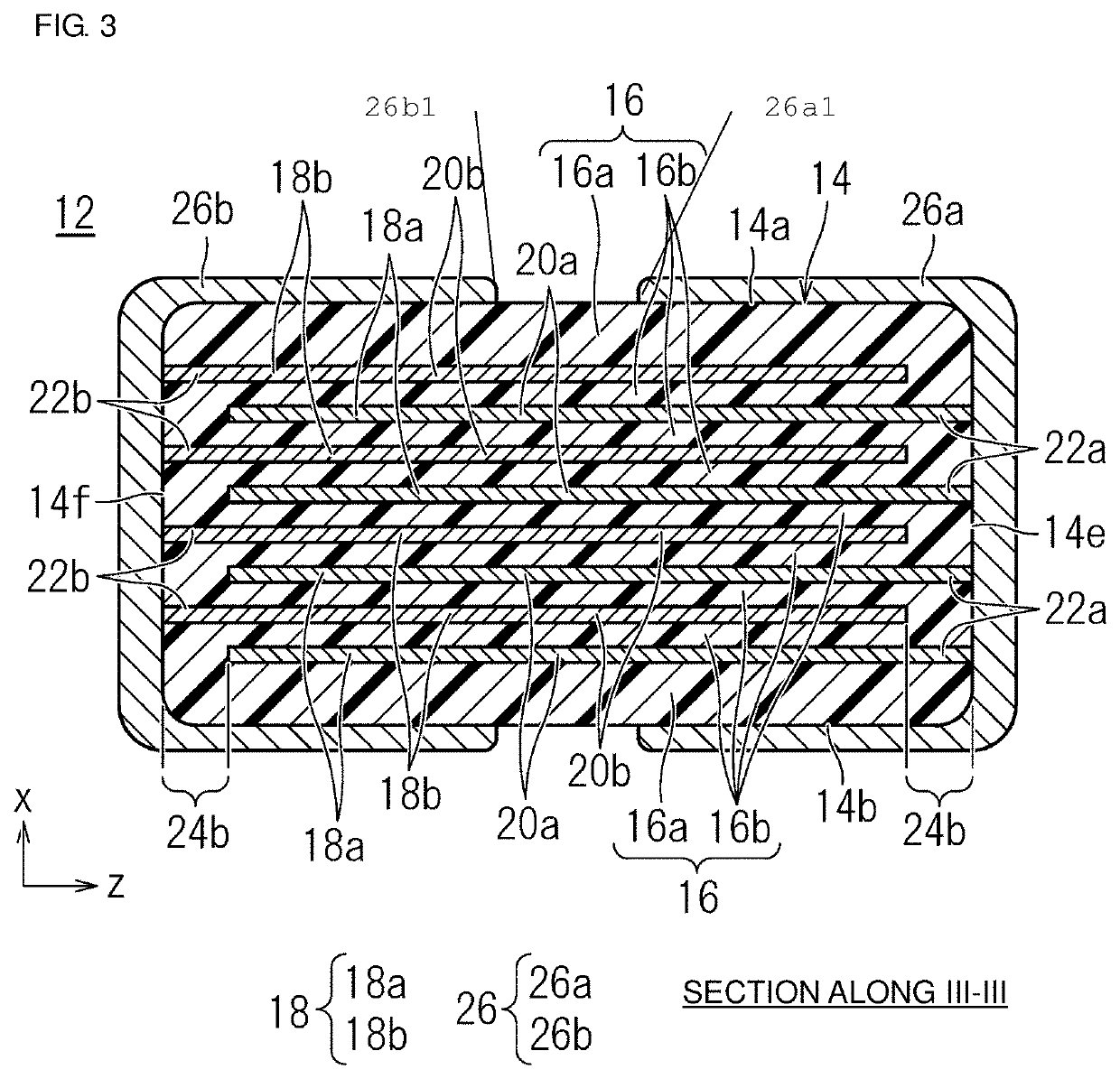

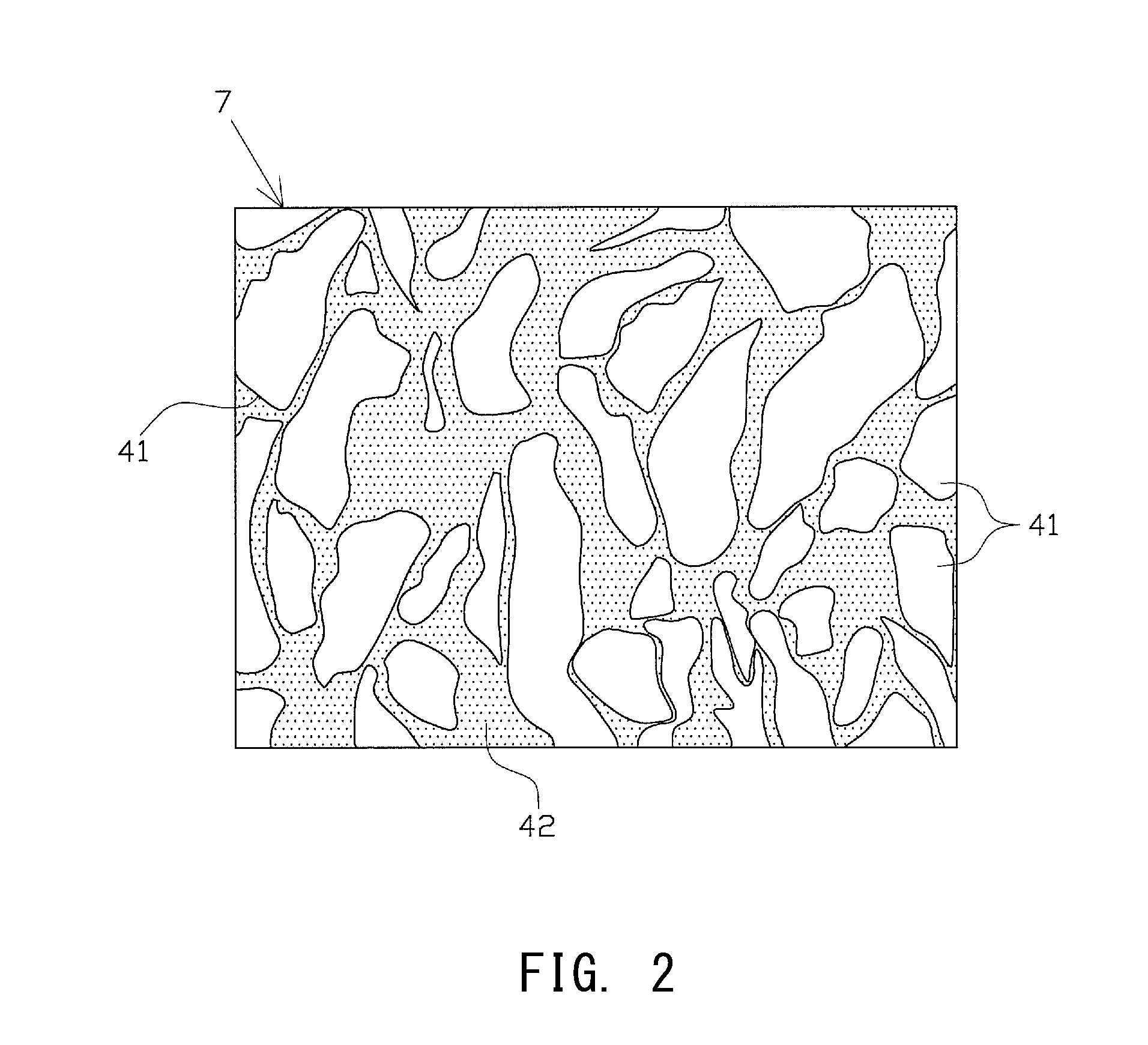

Multilayer ceramic electronic component

ActiveUS20200006002A1Reduce heat generationLow heat generationMultiple fixed capacitorsFixed capacitor electrodesComposite materialElectronic component

A multilayer ceramic electronic component includes a multilayer ceramic electronic component body and a pair of metal terminals. The multilayer ceramic electronic component body includes a multilayer body including laminated ceramic layers and inner electrode layers and first and second outer electrodes provided on both end surfaces of the multilayer body. The metal terminals are connected to the outer electrodes. The inner electrode layers are perpendicular or substantially perpendicular to a mounting surface and include extended portions that extend to the end surfaces and portions of the first and second side surfaces. The distance between ends of the first and second outer electrodes on one of the first and second side surfaces is in a range from about 1.8% to about 31.3% of a length dimension of the multilayer ceramic electronic component in a direction connecting both end surfaces of the multilayer ceramic electronic component body.

Owner:MURATA MFG CO LTD

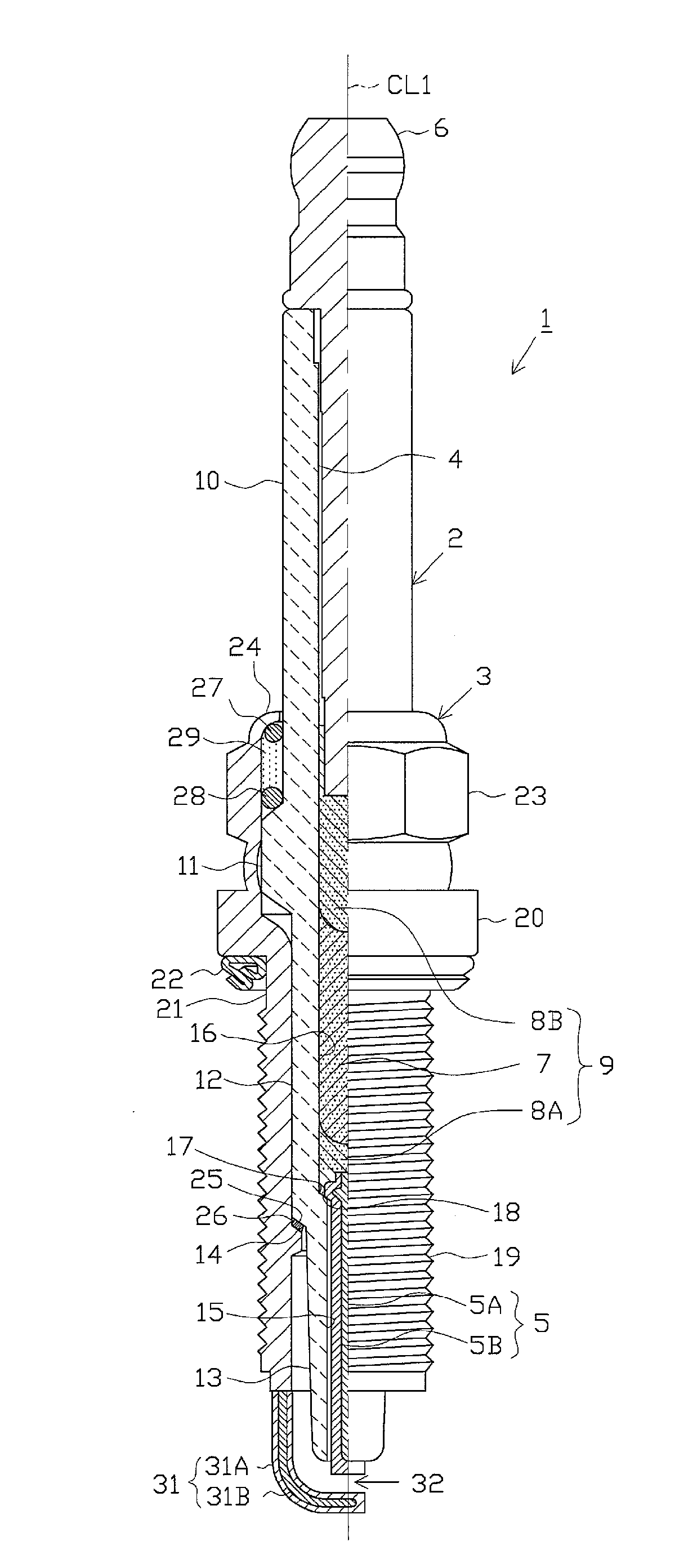

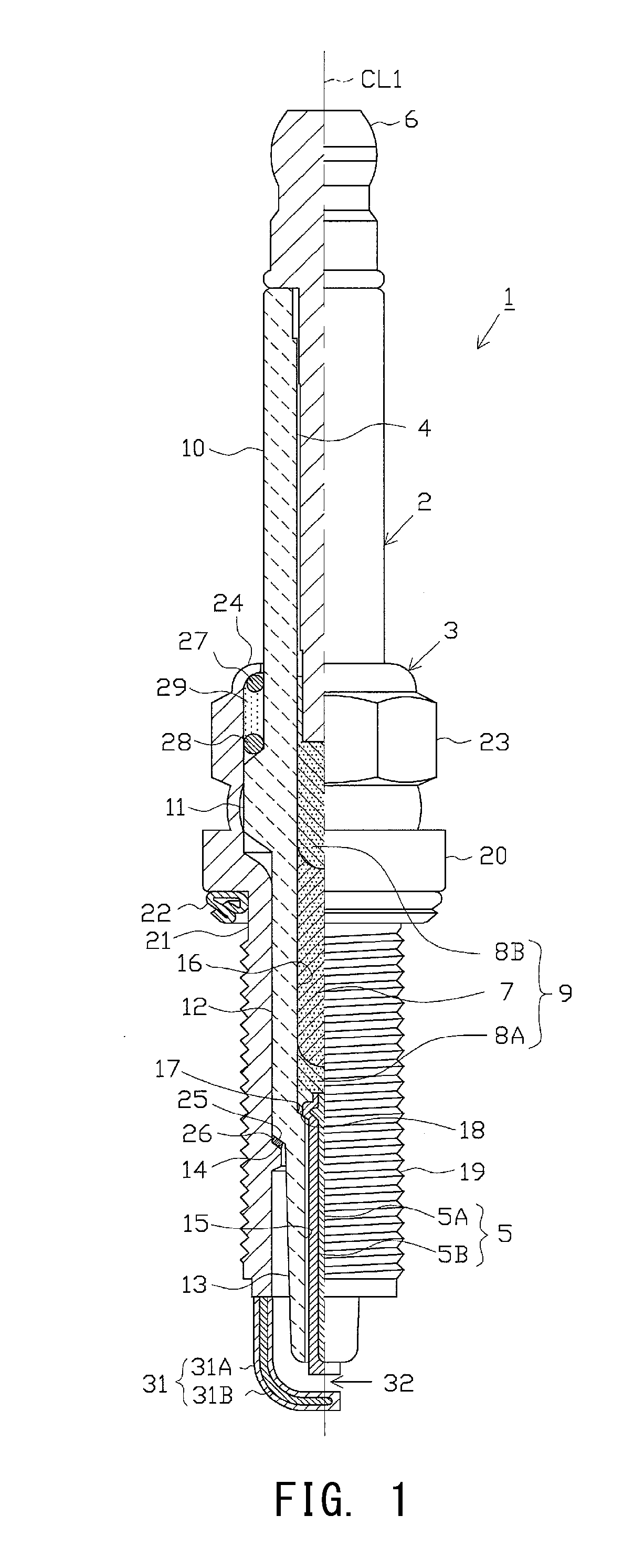

Spark plug

ActiveUS20160204580A1Reduce heat generationRestrain cohesionSparking plugsElectrically conductiveEngineering

A spark plug includes an insulator having an axial hole, a center electrode inserted into a forward portion of the axial hole, a terminal electrode inserted into a rear portion of the axial hole, and an interelectrode insert which contains glass and electrically conductive carbon and is disposed in the axial hole between the center electrode and the terminal electrode. The interelectrode insert has a resistance of 1.0 kΩ to 3.0 kΩ, and the interelectrode insert has a carbon content of 1.5% by mass to 4.0% by mass at a forward portion located forward of a center point between the rear end of the center electrode and the forward end of the terminal electrode. Furthermore, the forward portion is lower in resistance than a rear portion of the interelectrode insert located rearward of the center point.

Owner:NGK SPARK PLUG CO LTD

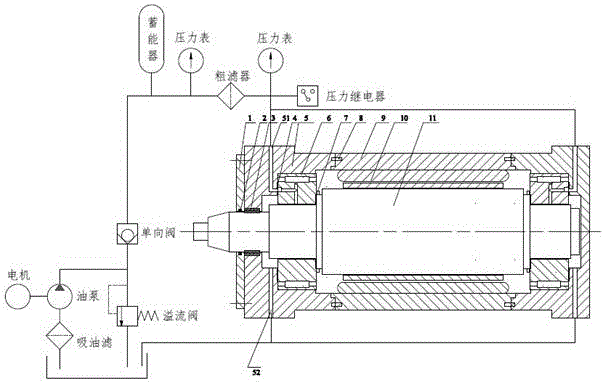

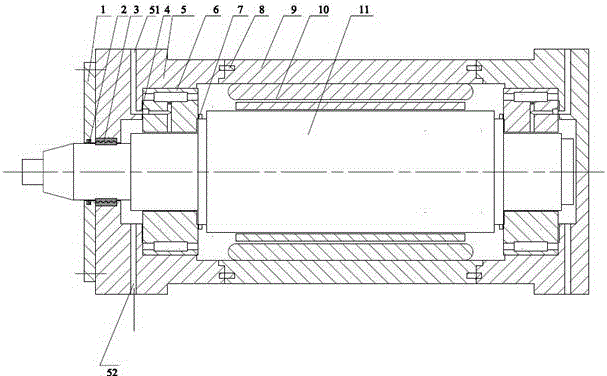

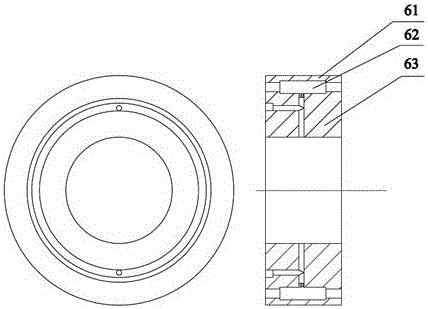

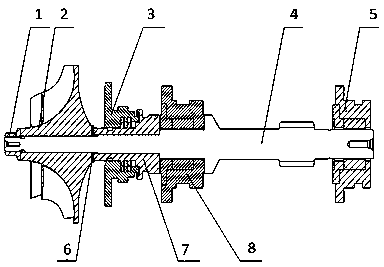

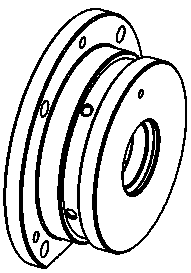

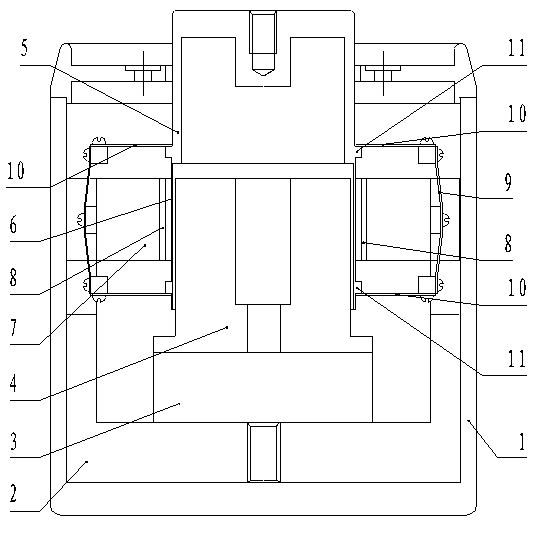

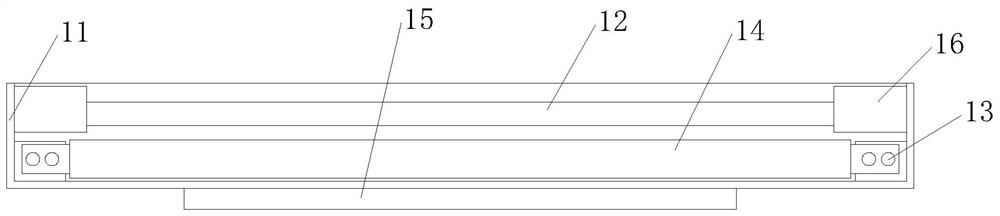

High-speed motorized spindle with composite bearing

ActiveCN106112022AIncrease absolute speedReduce heat generationLarge fixed membersLubricationEngineering

The invention relates to a high-speed motorized spindle with a composite bearing. The high-speed motorized spindle with the composite bearing comprises a sealing end cover, an outer sealing ring, an inner sealing ring, a sealing ring made of a special material, a bearing block, the composite bearing, a sealing ring, keys, a motorized spindle shell, a motorized spindle coil and a rotor. The motorized spindle coil is arranged in the motorized spindle shell. The rotor is mounted in the motorized spindle shell. The composite bearing is mounted in the bearing block. The sealing ring made of the special material is arranged between the composite bearing and the bearing block. The bearing block is positioned on the two sides of the motorized spindle shell through the keys. The bearing block and the motorized spindle shell are concentric. The sealing ring is arranged between the composite bearing and the rotor. The inner sealing ring is arranged between the bearing block and the rotor. The sealing end cover is fixed to the bearing block. The outer sealing ring is arranged between the sealing end cover and the rotor. By adopting the high-speed motorized spindle with the composite bearing, the absolute rotating speed of a shaft is greatly increased, and heat generated by lubricating fluid is reduced, so that the lubrication effect of the bearing is improved, and abrasion to the sealing rings is greatly relieved. Double-layer sealing is adopted for a sealing device, and the sealing effect is good.

Owner:SHANGHAI UNIV

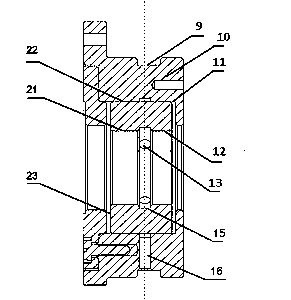

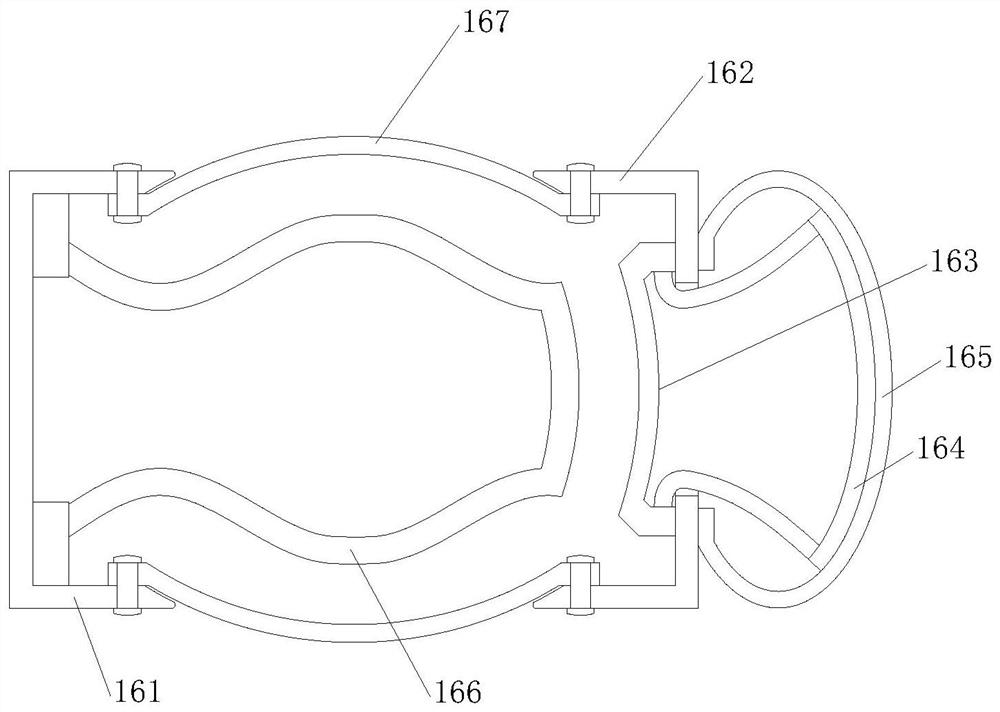

High-speed floating ring bearing and rotor system support manner

ActiveCN109027002AReduce heat generationReduce oil supplyLiquid cushion bearingsMechanical energy handlingHollow cylinderDynamic pressure

The invention discloses a high-speed floating ring bearing sleeving a rotor. The high-speed floating ring bearing comprises a bearing block and a floating ring. The bearing block is of a hollow cylinder structure. The floating ring is arranged in the hollow cylinder structure. When the rotor runs, the floating ring and the rotor relatively rotate, and the bearing block is provided with a bearing block oil passing hole and a bearing block oil passing groove. The floating ring is provided with a floating ring oil passing hole and a floating ring oil groove. Lubricating media enter the bearing block oil passing groove through the bearing block oil passing hole and enter the floating ring oil groove through the floating ring oil passing hole, and when the rotor rotates, a dynamic pressure oilfilm is formed to support the rotor. A high-speed floating ring bearing-rotor supporting system comprises the above high-speed floating ring bearing, and further comprises a floating ring and thrust combined bearing, a rotor system and an oil supply system.

Owner:湖南泛航智能装备有限公司

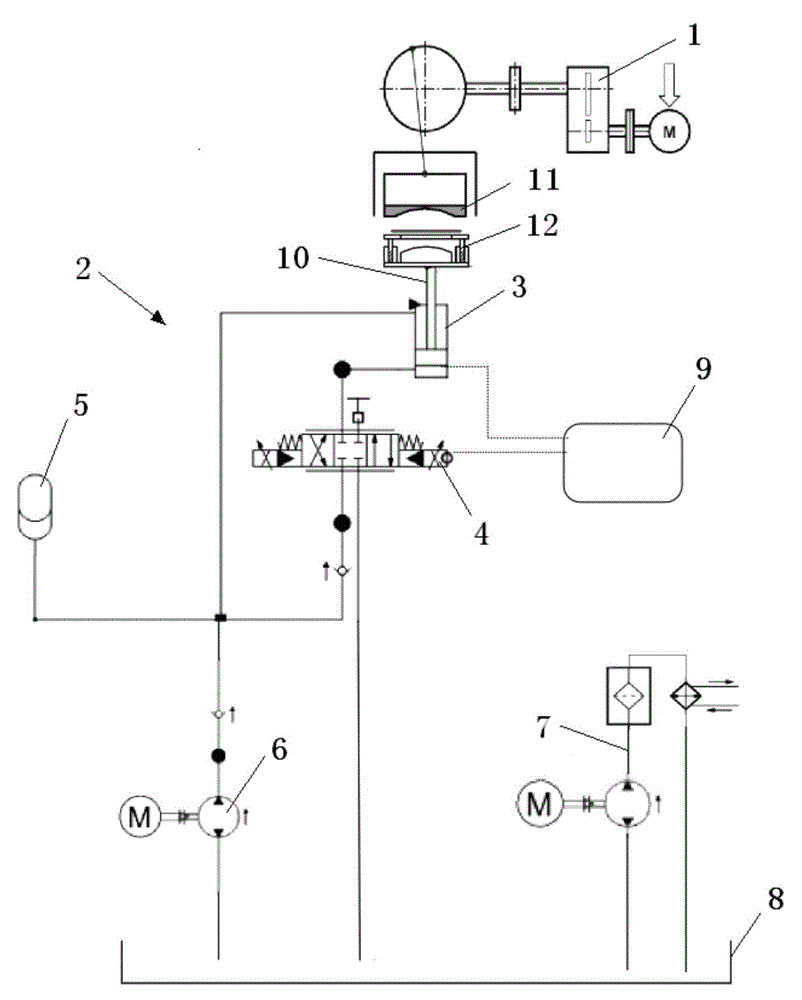

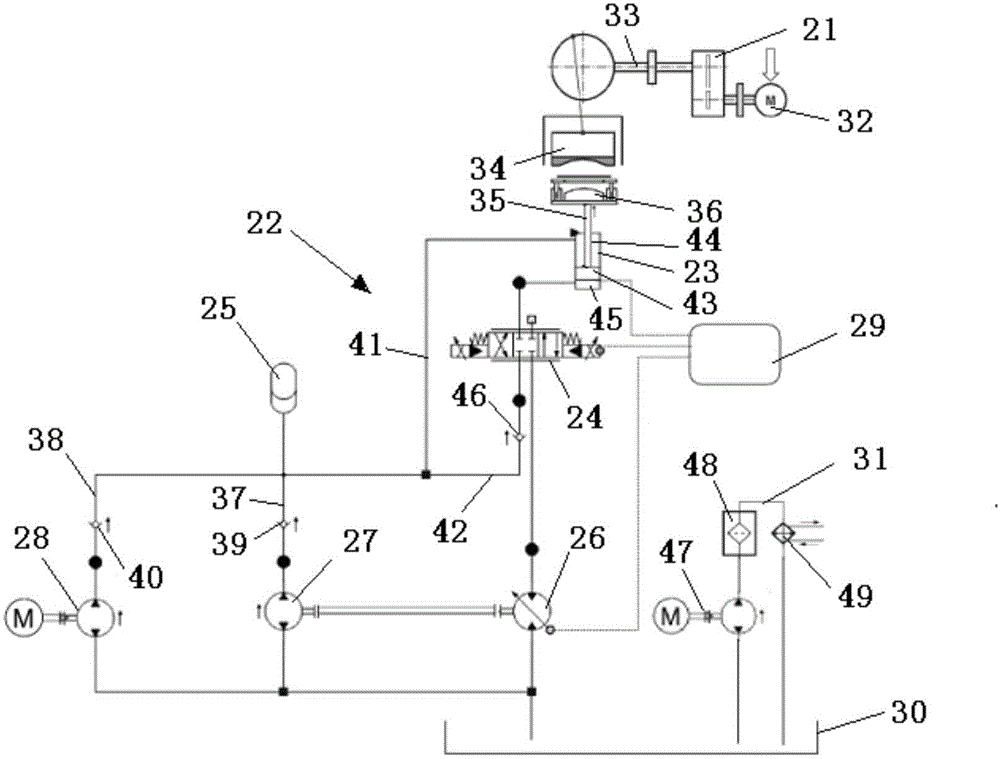

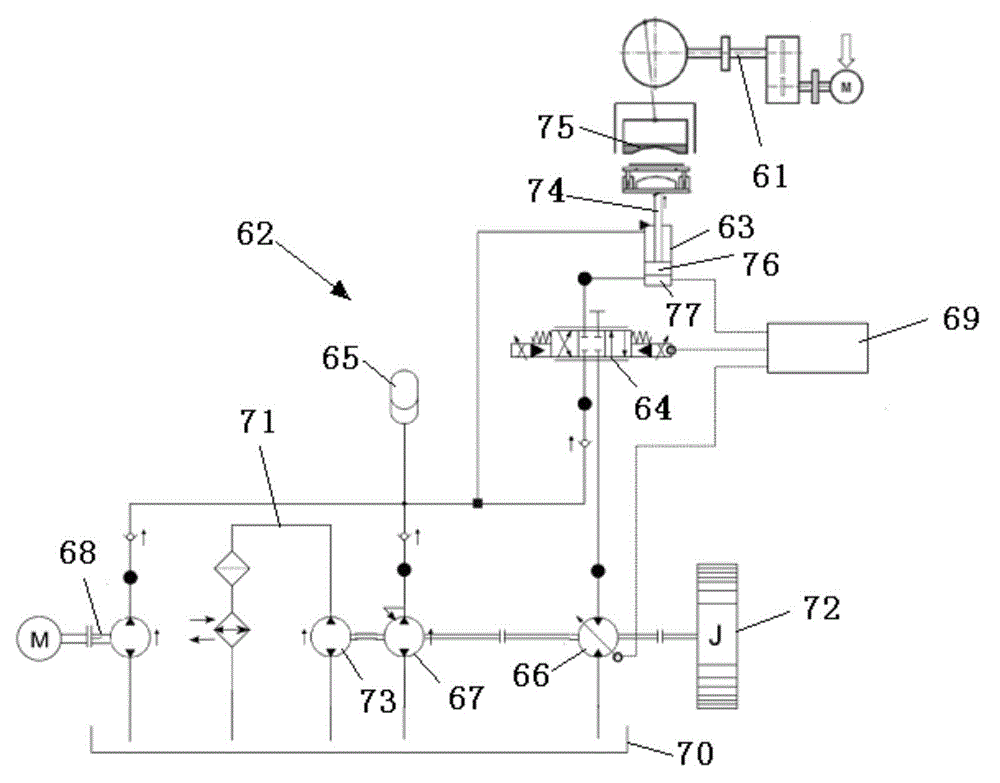

Hydraulic buffering system and equipment comprising hydraulic buffering system

ActiveCN105276075AImprove energy efficiencyReduce heat generationServomotorsVibration suppression adjustmentsControl engineeringHydraulic connection

The invention discloses a hydraulic buffering system. The hydraulic buffering system comprises an oil tank, a hydraulic cylinder suitable for receiving external action force, a main pump unit in hydraulic coupling with the hydraulic cylinder, an auxiliary pump unit, energy accumulators, and a hydraulic motor, wherein the auxiliary pump unit is in hydraulic coupling with the hydraulic cylinder and used for making the hydraulic cylinder be in an initial position to get ready for receiving the external action force when the hydraulic buffering system is started; the energy accumulators are in hydraulic connection with the main pump unit as well as with the auxiliary pump unit and used for accumulating hydraulic oil pressurized by the main pump unit and the auxiliary pump unit; the hydraulic motor is in drive connection with the main pump unit and in hydraulic coupling with the hydraulic cylinder, and when the hydraulic oil in the hydraulic cylinder is squeezed to flow through the hydraulic motor due to the external action force, the hydraulic motor is driven to drive the main pump unit to rotate to fill the energy accumulators. The invention further discloses equipment comprising the hydraulic buffering system. The hydraulic buffering system is high in energy utilization efficiency and capable of reducing the operation cost at the same time.

Owner:BOSCH REXROTH (CHANGZHOU) CO LTD

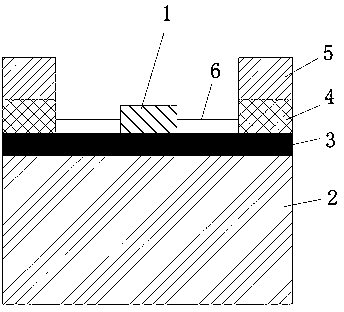

LED device based on glass substrate and preparation method of LED device

InactiveCN103346242AReduce heat generationGood adhesion and conductive propertiesSemiconductor devicesDlc coatingLight source

The invention provides an LED device based on a glass substrate and a preparation method of the LED device. The device comprises the glass substrate. A DLC coating on the glass substrate is prepared through a vapor deposition technology, an LED chip and electrodes are arranged above the DLC coating, and the LED chip and the electrodes are electrically communicated through wires. The LED device based on the glass substrate and the preparation method of the LED device have the advantages that common glass is used as the substrate of an LED circuit board, completely circumferential light emission of a light source can be achieved, the defect that due to the fact that a traditional substrate is light tight, the light source can only emit light within the angle of 180 degrees is overcome, the light can be fully utilized, and heat generation is reduced. By the adoption of the vapor deposition technology for manufacturing circuits on the glass substrate, the good adhesiveness and conduction characteristics of the circuits are ensured, and meanwhile due to the fact that a layer of diamond-like materials is deposited on the glass substrate, the heat transmission capacity of the LED circuit board is greatly improved.

Owner:苏州热驰光电科技有限公司 +1

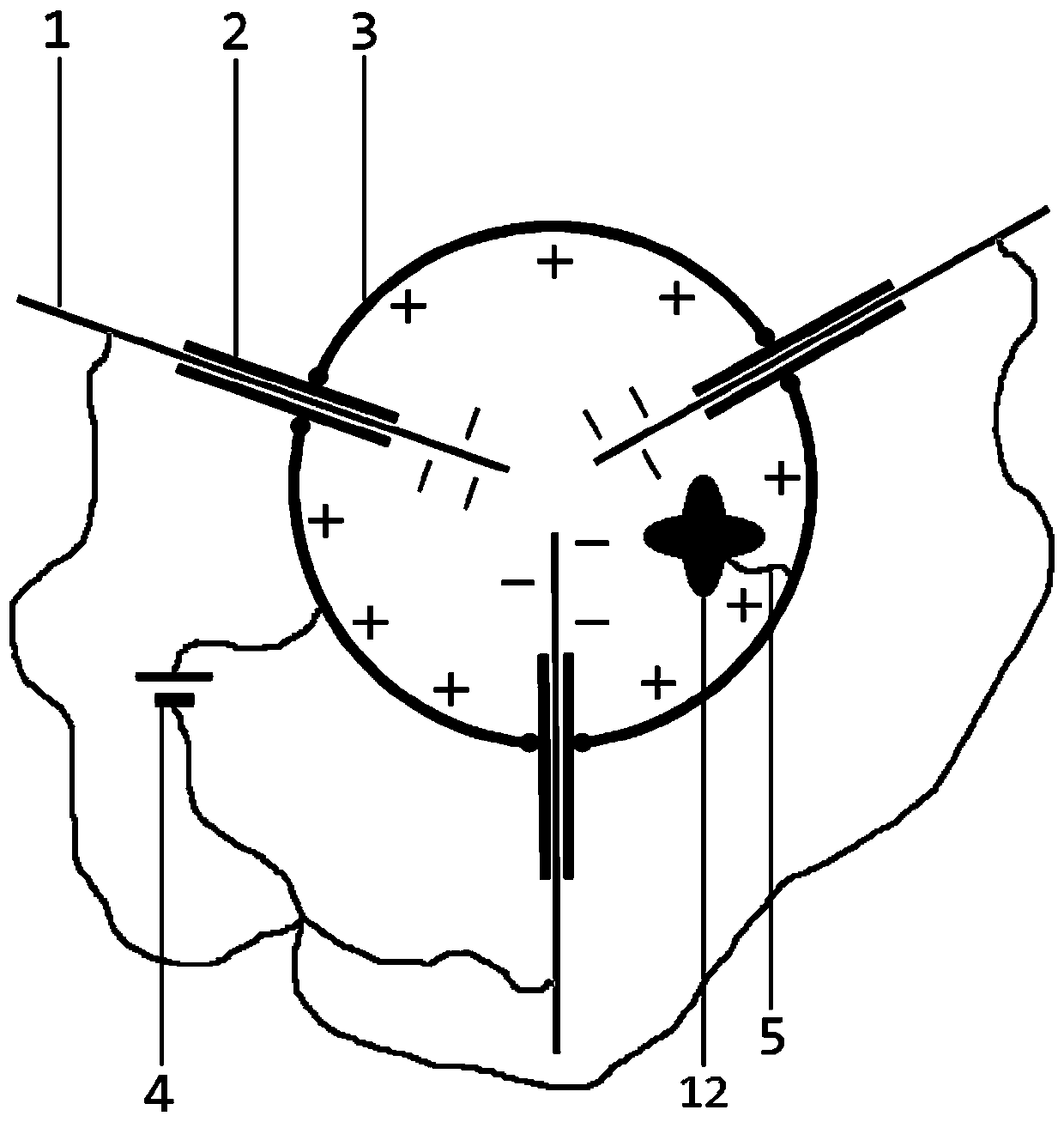

Anti-fatigue permanent magnetic vibration table

ActiveCN103831226AReduce resistanceReduce heat generationMechanical vibrations separationPhysicsLap joint

The invention discloses an anti-fatigue permanent magnetic vibration table which comprises an outer cover. A permanent magnet is arranged at the bottom of the outer cover and provided with a magnet core. A vibration column is connected with a gap outside the magnet core in a sleeved mode and extends out of the outer cover. An electromagnetic coil is arranged outside the position, coinciding with the magnet core, of the bottom of the vibration column. A support fixed to the outer cover is connected with a gap outside the vibration column in a sleeved mode. Vertical spring pieces which are vertically arranged are evenly distributed on the periphery of the support. The two ends of the vertical spring pieces are connected with horizontal spring pieces. The two layers of horizontal spring pieces are connected with an upper step arranged outside the vibration column and a lower step arranged outside the vibration column in a lap joint mode. The spring pieces are connected with the vibration column in a lap joint mode, and therefore resistance of the spring pieces to the vibration column is reduced, generated heat is reduced, limitation on the freedom degree of the spring pieces is reduced as well, and the service life of the spring pieces is prolonged; the two layers of horizontal spring pieces well guide the vibration column, and therefore the moving track of the vibration column is stable, and the service life of the vibration table is prolonged.

Owner:YMC PIEZOTRONICS

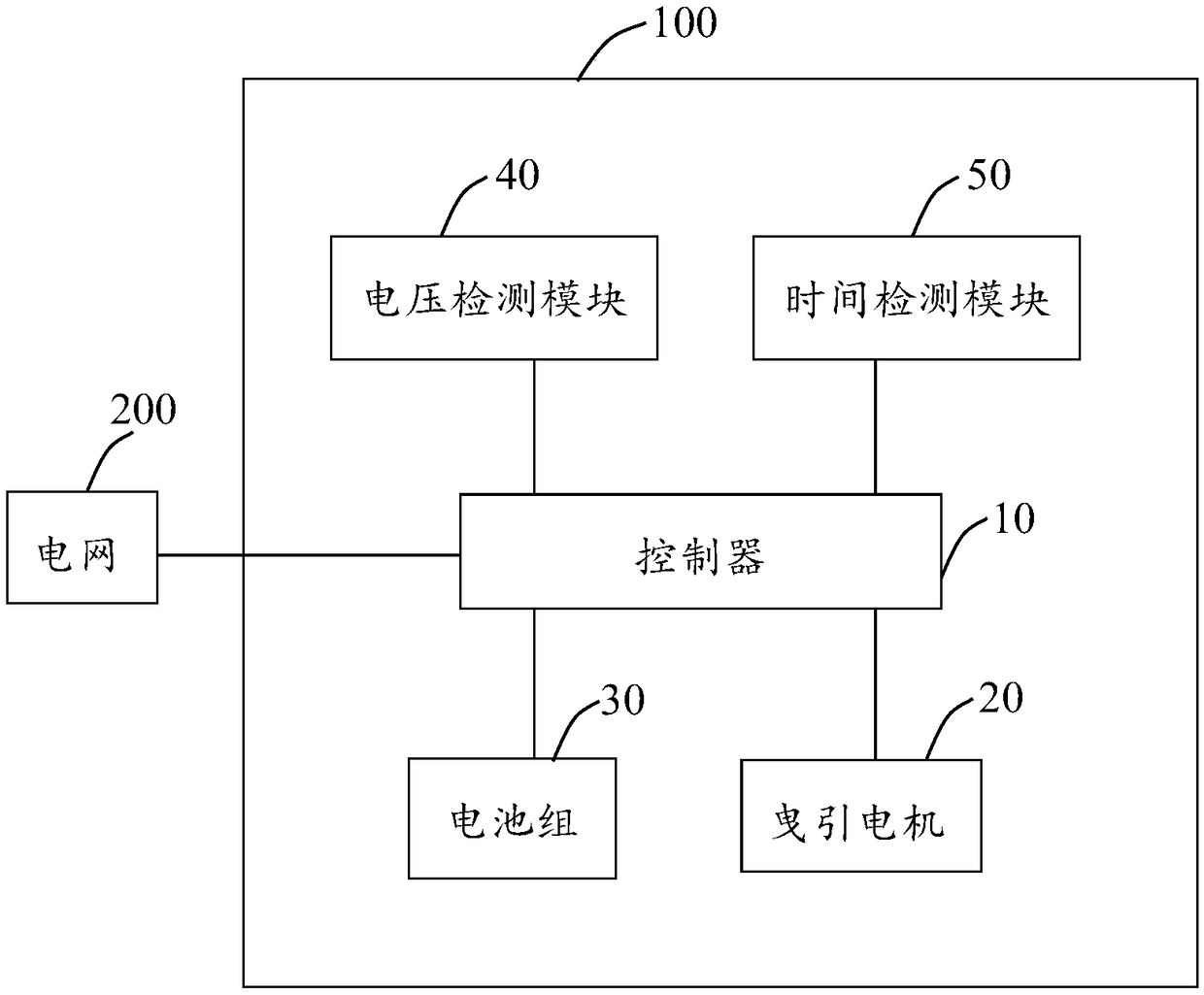

Elevator energy-saving device

InactiveCN108390449AAvoid the Use of Dissipating ResistorsReduce heat generationBatteries circuit arrangementsElectric powerTraction motorPower grid

The invention provides an elevator energy-saving device. The elevator energy-saving device is connected with a power network, and comprises a controller, a traction motor and a battery pack; one end of the controller is connected with the power network, and the other end of the controller is connected with the traction motor and the battery pack; the controller is used for rectifying and invertingalternating current output by the power network to output the rectified and inverted alternating current to the traction motor for driving the traction motor to work; the controller is also used forcontrolling the power network to charge the battery pack; when an elevator is in the descending running state, the controller is also used for modulating alternating current generated by the tractionmotor into direct current to output the direct current to the batter pack for storage. According to the elevator energy-saving device, the elevator running safety is improved while energy is saved.

Owner:深圳市博德科创新能源技术有限公司

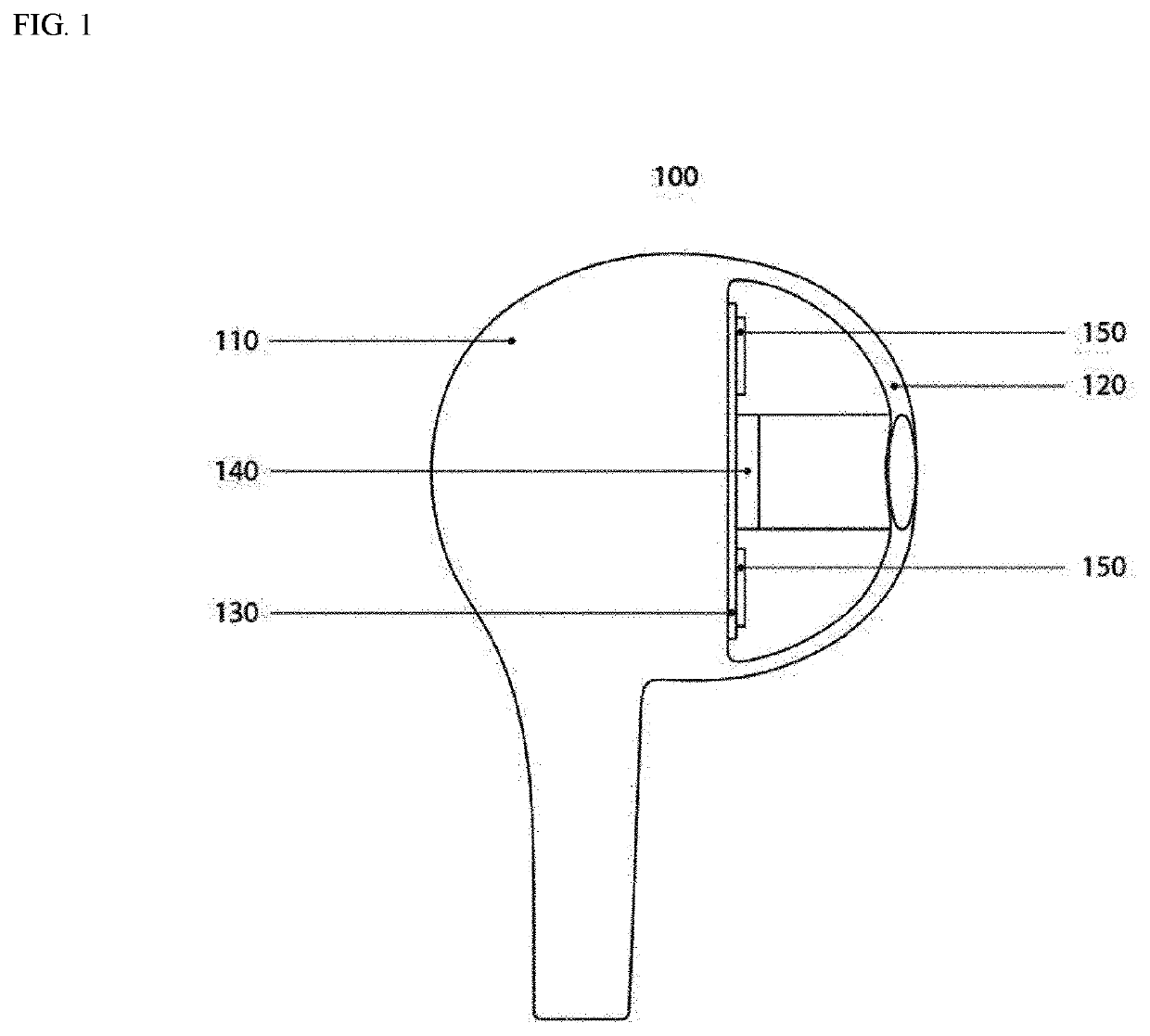

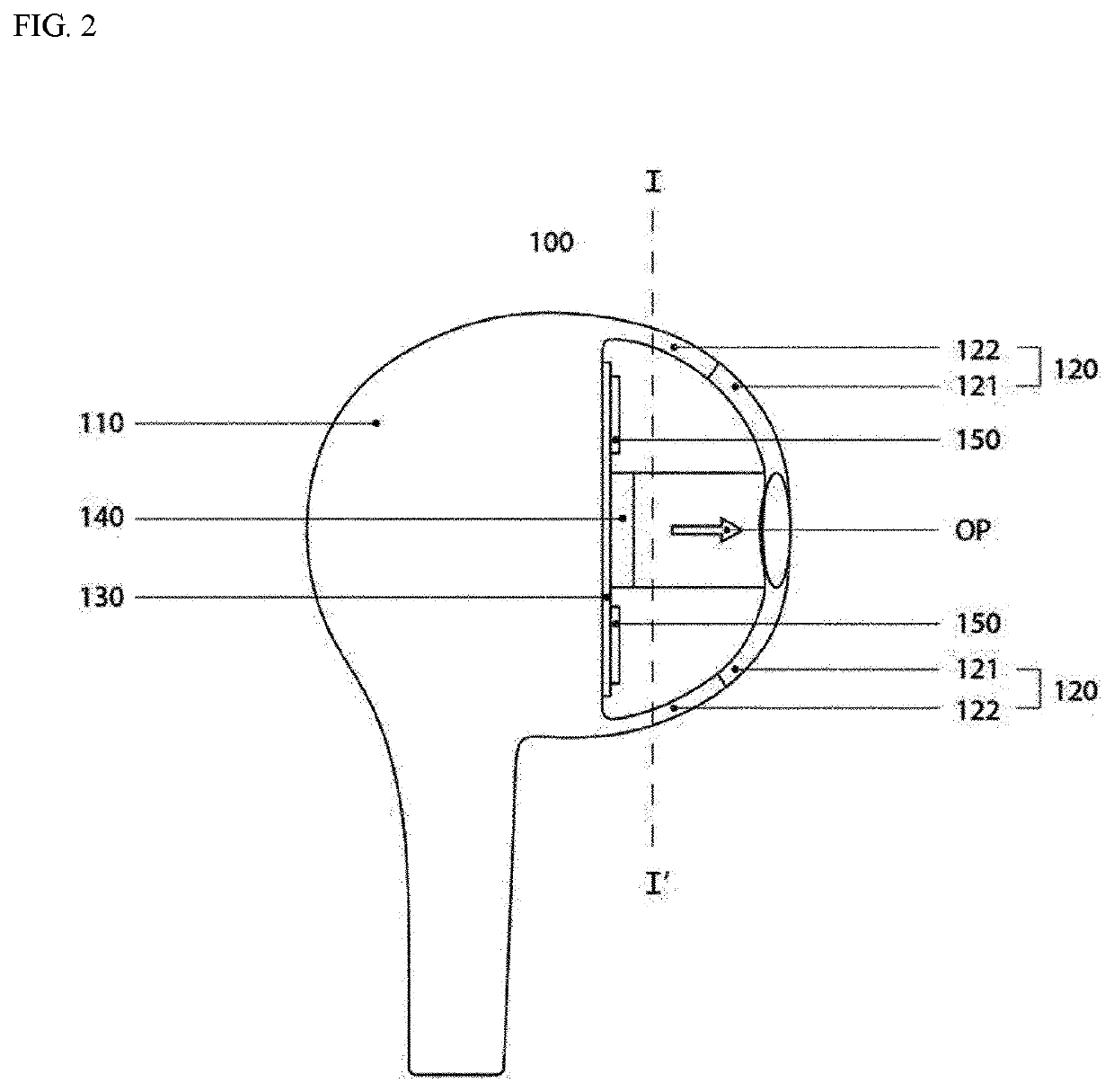

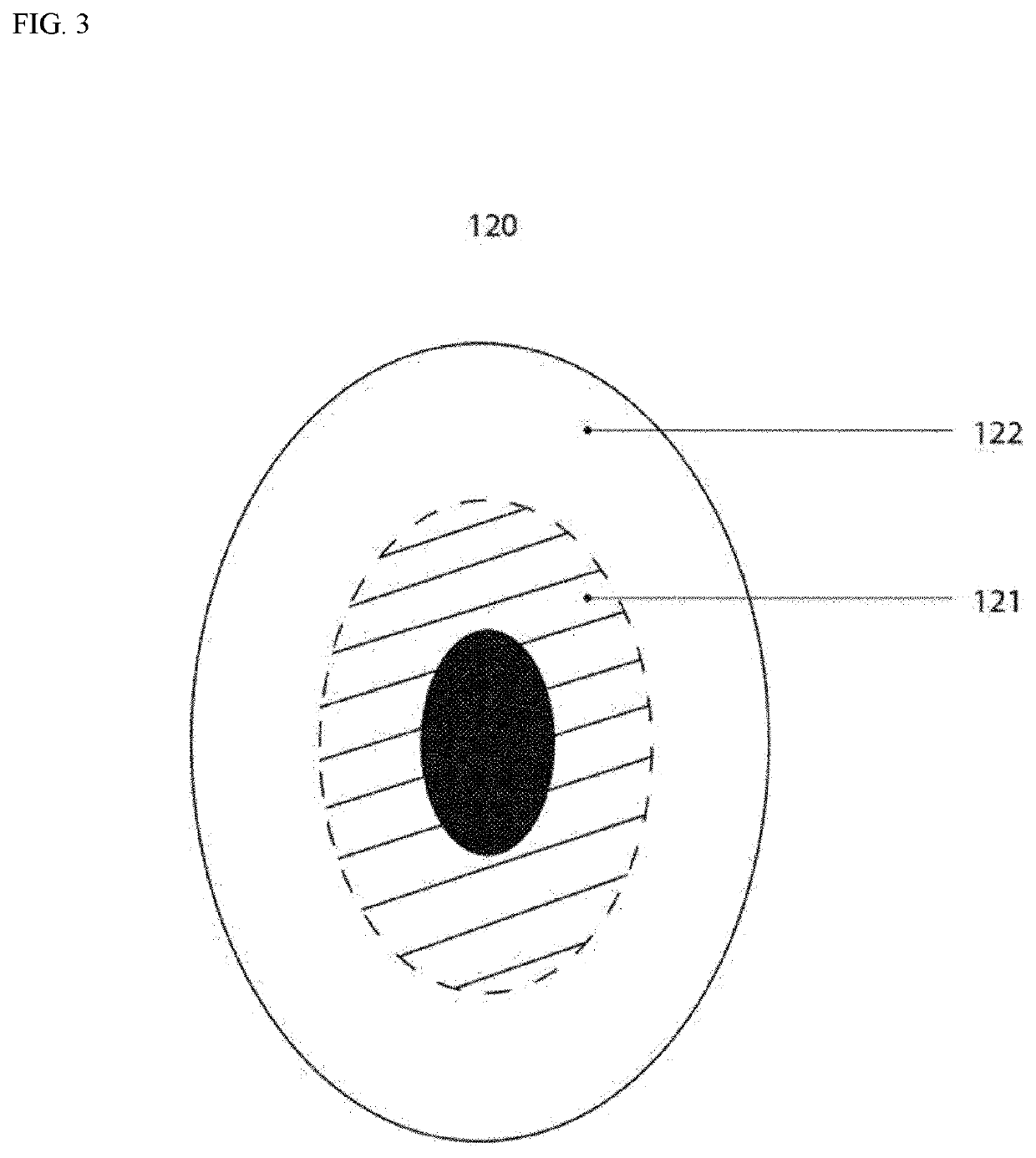

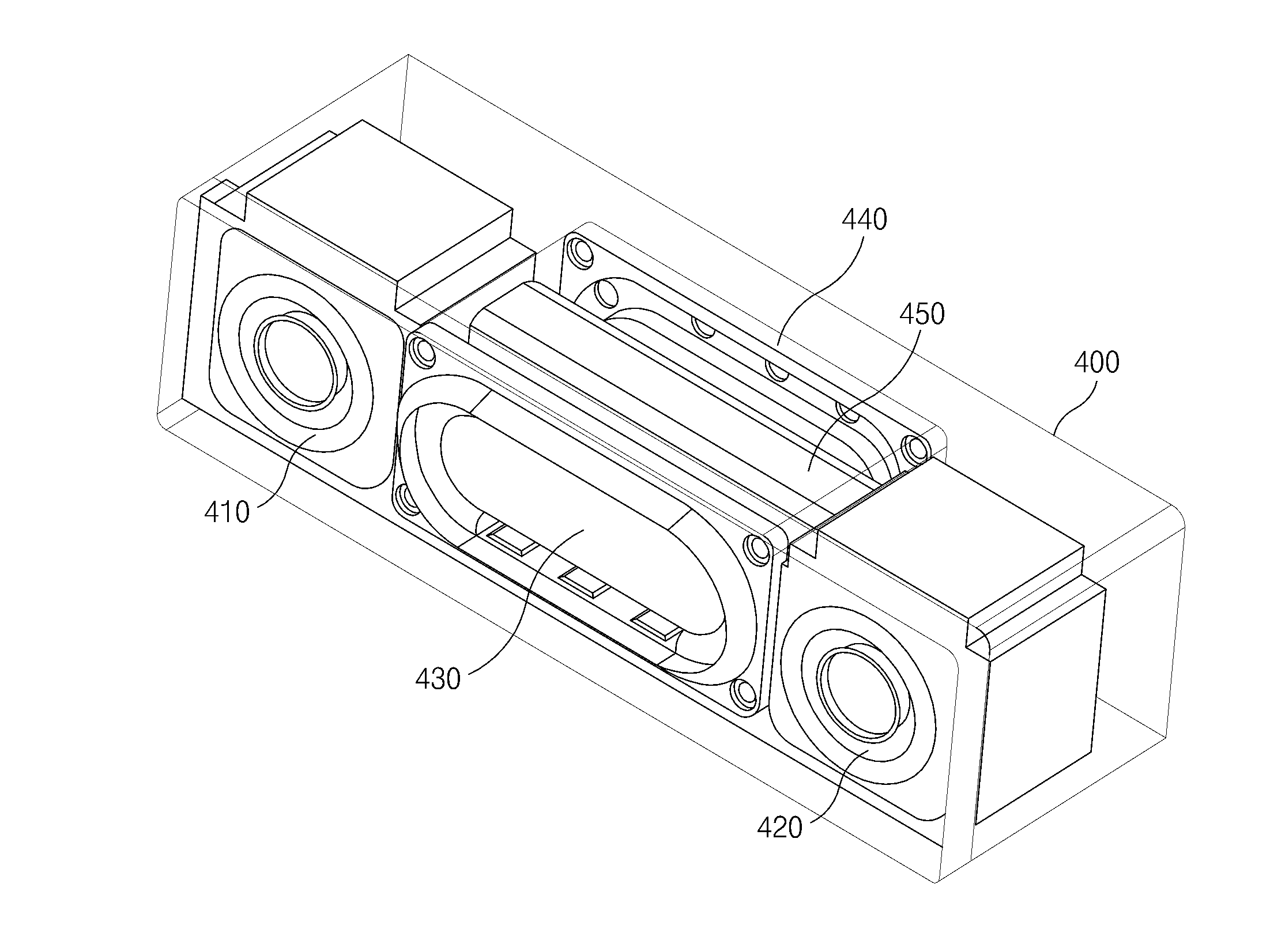

Sound output device

PendingUS20220086547A1Reduce heat generationLow heat generationMechanical apparatusLoudspeaker transducer fixingWavelength selectivityEngineering

A sound output device according to an exemplary embodiment of the present invention includes: a first housing; a second housing; a substrate; a light emitting unit; and a sound output unit, in which the second housing is connected with the first housing, the substrate is disposed inside the first housing or the second housing, the sound output unit is connected with the substrate, the light emitting unit is connected with the substrate, and the second housing selectively transmits light emitted by the light emitting unit based on a wavelength thereof.

Owner:IRTRONIX INC

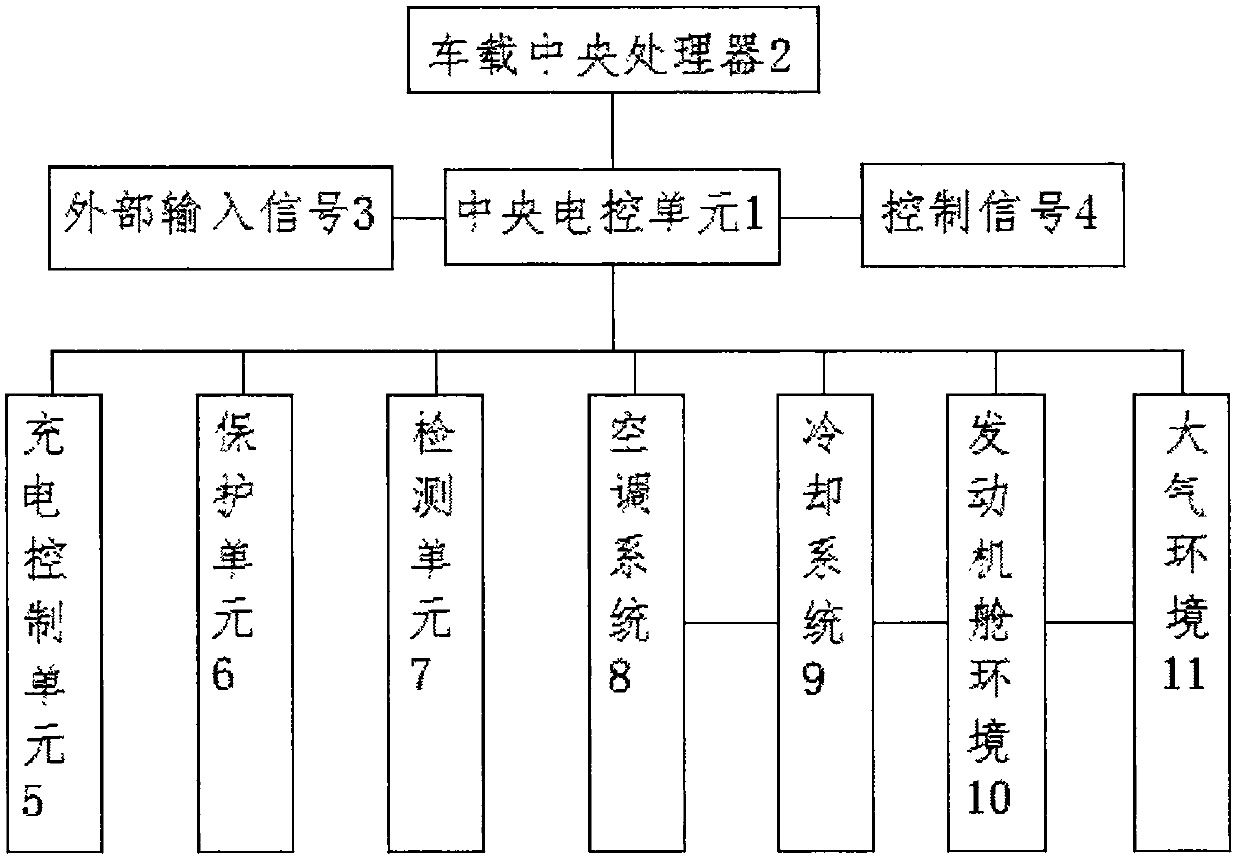

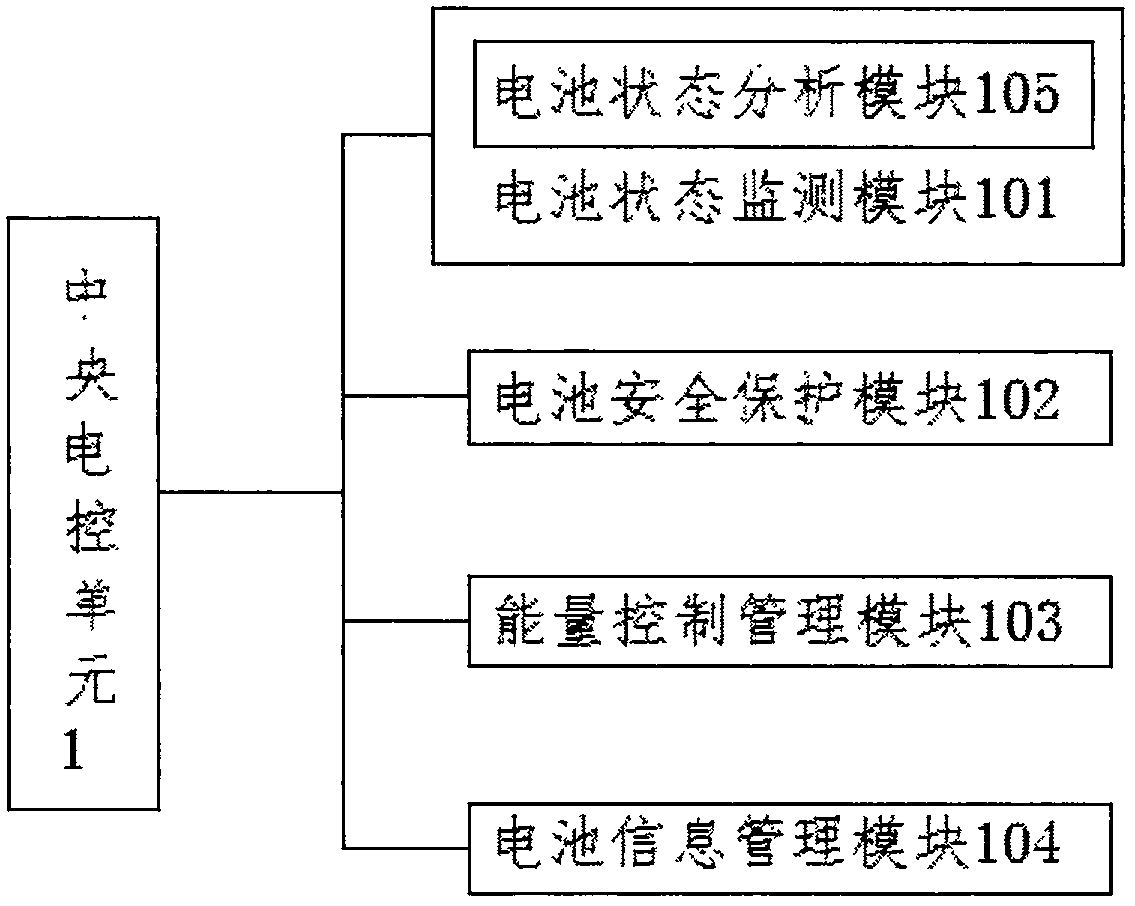

Battery management system and protection system of electric vehicle

InactiveCN110015135AIncrease capacityReduce heat generationCells structural combinationElectric vehicle charging technologyCommunications protocolHeat generation

The invention relates to a battery management system and a protection system of an electric vehicle, and belongs to the technical field of electric vehicles. An external input signal is connected witha central electric control unit. A control signal is mutually connected with the central electric control unit. A charging control unit, a protection unit and a detection unit are all connected withthe central electric control unit. An air conditioning system, a cooling system, an engine compartment environment and an atmospheric environment are arranged in the detection unit. The air conditioning system is connected with the cooling system. High-speed acquisition of battery voltage, temperature and other information can be realized. High efficiency and balance of a battery are realized, thecapacity of a battery integrated system is given full play so as to prolong the service life of the battery integrated system and reduce heat generation meanwhile. The health status and remaining power of the battery can be estimated and displayed. A communication protocol is highly reliable.

Owner:江苏智谋科技有限公司

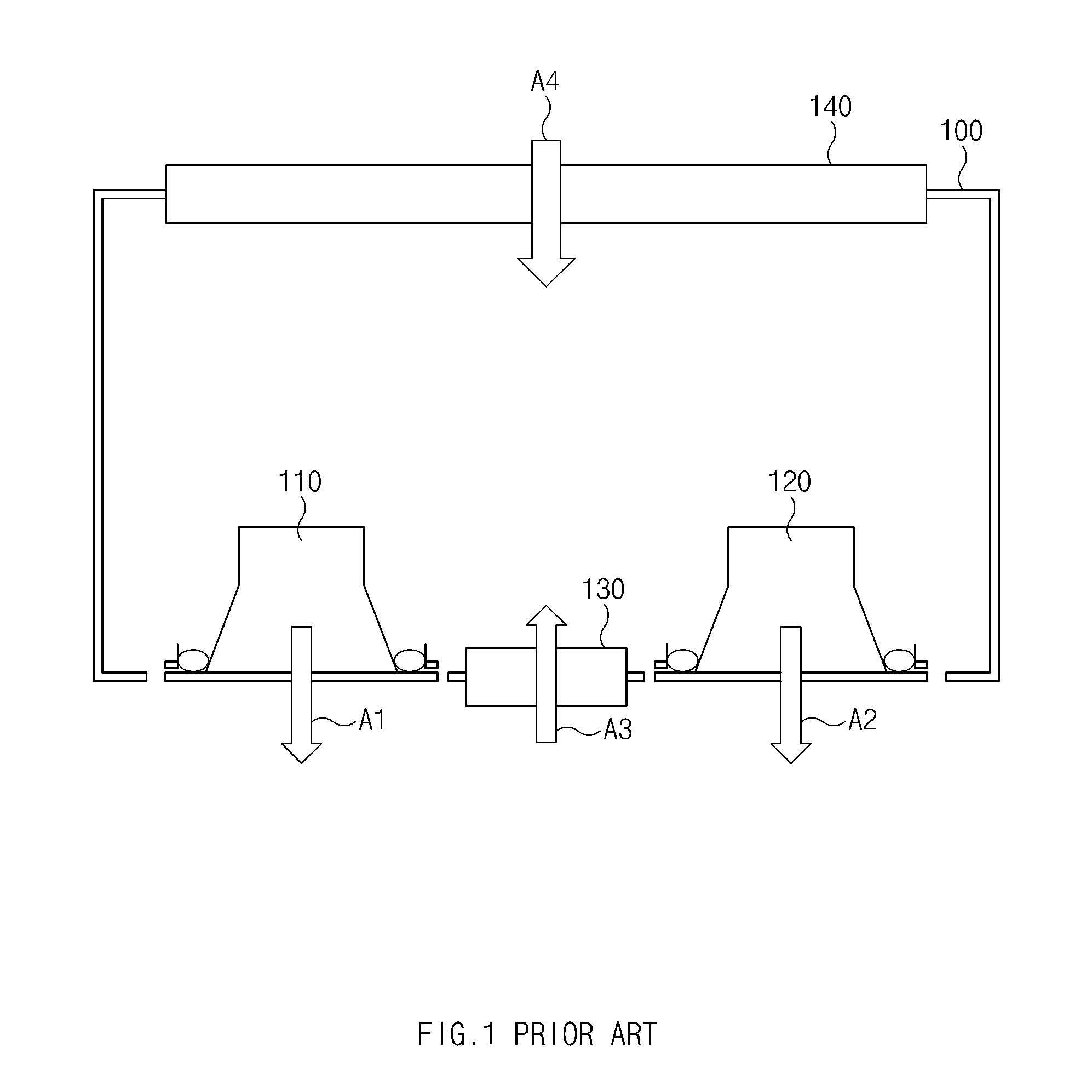

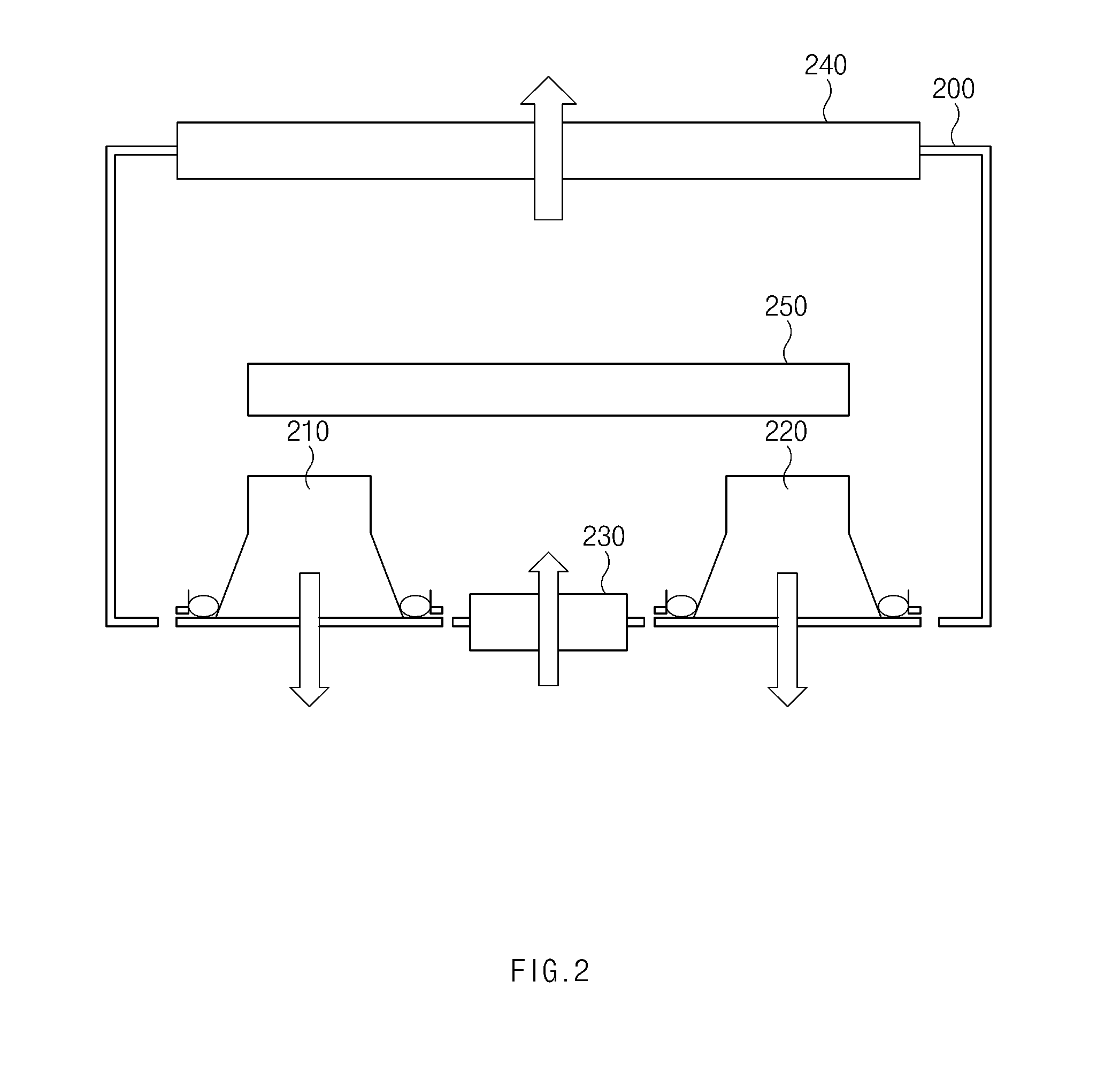

Speaker device

ActiveUS20160373854A1Reduce heat generationLow heat generationLoudspeaker transducer fixingLoudspeakersLoudspeakerEngineering

The present disclosure provides a speaker device. The speaker device includes a housing, first speaker unit disposed at a front surface of the housing, a second speaker unit disposed at the front surface, a first passive radiator disposed at the front surface, a second passive radiator disposed at a rear surface of the housing, and at least one structure disposed inside the housing, where the one of the at least one structure is disposed between the first passive radiator and the second passive radiator and disposed to form a gap, through which air flows, between the structure and at least one of the housing, the first speaker unit, the second speaker unit, and another of the at least one structure.

Owner:SAMSUNG ELECTRONICS CO LTD

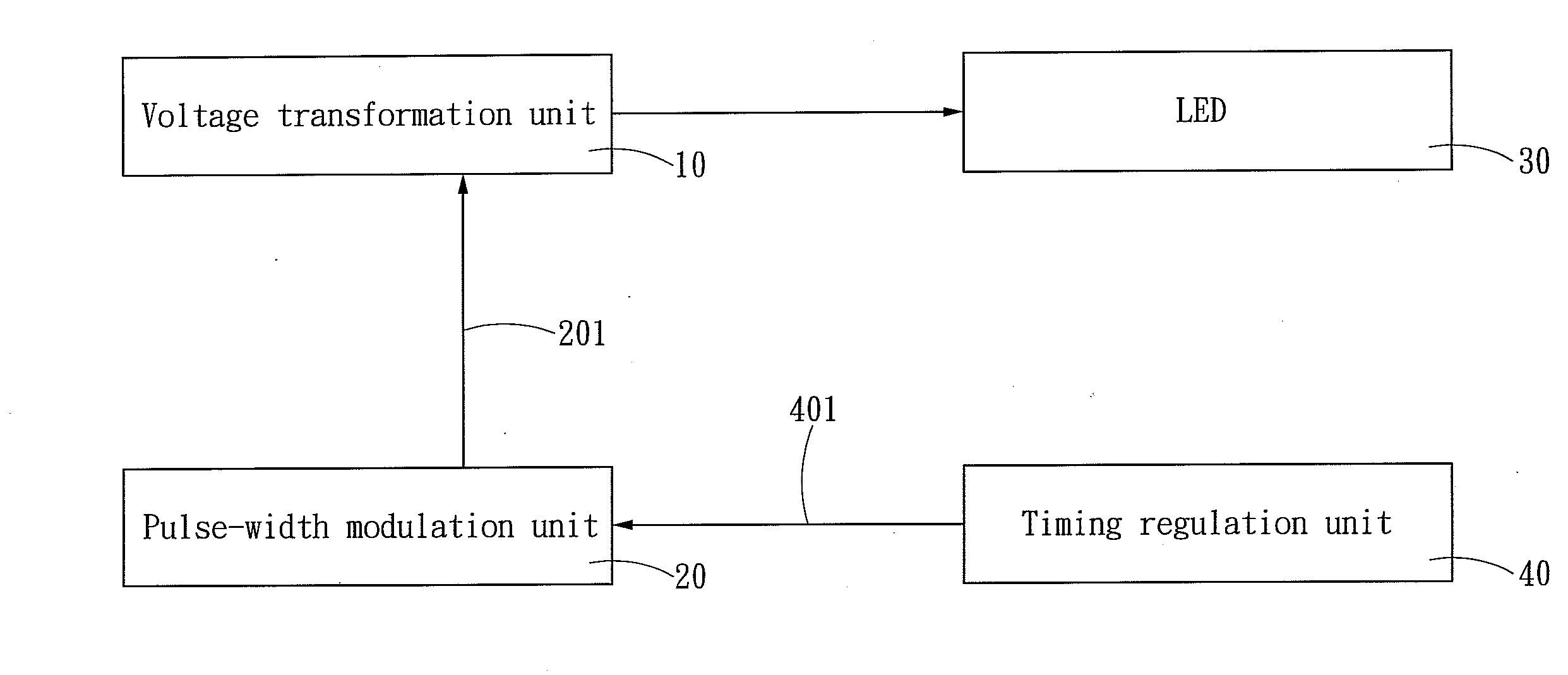

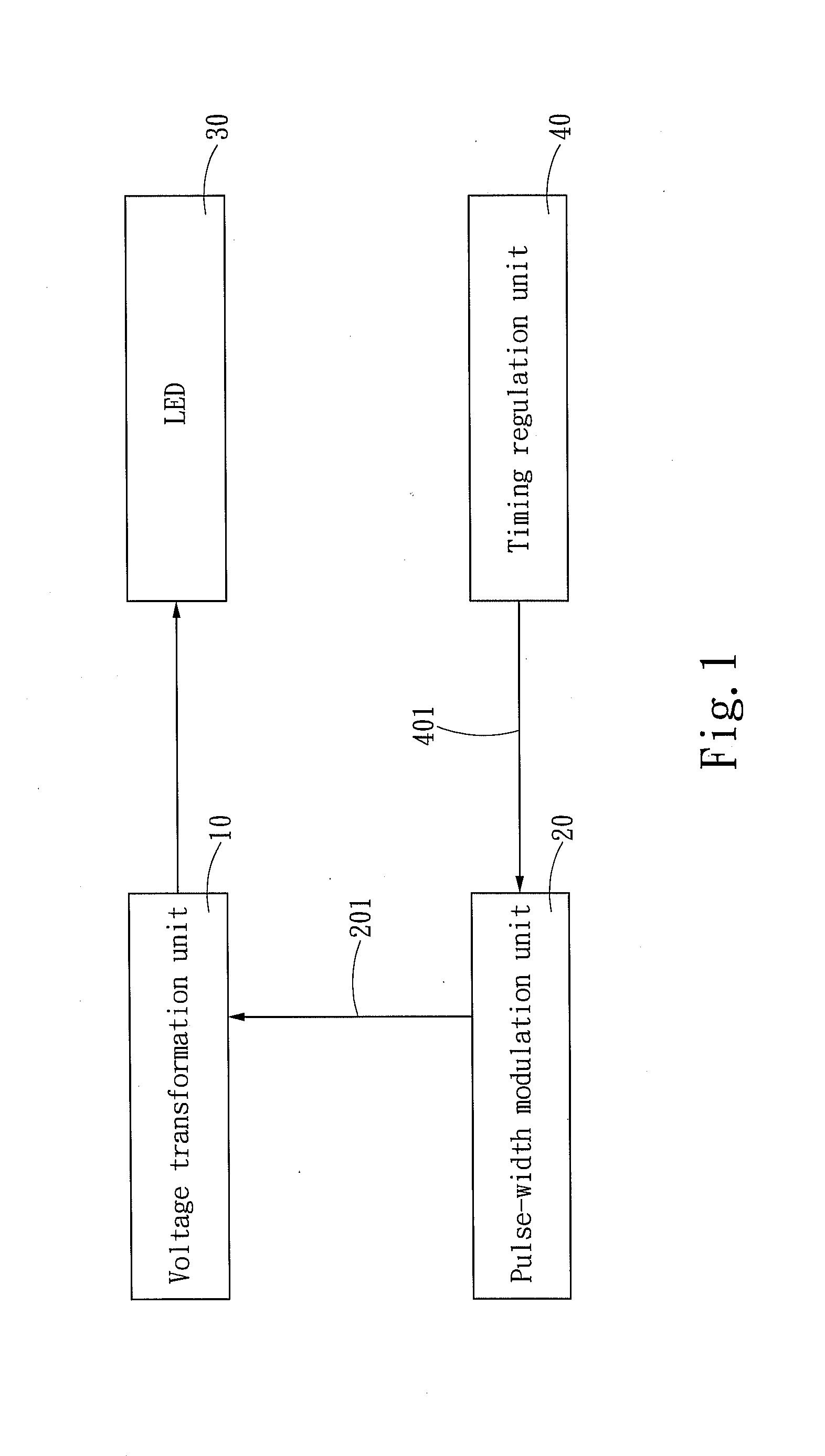

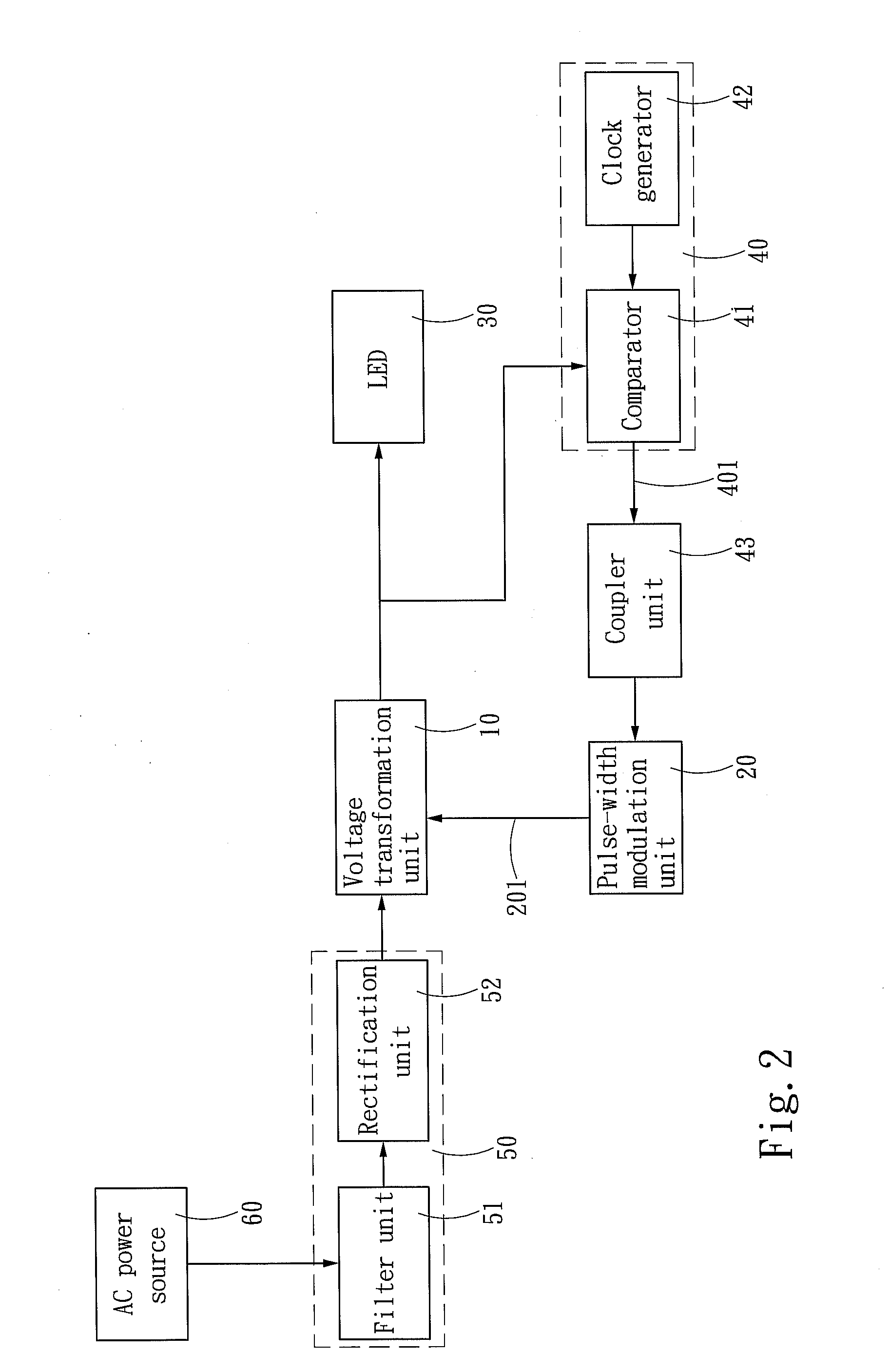

LED regulation circuit and method

InactiveUS20100052573A1Reduce heat generationDecreasing of life span and brightnessElectrical apparatusElectroluminescent light sourcesEngineeringPulse-width modulation

An LED regulation circuit and method include a voltage transformation unit to receive DC power and provide a constant current to drive at least one LED and a pulse-width modulation unit to generate a driving signal to control the voltage transformation unit. The driving signal of the pulse-width modulation unit has an operation period. In the operation period, the driving signal drives the voltage transformation unit to output regular operation power. The pulse-width modulation unit is connected to a timing regulation unit which generates a regulation signal sent to the pulse-width modulation unit to regulate the operation period of the driving signal by adding a sleep period. In the sleep period, the driving signal lowers the power of the voltage transformation unit that drives the LED. Through alternately controlling the operation period and sleep period of the driving signal, continuous heat generation and heat accumulation can be reduced.

Owner:ZIPPY TECH

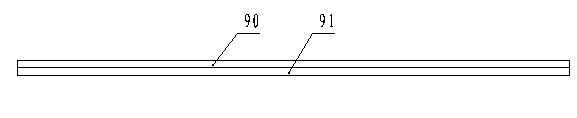

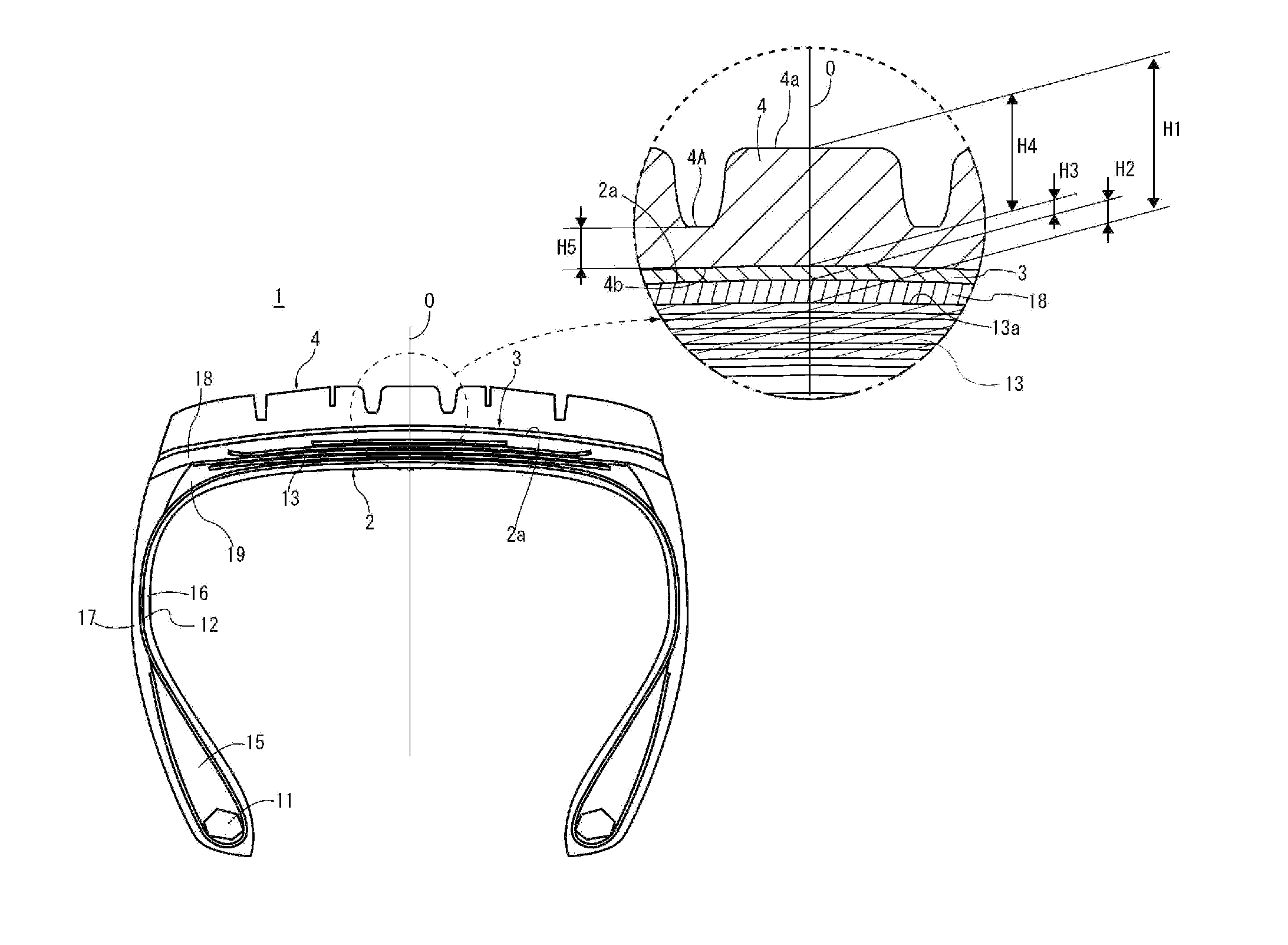

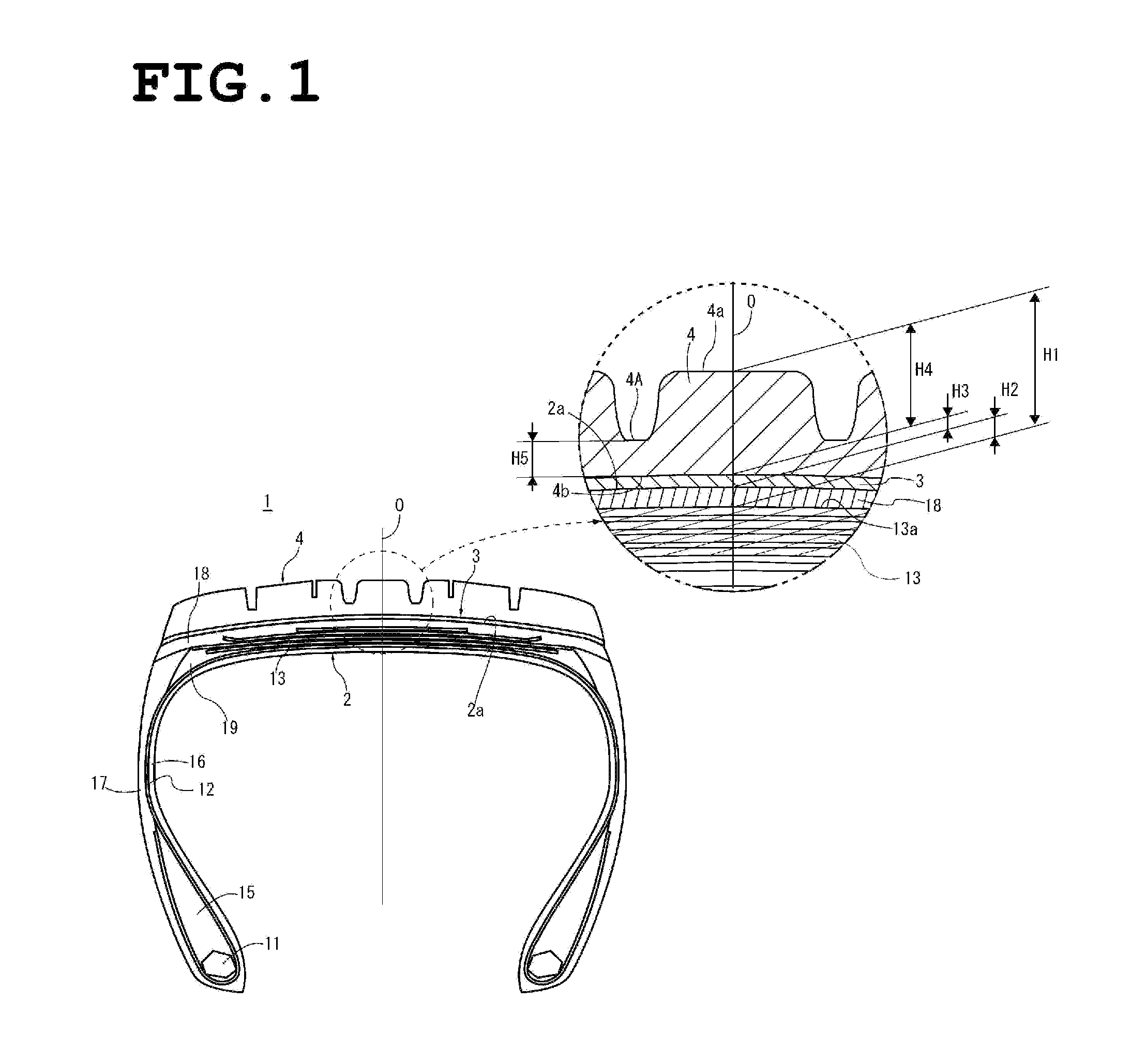

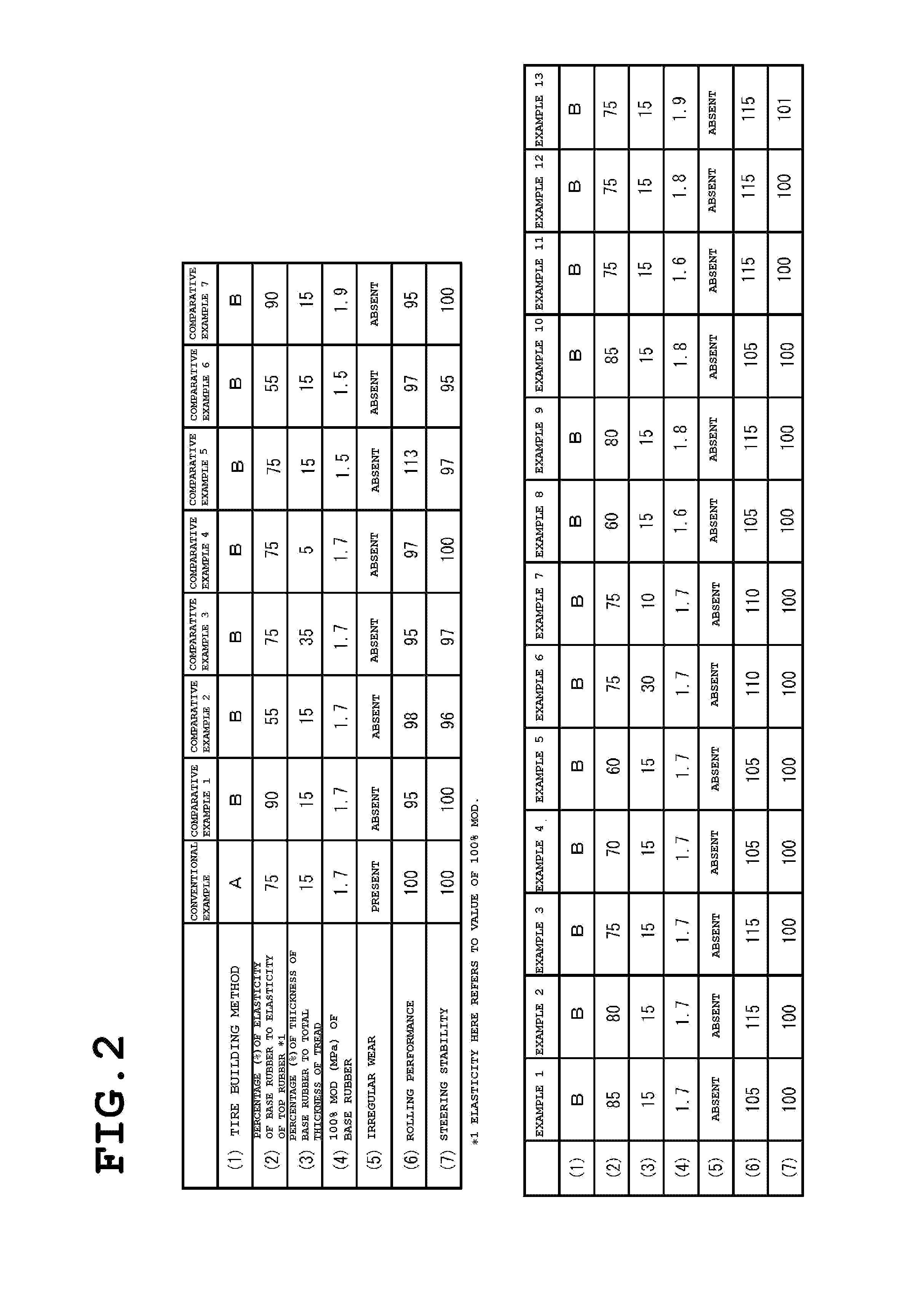

Tire manufacturing method and tire

InactiveUS20140326394A1Improve rolling performanceReduce heat generationTyresRolling resistance optimizationTotal thicknessEngineering

A tire manufacturing method including cure-molding a top rubber, which serves as the tread surface coming in contact with the road surface, cure-molding abase tire having abase rubber on its outer periphery to which the top rubber is bonded, and forming a tire by integrating the top rubber and the base tire together. The tire is characterized in that the loss tangent (tan δ) of the base rubber is smaller than the loss tangent (tan δ) of the top rubber, the 100% Mod of the base rubber is within a range of 60% to 85% of the 100% Mod of the top rubber, and the thickness of the base rubber is within a range of 10% to 30% of the total thickness of the tread on the tire.

Owner:BRIDGESTONE CORP

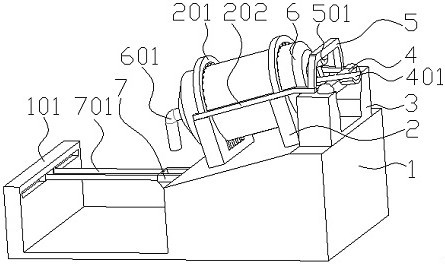

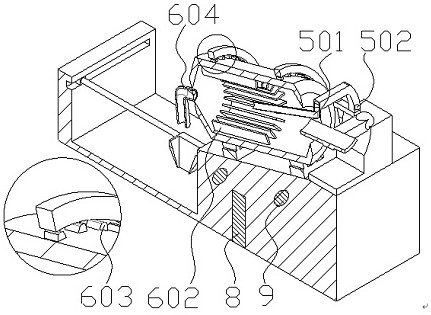

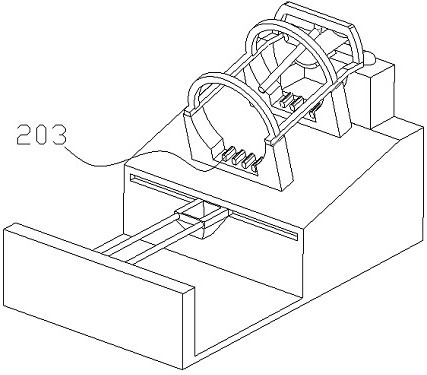

Continuous glue sprayer

PendingCN113580311AReduce frictionReduce heat generationDomestic articlesFlat articlesProcess engineeringFiber

The invention relates to a continuous glue sprayer, and belongs to the technical field of industrial equipment machinery. According to the continuous glue sprayer, a roller is adopted to mix a glue solution and a fiber material, friction between a stirring device and a mixture is reduced, heat is further reduced, the glue solution is effectively prevented from being solidified in advance, a material turning baffle is arranged in the roller, mixing of the glue solution and the fiber material is completed by using resistance, heat generated by friction is reduced, and the mixing quality can be effectively improved; meanwhile, a temperature sensor is further arranged on a glue supply device and used for monitoring the temperature and preventing the glue solution from being solidified, when the temperature is too high, the quality of the mixed solution can be effectively guaranteed by adding the glue solution and reducing the temperature; and a discharging funnel is connected to guide rails in a sliding mode, it is guaranteed that a mixture in a mold can be rapidly and evenly laid through alternate cooperation between the transverse guide rails and the longitudinal guide rails, meanwhile, the discharging speed of the mixture is controlled through a semicircular baffle on a discharging pipe, the flow speed of the mixture can be accurately mastered, and the continuous glue sprayer has wide application prospects.

Owner:成都典惟宁建筑科技有限公司

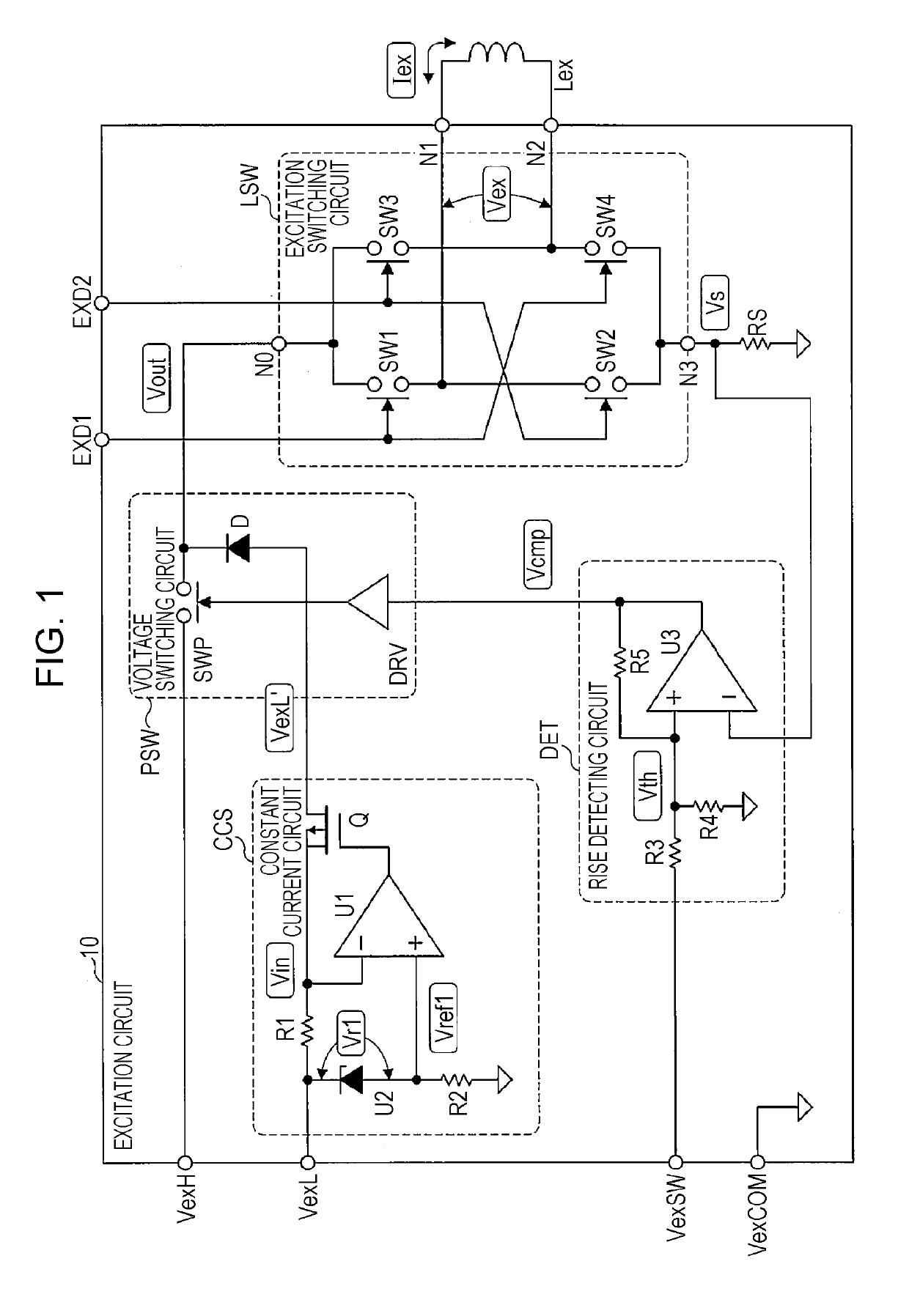

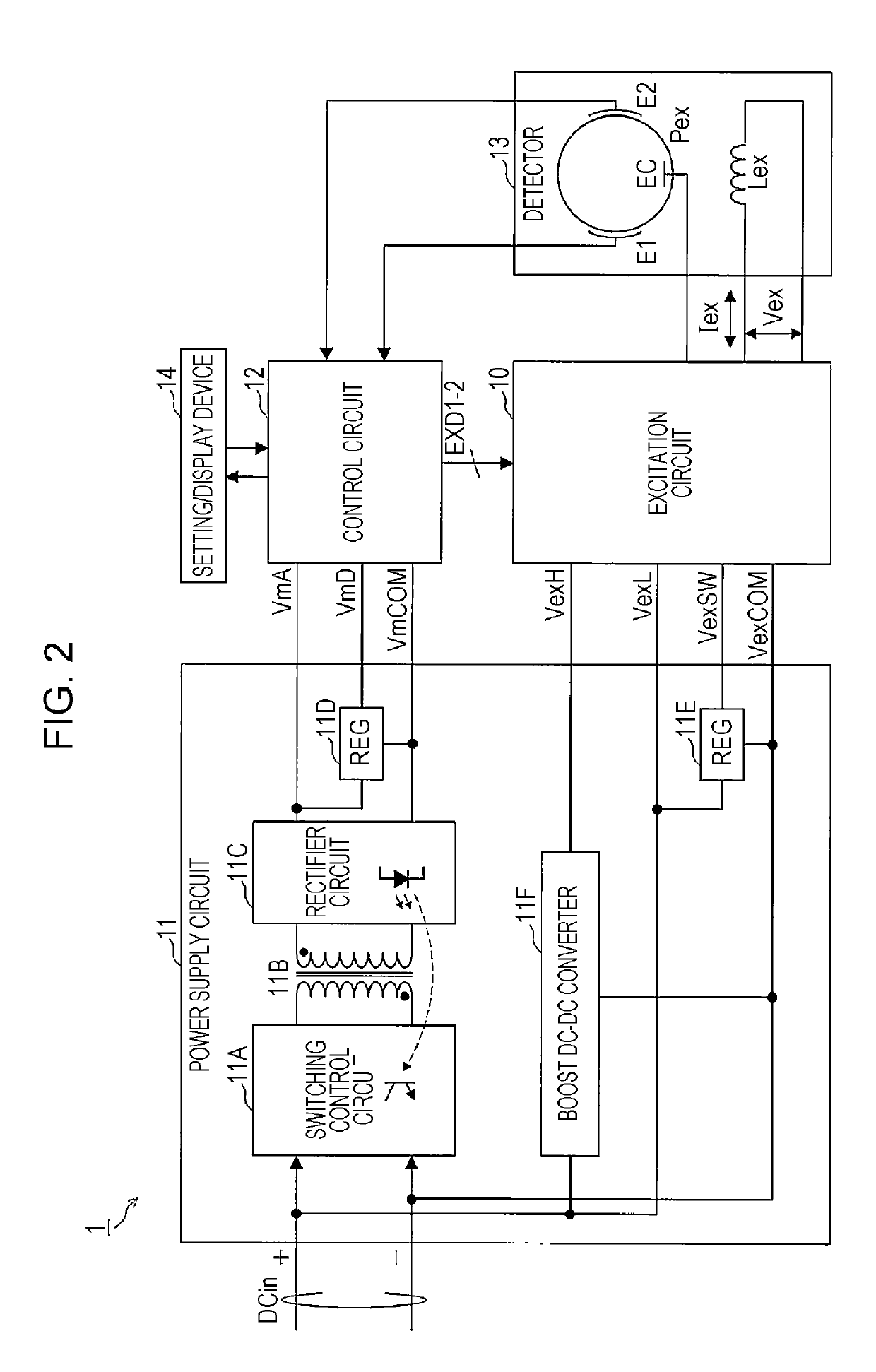

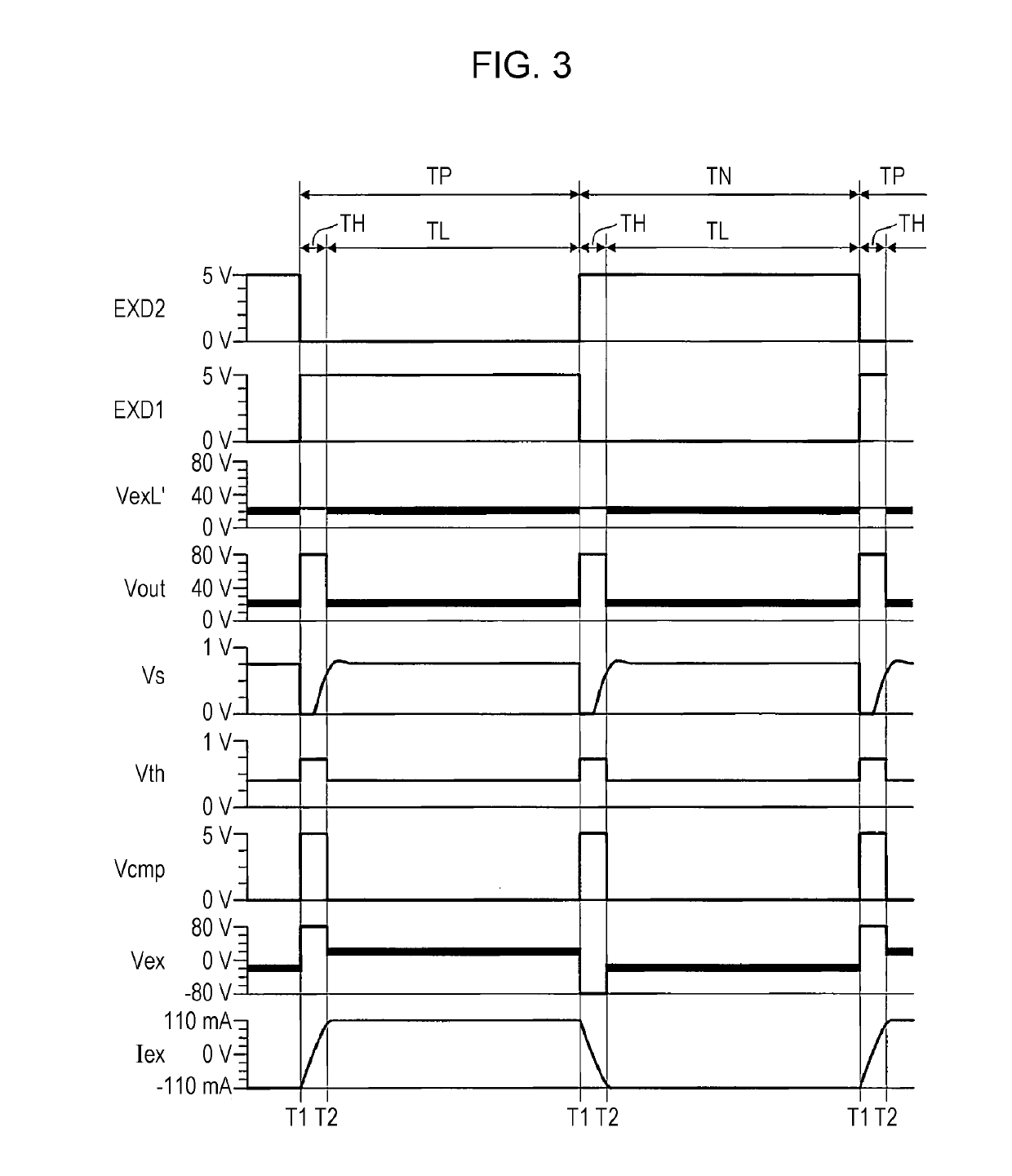

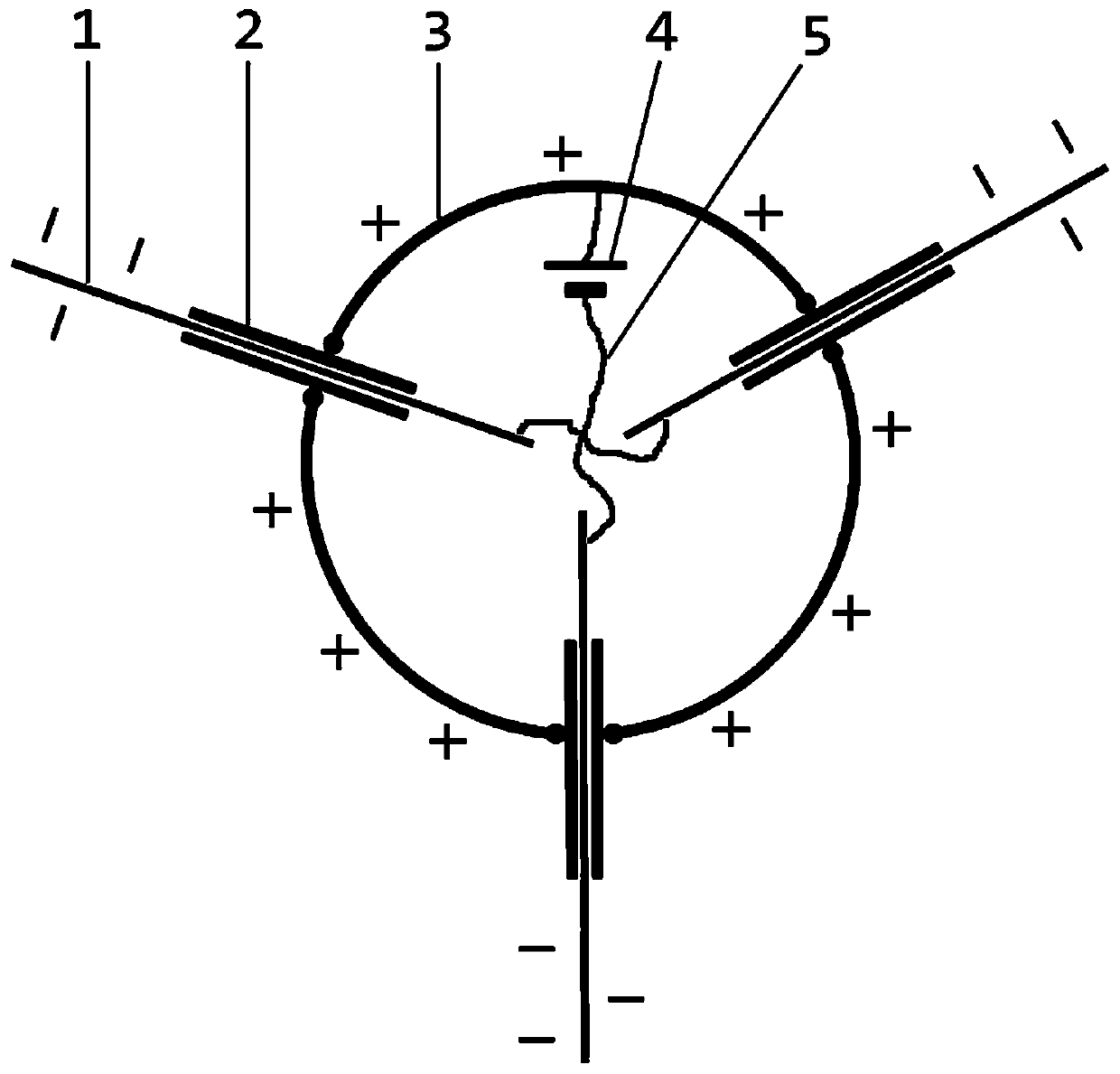

Excitation circuit for electromagnetic flowmeter, and electromagnetic flowmeter

ActiveUS20190285447A1Reduce heat generationEasily obtainVolume/mass flow by electromagnetic flowmetersPhysicsElectromagnetic flowmeter

A voltage switching circuit applies a high excitation voltage to an excitation switching circuit during a period from an excitation period starting point to a rise point in an excitation period, and applies a low excitation voltage lower than the high excitation voltage to the excitation switching circuit during a period from the rise point to an excitation period ending point in the excitation period. A constant current circuit makes the current of the low excitation voltage to be input from a power supply circuit to the voltage switching circuit constant.

Owner:YAMATAKE HONEYWELL CO LTD

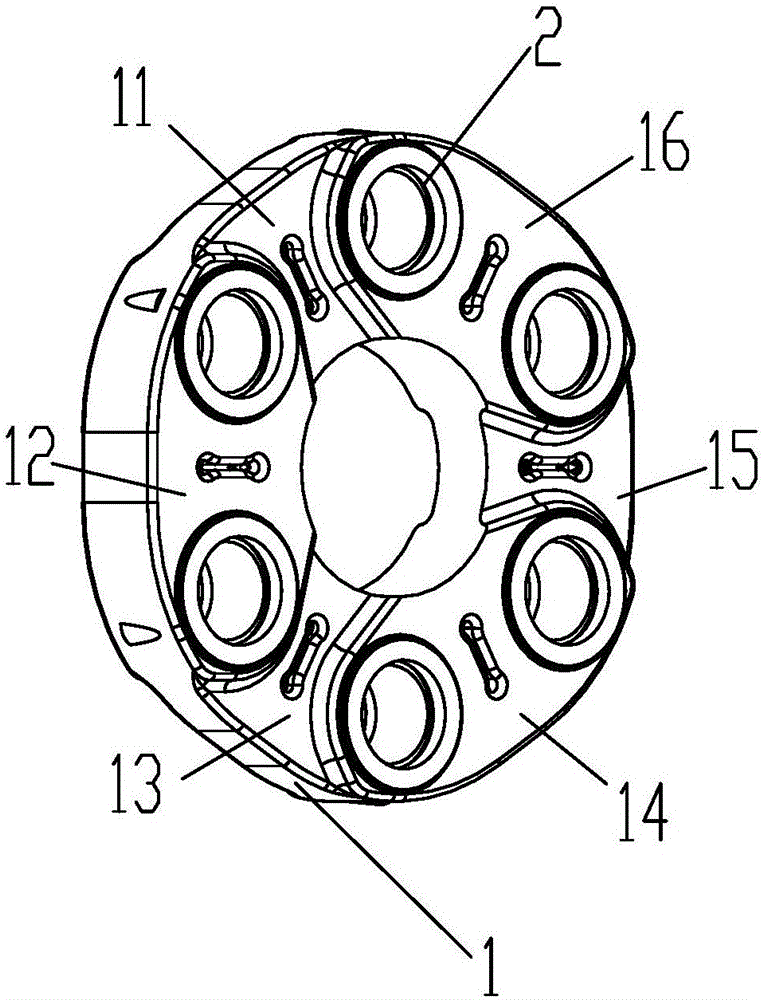

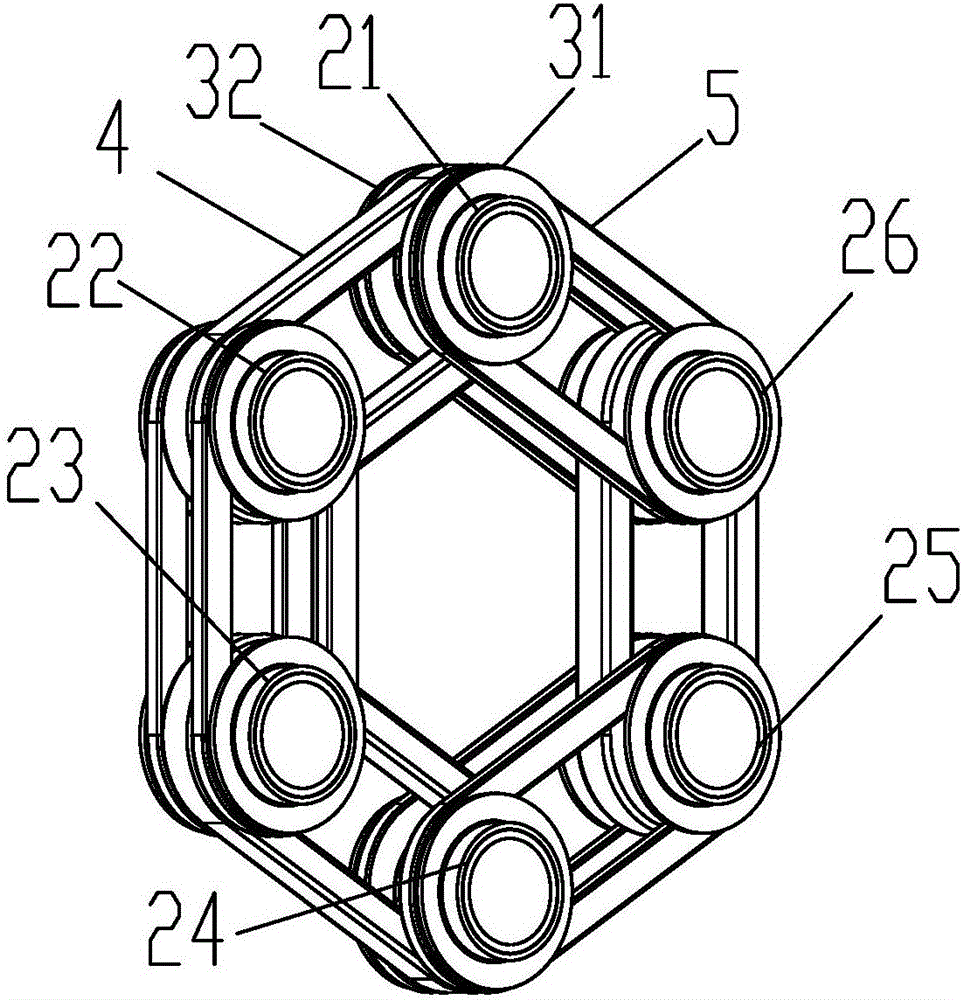

Flexible coupling

InactiveCN106763260AGood reverse torqueReduce heat generationYielding couplingEngineeringCable harness

The invention provides a flexible coupling. The flexible coupling comprises an even number of sleeve pipes arrayed annularly, sleeve pipe rings arranged at the two ends of each sleeve pipe, and wire harnesses wound on each pair of peripherally adjacent sleeve pipes. The wire harnesses are driving wire harnesses or reverse wire harnesses, and the driving wire harnesses and the reverse wire harnesses are arranged alternately in the annular direction. All the sleeve pipes and wire harnesses are embedded in a rubber body. The hardness of the rubber body is different in the circumferential direction according to the different embedded wire harnesses. The rubber body is composed of rubber body first sections where the driving wire harnesses are embedded and rubber body second sections where the reverse wire harnesses are embedded alternately, and the harness of the rubber body first sections is lower than that of the rubber body second sections. The service life of the rubber body is prolonged, and the service life of the flexible coupling is prolonged without adding other structure forms.

Owner:SHANGHAI GKN DRIVE SYST

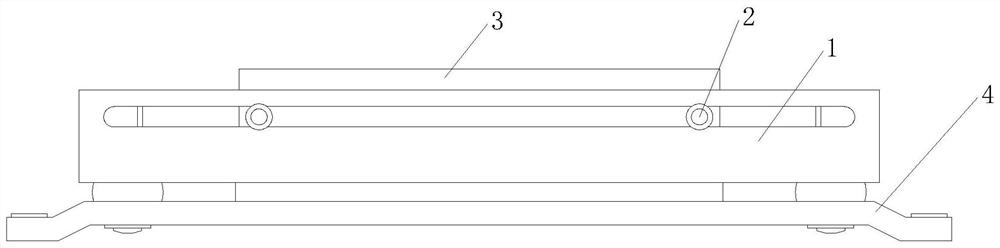

X-axis reciprocating vibration motor for mixing barrel

ActiveCN112803699AAchieve self-cleaning effectReduce heat generationCleaning using gasesSupports/enclosures/casingsPhysicsDynamic energy

The invention discloses an X-axis reciprocating vibration motor for a mixing barrel, and relates to the technical field of motors. The X-axis reciprocating vibration motor comprises an electromagnet mechanism, the electromagnet mechanism is in transmission connection with a permanent magnet through a sliding shaft rod, the sliding shaft rod is fixedly installed on the side edge of the permanent magnet, and a base is arranged at the bottom of the electromagnet mechanism; and the electromagnet mechanism comprises a shell, a side edge sliding groove is formed in a side edge panel of the shell in a penetrating mode, the sliding shaft rod is arranged in the side edge sliding groove in a sliding mode, and the two ends of the interior of the shell are connected with the two ends of an electromagnet body through mounting bases correspondingly. Kinetic energy generated when the permanent magnet moves is converted through the designed buffer, so that gas in the buffer can be sprayed out in a high-pressure state, dust in internal gaps can be automatically blown away through the design during use, and the self-cleaning effect is achieved; and the probability of the problems of easy heat generation, power reduction and the like caused by excessive dust accumulation in the shell is reduced.

Owner:JINAN SINOFLON NEW MATERIAL CO LTD

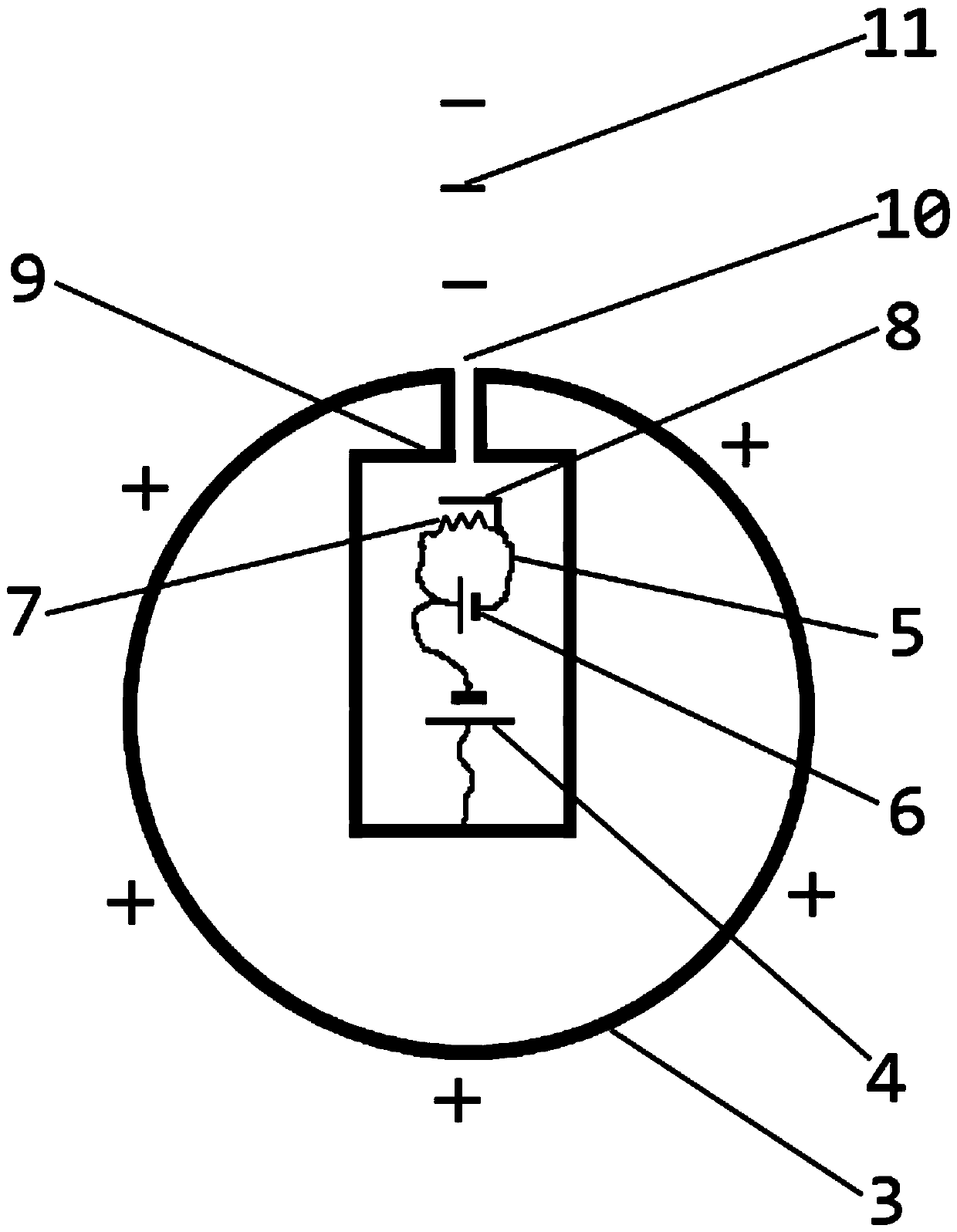

Anode high temperature protection method and protection device

PendingCN109515762AReduce heat generationEffective high temperature protectionCosmonautic thermal protectionGas turbine plantsIonSpacecraft

The invention relates to an anode high temperature protection method and protection device. A positive charge is applied to a shell or a component, meanwhile, a negative charge is applied to a self-renewing or easy-to-replace sacrificial electrode or a substance most in need of heating, or electrons (the negative charge) are emitted to a place far away from a spacecraft by an electron gun, and thespacecraft loses part of the negative charge and gains the positive charge. Positive ions in a high-temperature plasma is repelled by applying the positive charge to the component or shell needing tobe protected, therefore the heating of the positive ions in the high-temperature plasma to the component or the shell is effectively reduced, and the purpose of high temperature protection is achieved. The anode high temperature protection method and protection device are suitable for protection for high temperature generated by friction between the spacecraft shell and atmosphere in the recoveryprocess of the spacecraft, and meanwhile is also suitable for high temperature protection of the inner parts of a rocket engine, a turbine engine and a high-temperature furnace.

Owner:THE FIRST HOSPITAL OF CHINA MEDICIAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com