Continuous glue sprayer

A glue spraying machine and glue supply technology, which is applied in the pretreatment of molding materials, flat products, household components, etc., can solve the problems affecting the stability of mechanical operation, the speed of fiber material feeding and discharging is not easy to control, and the fiber materials are not scattered when they fall. Uniformity and other issues, to achieve the effect of easy control, prevent early solidification, and reduce heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

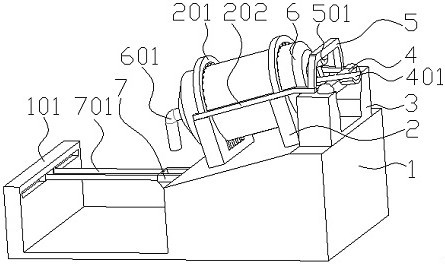

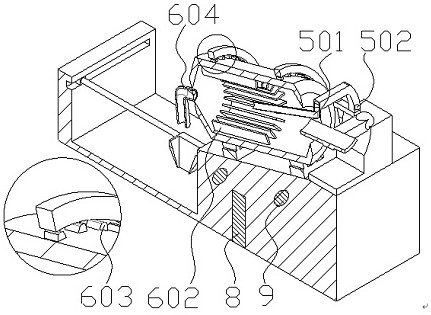

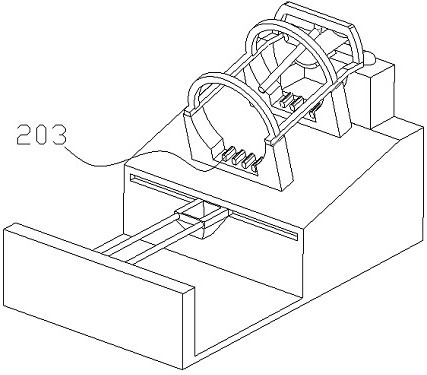

[0022] see Figure 1~4 , a continuous glue spraying machine according to the present invention, comprising a base 1, a bracket 2, a feeding device 4, a glue supply device 5, a drum 6, a discharge funnel 7, and a motor 8; it is characterized in that: the inclined plane of the base 1 The upper part is provided with a bracket 2, the center line of the bracket 2 is provided with a groove, the bottom of the groove is provided with a gear 203, and a motor 8 is provided inside the slope of the base 1, and a gear transmission shaft 9 is provided between the motor 8 and the slope of the base 1, and the gear transmission The shaft 9 meshes with the gear 203, the top of the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com