Patents

Literature

39results about How to "Prevent premature solidification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

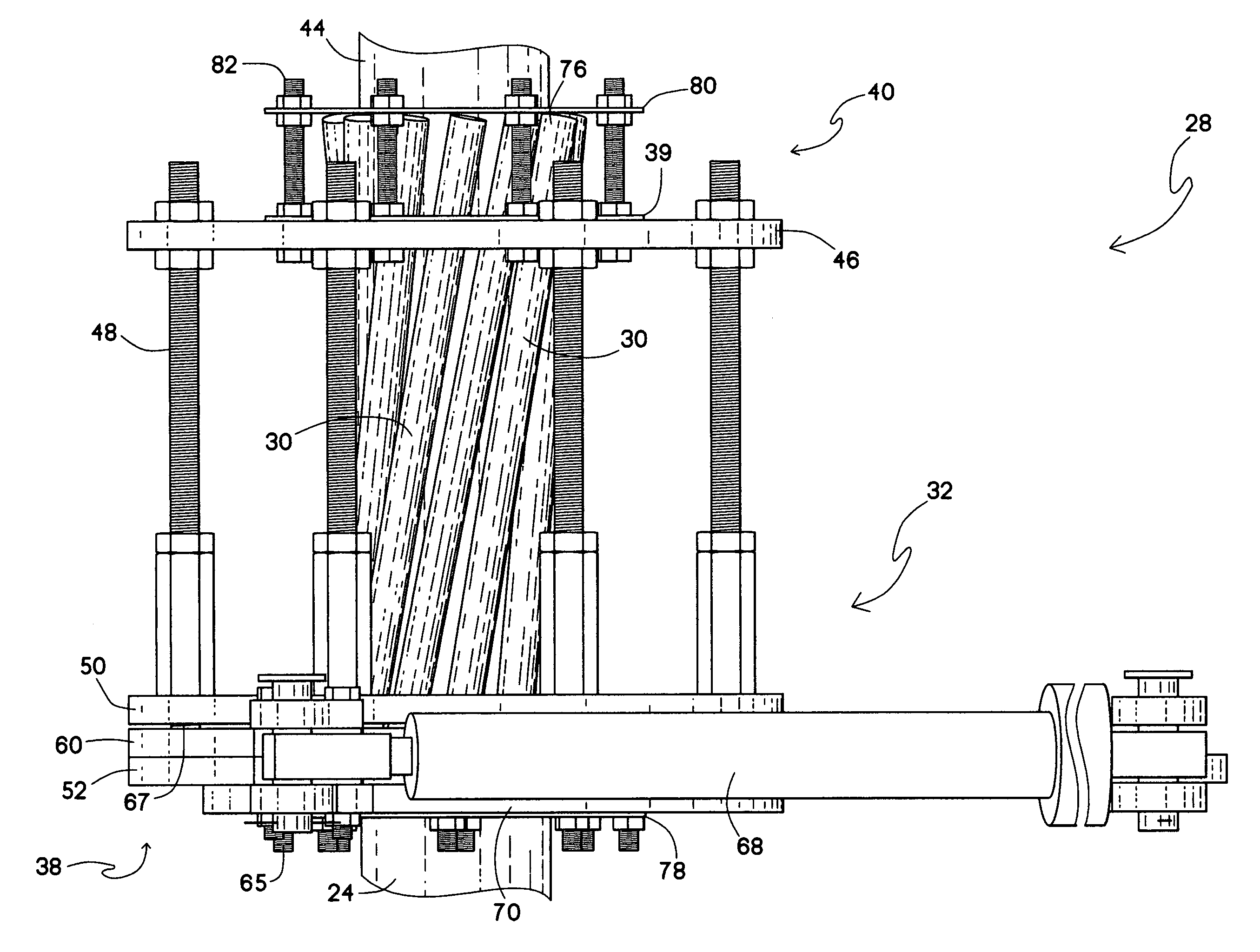

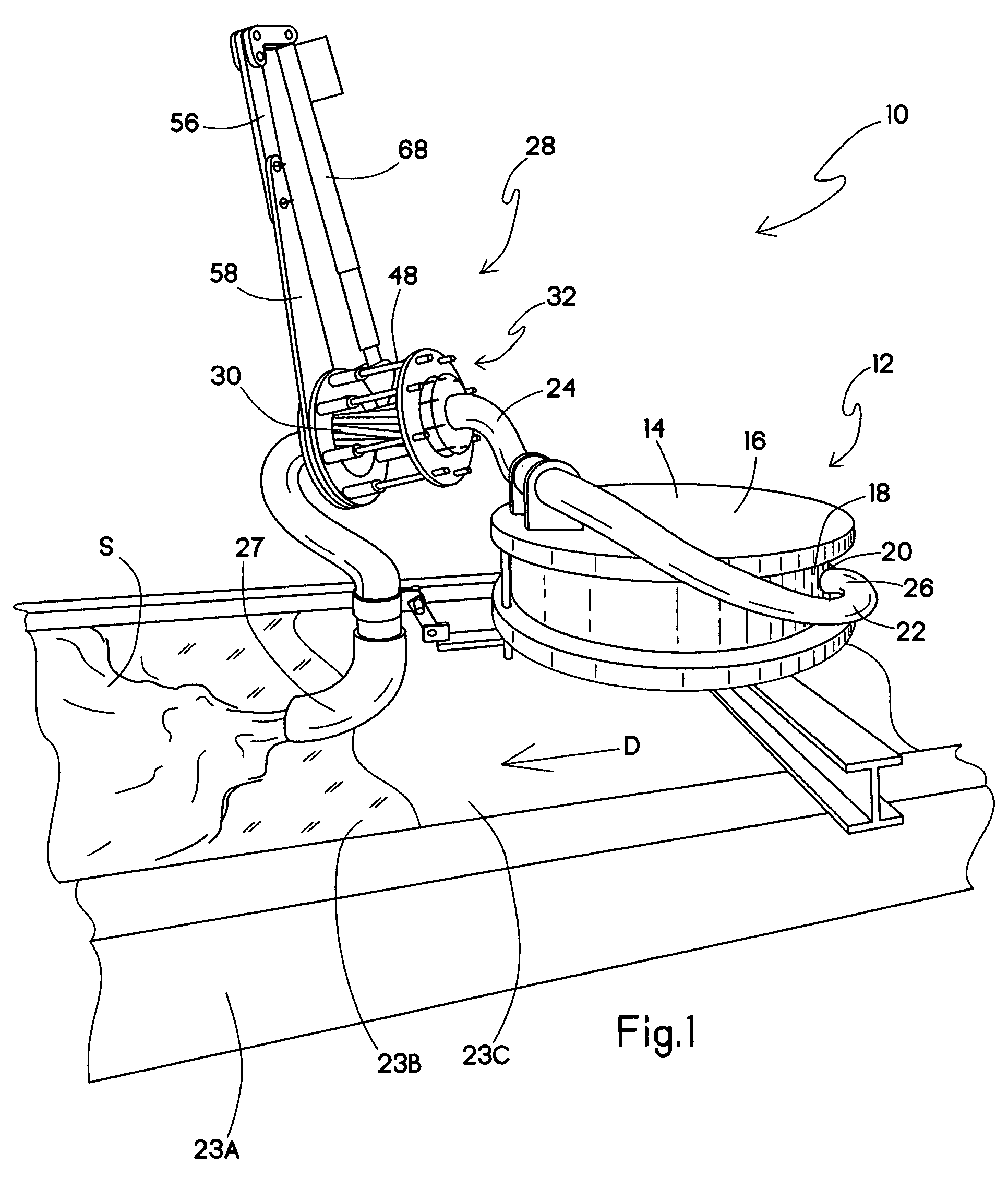

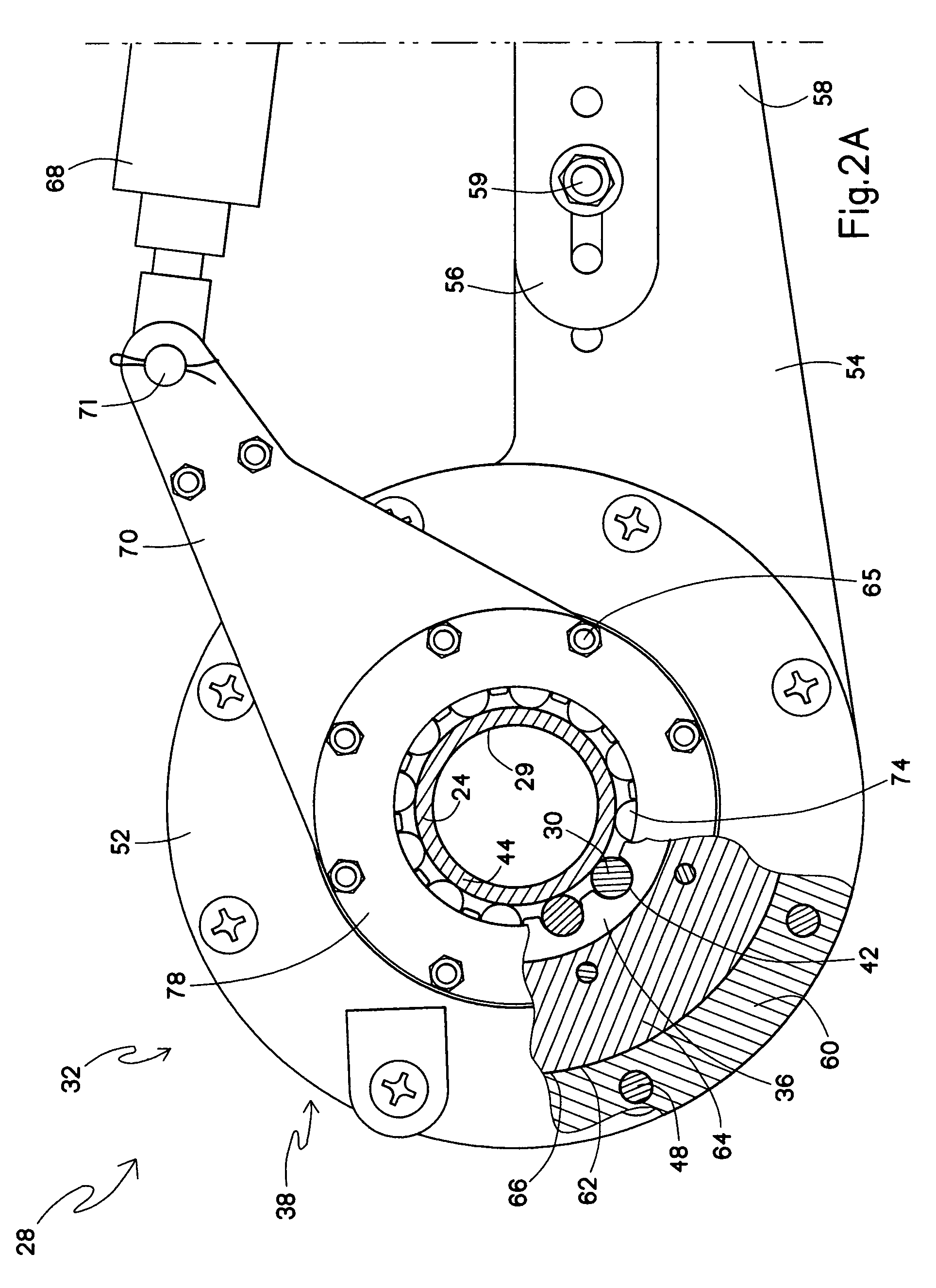

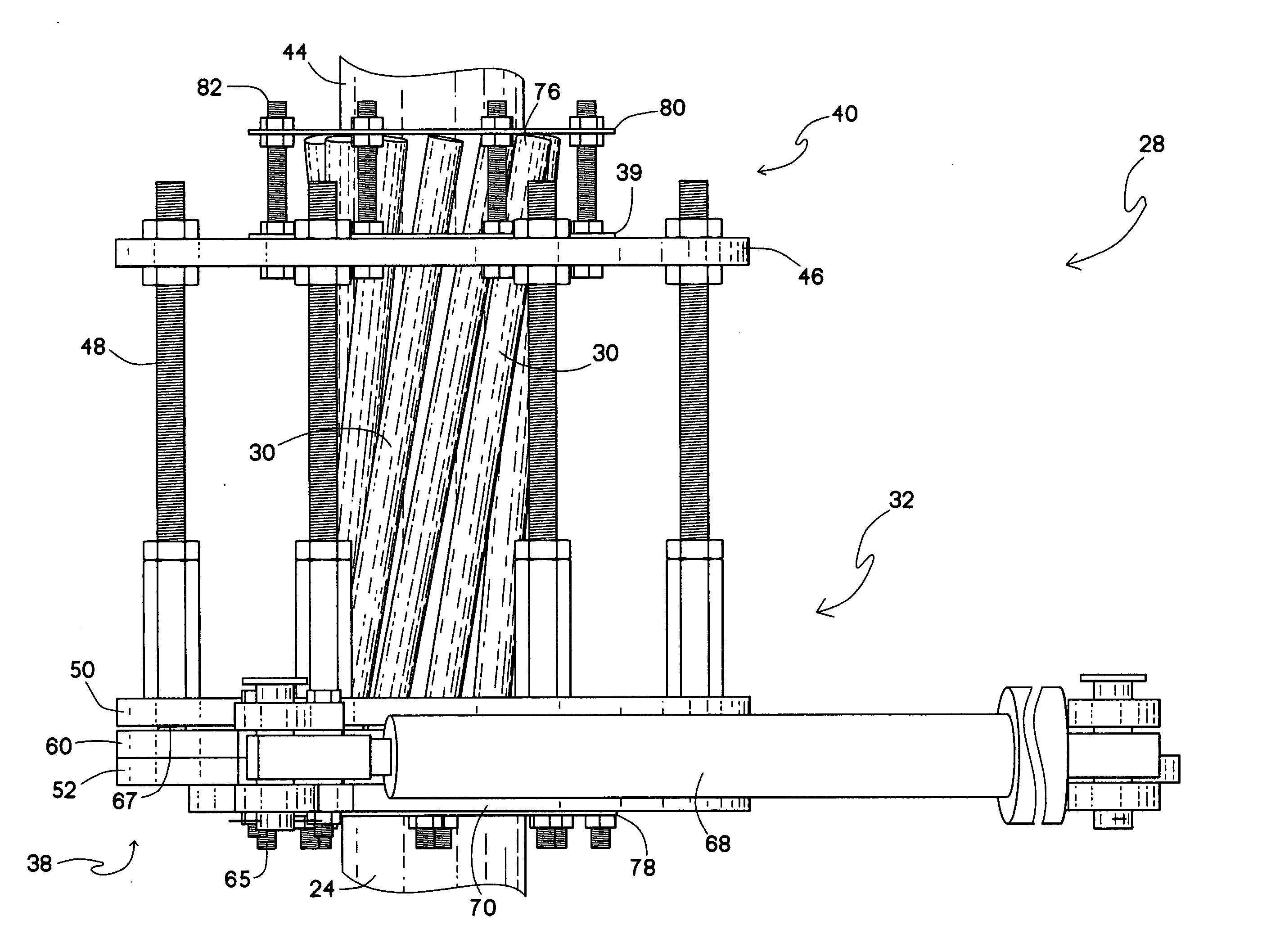

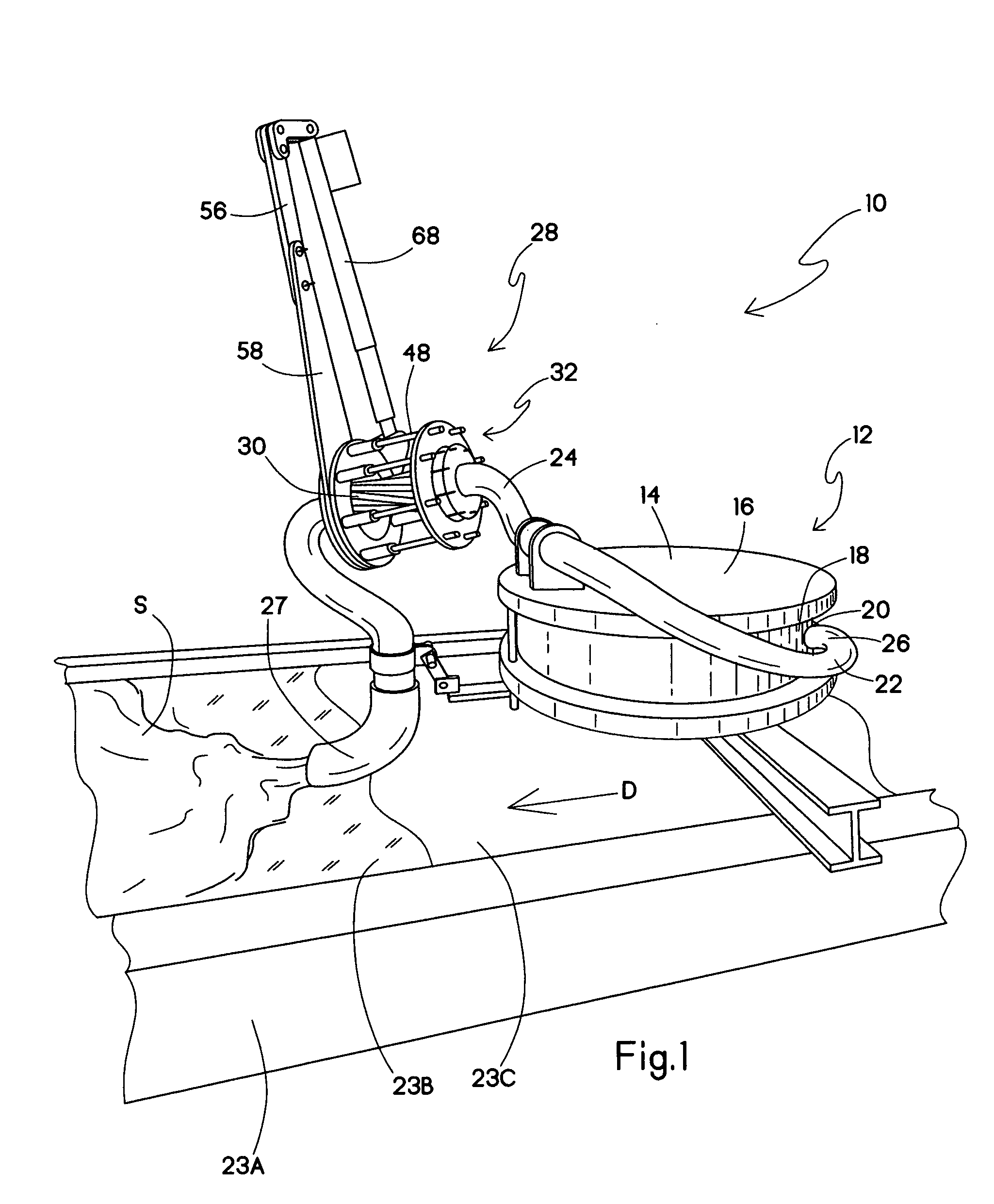

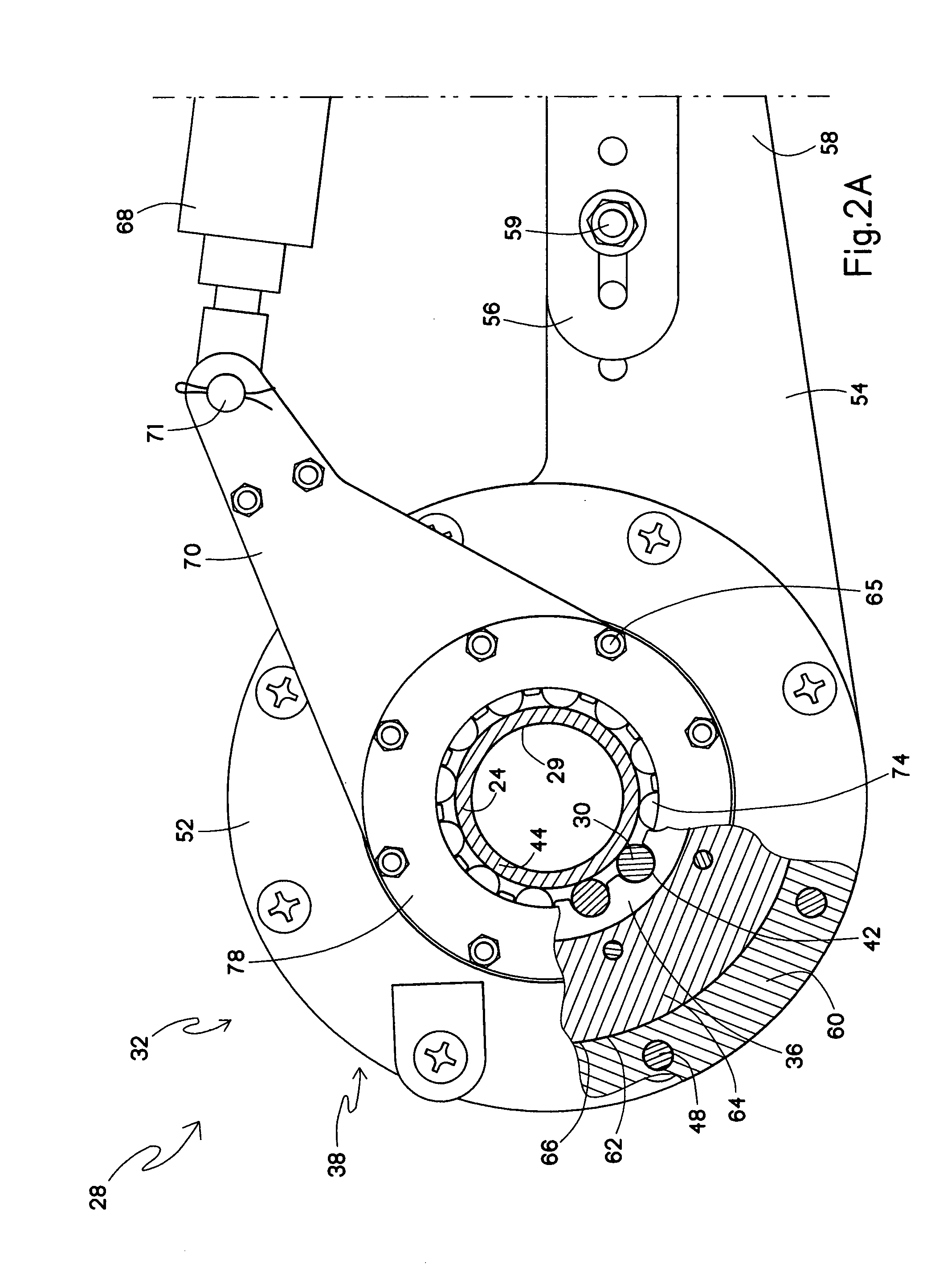

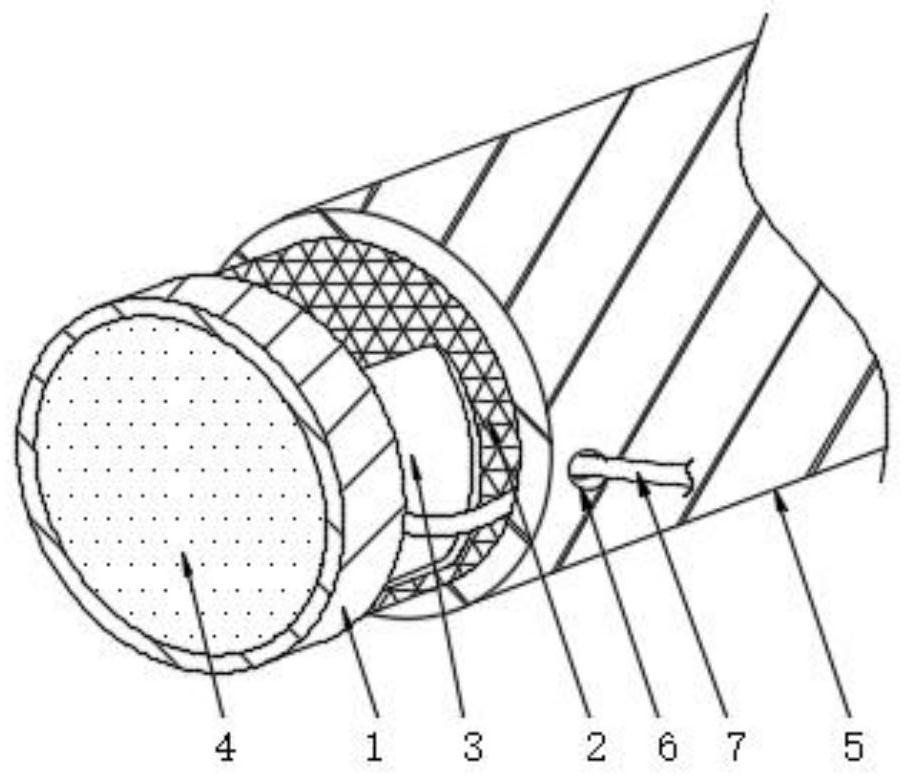

Slurry mixer constrictor valve

ActiveUS7007914B2Increase volumePrevent premature solidificationDiaphragm valvesEngine diaphragmsSlurryEngineering

Owner:UNITED STATES GYPSUM CO

Slurry mixer constrictor valve

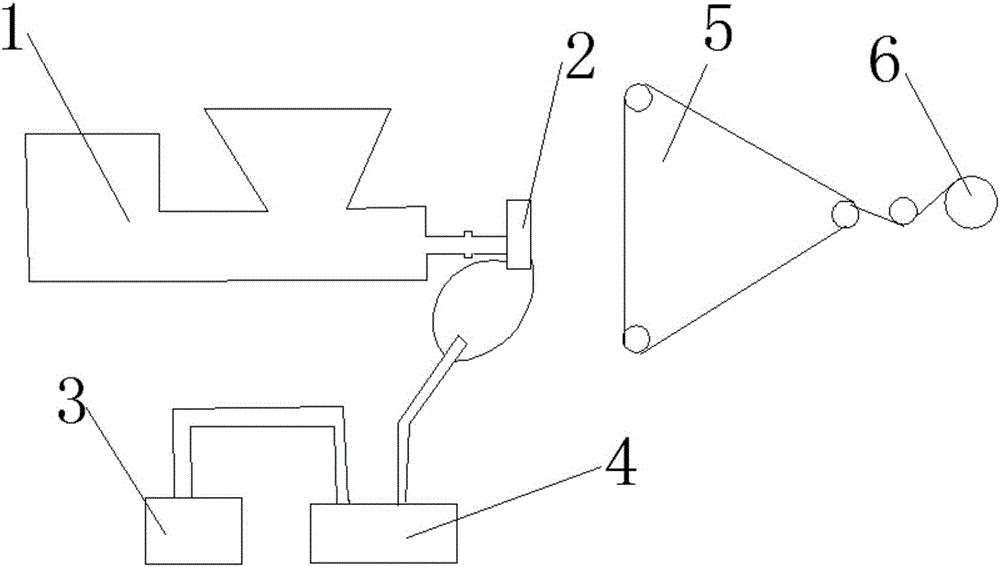

An apparatus and method for controlling the flow of a slurry is provided which includes using a constrictor valve on a mixing and dispensing apparatus. The constrictor valve includes a first guide plate and a second guide plate that are spaced a distance apart along the length of the conduit. Extending between the two guide plates, a plurality of elongate members have first and second ends engaged on the first and second guide plates. Upon rotation of at least one of the first and second guide plates, the elongate members are configured to impart pressure on, and constrict the conduit.

Owner:UNITED STATES GYPSUM CO

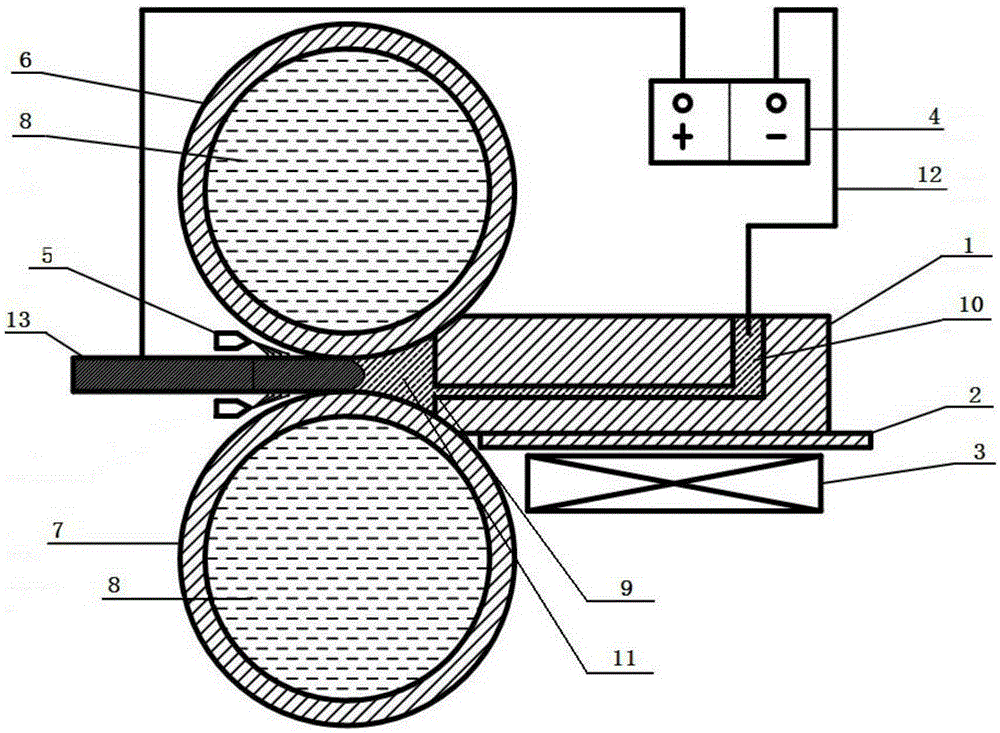

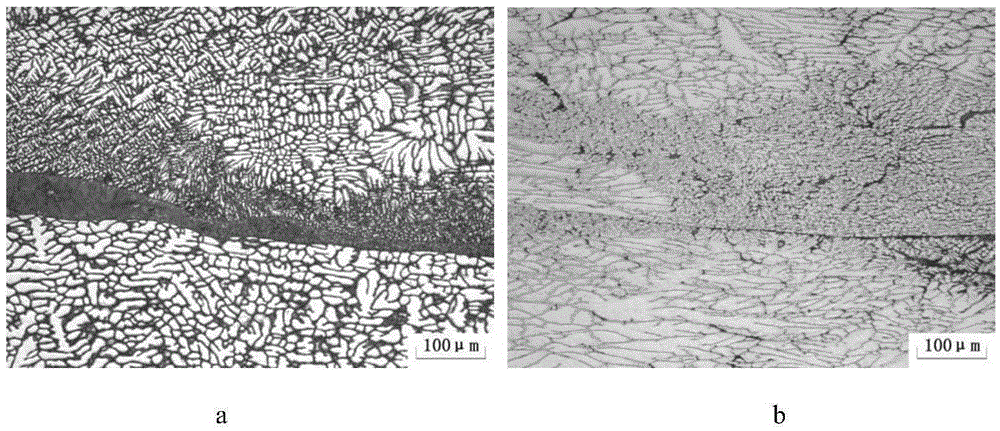

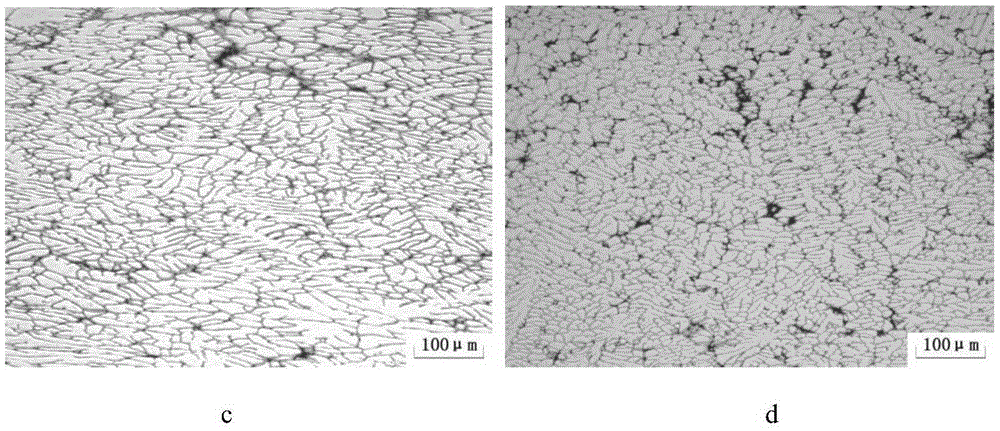

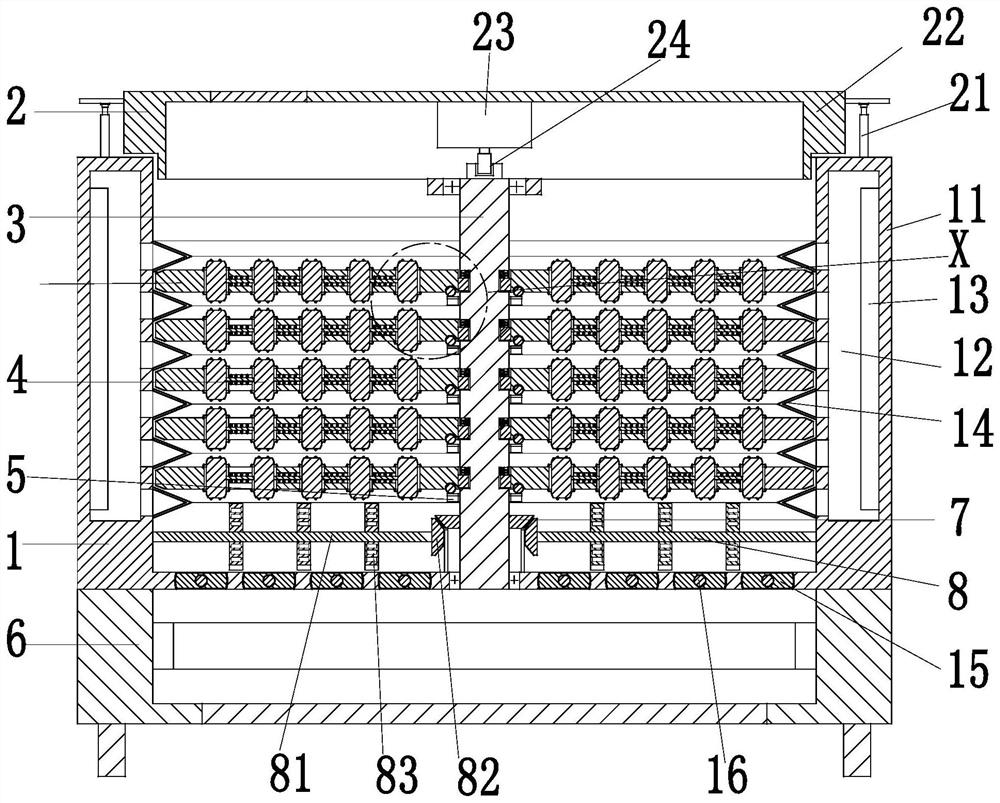

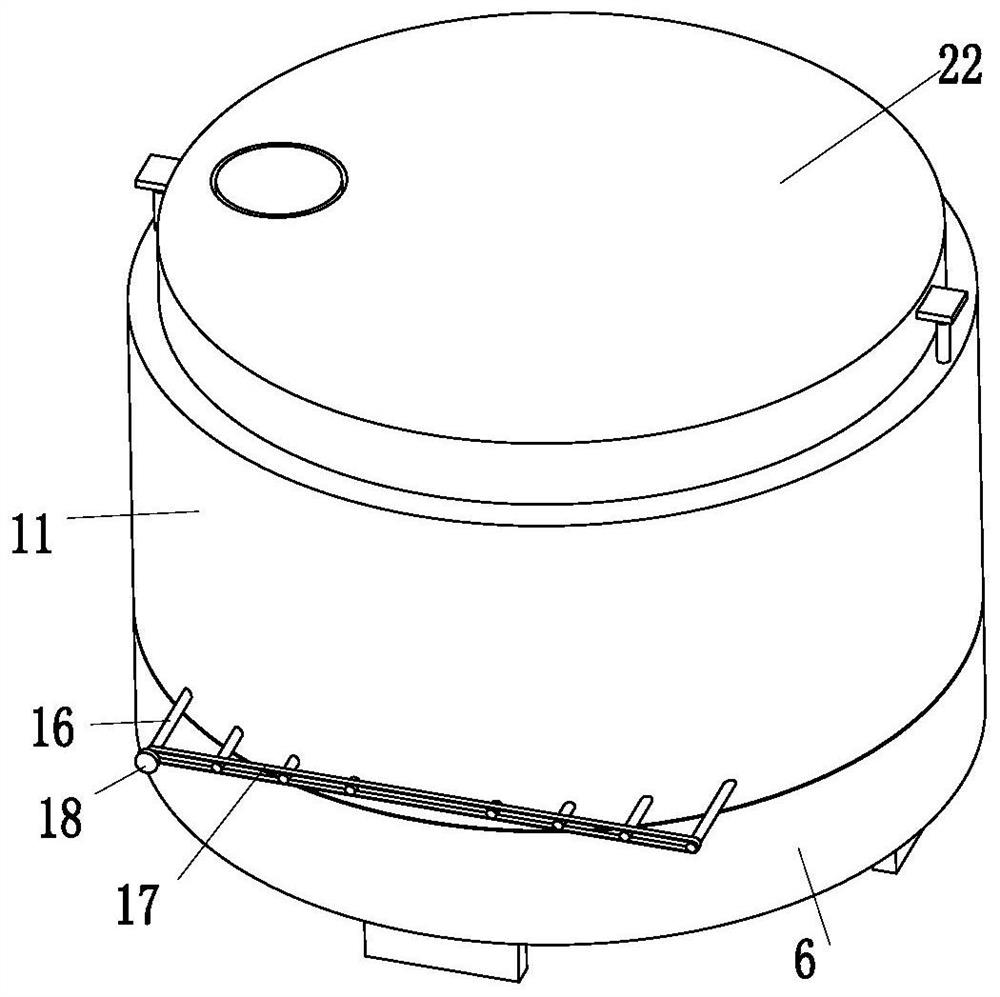

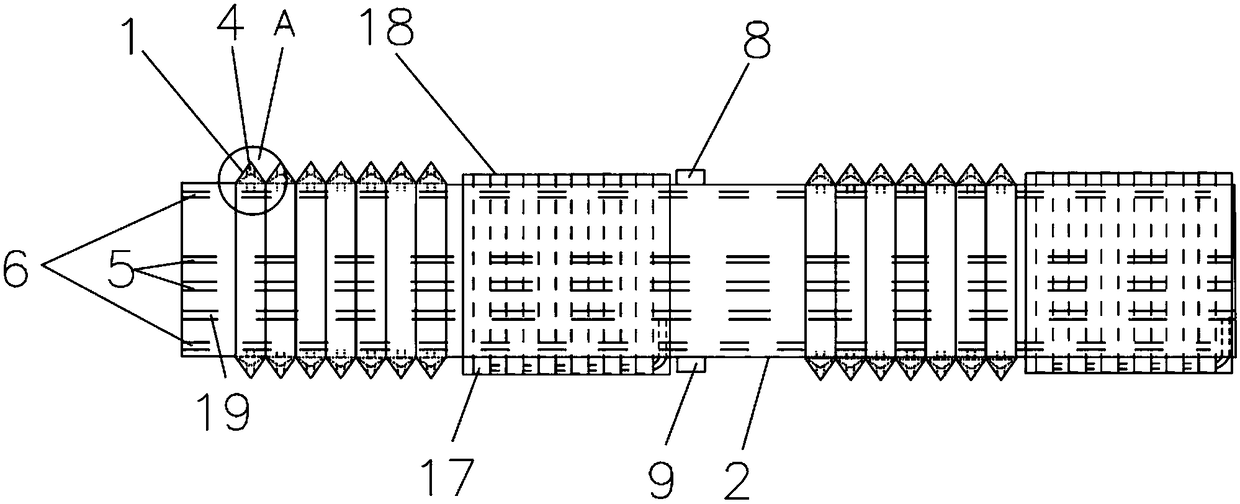

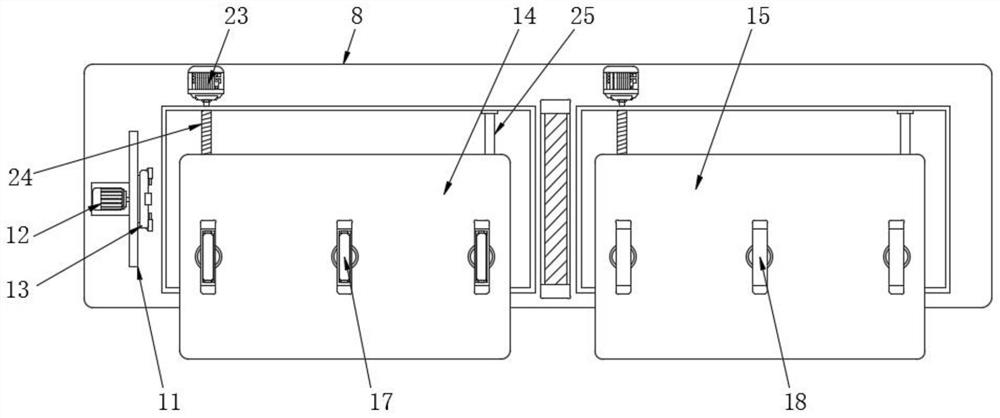

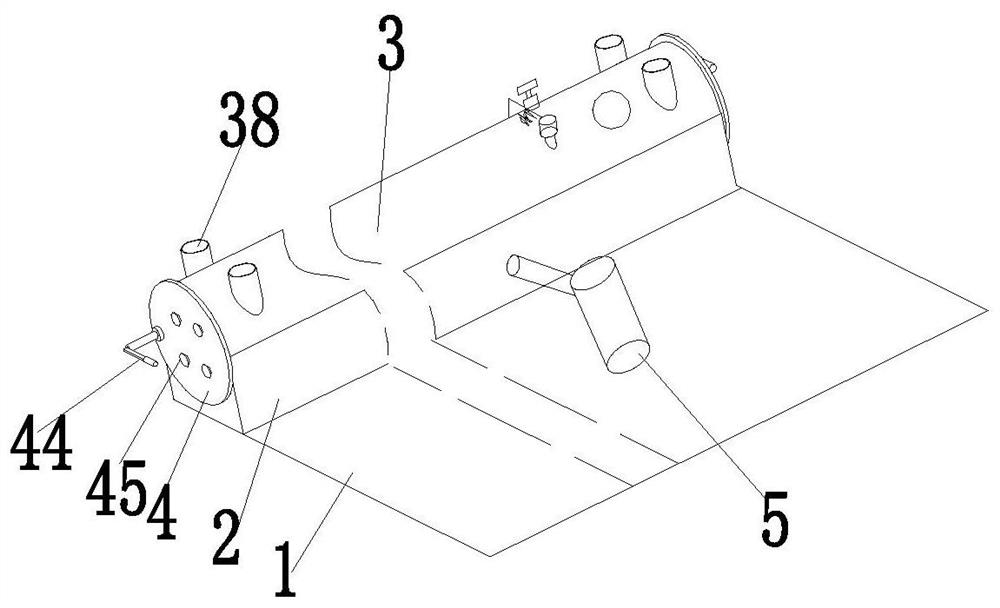

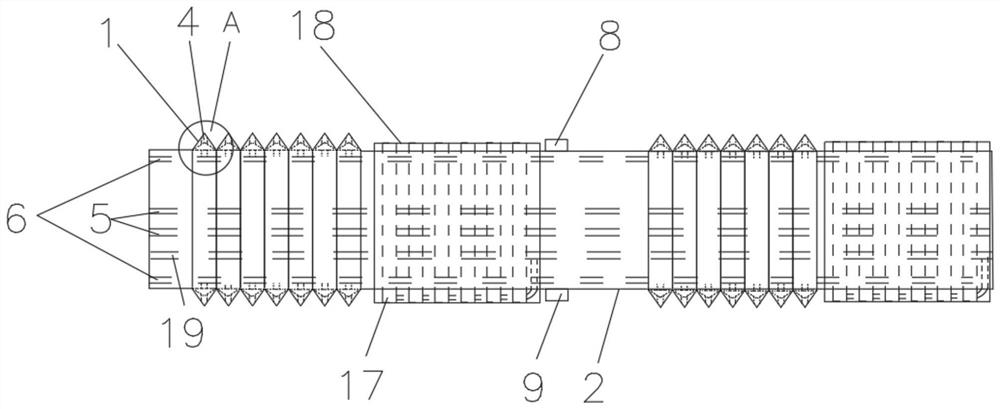

Casting rolling device and method for aluminum alloy plate blank

ActiveCN105397045AAvoid surface and central bandingRefining the slab structureElectromagnetic fieldPulse power supply

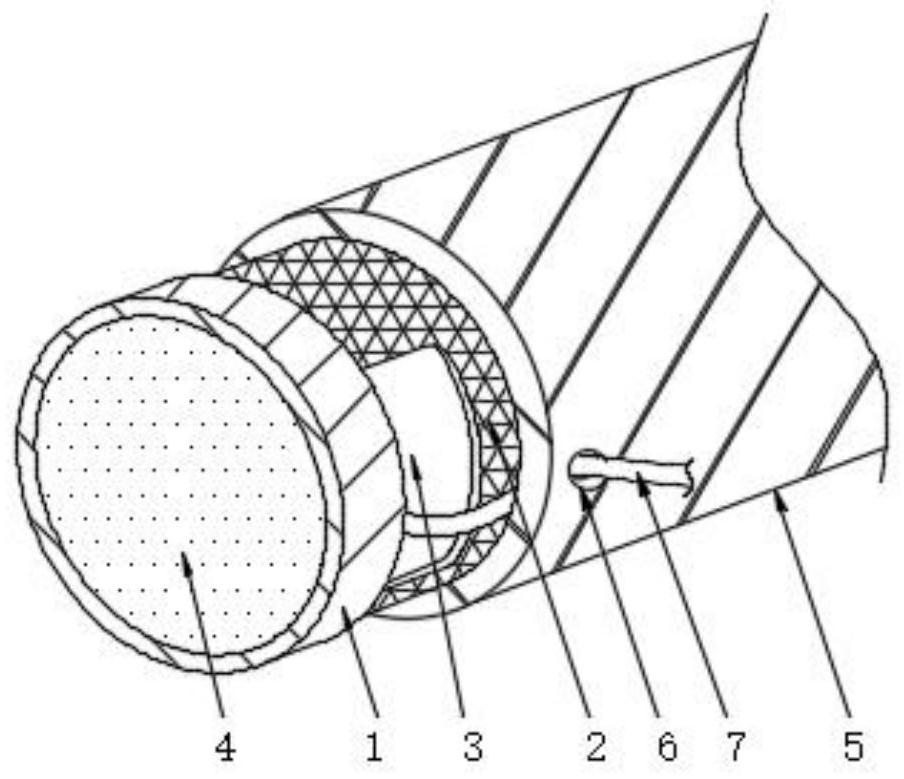

The invention provides a casting rolling device and method for an aluminum alloy plate blank, belongs to the field of aluminum alloy casting-rolling equipment and production, and aims at solving the technical problems of the casting rolling method for producing thick aluminum alloy plate blanks. The device comprises a casting port, a platform, a casting-rolling roller, an electromagnetic field generating device and / or a pulse power supply, and a water spraying cooling device. The casting rolling method comprises the following steps: mixing materials of the aluminum alloy based on the content ratio of each component, and smelting into a melt; conveying the aluminum alloy melt into the casting port of the device to form a standing plate so as to form a solidified housing with proper thickness on the surface of the plate blank; starting the water spraying cooling device, the electromagnetic field generating device and / or the pulse power supply to perform casting-rolling after the standing plate is formed; stopping casting-rolling after the plate blank reaches a certain length, so as to obtain the aluminum alloy plate blank. With the adoption of the device and the method, a casting-rolling area can be prevented from early solidifying, so that the segregation of the plate blank can be reduced; in addition, the melt can be prevented from pollution while a structure is refined.

Owner:NORTHEASTERN UNIV

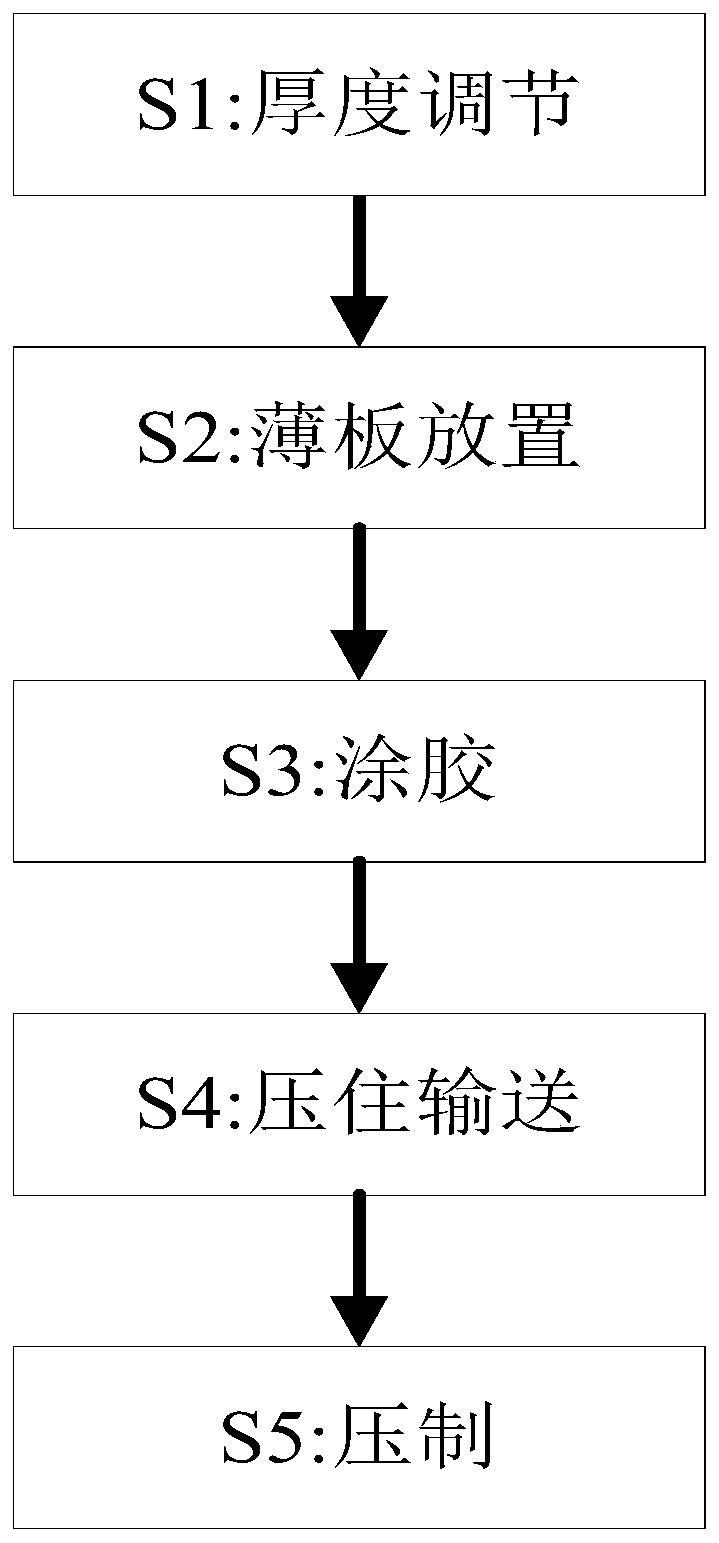

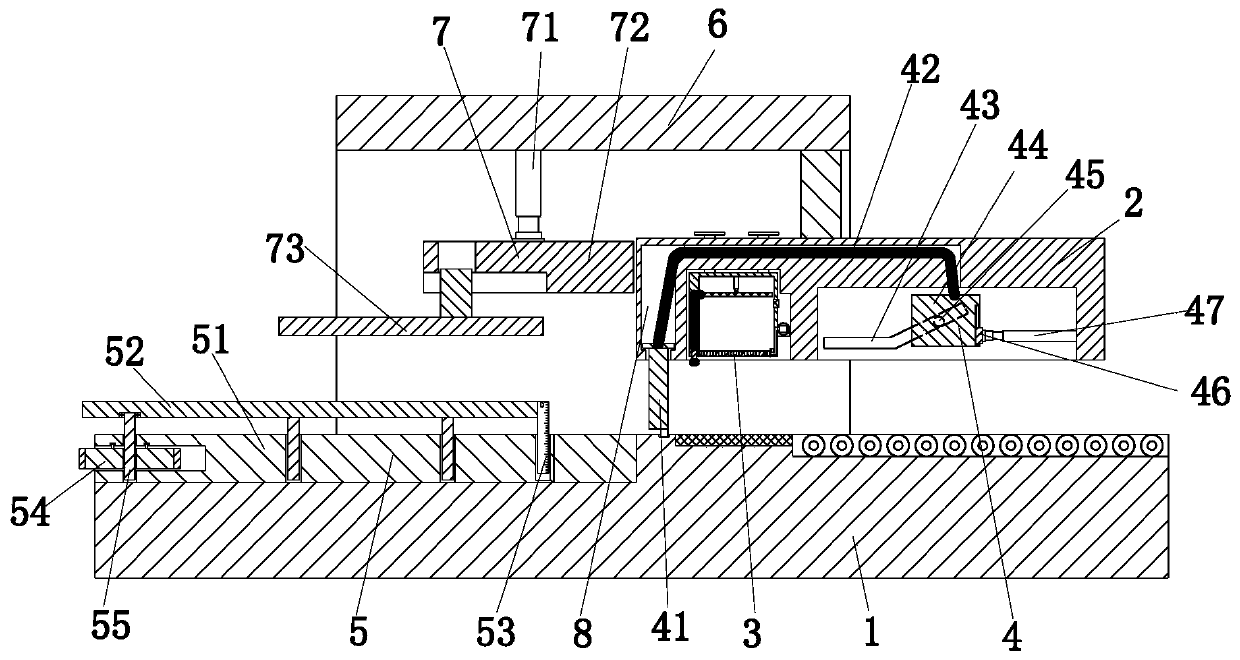

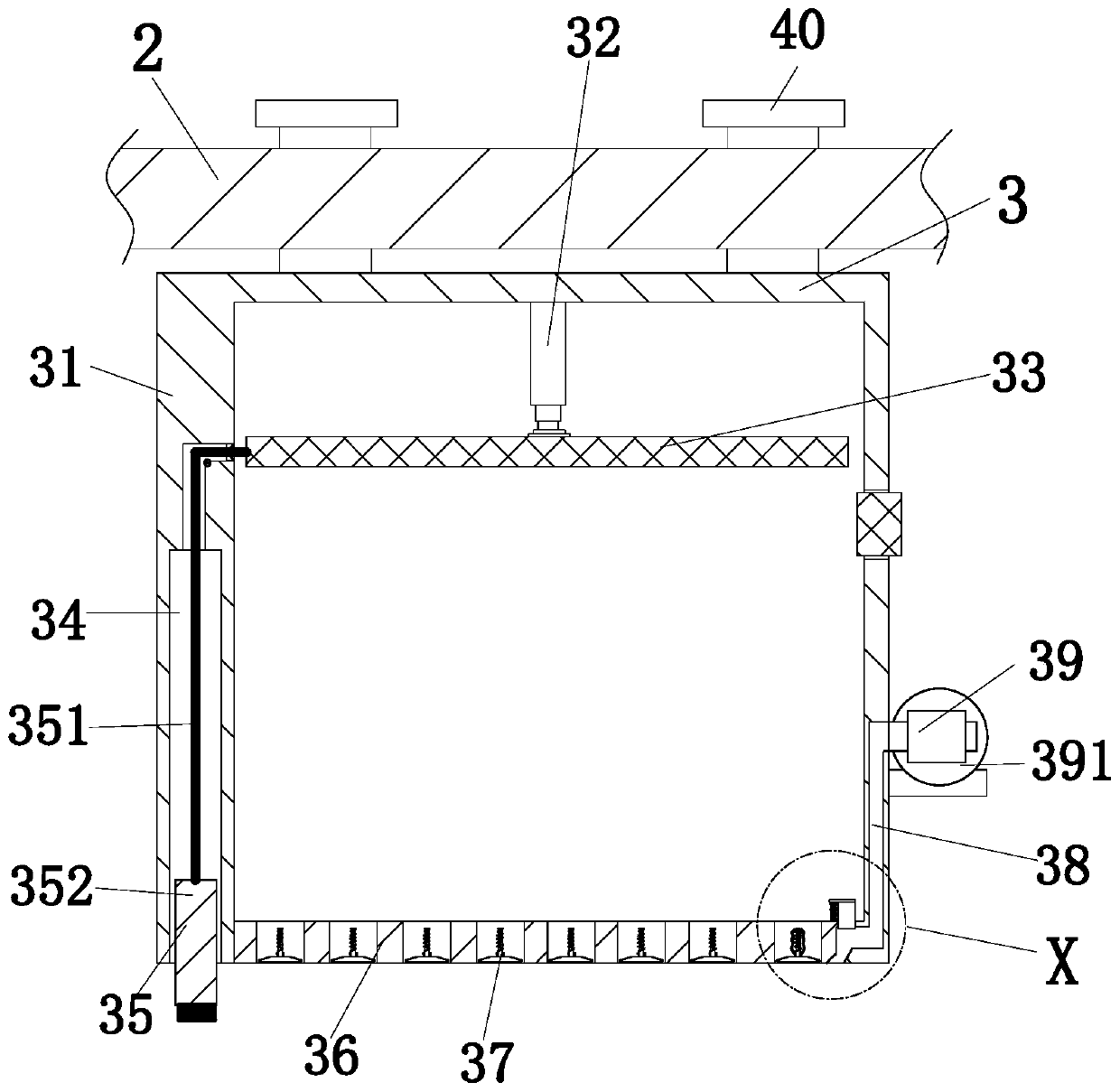

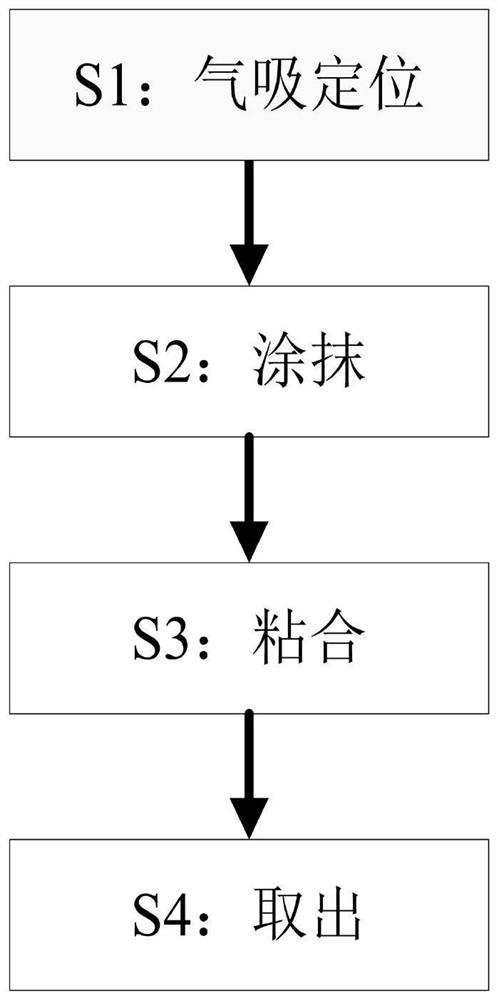

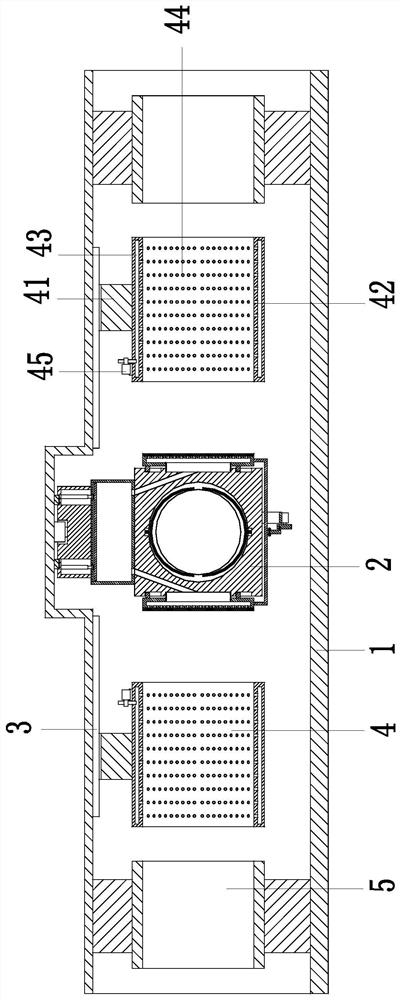

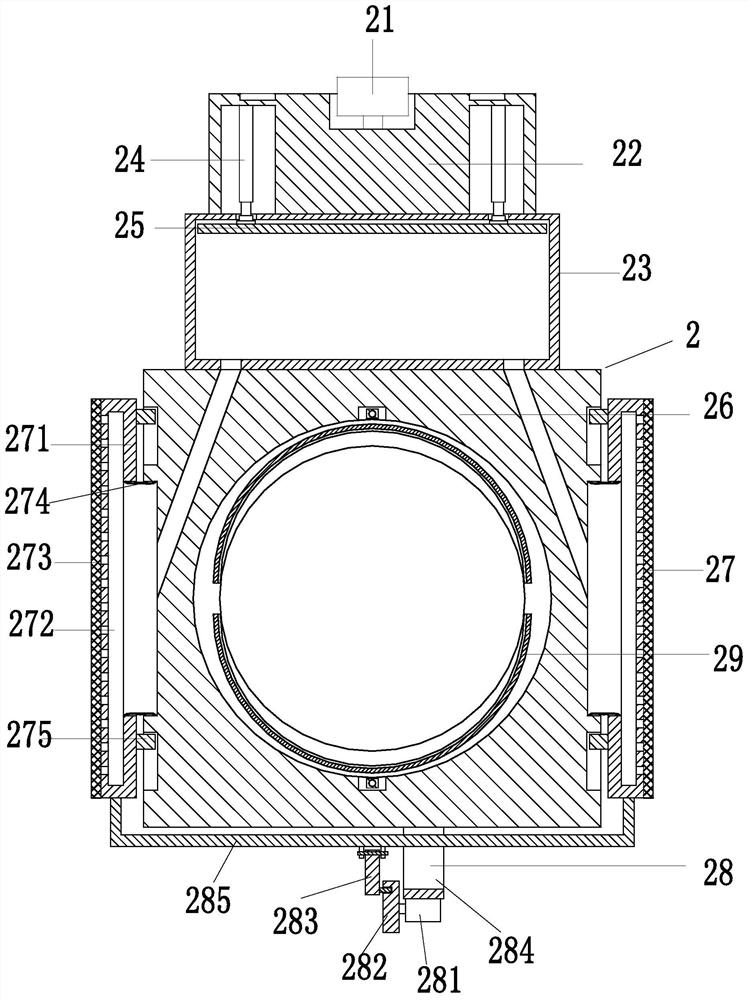

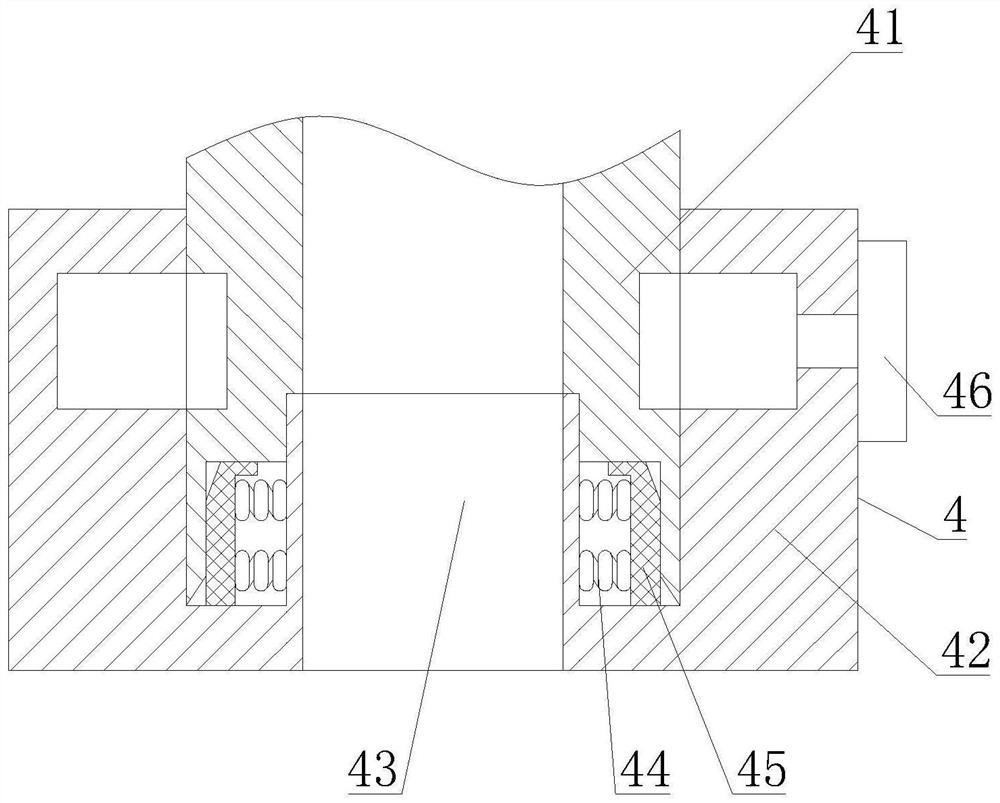

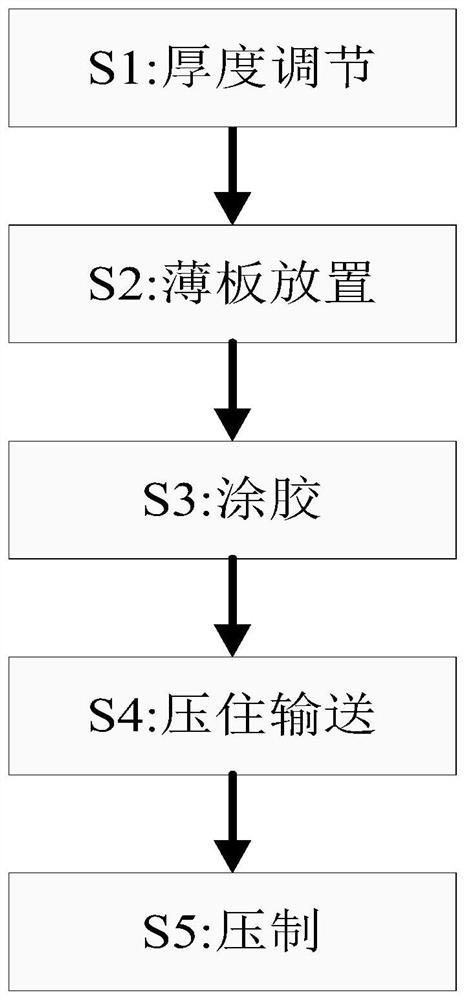

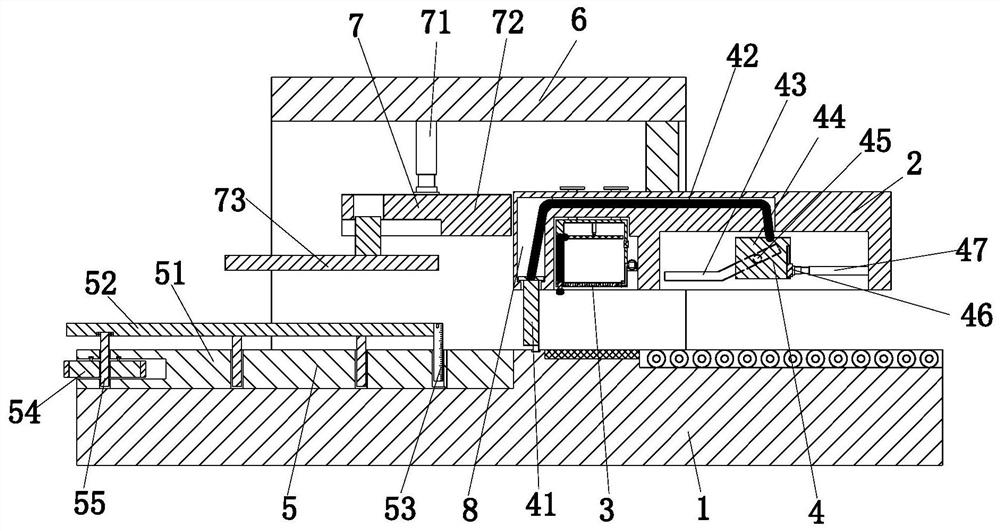

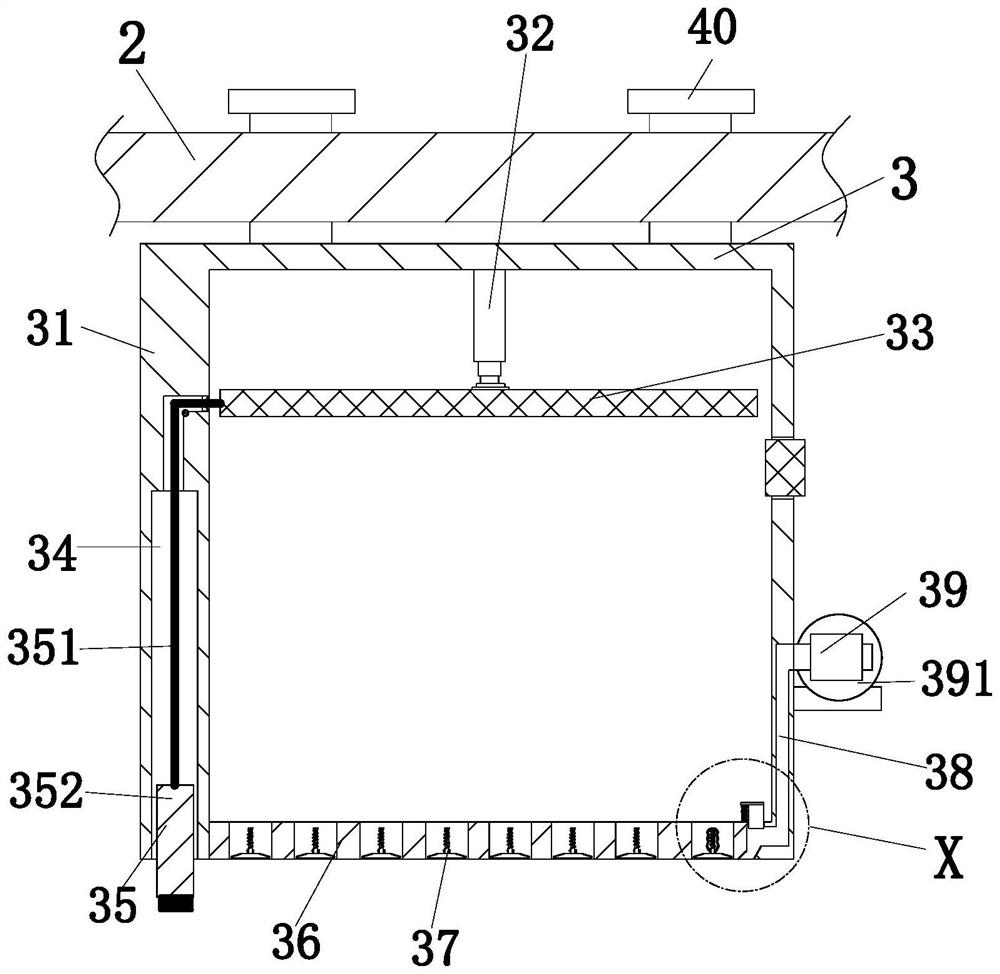

Hot press splicing process for plate manufacturing

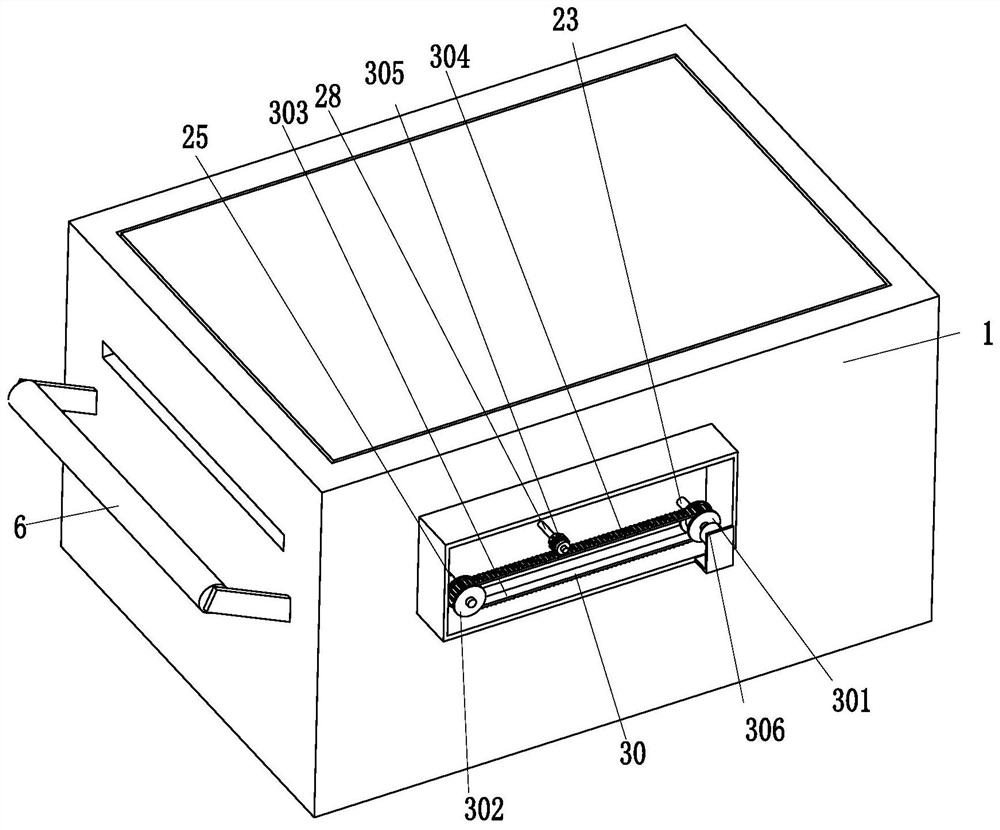

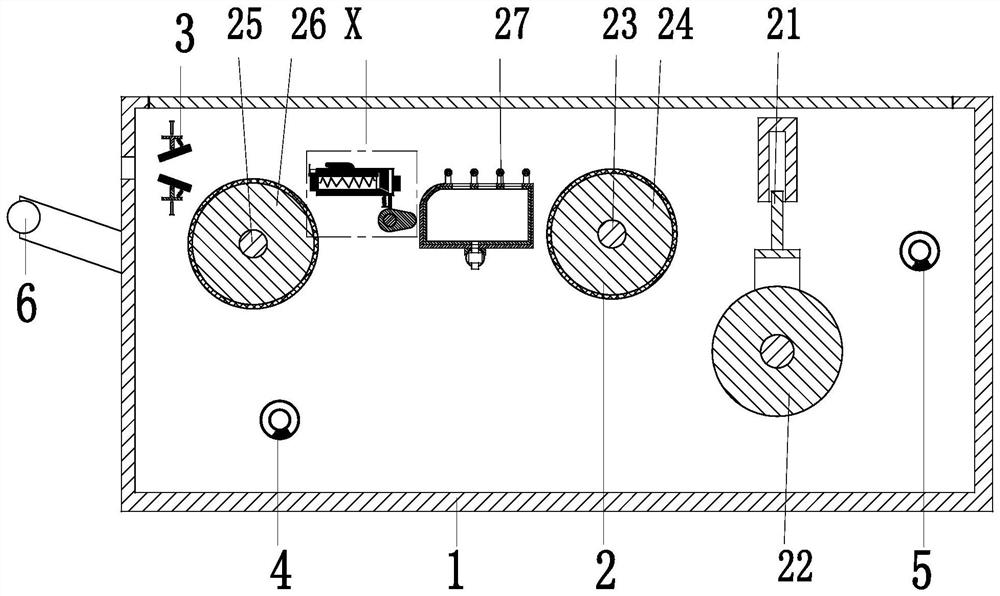

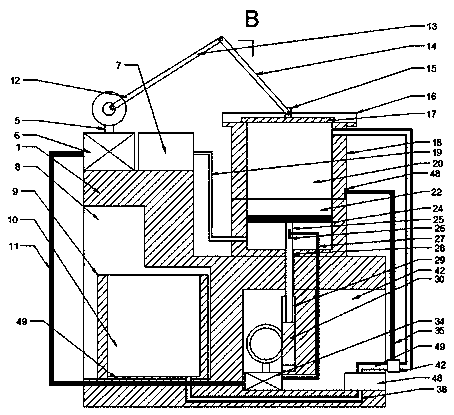

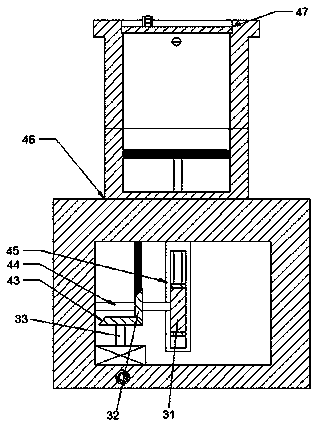

ActiveCN111319105AImprove efficiencyAvoid unevennessLiquid surface applicatorsWood veneer joiningAdhesive glueMachining process

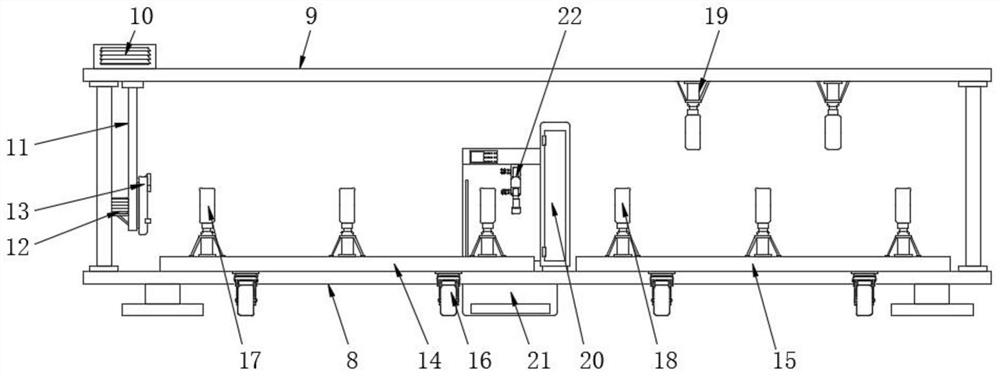

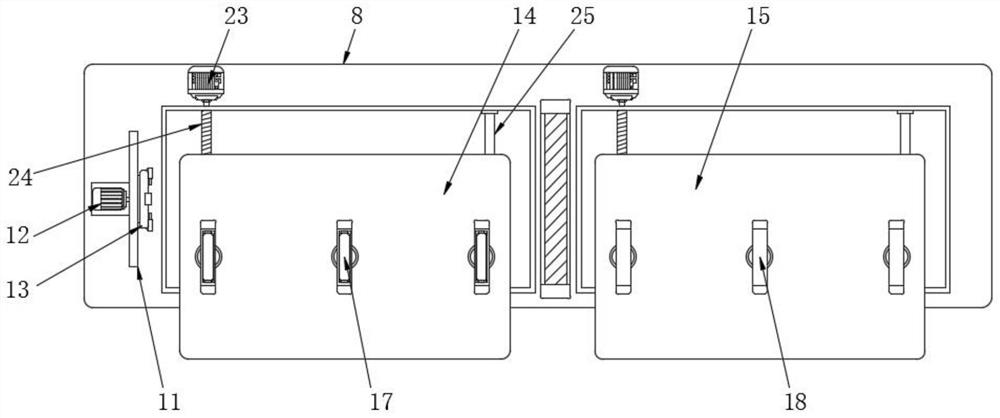

The invention provides a hot press splicing process for plate manufacturing. A base, a frame, a gluing device, a positioning device, a thickening device, a U-shaped frame, a pressing device and a conveying cavity are cooperated to complete work. The problems that manual gluing is low in efficiency and long in consumed time, glue is likely to be solidified in advance due to long consumed time, thesplicing quality of two thin plates is lowered, during splicing, glue is not evenly spread, the solidified spliced position is locally unglued, the two thin plates are difficult to align due to manualplacement, the two thin plates have two many splicing areas, and therefore waste is caused can be solved.

Owner:广东国景家具集团有限公司

Tenacity anti-fluid-channeling cement slurry for solid expansion pipe fixed well

ActiveCN103320107AImprove engineering performancePrevent premature solidificationDrilling compositionPhysical chemistryEngineering

The invention discloses tenacity anti-fluid-channeling cement slurry for a solid expansion pipe fixed well. The tenacity anti-fluid-channeling cement slurry comprises the following components: 100g of a mixture of G-level oil well cement or G-level cement and silica powder ( when the static temperature of the bottom of the well is more than 110 DEG C), 2.5g-4.2 g of a delaying coagulating agent, 8g-11g of a fluid loss agent, 1g-1.2g of a dispersing agent, 0.5g-0.8g of a toughening agent, 3g-5g of an anti-fluid-channeling agent, 0.1g-0.3g of an antifoaming agent, and 37.3g-41g of tap water, wherein the toughening agent is formed by mixing fiberglass the length of which is 0.3-2mm and polyamide fiber the length of which is 3-5mm according to the mass ratio of 2:1, and the other matters are sold in a market. The cement slurry provided by the invention has the advantages that the cement slurry has the strong sealing property and good comprehensive property, can ensure that a solid expansion pipe is safely and reliably expanded and improve the sealing quality of a cement ring of the solid expansion pipe, and supplements the defects and disadvantages of the prior art.

Owner:成都西南石大石油工程技术有限公司

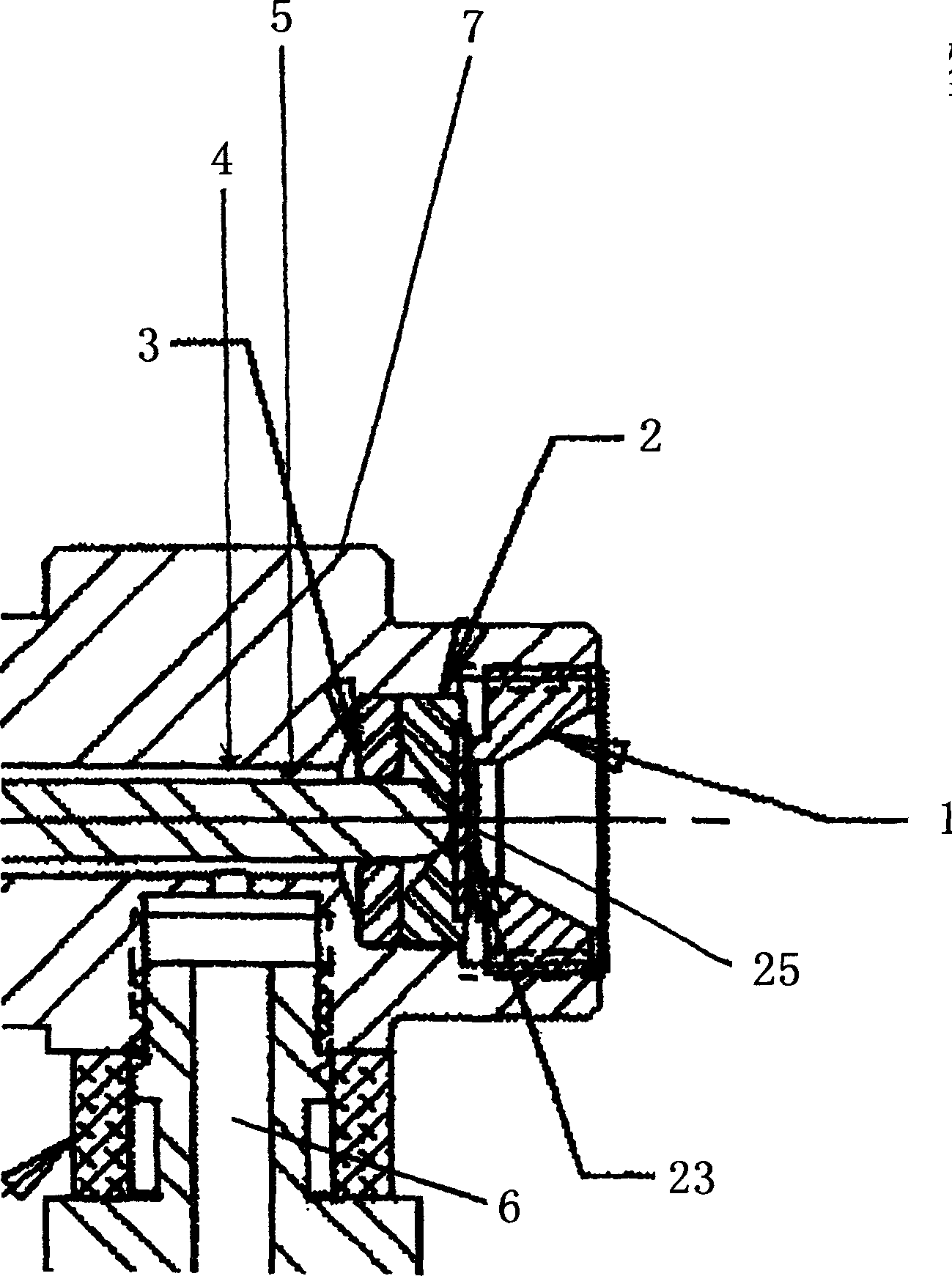

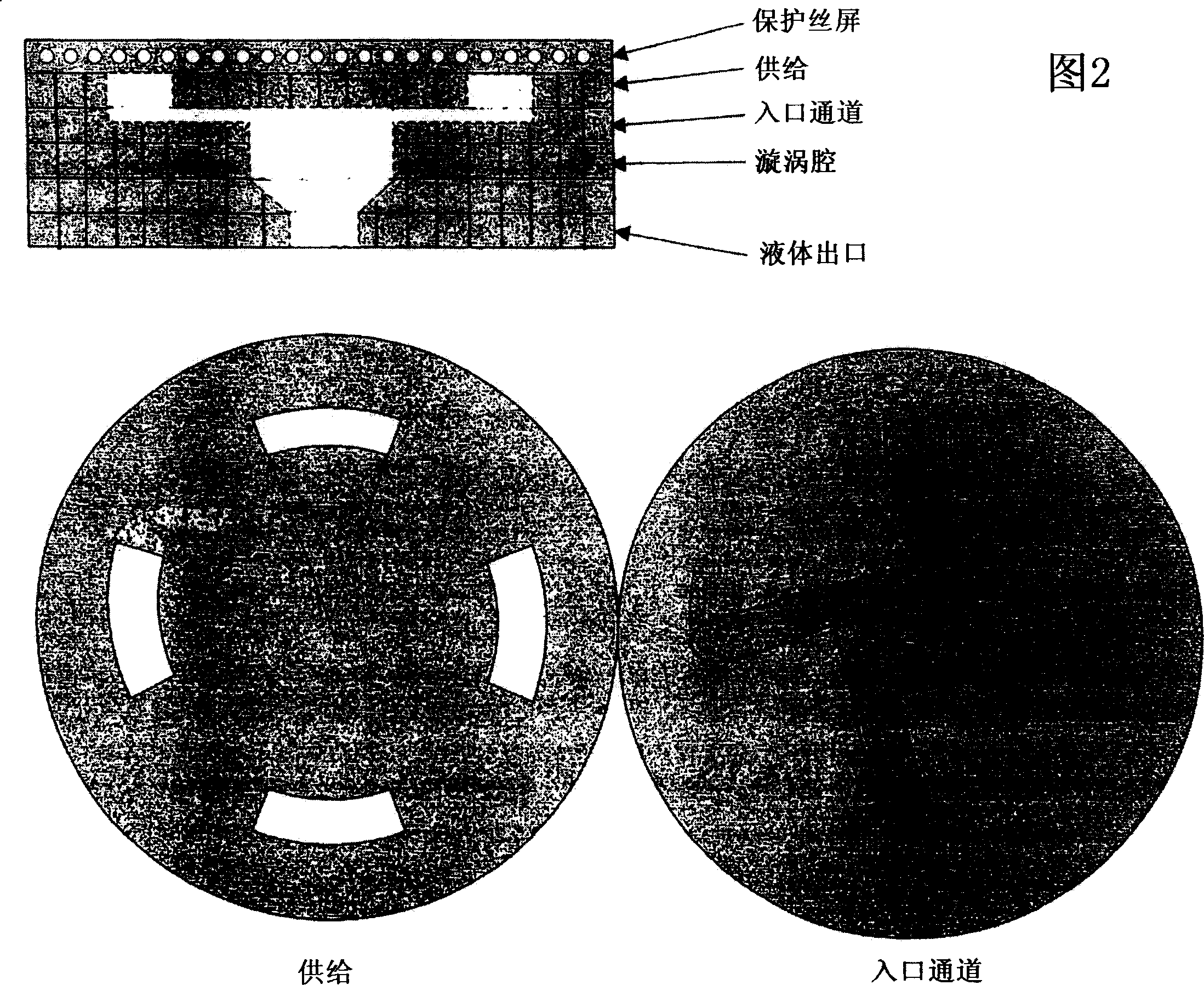

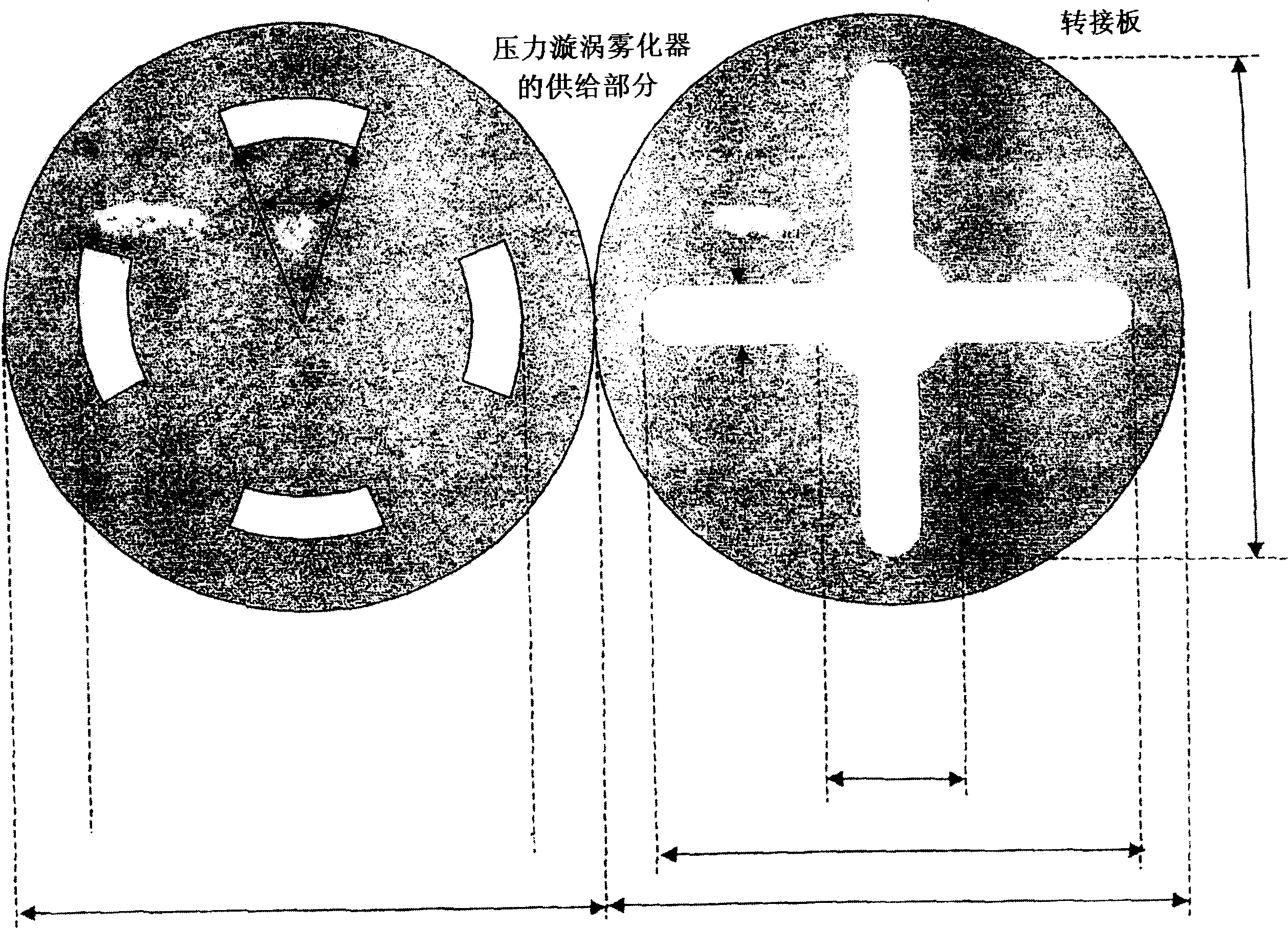

Injection device for the treatment of exhaust fumes from motor vehicles

ActiveCN1840872ACheap and simpleReduce work stressInternal combustion piston enginesExhaust apparatusCombustionExhaust fumes

Owner:CUMMINS LTD

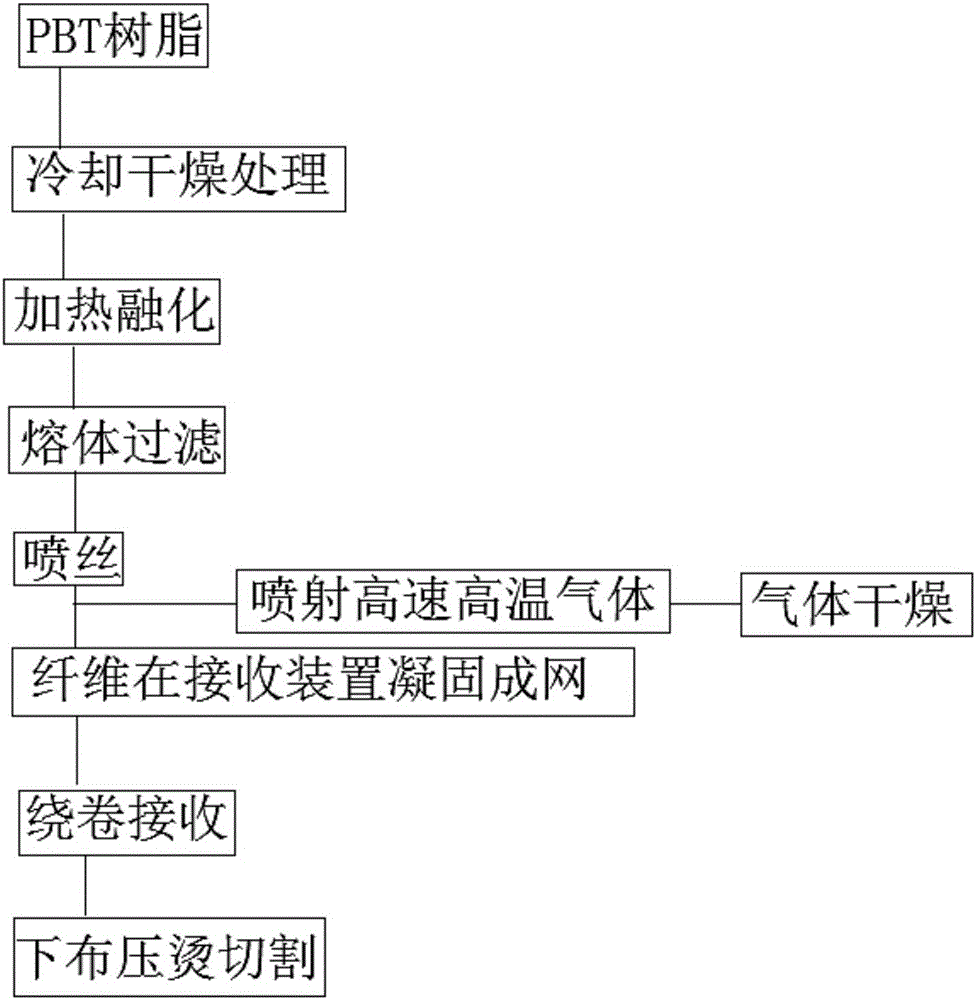

Continuous non-woven fabric melt-blowing method and non-woven fabric

InactiveCN105734834ASimple methodHigh degree of mechanizationMelt spinning methodsNon-woven fabricsNonwoven fabricMelt blowing

The invention discloses a continuous non-woven fabric melt-blowing method and a non-woven fabric. The method comprises the following specific steps that a PBT raw material is prepared, subjected to drying treatment and then fed to an extruding machine through a feeding machine, the particle PBT material is heated and melted by the extruding machine, the heated and melted PBT is fed to a spinneret plate at a mold spinneret for spinning, ultrafine fibers are formed under gas drafting, sprayed to a receiving device moving transversely at a high speed and moving longitudinally at a low speed, and cooled with air to form the non-woven fabric, and then the non-woven fabric is fed to a roller receiving machine to be rolled. The method is simple and high in mechanization degree and production efficiency, and the non-woven fabric meeting medical application can be produced.

Owner:ZHANGJIAGANG GAOPINCHENG MEDICAL EQUIP TECH

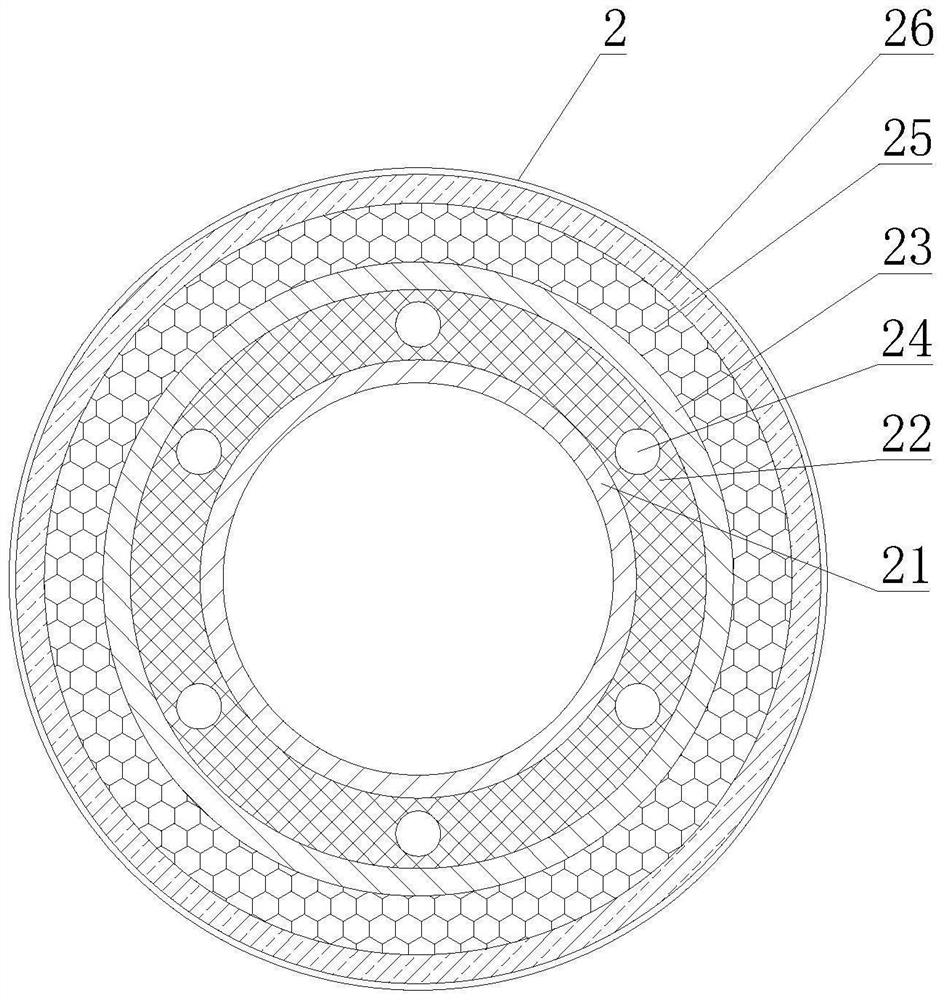

Heat-resistant insulating MPP power cable tube and preparation method thereof

ActiveCN112310906AStrong heat resistanceImprove high temperature resistanceElectrical apparatusTubular articlesElastomerPower cable

The invention discloses a heat-resistant insulating MPP power cable tube and a preparation method thereof, belonging to the technical field of cable tube processing. The heat-resistant insulating MPPpower cable tube comprises an inner pipeline, wherein the outer surface of the inner pipeline is sleeved with an insulating net, the inner wall of the inner pipeline is coated with a lubricating layer, one side of the insulating net is provided with a storage groove, one end of the insulating net is fixedly connected with a wire, and the outer side of the inner pipeline and the outer side of the storage groove are sleeved with an MPP outer pipeline. The MPP outer pipeline comprises the following raw materials by weight: 60-80 parts of isotactic polypropylene resin, 5-10 parts of block copolymer polypropylene, 3-5 parts of olefin block copolymer elastomer OBC, 0.5-2 parts of heat-resisting insulating orange master batch and 10-20 parts of ultra-high-molecular-weight polyethylene resin. TheMPP outer pipeline on the outermost side of the heat-resistant insulating MPP power cable tube is higher in heat resistance and external pressure resistance, the inner pipeline on the innermost side is higher in high-temperature resistance and has good flame-proof capacity, so fire spreading can be avoided when a fire breaks out.

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

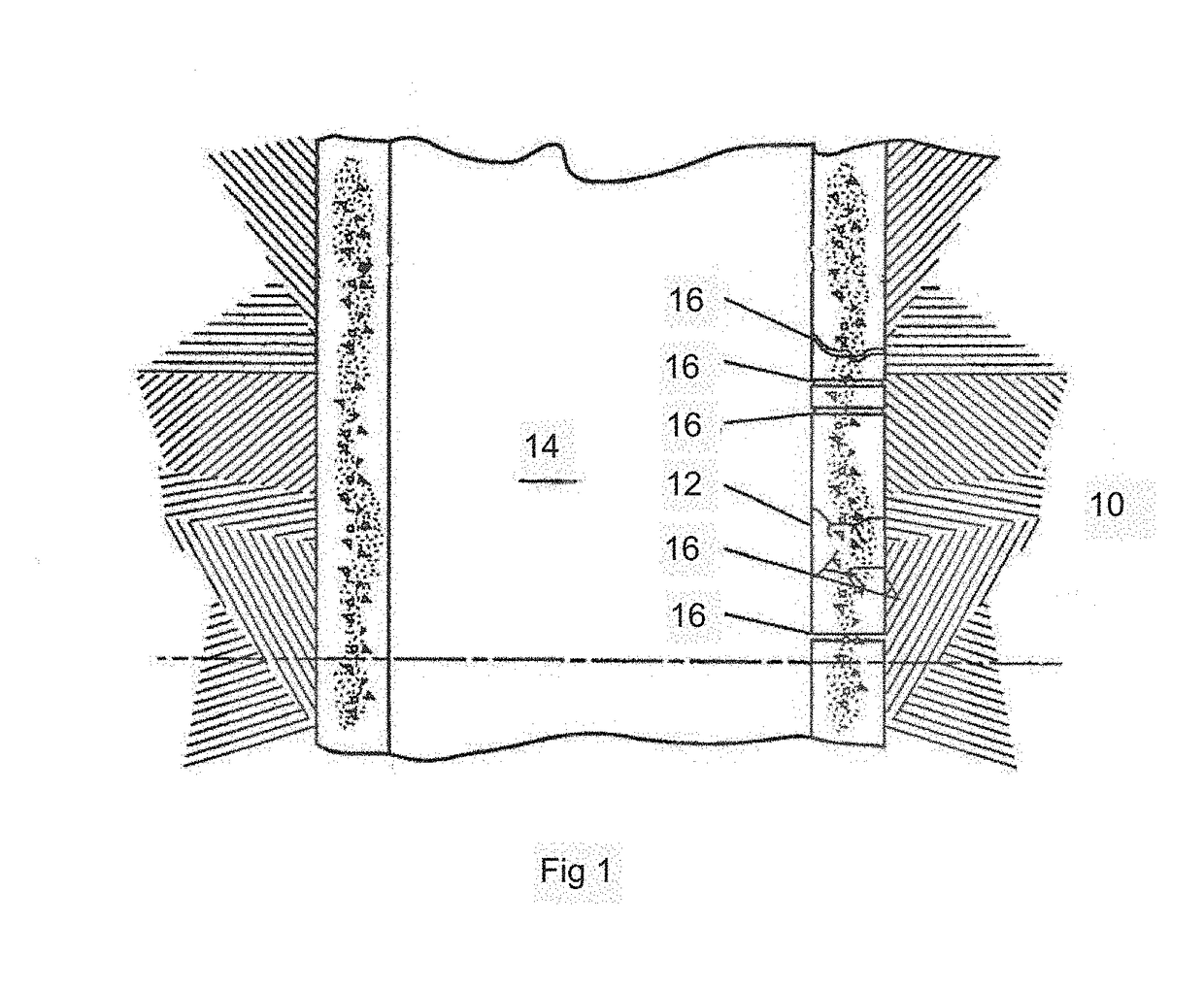

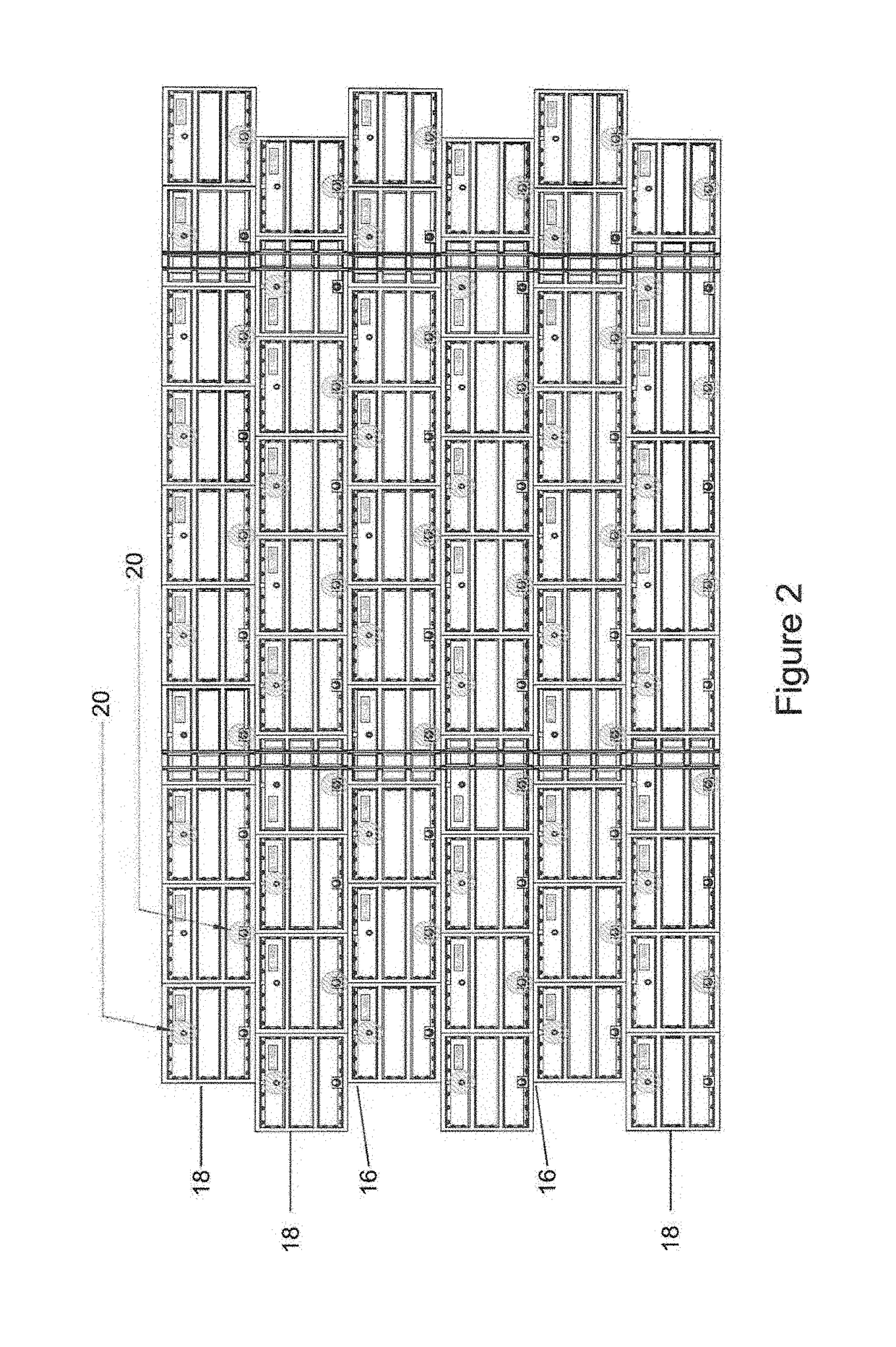

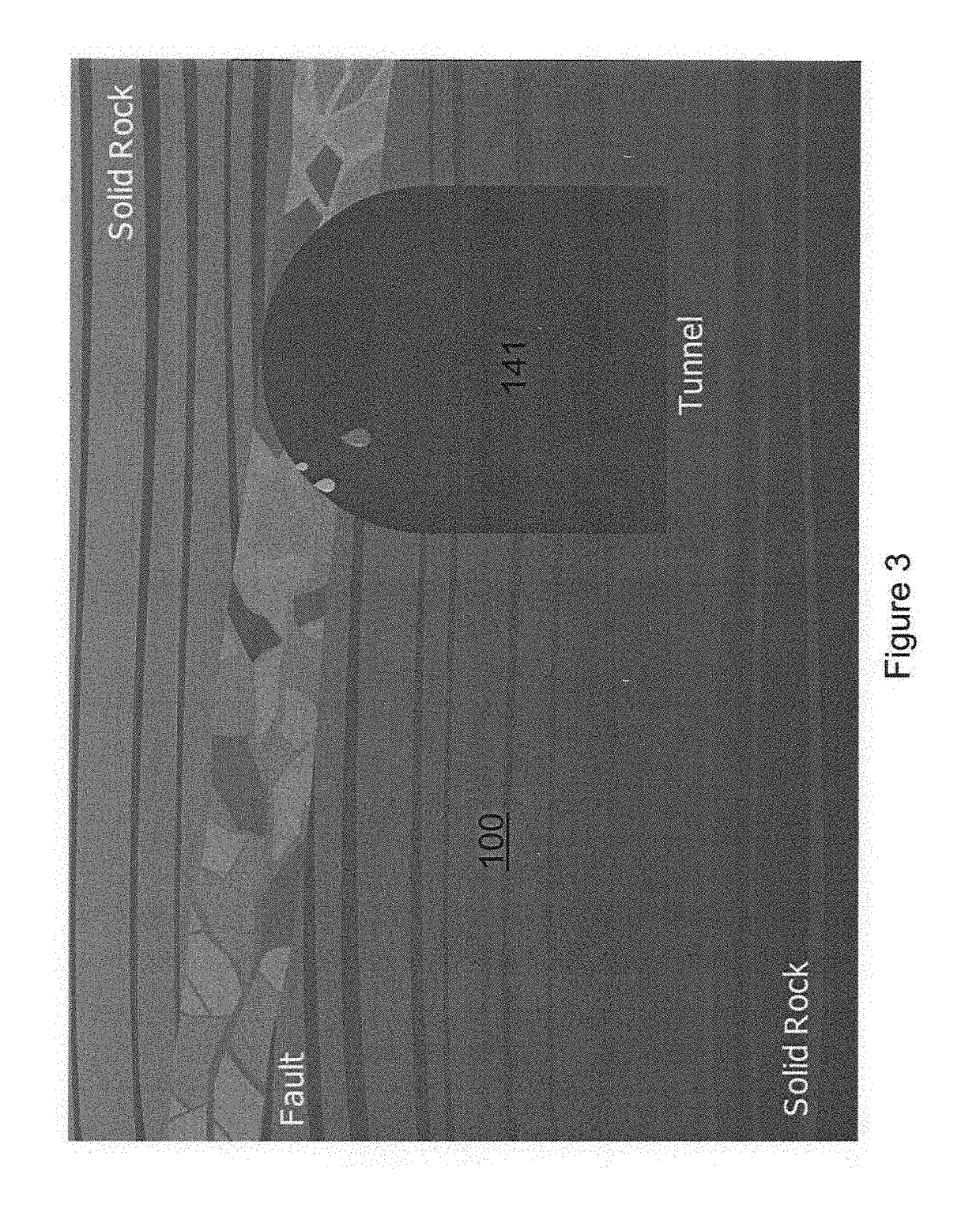

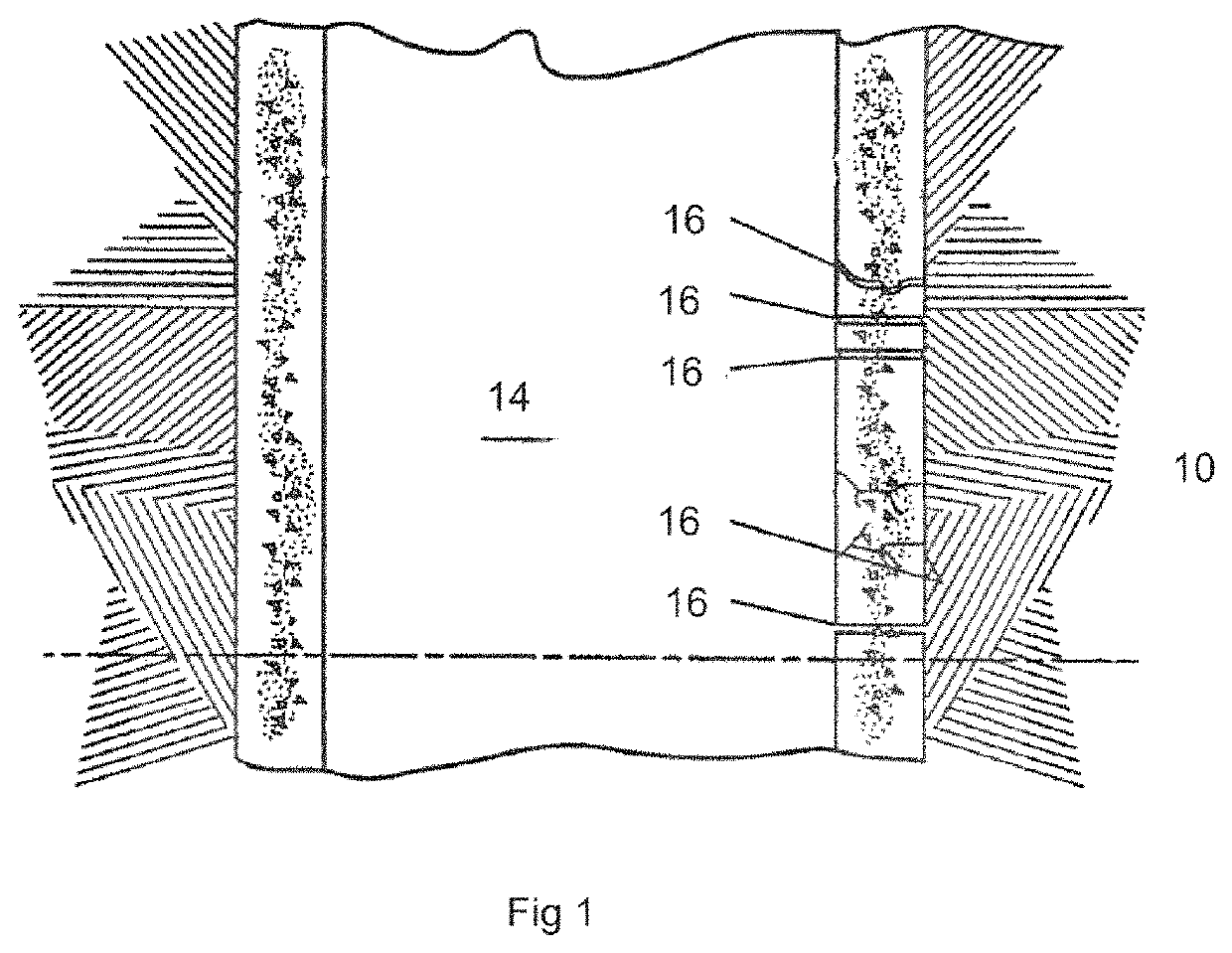

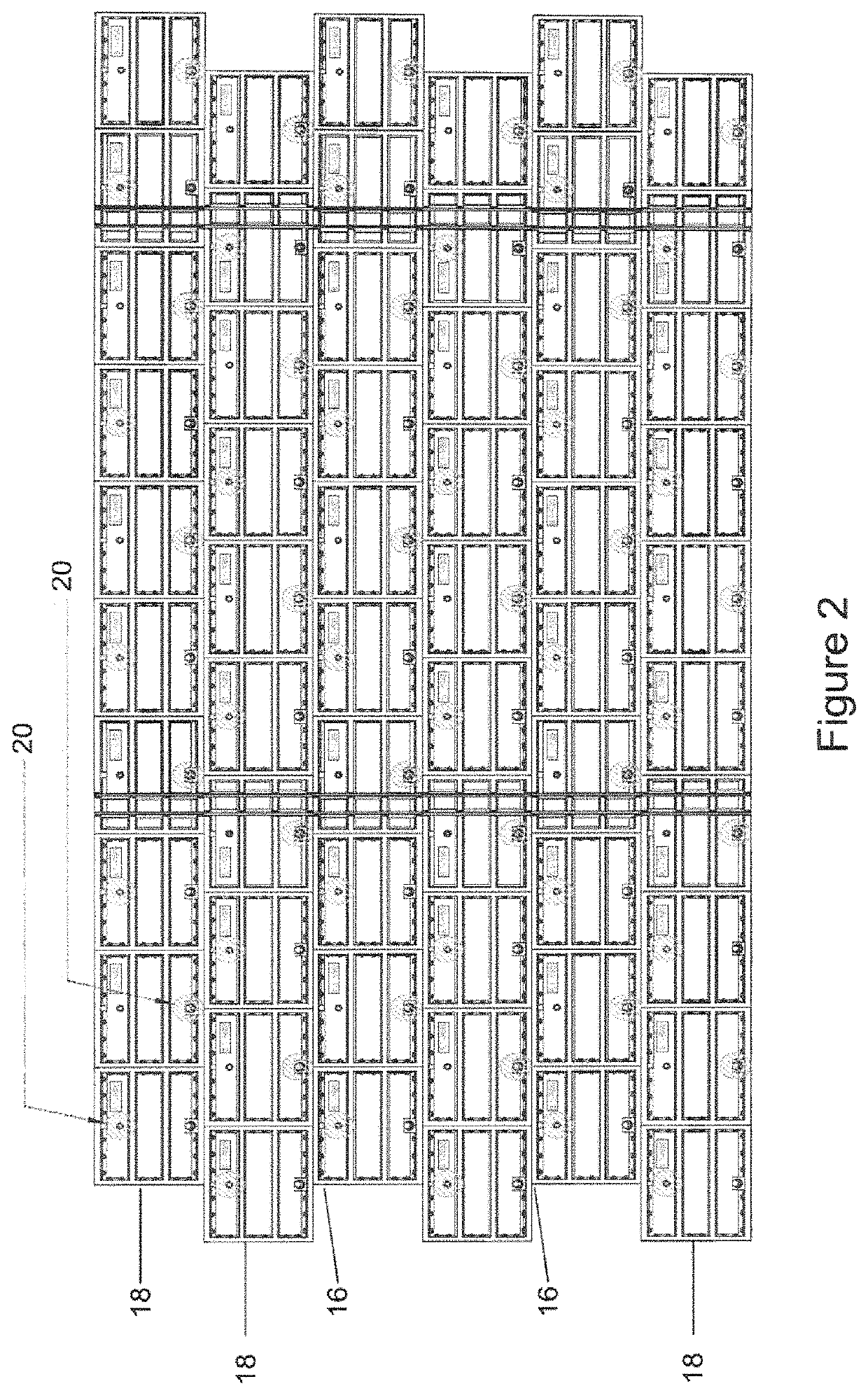

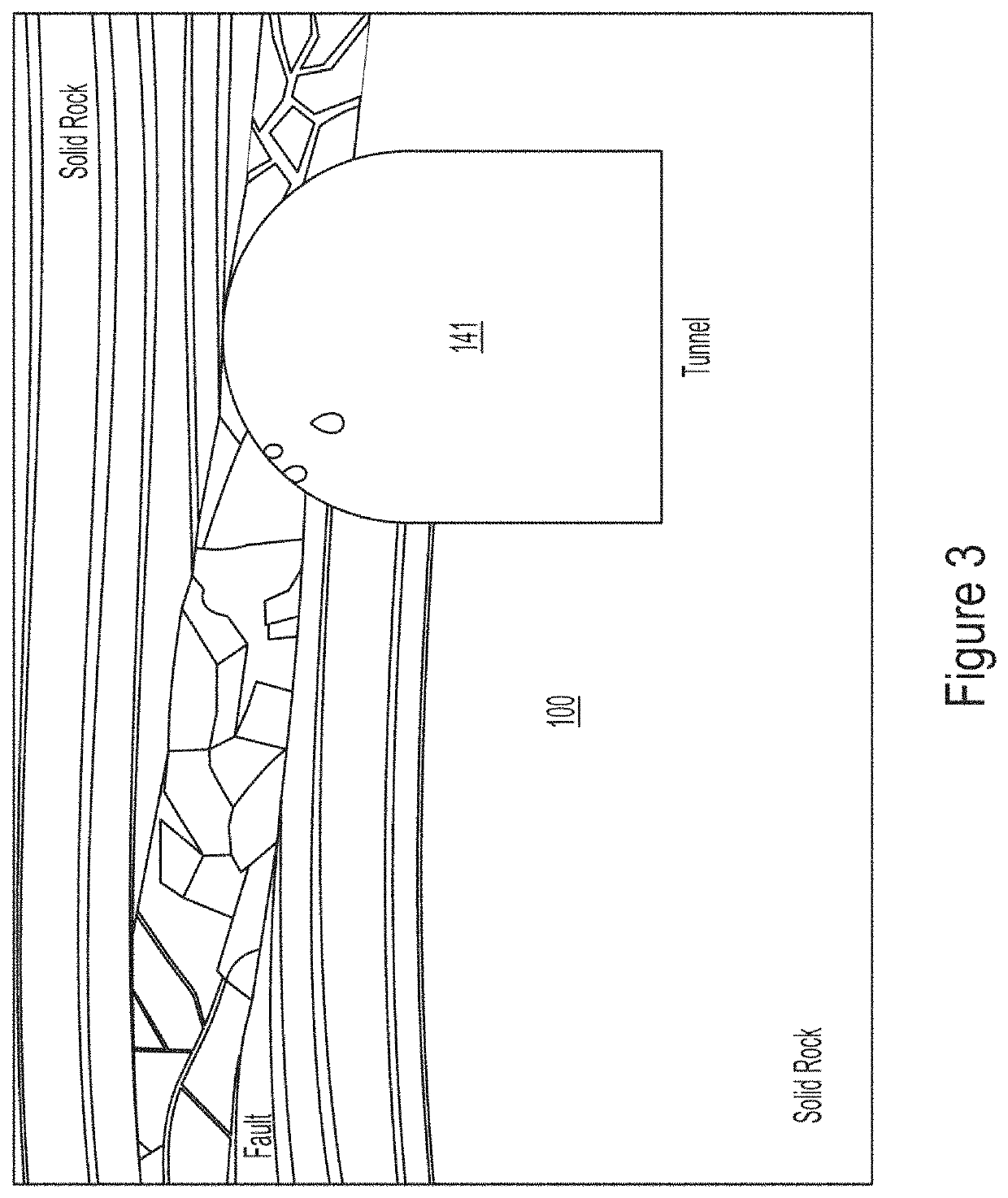

Method of limiting permeability of a matrix to limit liquid and/or gas inflow

ActiveUS20180340112A1Quality improvementPrevent premature solidificationProtective foundationDrilling compositionPortland cementExothermic process

A method of limiting or reducing permeability of a matrix to liquid and / or gas inflow is described. The method includes limiting inflow of water, liquid and / or gas into passages such as cavities, fissures, voids and the like, encountered in formations such as geological formations though can be used to form barriers to water, liquid or gas flow through a matrix. The method includes steps of measuring one or more parameters relating to the matrix and selecting one or more components of a multi-component sealing composition with reference to the measured parameters. The selected components are introduced into the matrix where it is set or coagulated in a non-exothermic or low exothermic process to form a seal barrier. Also disclosed is a sealing composition comprising a coagulable polymer emulsion or colloid contactable with at least one selected additive which interacts with the polymer emulsion or colloid to form a coagulated mass for forming a sealing barrier in a non-exothermic or low exothermic setting process in which the polymer emulsion or colloid contains, prior to purposeful coagulation due to interaction with the selected additive, particles having a size distribution smaller than for Portland cement.

Owner:RELBORGN +1

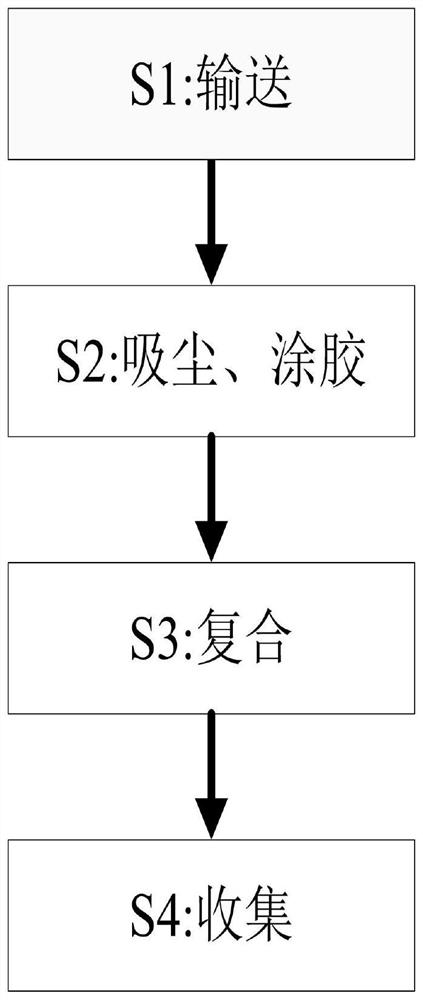

Manufacturing method of self-adhesive label

InactiveCN112606528AEnsure the uniform amount of glueWon't squeeze inLamination ancillary operationsLaminationAdhesive cementAdhesive glue

The invention provides a manufacturing method of a self-adhesive label. The manufacturing method is implemented by matching a frame body, a tightening type gluing device, two pressing devices, a backing paper collecting roller, a base material collecting roller, an electric roller and wiping cotton. The manufacturing method can solve the problems that in a traditional compounding process, an adhesive is difficult to be uniformly smeared on the back surface of a base material by manual brushing, dust is likely to be attached to the back face of the base material along with the adhesive, workers easily suffer from sour and numb feeling during manual brushing, and manual brushing is not suitable for long-time assembly line production; and when the base material and backing paper are being pressed after the adhesive is brushed, pressing is generally conducted in the mode that an upper die and a lower die get close to each other to realize direct pressing, and the pressing mode easily causes scattered extrusion of the adhesive in the pressing area and leads to the situation that the compounded self-adhesive label is separated for the second time under the extrusion of redundant adhesive.

Owner:倪敏跃

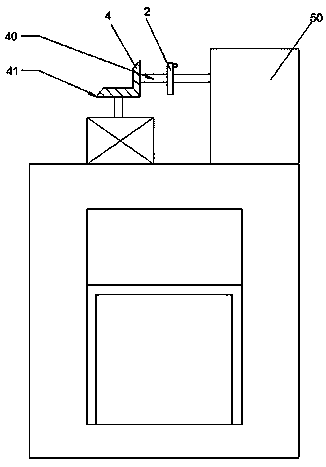

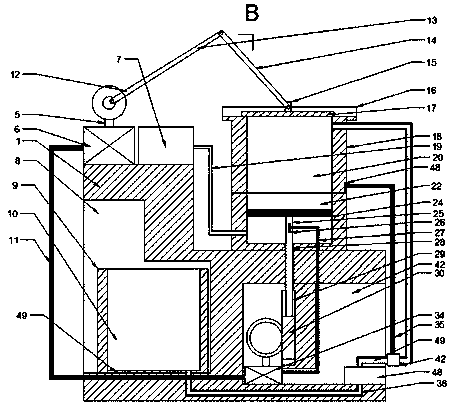

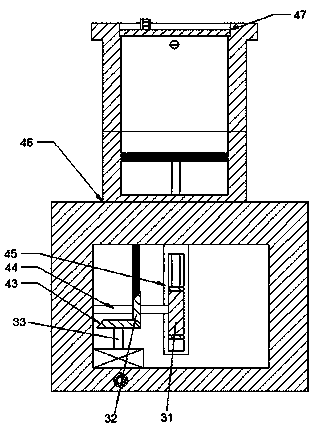

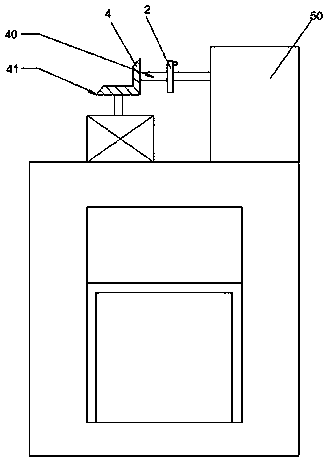

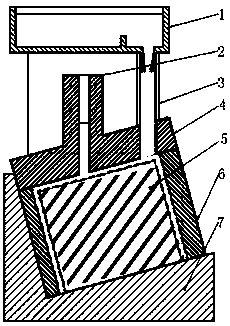

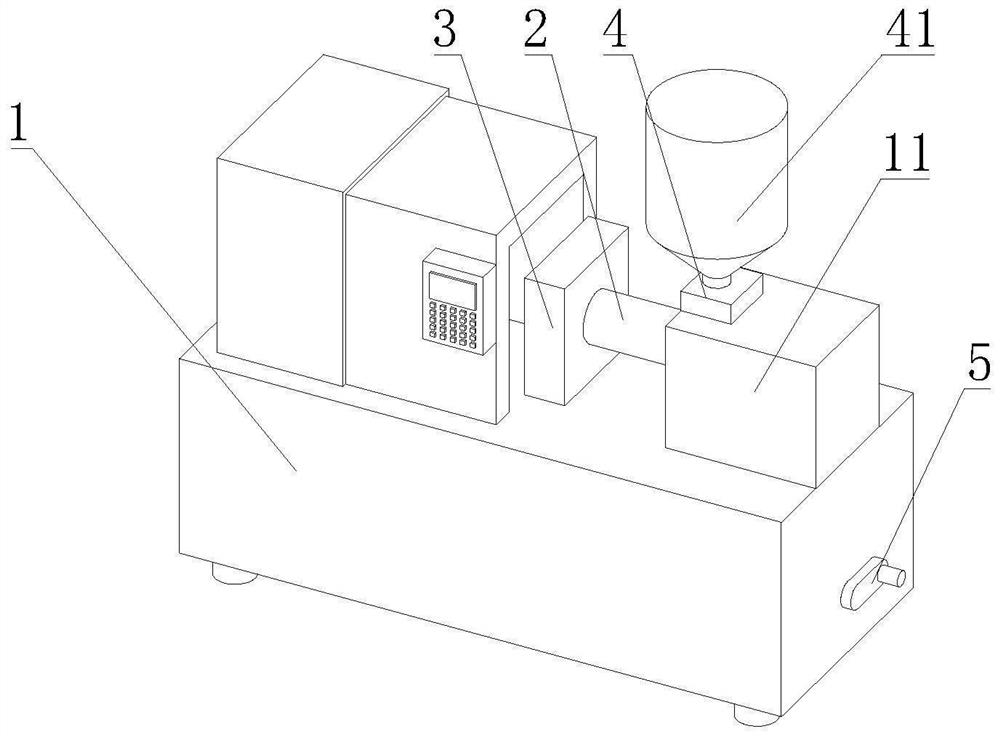

Injection mold

The invention discloses an injection mold. The injection mold comprises a fixed machine body; a hydraulic pump and a second motor are arranged at the right end inside the fixed machine body; the hydraulic pump provides power for a plastic solution to enter an injection molding space; the second motor is used for controlling a transmission mechanism to enable a finished product to be smoothly pushed out; a liquid storage tank is arranged on the left side of the fixed machine body; a resistance wire is arranged below the liquid storage tank, so that the phenomenon that the plastic solution is solidified in advance can be avoided through heating of the resistance wire; a first motor and a cooling device are arranged on the left side of the upper end surface of the fixed machine body; the first motor is used for controlling the transmission mechanism to push a push plate away; and the cooling device can be used for forming the plastic solution.

Owner:义乌市德恒信息科技有限公司

Intelligent injection mold and application method thereof

InactiveCN109228078APrevent premature solidificationLaunched smoothlyHydraulic pumpLiquid storage tank

The invention discloses an intelligent injection mold and an application method thereof. The intelligent injection mold comprises a fixed machine body; a hydraulic pump and a second motor are arrangedat the right end inside the fixed machine body; the hydraulic pump provides power for a plastic solution to enter an injection molding space; the second motor is used for controlling a transmission mechanism to enable a finished product to be smoothly pushed out; a liquid storage tank is arranged on the left side of the fixed machine body; a resistance wire is arranged below the liquid storage tank, so that the phenomenon that the plastic solution is solidified in advance can be avoided through heating of the resistance wire; a first motor and a cooling device are arranged on the left side ofthe upper end surface of the fixed machine body; the first motor is used for controlling the transmission mechanism to push a push plate away; and the cooling device can be used for forming the plastic solution.

Owner:义乌市德恒信息科技有限公司

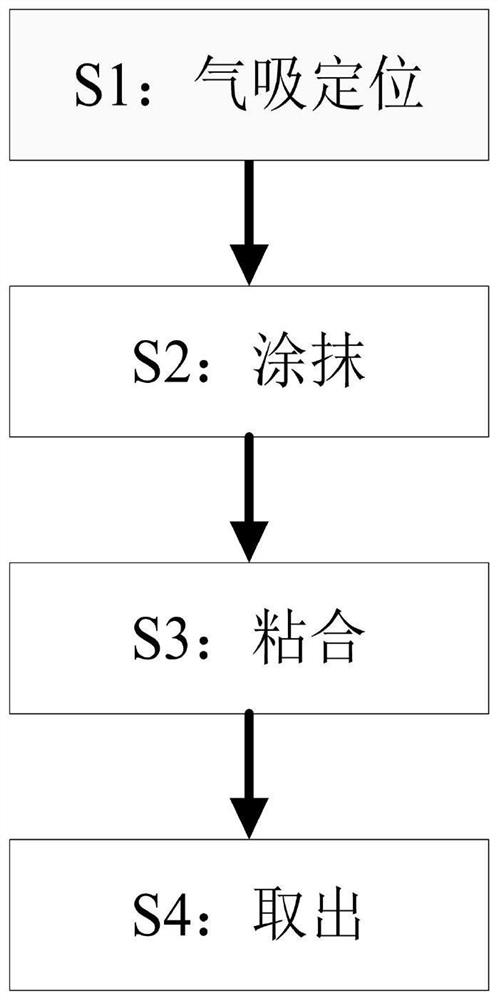

Anti-static EPE pearl cotton butt bonding treatment method

ActiveCN111823605AAffect aestheticsPrevent premature solidificationAdhesive glueMechanical engineering

The invention provides an anti-static EPE pearl cotton butt bonding treatment method. The method is completed by the cooperation of an outer frame, a gluing unit, two electric sliders, two positioningunits and two placement sleeves. The method can solve the problems that a single person needs to glue pearl cottons one by one during bonding, thus difficult to apply glue at the same time; when applying glue on other pearl cottons, the glued pearl cottons are solidified, resulting in failure of viscosity; when holding pearl cotton in both hands for drying, because the pearl cottons are soft andthe strength is difficult to control, the pearl cottons may be misaligned or squashed; when the pearl cotton is in butt contact with each other, the excess glue can be squeezed out, due to the hands of the person are busy with the butting of the pearl cottons, the extra glue can not be removed, and the unremoved glue can easily affect the aesthetics of the pearl cottons after solidification.

Owner:哈工大泰州创新科技研究院有限公司

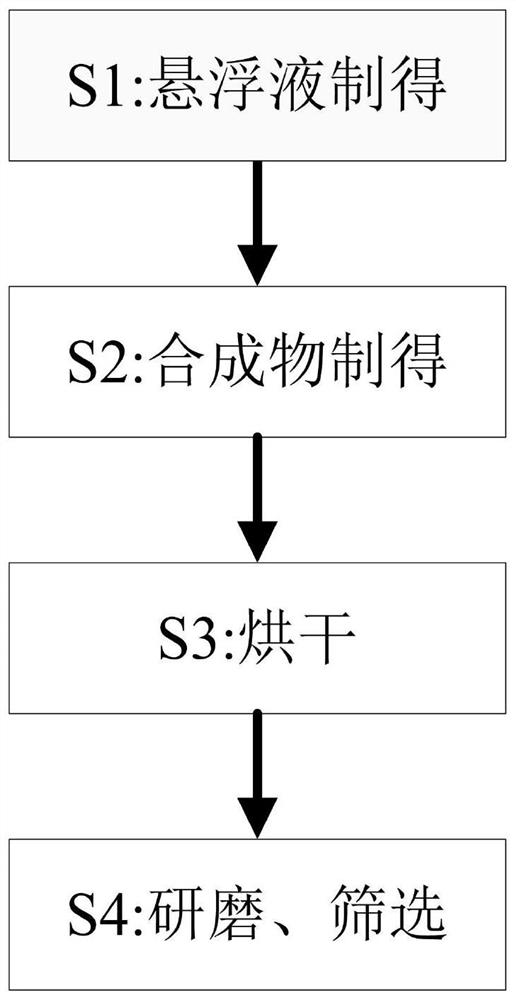

Preparation process of high-performance composite bentonite

InactiveCN112279259AAvoid premature solidificationImprove stirring efficiencyShaking/oscillating/vibrating mixersTransportation and packagingProcess engineeringSolid particle

The invention provides a high-performance composite bentonite preparation process, which is completed by matching a stirring frame group, a driving unit, a rotating shaft, a stirring paddle group, a guide ring, a drying frame, a first bevel gear and a turning unit, and can solve the problems that in the traditional mixing process, liquid is usually put in sequence and then stirred through a stirring paddle, however, due to the fact that most of traditional stirring paddles conduct stirring in an axial rotation mode, the mixed liquid is difficult to effectively and rapidly stir, part of the mixed liquid is likely to be solidified in advance after long-time stirring, and solid particle liquid in the mixed liquid often deposits at the bottom, and is difficult to be turned up to cause a lowerdegree of uniformity after stirring.

Owner:张百顺

Sand casting process for large-size aluminum alloy thin-wall part

InactiveCN108273959ASolving Common Defects of Insufficient PouringPouring area is smallFoundry mouldsFoundry coresSlagSand casting

The invention discloses a sand casting process for a large-size aluminum alloy thin-wall part and aims to provide the sand casting process, which realizes good finished product quality, for the large-size aluminum alloy thin-wall part. The sand casting process comprises the following steps: (I) manufacturing a sand mold; (Ii) smelting aluminum alloy and performing exhausting and slag discharging treatment; and (III) performing cast molding. By repeated research experiments and systematic data organization of experimenters and by optimizing various aluminum alloy casting processes, the sand casting process disclosed by the invention solves the problem that a large-size aluminum alloy cast piece has many defects, especially various problems such as incomplete casting of a thin-wall part, generation of air holes, mixing of sand and poor surface molding.

Owner:YUNNAN ALUMINUM

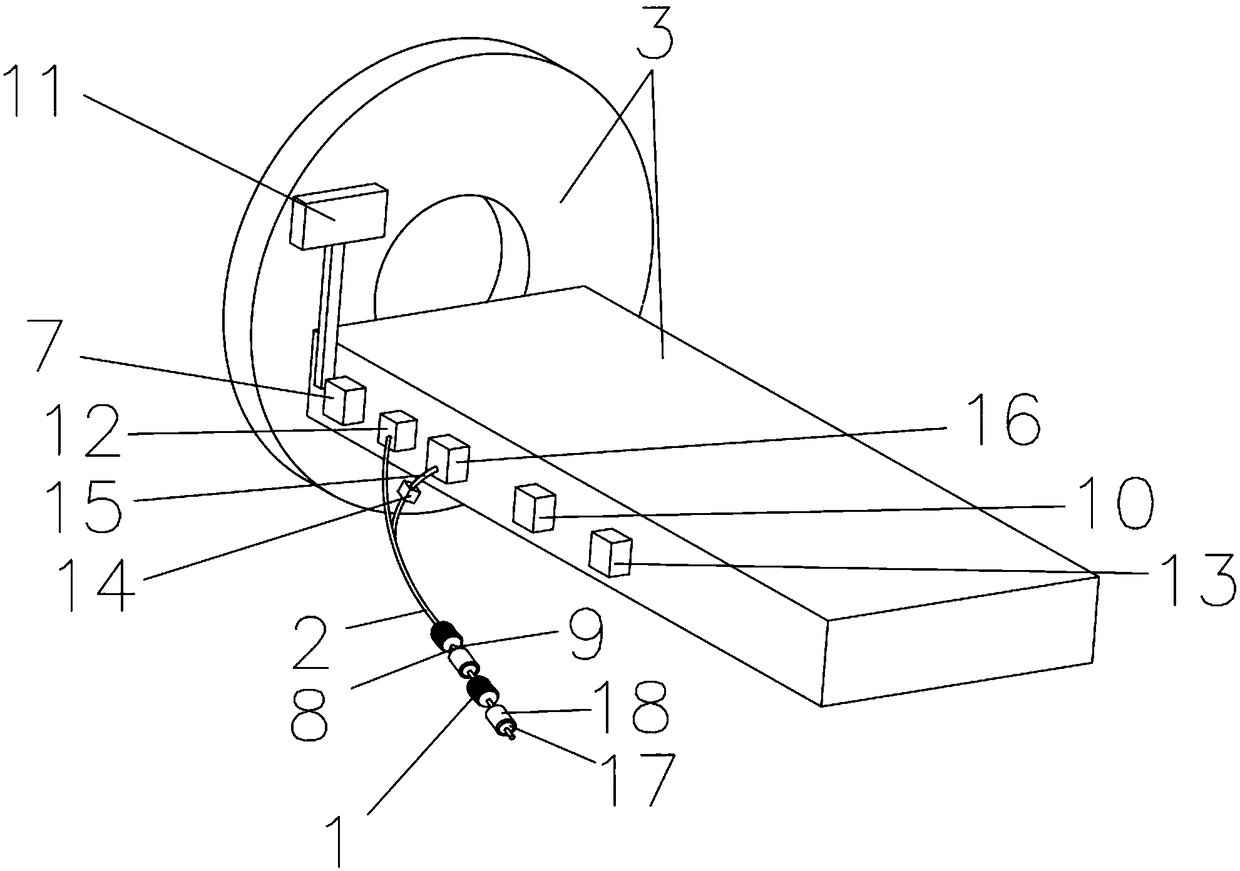

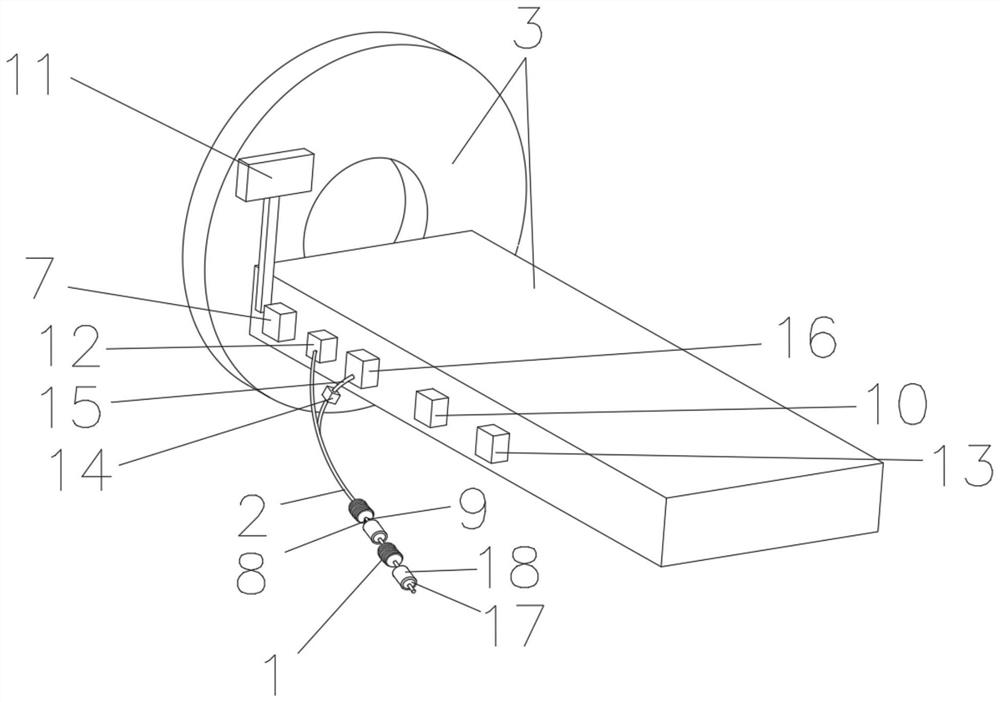

Vascular stent device for interventional operation

ActiveCN109223082AAvoid excessive stressPrevent premature solidificationCatheterDiagnostic recording/measuringResonanceBlood vessel

The invention discloses a vascular stent device for the interventional operation, which comprises a plurality of bellows having elasticity, Flexible rod and magnetic resonance machine, the axial position of the bellows is hollow, the hollow position brittle connection of the soft rod and the bellows, the surface of the bellows is provided with a plurality of longitudinal first through holes, A plurality of second through holes are arranged in the transverse direction of the flexible rod, A plurality of first passages are also provided in the flexible rod, the first passage communicates with the wall surface of the flexible rod in the longitudinal direction, a first channel of a surface of the flexible rod is aligned with the first through hole, the surface of the flexible rod is provided with a detecting device, A magnetic resonance machine is also provide with a blood collecting device, The blood collecting device is communicated with the second through hole of the soft rod, and the magnetic resonance machine is also provided with a glue conveying device which is communicated with the first channel. The device can monitor the electrocardiogram status of the patient in real time during the interventional operation, and can avoid intermittent blood leakage caused by poor blocking effect after the blood vessel leakage is compensated.

Owner:海南煊烨生物科技有限公司

A heat-resistant insulating MPP power cable tube and its preparation method

ActiveCN112310906BStrong heat resistanceImprove high temperature resistanceElectrical apparatusTubular articlesElastomerMasterbatch

The invention discloses a heat-resistant insulating MPP power cable pipe and a preparation method thereof, which relate to the technical field of cable pipe processing and include an inner pipe, the outer surface of the inner pipe is covered with an insulating net, and the inner wall of the inner pipe is coated with lubricating One side of the insulation net is provided with a storage tank, and one end of the insulation net is fixedly connected with a wire, and the outer side of the inner pipeline and the storage tank is provided with an MPP outer pipeline, and the MPP outer pipeline includes the following raw materials by weight: 60-80 parts of isotactic polypropylene resin, 5-10 parts of block copolymerized polypropylene, 3-5 parts of olefin block copolymerized elastomer OBC, 0.5-2 parts of heat-resistant insulating orange masterbatch, 10 parts of ultra-high molecular weight polyethylene resin ‑20 servings. In the present invention, the outermost MPP outer pipeline has stronger heat resistance and external pressure resistance, and the innermost inner pipeline has stronger high temperature resistance and good flame resistance, which can prevent fire from spreading when a fire occurs.

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

Method of limiting permeability of a matrix to limit liquid and/or gas inflow

ActiveUS10947436B2Quality improvementPrevent premature solidificationProtective foundationDrilling compositionPortland cementExothermic process

A method of limiting or reducing permeability of a matrix to liquid and / or gas inflow is described. The method includes limiting inflow of water, liquid and / or gas into passages such as cavities, fissures, voids and the like, encountered in formations such as geological formations though can be used to form barriers to water, liquid or gas flow through a matrix. The method includes steps of measuring one or more parameters relating to the matrix and selecting one or more components of a multi-component sealing composition with reference to the measured parameters. The selected components are introduced into the matrix where it is set or coagulated in a non-exothermic or low exothermic process to form a seal barrier. Also disclosed is a sealing composition comprising a coagulable polymer emulsion or colloid contactable with at least one selected additive which interacts with the polymer emulsion or colloid to form a coagulated mass for forming a sealing barrier in a non-exothermic or low exothermic setting process in which the polymer emulsion or colloid contains, prior to purposeful coagulation due to interaction with the selected additive, particles having a size distribution smaller than for Portland cement.

Owner:RELBORGN +1

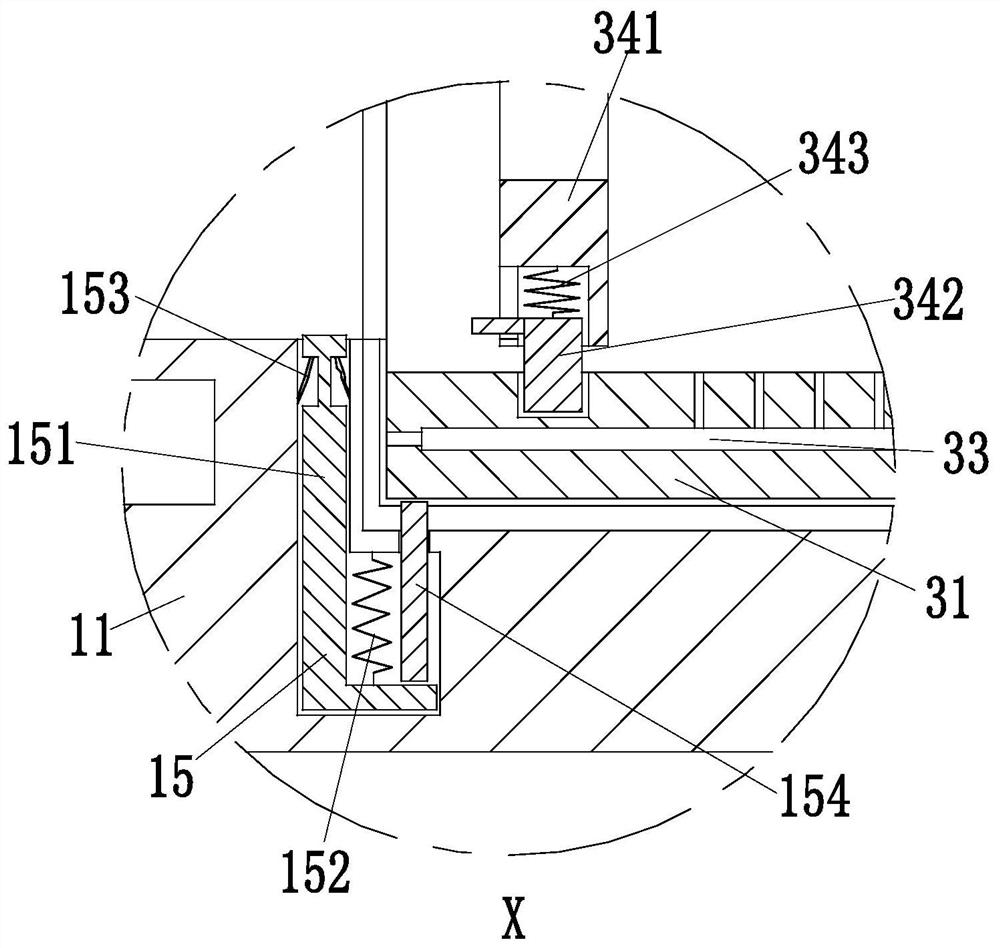

Injection molding mold with flange plastic exhausting pipe

The invention discloses an injection molding mold with a flange plastic exhausting pipe. A parting mold is composed of 3-4 pieces of mold petals. Sliding blocks are arranged at the lower ends of the middle parts of the mold petals. A core is arranged in a cavity which is located in the parting mold. A push plate is arranged on the outer side of the lower portion of the core. The push plate is arranged on the lower portion of the core. An injection molding cavity is formed between the core, the push plate and the parting mold. The sliding blocks are arranged in a sliding groove which is formedin a parting mold fixed plate, the end portions of the sliding blocks are connected with an outer sleeve plate through springs, the springs are located in the sliding groove, and a sliding sleeve which is matched with the conical surface of the parting mold is arranged on the outer side of the lower portion of the parting mold. The sliding sleeve is fixed on the lower portion of a conical cavity in an upper mold, a nozzle is fixed at the center of the upper portion of the upper mold, and a material inlet hole on the lower portion of the nozzle communicates with the upper end of the injection molding cavity. The parting mold fixed plate and the outer sleeve plate are fixed on a lower mold seat, and a material ejecting rod is connected to the lower portion of the push plate. The injection molding mold with the flange plastic exhausting pipe has the advantages of simple structure, high production efficiency and good product quality.

Owner:安庆市洁达塑业有限公司

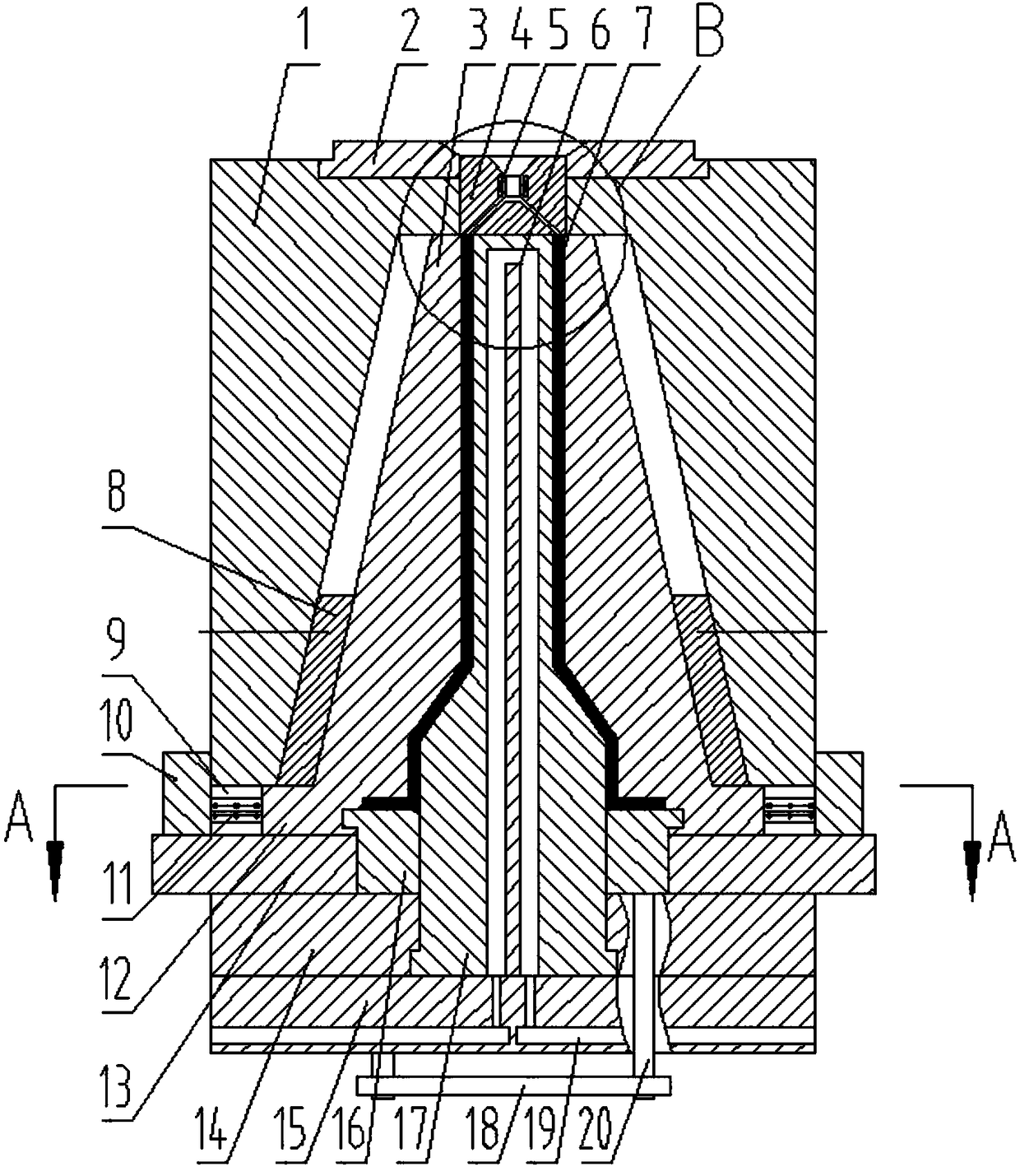

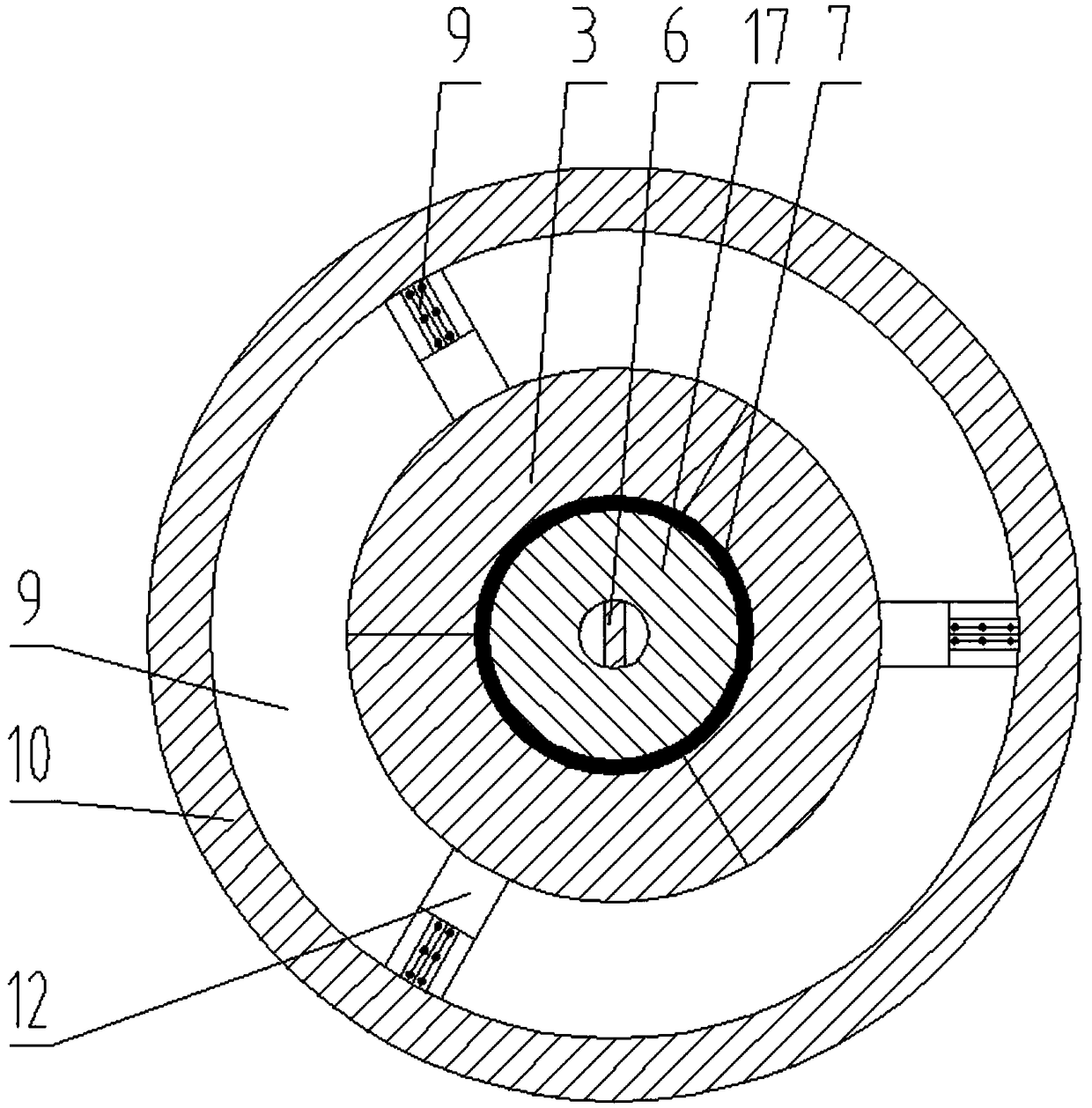

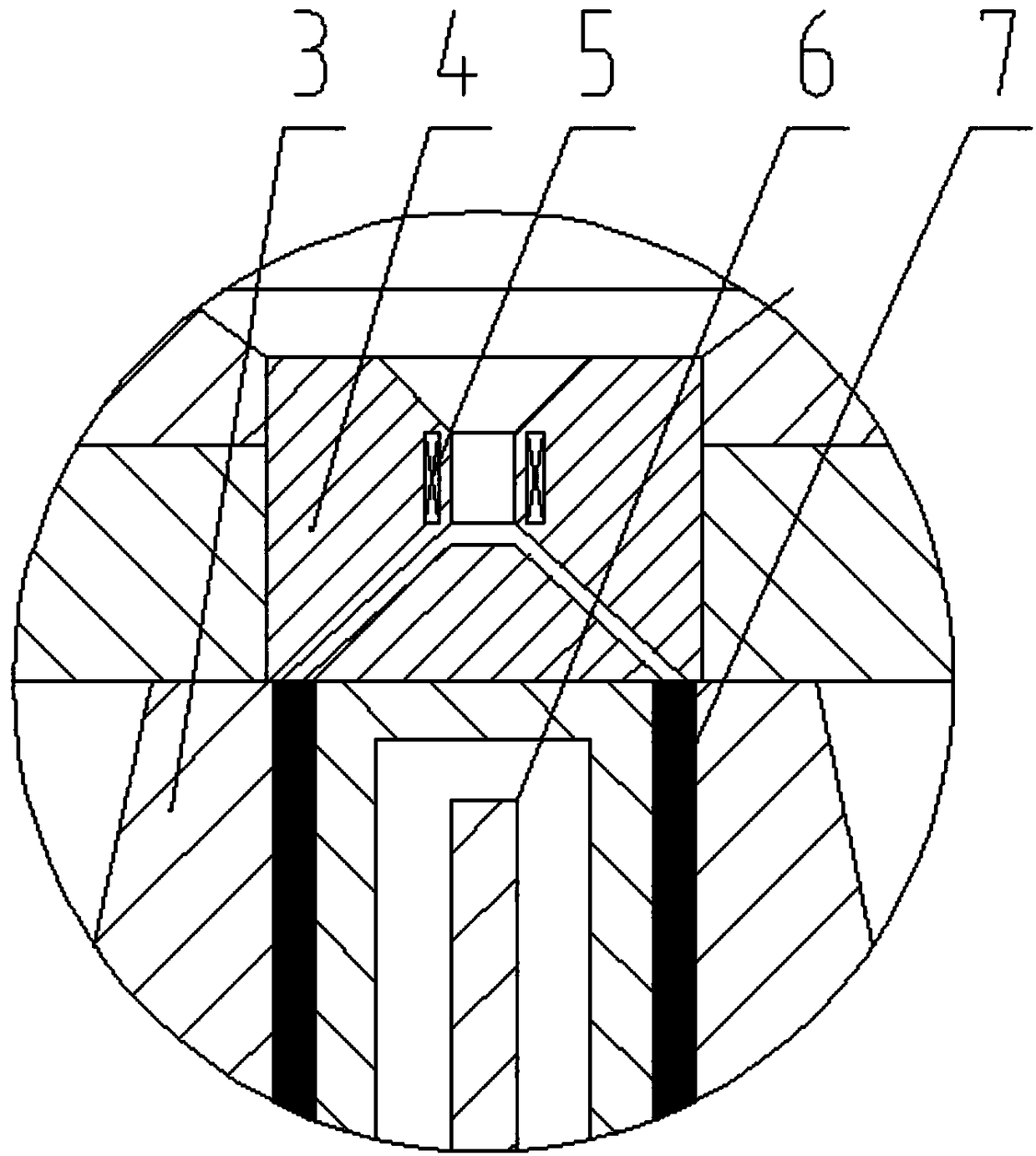

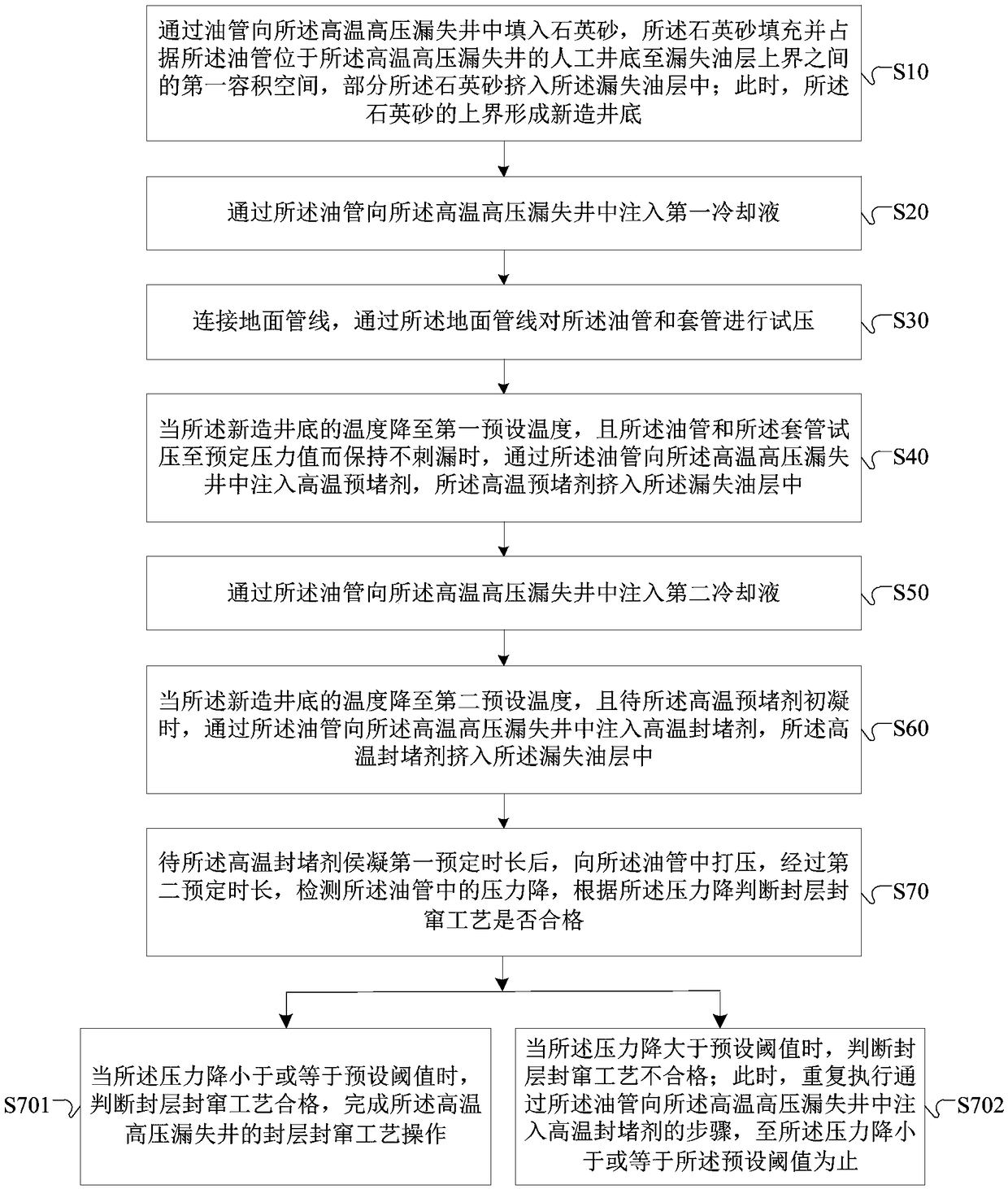

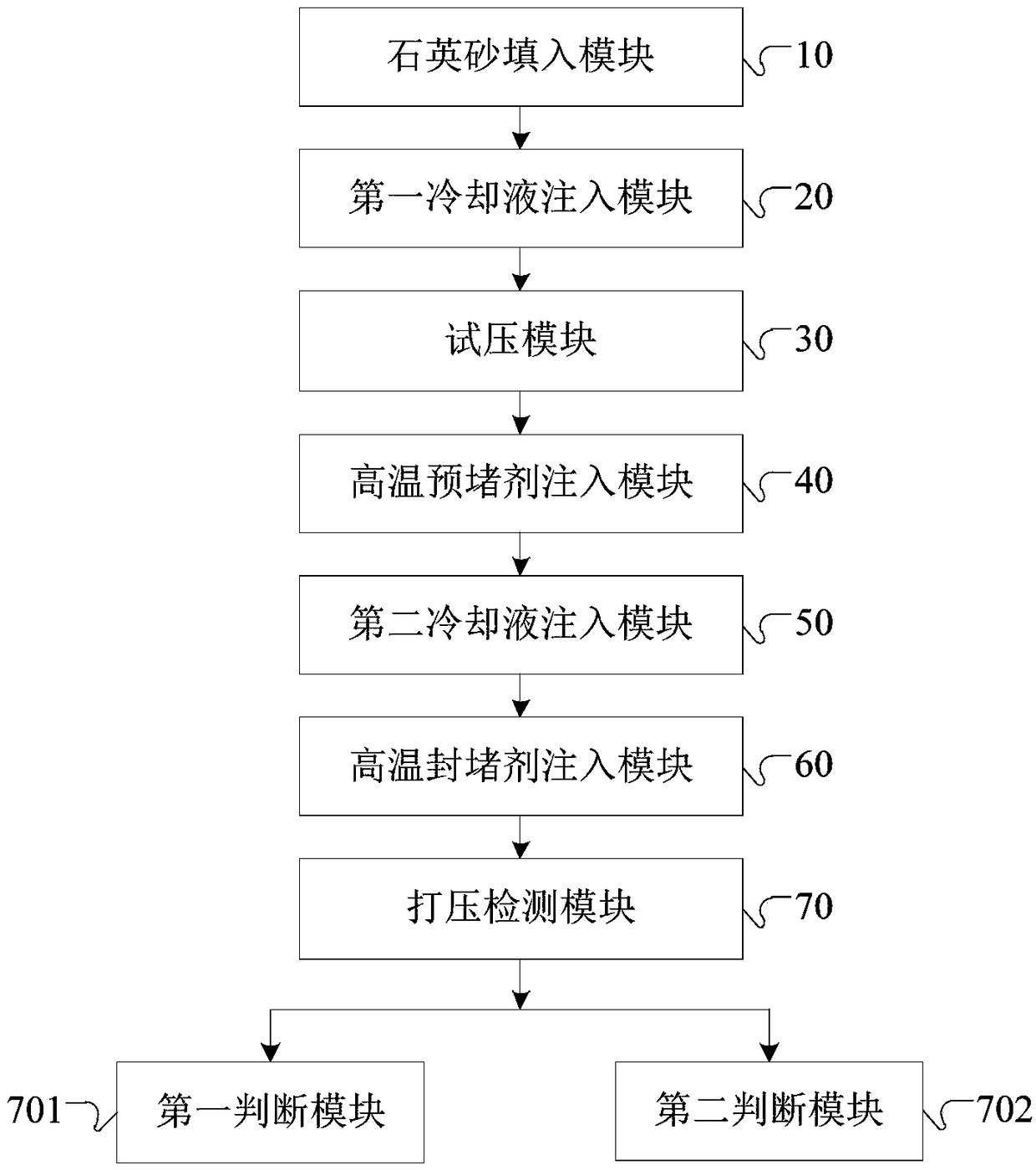

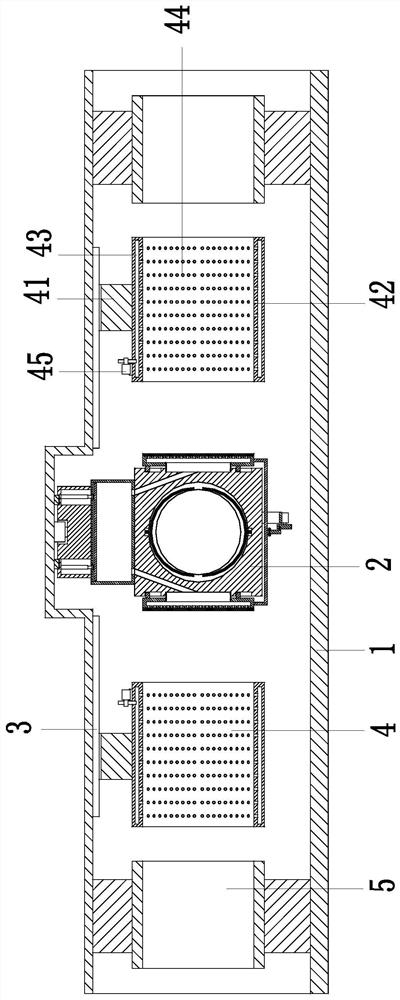

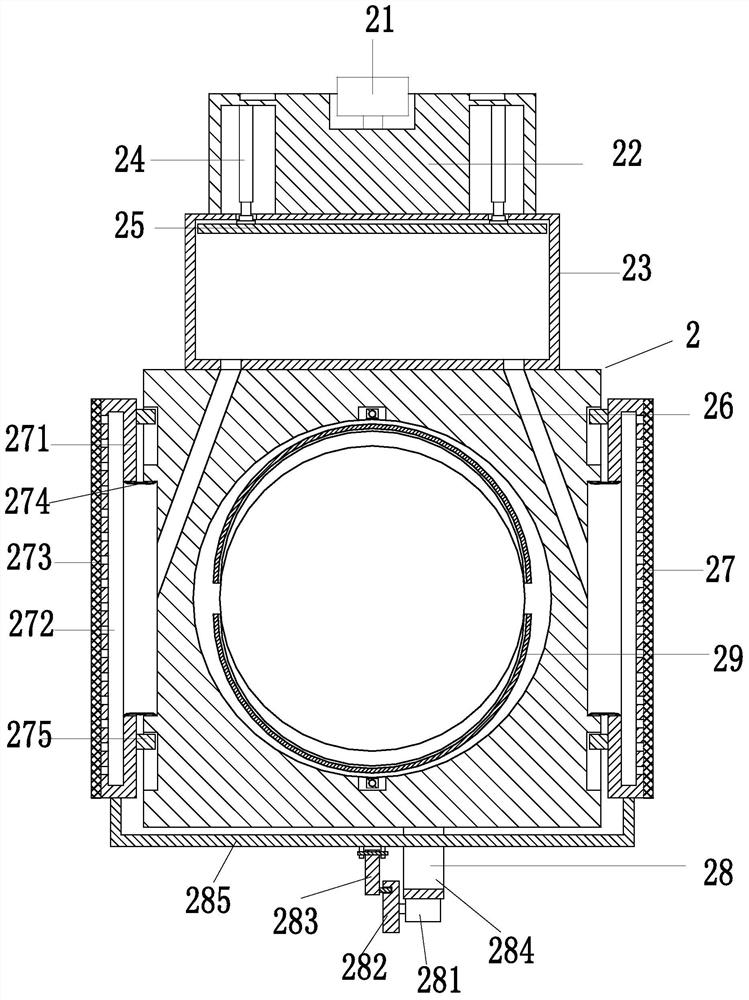

Process method and device for layer-sealing channeling-sealing of high temperature and high pressure leaking well

ActiveCN109403936AReduce leakagePre-blocking benefitsFluid removalSealing/packingLine tubingHigh pressure

The invention provides a process method and device for layer-sealing channeling-sealing of a high temperature and high pressure leaking well. The process method for layer-sealing channeling-sealing ofthe high temperature and high pressure leaking well comprises the steps that the high temperature and high pressure leaking well is filled with quartz sand, and a new shaft bottom is formed at the upper boundary of the quartz sand; first cooling liquid is injected into the high temperature and high pressure leaking well; a ground pipeline is connected, and an oil pipe and a casing pipe are subjected to pressure tests through the ground pipeline; when the temperature of the newly formed shaft bottom falls to a first preset temperature, the oil pipe and the casing pipe are subjected to the pressure tests to predetermined pressure values while no puncture occurs, and a high temperature pre-sealing agent is injected into the high temperature and high pressure leaking well through the oil pipe; second cooling liquid is injected into the high temperature and high pressure leaking well; and when the temperature of the newly formed shaft bottom falls to a second preset temperature and the high temperature pre-sealing agent is initially set, a high temperature sealing agent is injected into the high temperature and high pressure leaking well. The process method and device for layer-sealingchanneling-sealing of the high temperature and high pressure leaking well can meet the process requirements for layer-sealing channeling-sealing of high temperature and high pressure leakage wells.

Owner:PETROCHINA CO LTD

A kind of antistatic epe pearl cotton butt bonding treatment method

Owner:哈工大泰州创新科技研究院有限公司

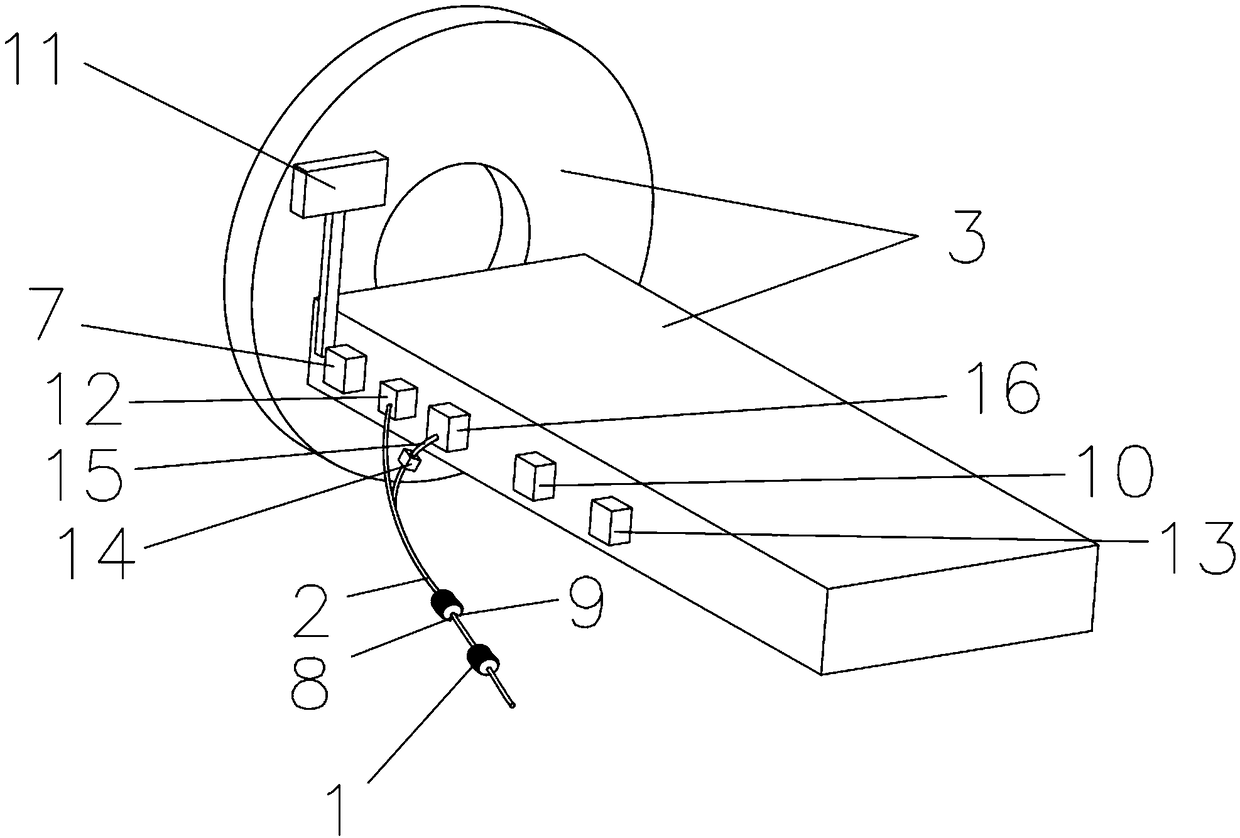

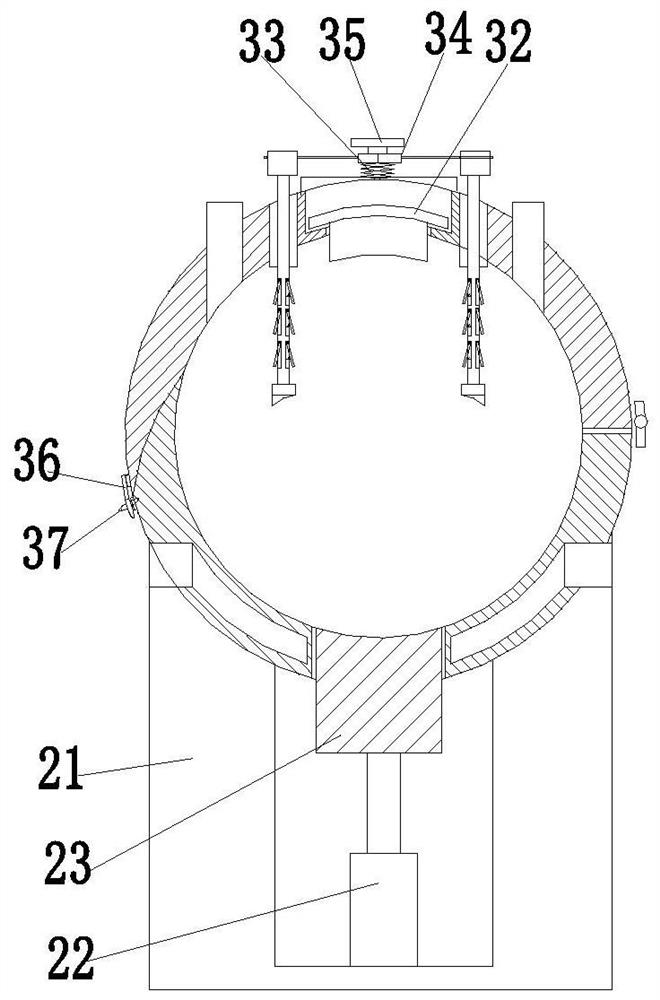

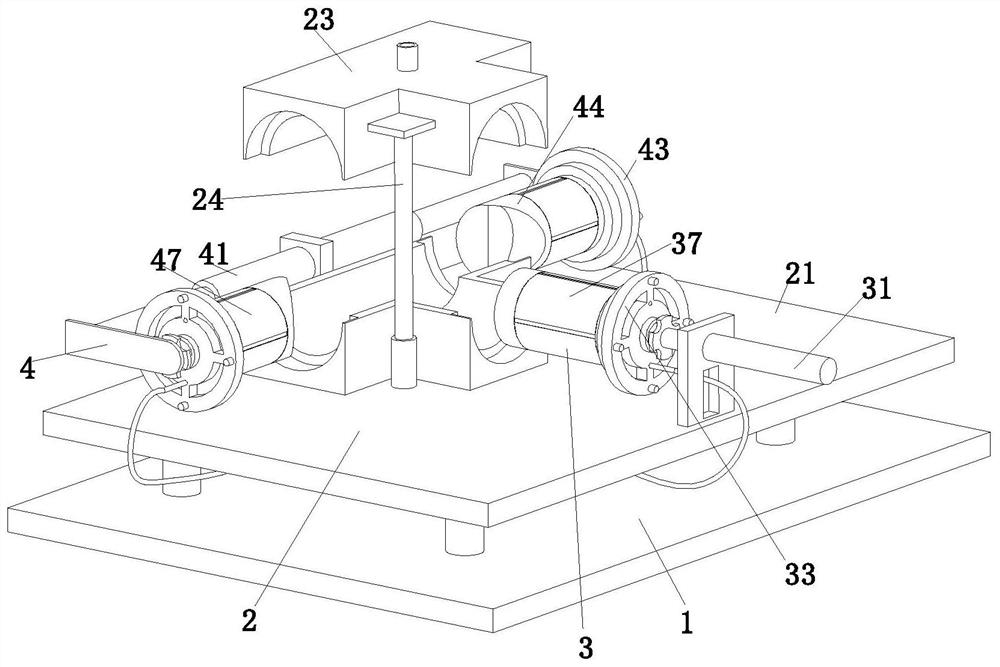

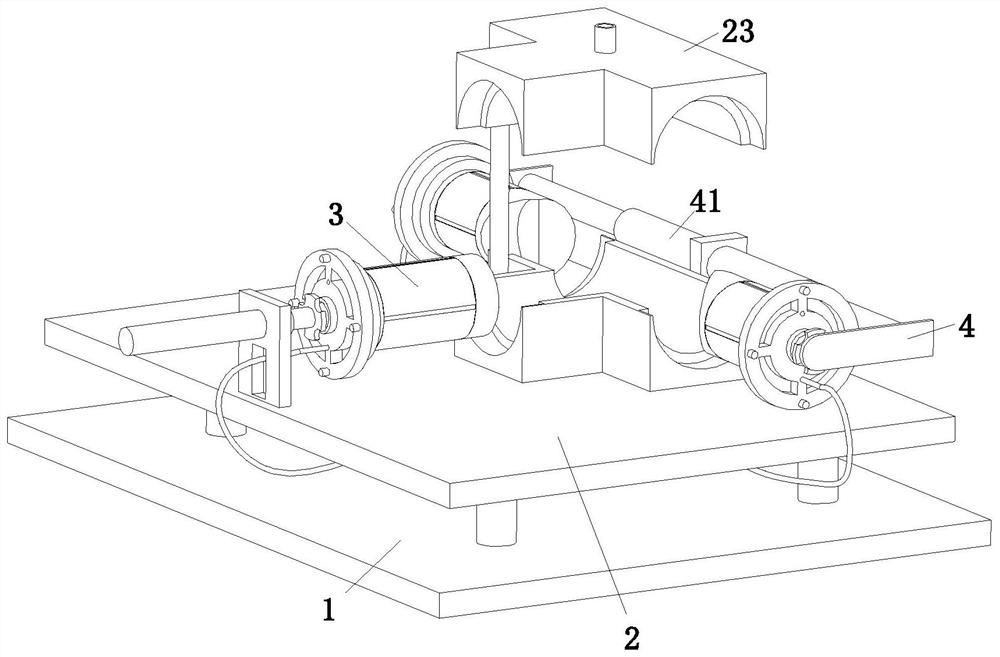

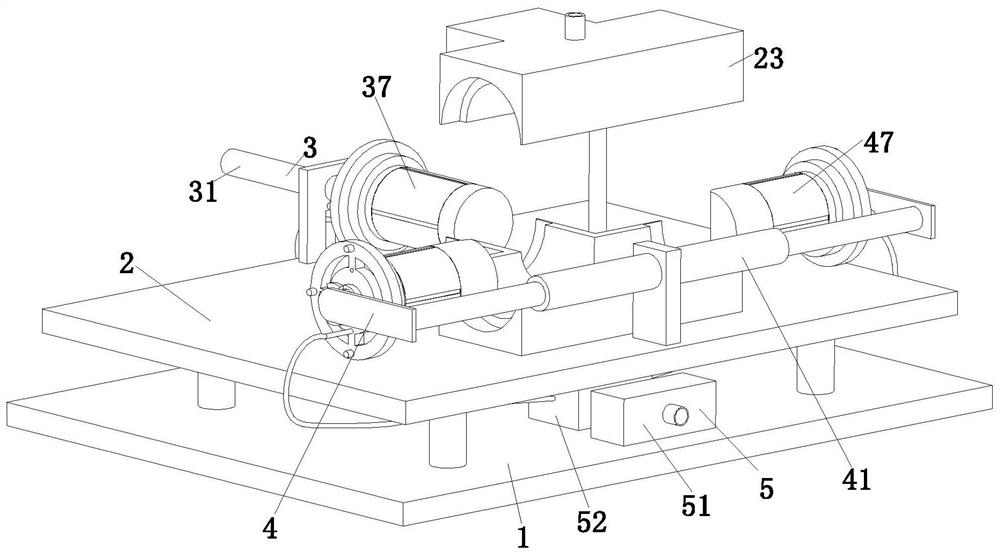

A mold for forming concrete utility poles

ActiveCN112025939BPrevent weak issuesSlow down the speed of solidificationCeramic shaping apparatusCement mixing apparatusWire rodClassical mechanics

The invention relates to a mold for forming a concrete utility pole, which comprises a bottom plate, a supporting mechanism, a circular template, a sealing cover and a cooling air pump. The upper end is equipped with a circular formwork, and the left and right ends of the circular formwork are equipped with sealing covers. The present invention can solve the problem that in the existing concrete utility pole molding production, due to the shortcomings of the traditional process, the concrete cannot be guaranteed to be solidified at the same time during the concrete solidification process. The concrete that first enters the mold will solidify in advance, and the connection between the first solidified concrete and the later solidified concrete will be loose, resulting in the problem that the utility pole is not firm.

Owner:保山市瑞峰水泥制品有限公司

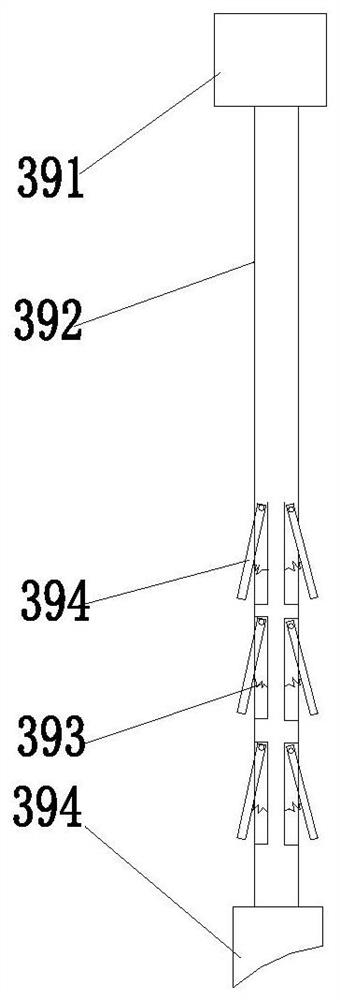

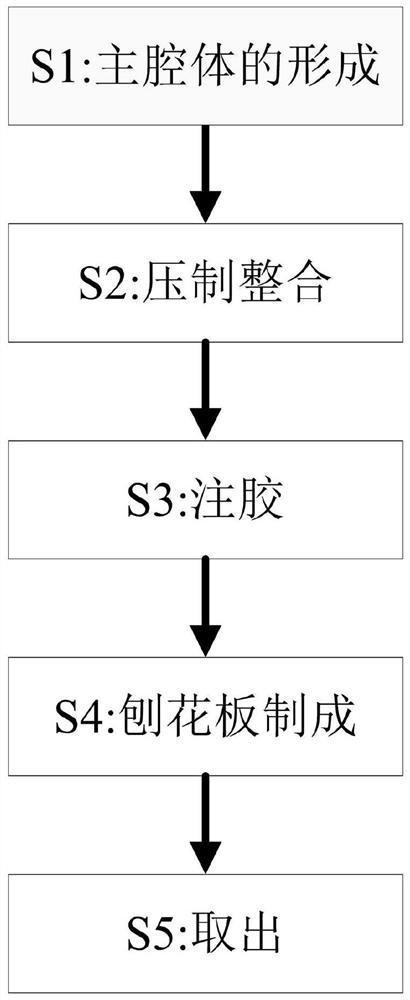

Shaving board manufacturing compression molding method

ActiveCN112372787AGuarantee smoothnessPenetration area shrinksFlat articlesDomestic articlesAdhesive glueComposite material

The invention provides a shaving board manufacturing compression molding method. The shaving board manufacturing compression molding method is implemented by matching a base, a template frame, two sealing plates, two linkage units, two glue injection units and a pressing unit. The shaving board manufacturing compression molding method can solve the problems that in a traditional glue injection mode, after wood fragments are put into a mold, glue is poured into the mold from top to bottom generally, and the glue permeates into different positions of the wood particles according to the liquidityof the glue, but because the liquidity of the glue among the dense wood particles is slow and the time before the glue is solidified is short, the situation that the glue cannot completely permeate into all the positions of the wood particles after being solidified possibly occurs, then broken materials around the pressed shaving board are broken due to no adhesion, and the percent of pass of theshaving board is reduced.

Owner:江苏乐宝板业有限公司

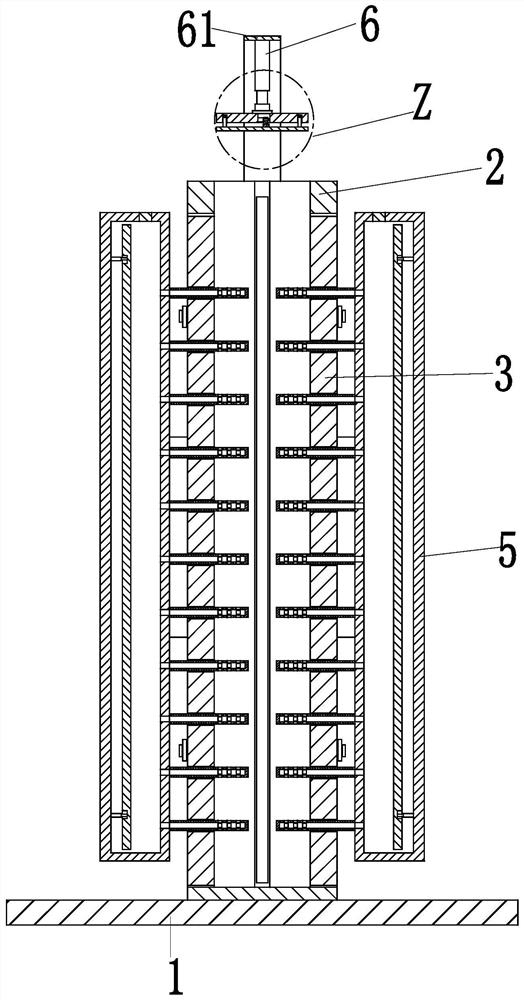

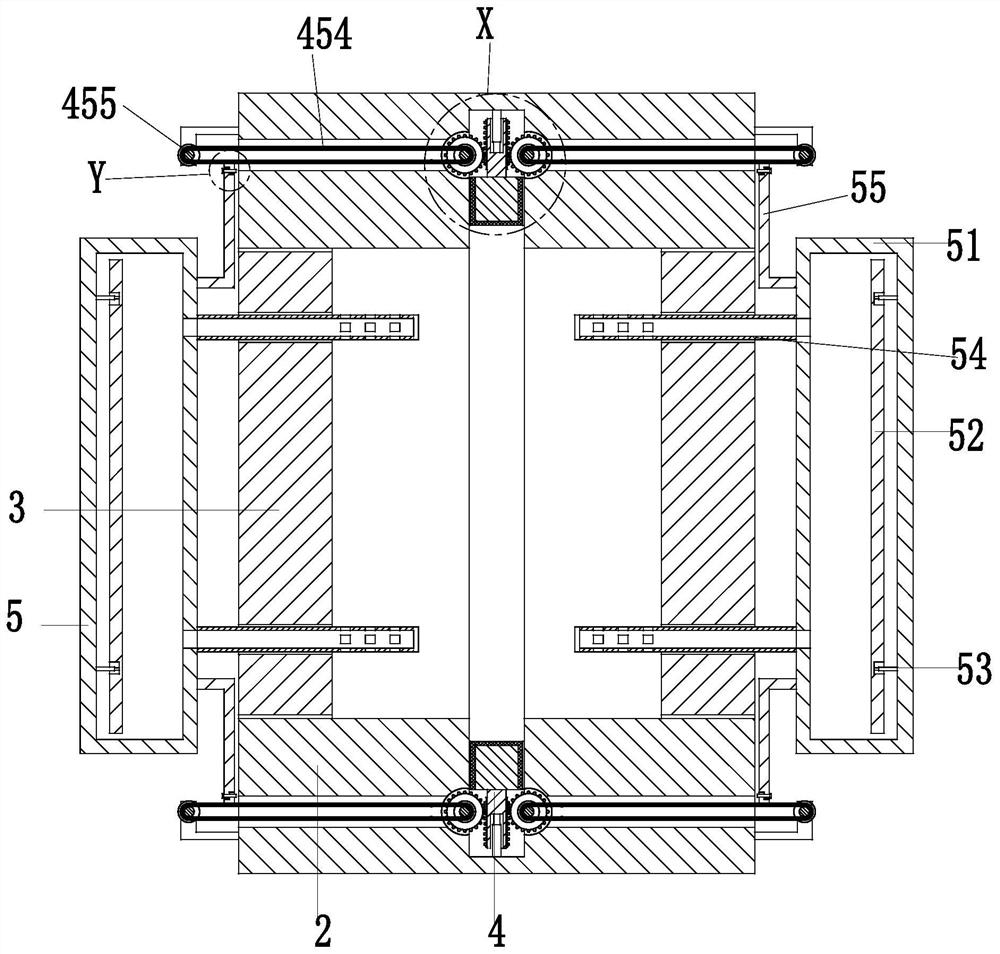

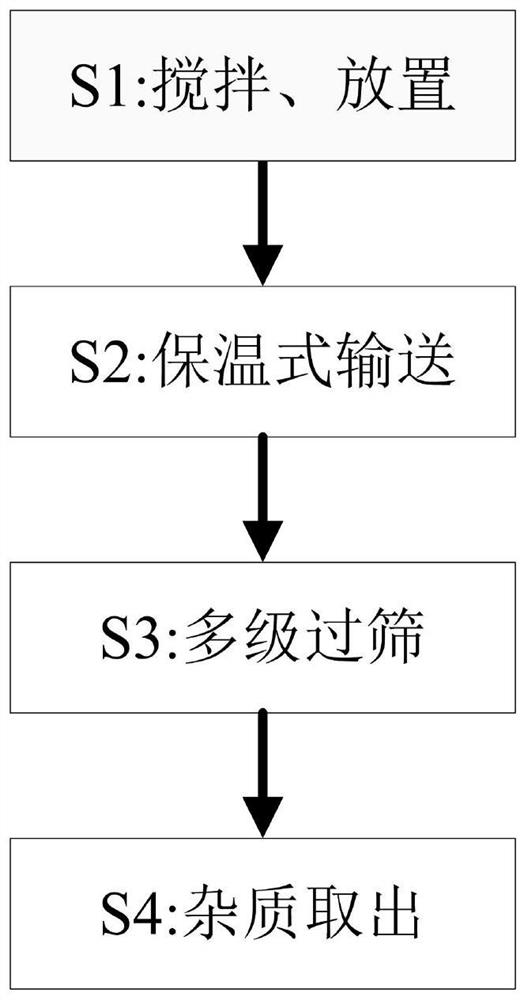

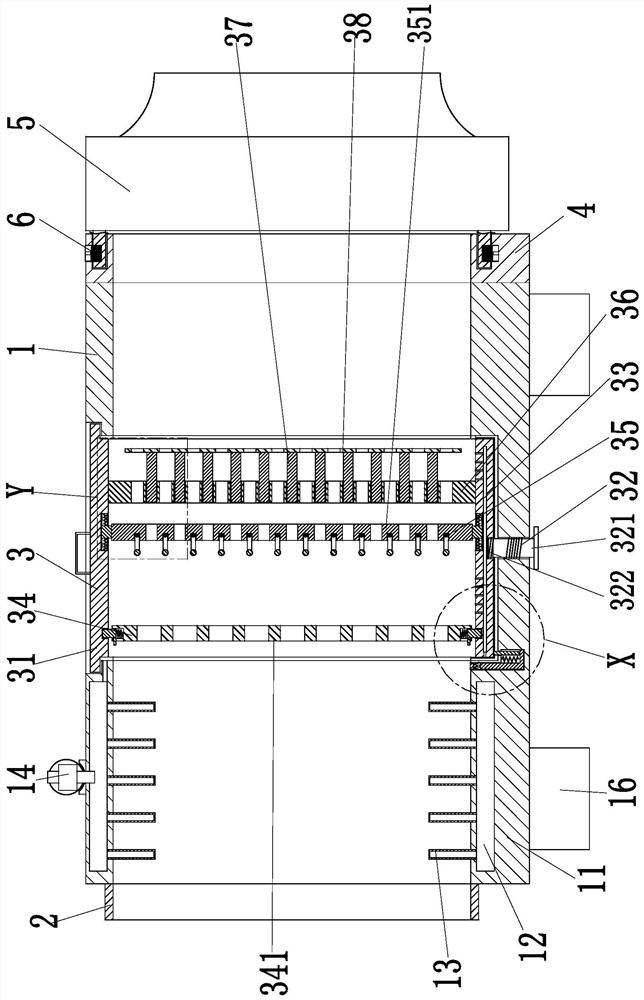

Preparation method of modified universal plastic master batches

The invention provides a preparation method of modified universal plastic master batches. The preparation method is completed by cooperation of a conveying frame, an interface frame, a sieving unit, abutt joint frame, a granulation head and a connecting piece. The preparation method can solve the problems that when a uniformly mixed mixture is heated and melted, a small amount of impurities may be mixed into the mixture; due to the fact that the impurities are difficult to separate out, the impurities may block a granulation head during later conveying, extrusion and granulation; no special screening equipment is provided for impurity filtering in the existing mixture conveying process; and meanwhile, the molten mixture may be solidified in advance in the conveying process, so that the situation that a machine is difficult to granulate due to blockage is caused, and the granulation head is directly damaged under a severe condition.

Owner:合肥范平塑胶科技有限公司

Injection molding processing system for three-way joint of plastic pipe

PendingCN113510910AIntegrity guaranteedGuaranteed success rateCleaning using toolsDomestic articlesStructural engineeringManufacturing engineering

Owner:潘兰民

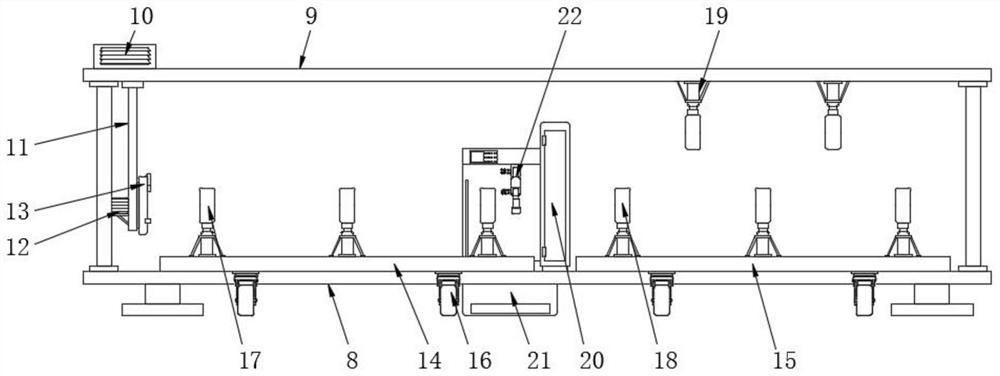

Automatic glue applying system for wind power blade production

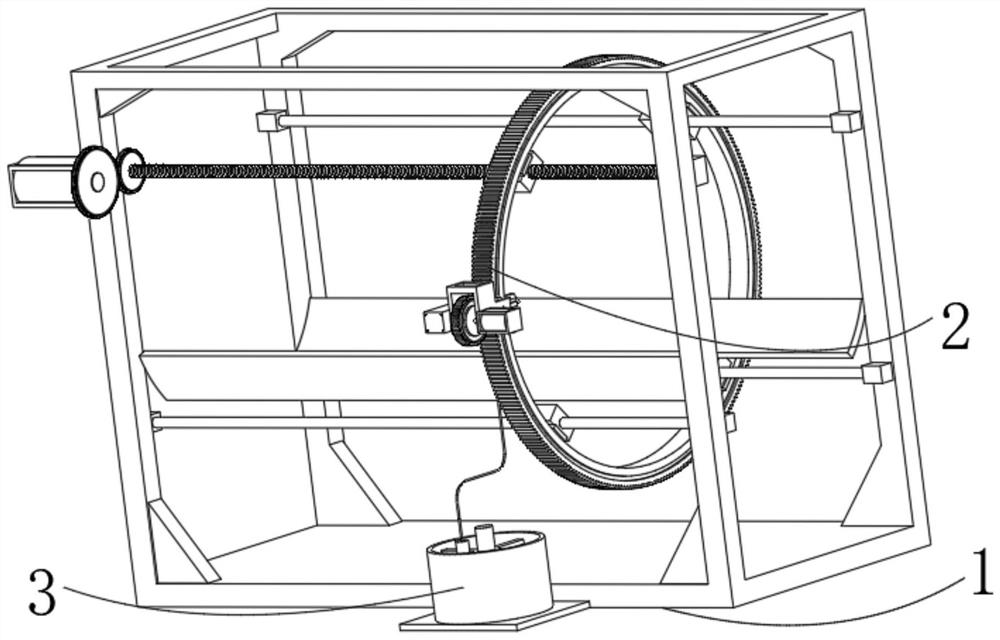

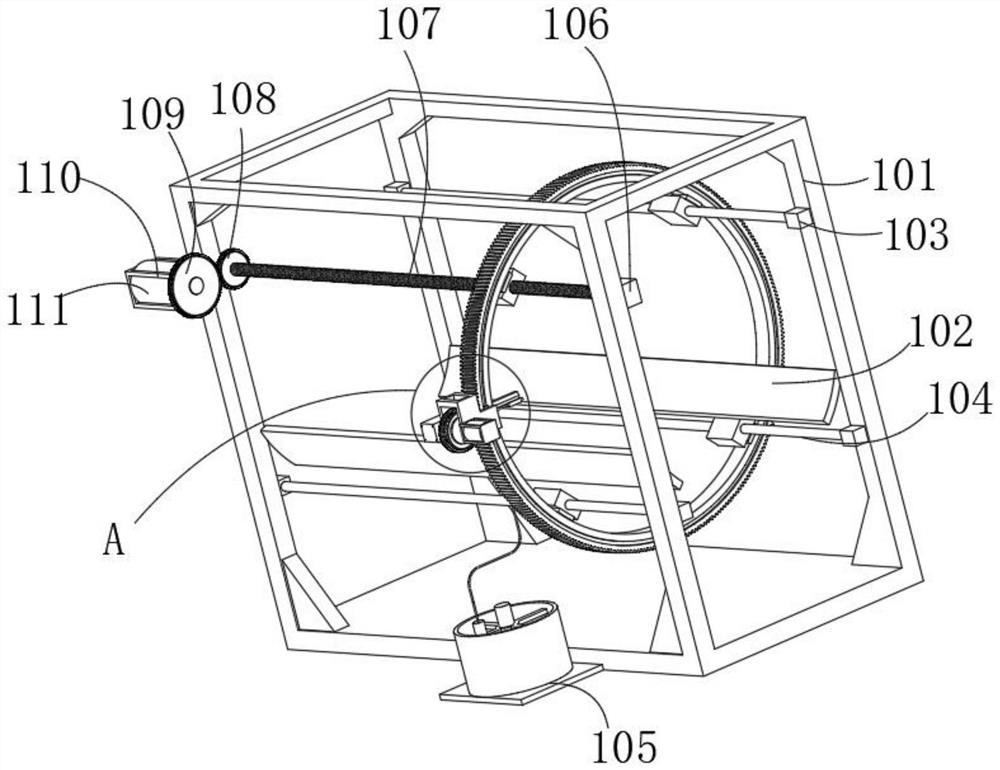

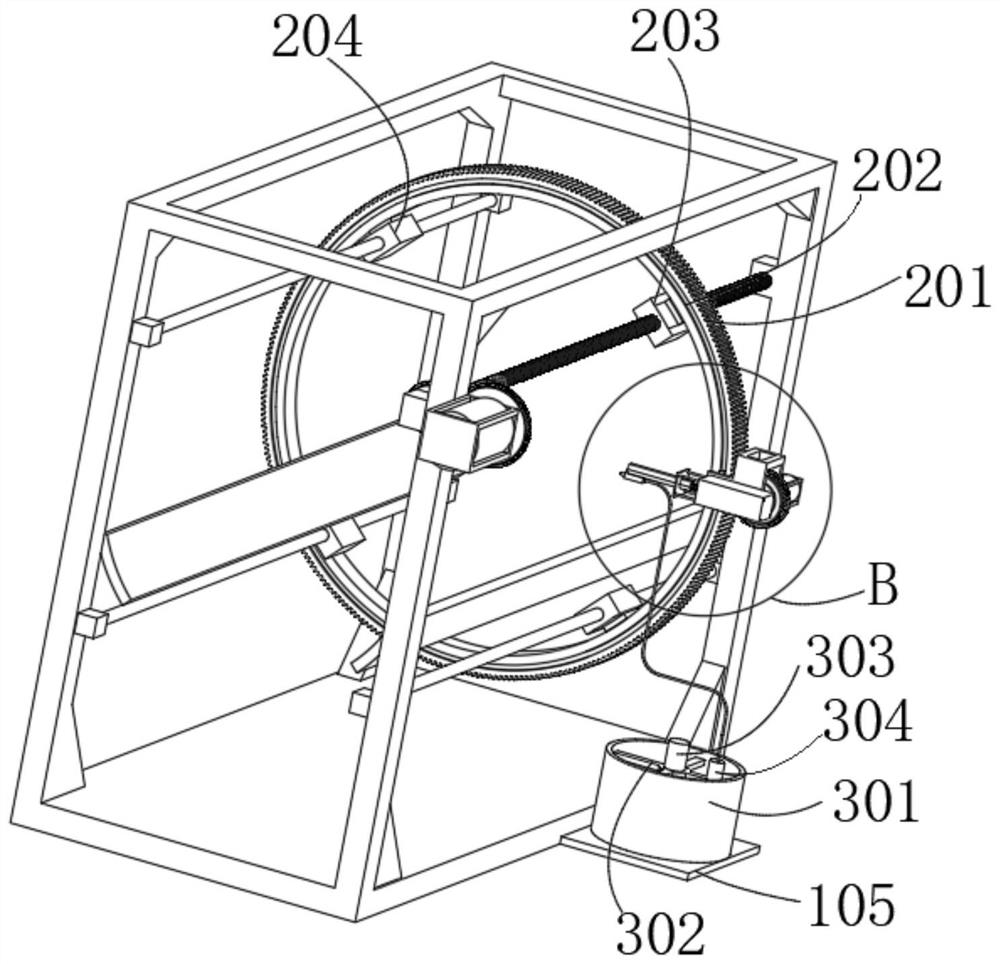

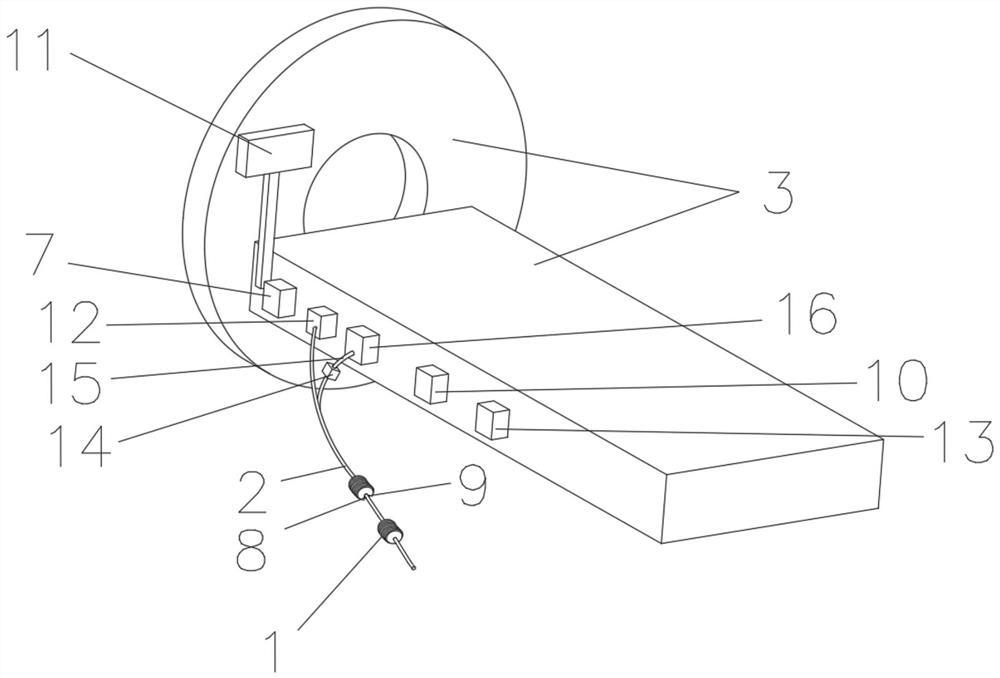

PendingCN114534992APrecise alignmentExact circular motionLiquid surface applicatorsFinal product manufactureAdhesive glueElectric machinery

The invention provides an automatic glue applying system for wind power blade production, and relates to the technical field of wind power blade manufacturing. The automatic glue applying system for wind power blade production comprises a main fixing mechanism, a circumferential driving mechanism and a transfer glue storage mechanism, the circumferential driving mechanism is arranged in the main fixing mechanism, and the transfer glue storage mechanism is arranged on the side portion of the main fixing mechanism; a stirring motor drives a rotating main shaft additionally arranged on an output shaft of the stirring motor and a stirring frame to rotate on a cross-shaped fixing frame, the rotating stirring frame continuously and automatically stirs adhesive glue transferred and stored in a transfer tank, the adhesive glue is prevented from being solidified in advance, and a set of fixing plates is additionally arranged on a hexagonal internal threaded column; and the rotation of the sliding rod is limited, so that the hexagonal internal threaded column in threaded connection with the sliding rod drives the glue injection end pipe to translate towards the inner side, and the glue injection end pipe is accurately aligned with a glue coating point, so that accurate glue dispensing work is carried out.

Owner:苏州天顺复合材料科技有限公司

A vascular stent device for interventional surgery

ActiveCN109223082BAvoid excessive stressPrevent premature solidificationCatheterDiagnostic recording/measuringReoperative surgeryBiomedical engineering

The invention discloses a vascular stent device for the interventional operation, which comprises a plurality of bellows having elasticity, Flexible rod and magnetic resonance machine, the axial position of the bellows is hollow, the hollow position brittle connection of the soft rod and the bellows, the surface of the bellows is provided with a plurality of longitudinal first through holes, A plurality of second through holes are arranged in the transverse direction of the flexible rod, A plurality of first passages are also provided in the flexible rod, the first passage communicates with the wall surface of the flexible rod in the longitudinal direction, a first channel of a surface of the flexible rod is aligned with the first through hole, the surface of the flexible rod is provided with a detecting device, A magnetic resonance machine is also provide with a blood collecting device, The blood collecting device is communicated with the second through hole of the soft rod, and the magnetic resonance machine is also provided with a glue conveying device which is communicated with the first channel. The device can monitor the electrocardiogram status of the patient in real time during the interventional operation, and can avoid intermittent blood leakage caused by poor blocking effect after the blood vessel leakage is compensated.

Owner:广东康盾高新技术产业集团股份公司

Tenacity anti-fluid-channeling cement slurry for solid expansion pipe fixed well

ActiveCN103320107BImprove engineering performancePrevent premature solidificationDrilling compositionPhysical chemistryEngineering

Owner:成都西南石大石油工程技术有限公司

Injection molding machine with heat preservation structure

The invention discloses an injection molding machine with a heat preservation structure, and relates to the technical field of injection molding machine equipment.The injection molding machine comprises an injection molding machine body, an injection device is fixedly connected to the top end of the injection molding machine body, a material barrel is fixedly connected to the left side of the injection device, and an injection mold is fixedly connected to the left side of the material barrel; a hopper fixing mechanism is fixedly connected to the top of the injection device, a hopper is arranged at the top of the hopper fixing mechanism, and a moving mechanism is arranged on the side face of the injection molding machine body. Through mutual cooperation of the material barrel inner pipe, the heat conduction plate, the heating device, the material barrel outer pipe, heat preservation cotton and a protective sleeve, plastic in the material barrel can be continuously heated through the arrangement of the heat conduction plate and the heating device, and through the arrangement of the heat preservation cotton and the protective sleeve, heat loss is avoided; the injection molding machine solves the problem that plastic is cooled in advance due to the fact that an existing injection molding machine is poor in heat preservation performance of the plastic in a material barrel, prevents the plastic from being solidified in advance, and facilitates forming of workpieces.

Owner:瞿壮

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com