Injection device for the treatment of exhaust fumes from motor vehicles

A technology for equipment and exhaust gas, which is applied in the field of injection equipment and can solve problems such as affecting efficiency and damaging components of injection equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

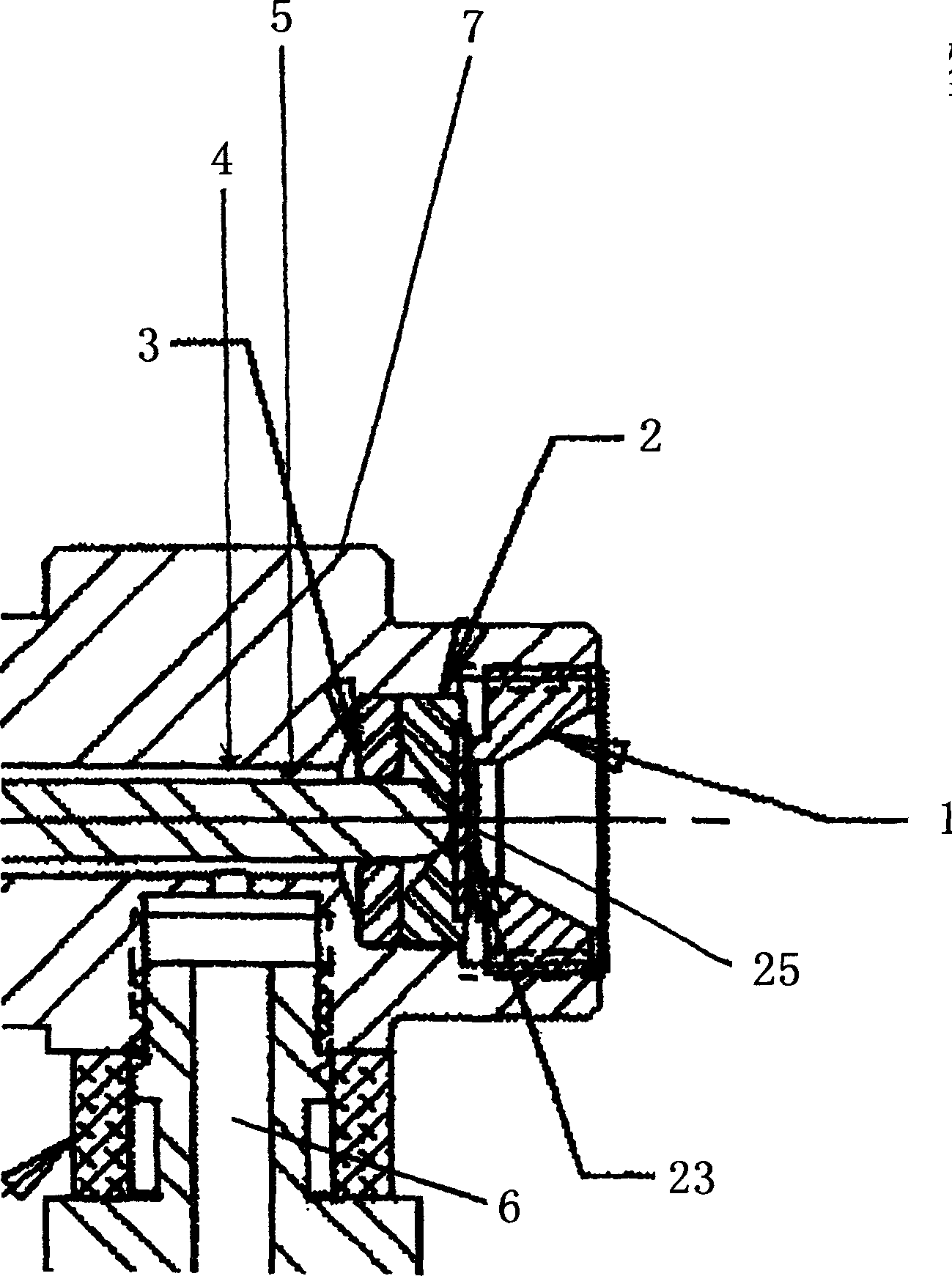

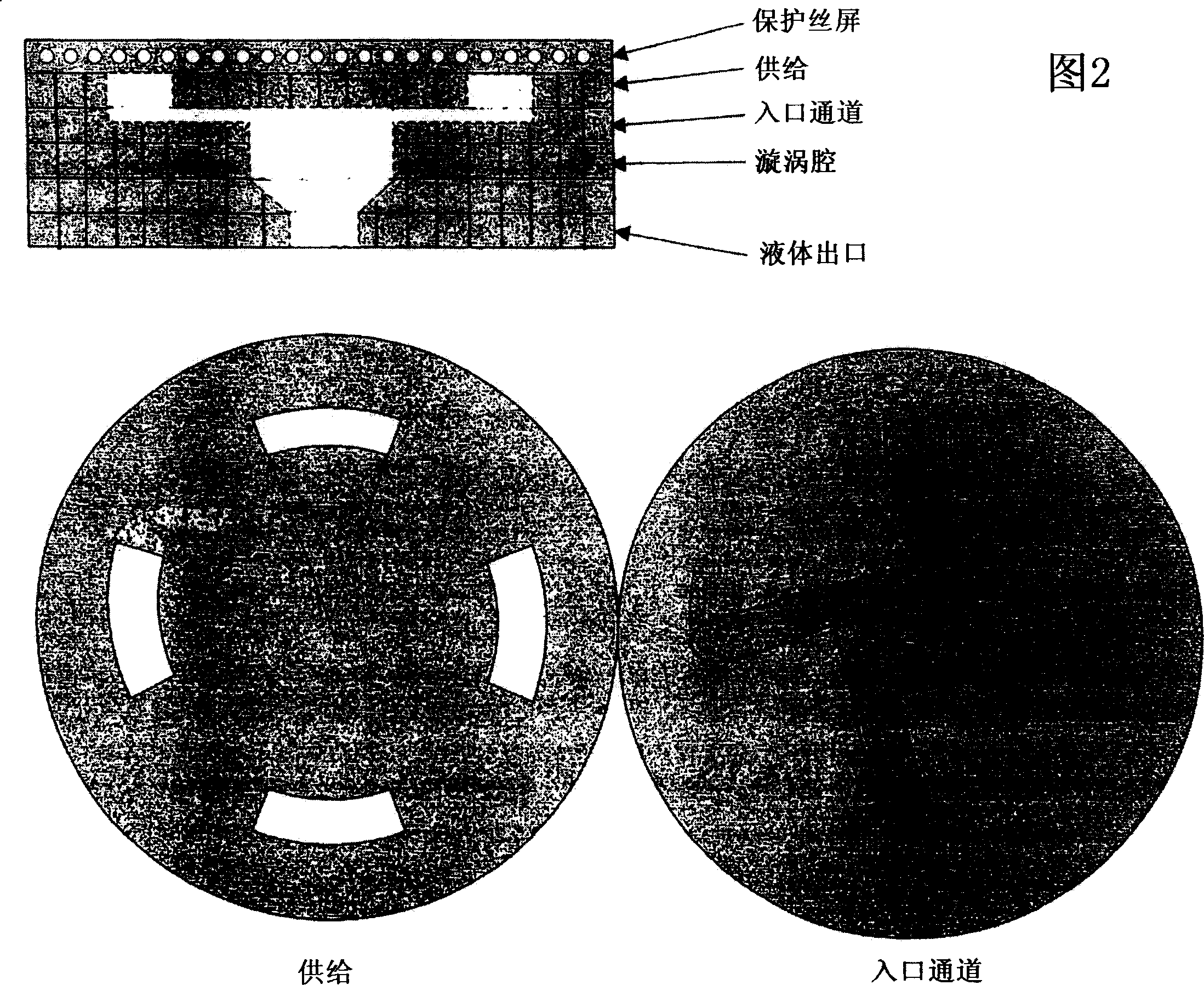

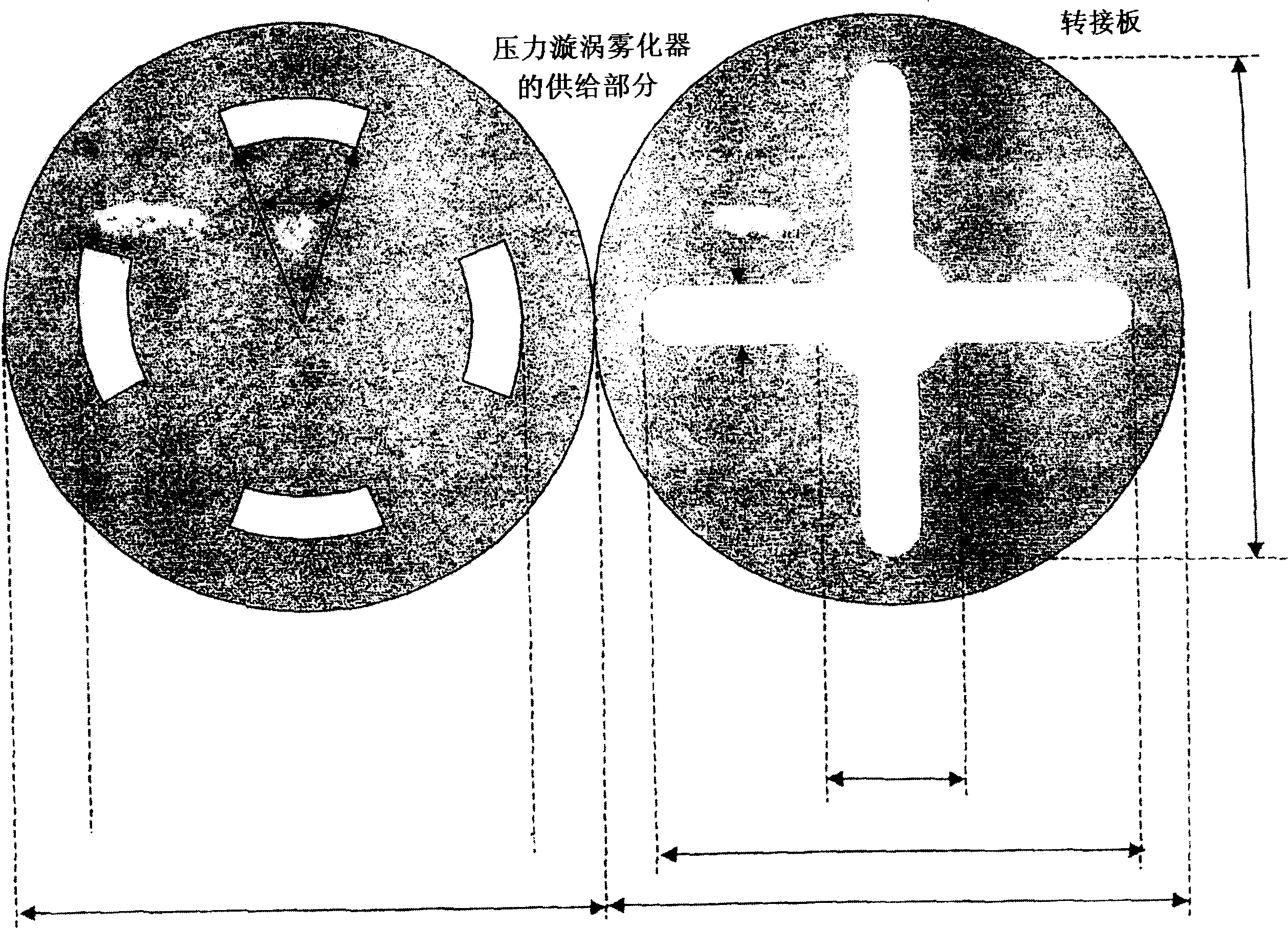

[0033] figure 1 A portion of an embodiment of an apparatus for treating exhaust gas by injecting an atomized substance into an exhaust gas stream is shown. The atomization (in this example an atomization of an aqueous urea solution) is sprayed via the valve spray nozzle 1 to an exhaust manifold (not shown). The atomization is produced in a pressure vortex atomizer 25 which rests against an adapter plate 23 in the valve seat 2 . The manifold (not shown) includes a catalytic converter for selective catalytic reduction of nitrogen oxides in the presence of aqueous urea aerosols.

[0034] Said liquid, in this example an aqueous urea solution, is supplied to the first chamber 4 via supply means 6 connected to the housing 7 . The figures show only one feeder, but multiple feeders are also conceivable. It is possible to inject liquids which are already mixtures into the first chamber, but the invention also contemplates introducing multiple liquids into the chamber in order to ach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com