Casting rolling device and method for aluminum alloy plate blank

A technology for aluminum alloy and slab, applied in the field of aluminum alloy casting and rolling equipment and manufacturing, to reduce segregation, avoid surface and center band segregation, and achieve good effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

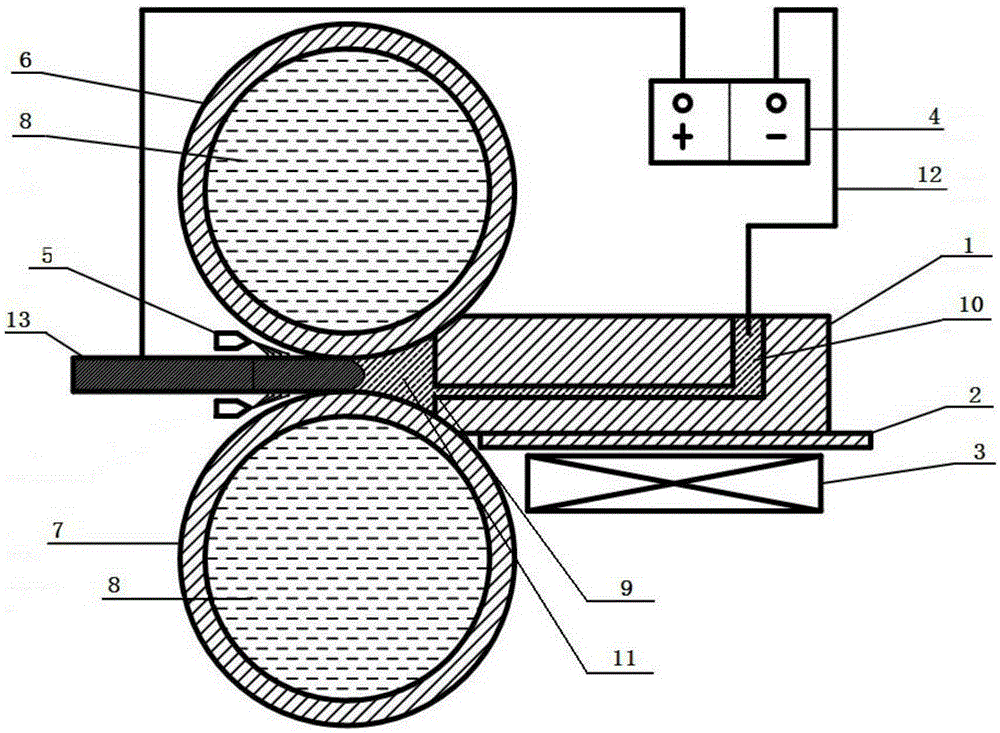

[0037] A casting and rolling device for an aluminum alloy slab, such as figure 1 As shown, it includes a casting nozzle (pouring nozzle) 1, a platform 2, a casting roll, an electromagnetic field generator 3, a pulse power supply 4 and a water spray cooling device;

[0038] There are two casting rolls, namely an upper roll 6 and a lower roll 7, which are placed symmetrically up and down, and the cooling water 8 is passed through the rolls; the platform 2 is located on the melt inflow side outside the casting roll; the casting nozzle 1 is placed on the platform 2, The nozzle outlet 9 is located between the upper roll 6 and the lower roll 7, and the height is below the centerline of the slab, which is used to send the melt 10 into the casting roll and prevent the casting zone 11 from solidifying in advance; the electromagnetic field generating device 3 is installed on the casting roll Outside, located on the melt inflow side, consists of a power supply and a magnetic field genera...

Embodiment 2

[0040] A casting and rolling device for aluminum alloy slabs, the structure of which is the same as that of the device in Example 1, the difference is that no pulse power supply is provided.

Embodiment 3

[0042] A casting and rolling device for aluminum alloy slabs, the structure of which is the same as that of the device in embodiment 1, the difference is that no electromagnetic field generating device is provided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com