Continuous non-woven fabric melt-blowing method and non-woven fabric

A technology of melt-blown non-woven fabrics and non-woven fabrics, applied in the field of continuous melt-blown non-woven fabrics, can solve the problems of large equipment investment, low production efficiency, and high production costs, and achieve high degree of mechanization, high production efficiency, and flow rate. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

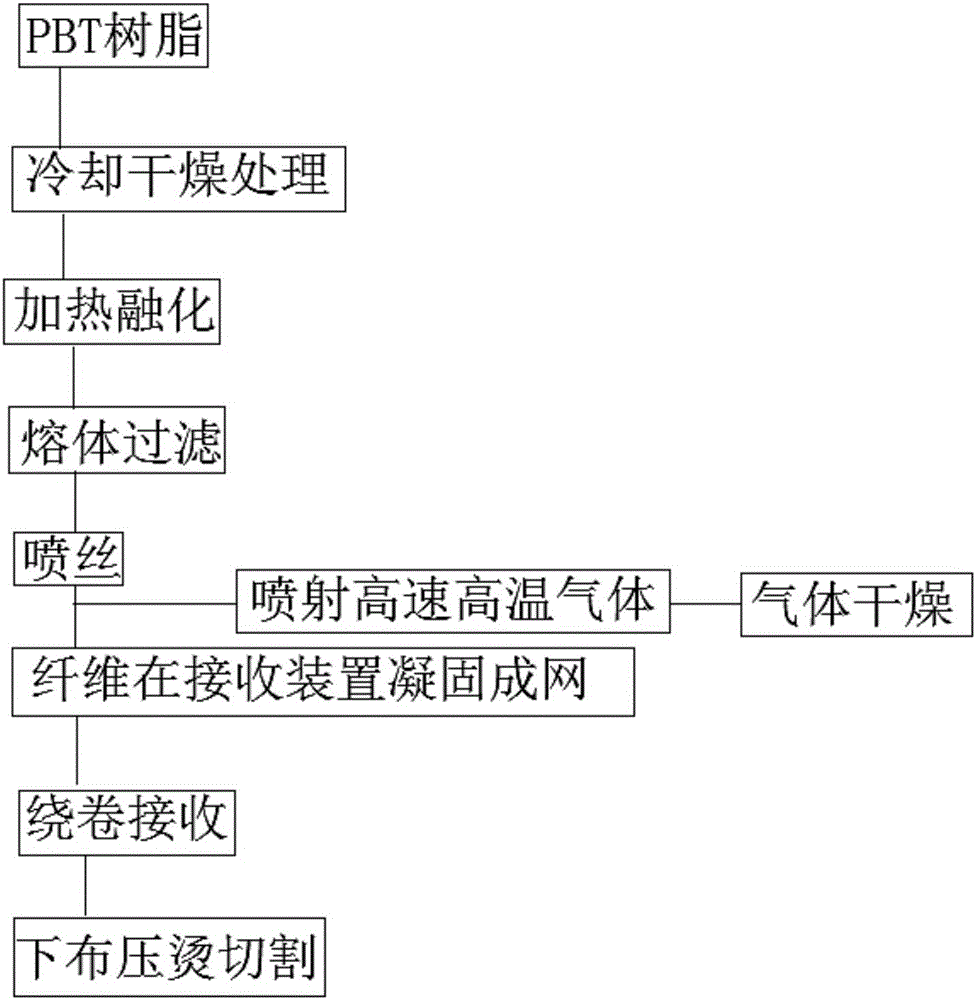

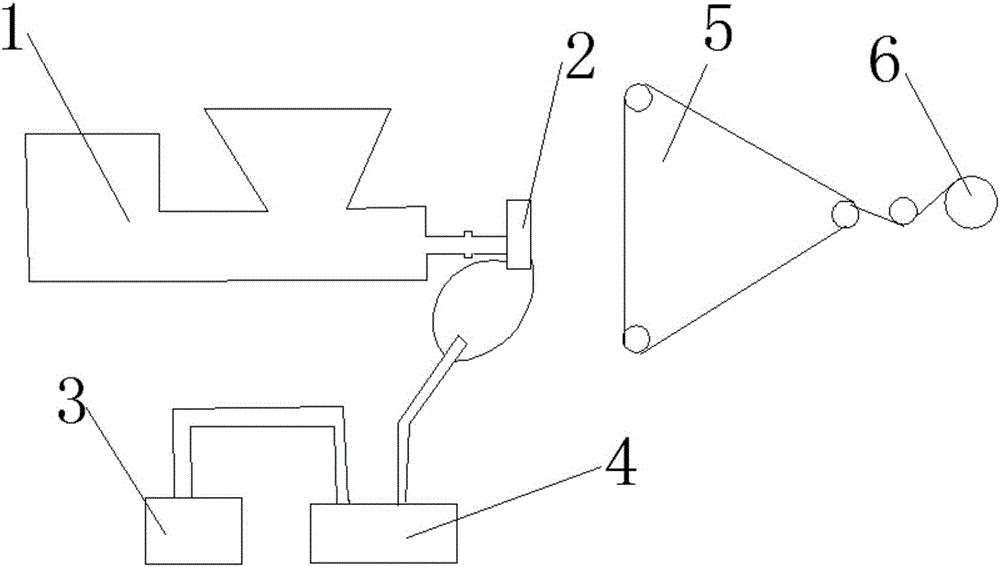

[0016] The invention introduces a method for continuous melt-blown non-woven fabrics, which includes the following specific steps: first, dry the PBT raw material, and then send the PBT raw material to the extruder by the feeder after the drying treatment, and the extruder feeds the PBT pellets Heat and melt, then send the heated and melted PBT to the spinneret at the spinneret die for spinning, and form ultra-fine fibers under gas drafting, the gas is ejected from both sides of the spinneret 2, and the air is compressed The machine 3 first compresses the air and transmits the compressed air to the air heater 4 for heating. The compressed and heated air is ejected in the same direction as the fibers ejected from the spinneret through the gas pipeline connected to the spinneret 2. The high-temperature air It can be 400°C, 410°C, 420°C, etc. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com