Shaving board manufacturing compression molding method

A compression molding and particle board technology, which is applied in the direction of manufacturing tools, pretreatment of molding materials, flat products, etc., can solve the problems of reduced particle board pass rate and short time, and achieve the goal of reducing the penetration area, ensuring smoothness, and improving pass rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings. It should be noted that the embodiments in the application and the features in the embodiments can be combined with each other if there is no conflict.

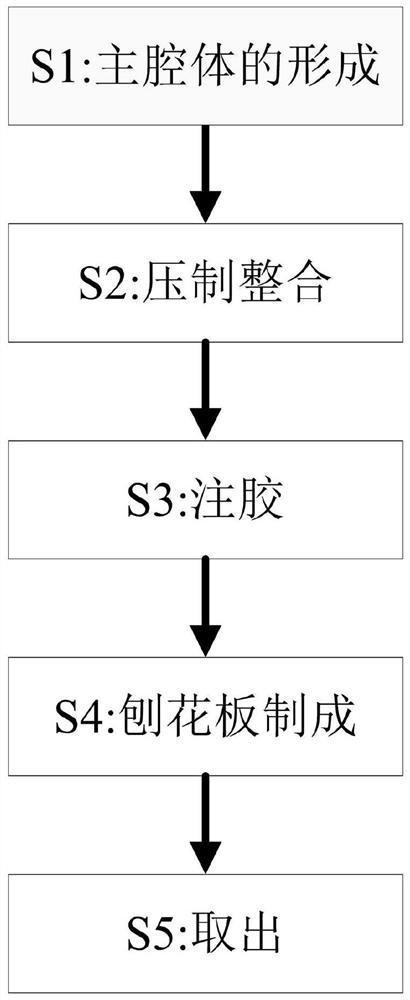

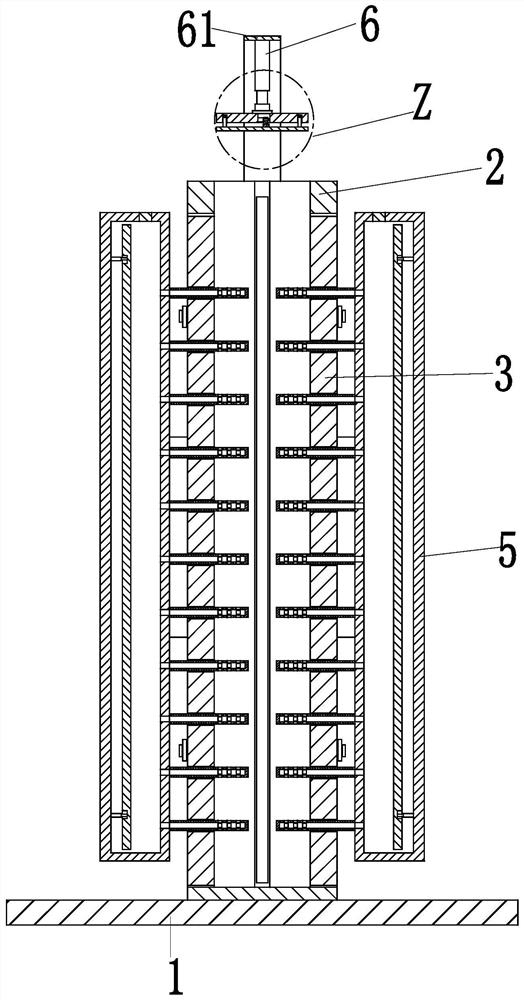

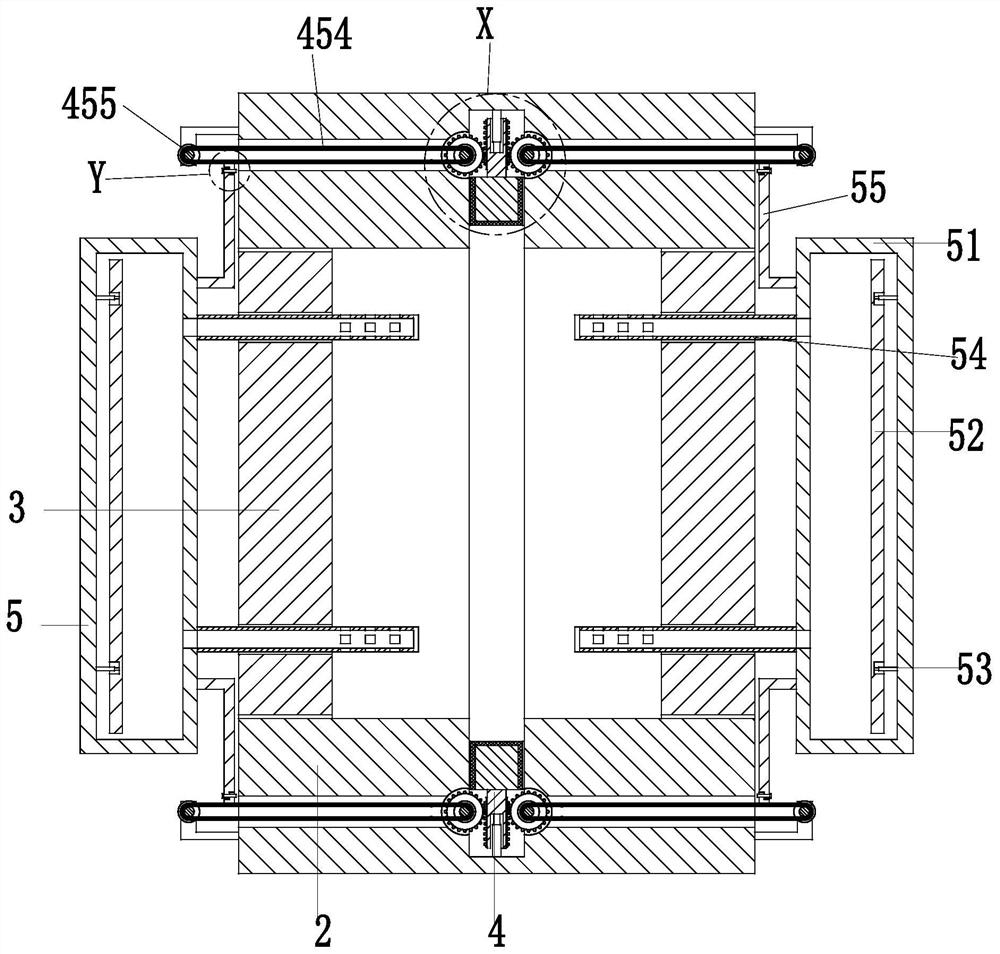

[0035]Such asFigure 1 to Figure 8As shown, a compression molding method for manufacturing particleboard uses a compression molding equipment. The compression molding equipment includes a base 1, a template frame 2, two sealing plates 3, two linkage devices 4, and two glue injection devices 5. And the pressing device 6, using the above-mentioned compression molding equipment to manufacture the particleboard and the compression molding method is as follows:

[0036]S1. Formation of the main cavity: the cylinder 41 drives the front and rear push blocks 43 to move toward each other. Under the action of the lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com