Gantry-type automatic fruit harvesting robot

A gantry-type, robot technology, applied in the field of agricultural robots, can solve the problems of low work efficiency, high labor intensity, long time consumption, etc., and achieve the effect of reducing labor volume, high degree of automation, and wide application scenarios.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

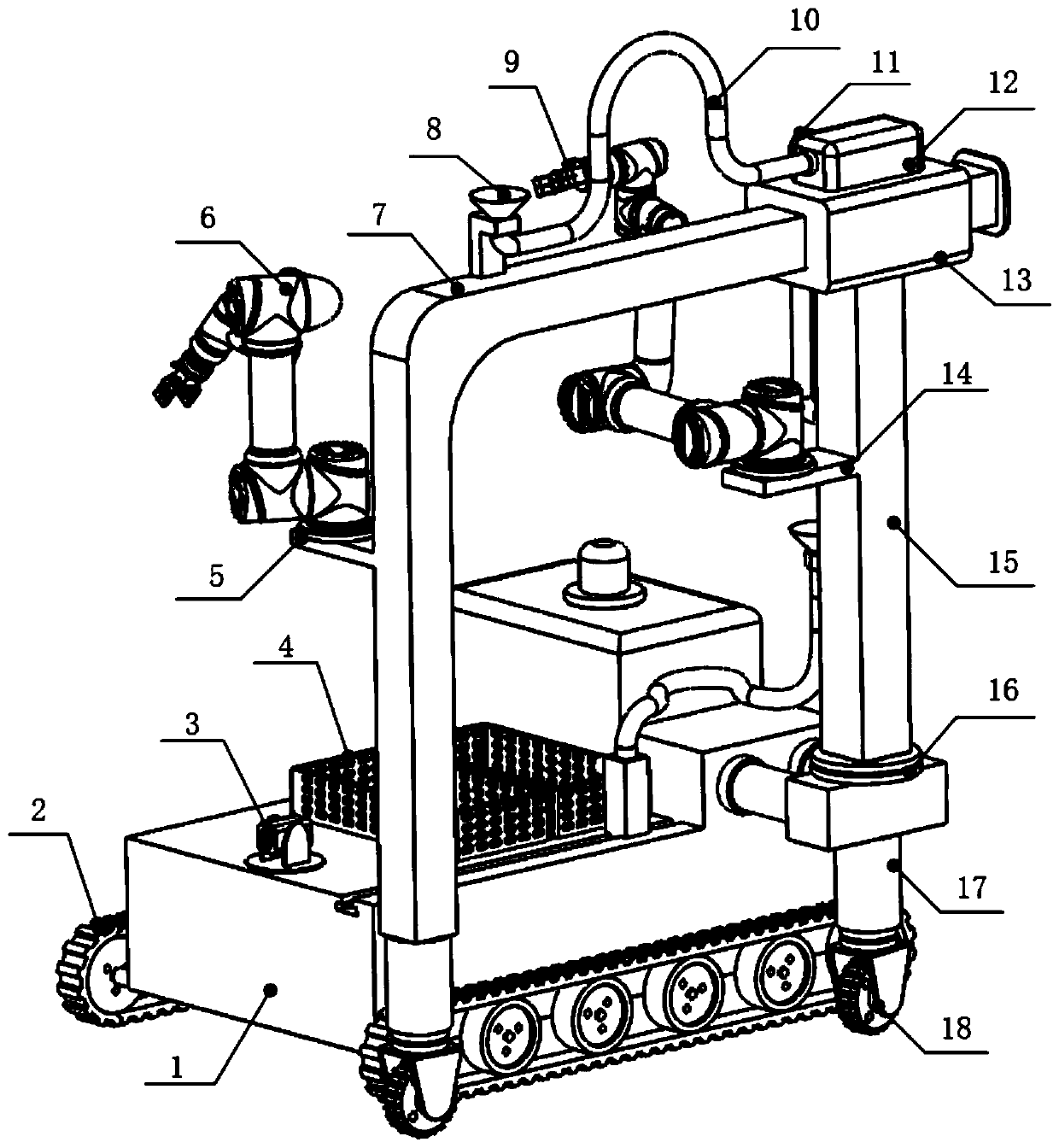

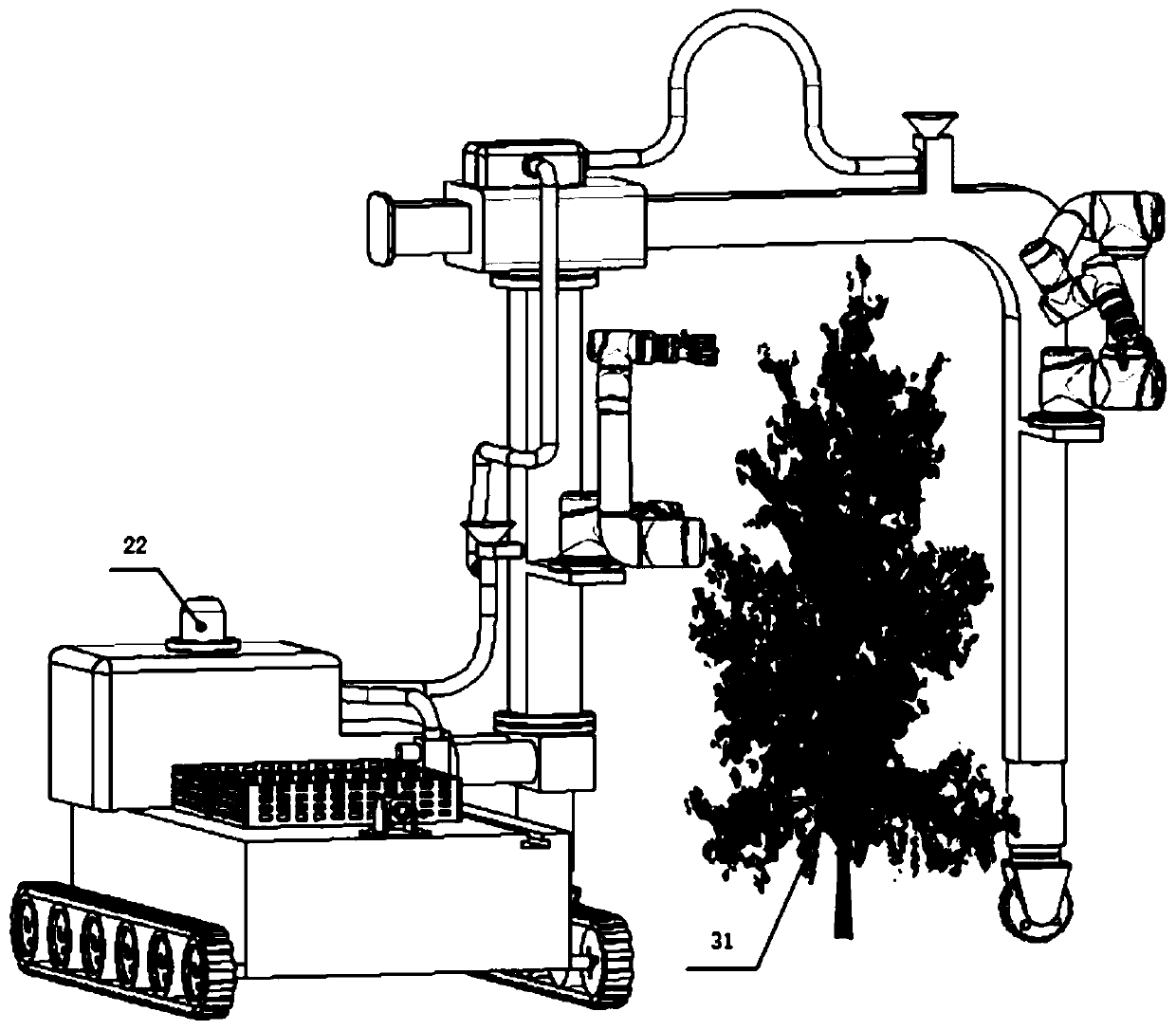

[0059] like Figure 1~5 As shown, the gantry type fruit automatic harvesting robot of the present invention includes a camera 3, a gyroscope 22, a traveling mechanism, a gantry mechanism, a harvesting mechanism and a collection system. in:

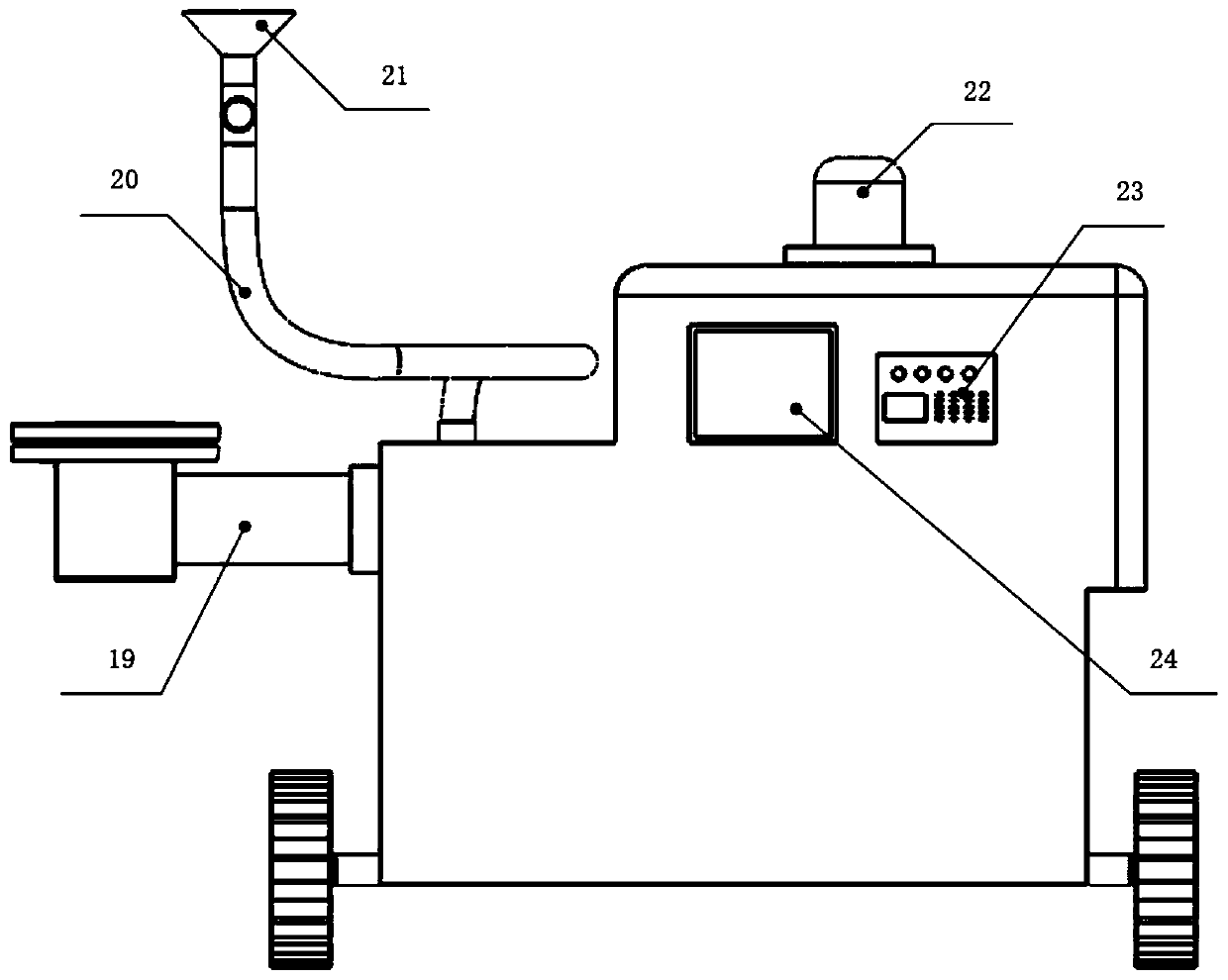

[0060] The running mechanism includes a chassis 1, crawler belts 2 and push rods 19.

[0061] Crawler belt 2 is located at chassis 1 bottom. The robot uses a crawler walking method, and the sprocket on the crawler adopts an elastic installation method, which can better adapt to the slightly undulating terrain in the field and ensure that the robot can walk more smoothly.

[0062] The push rod 19 includes a fixed end and a movable end, and the fixed end of the push rod 19 is arranged on the chassis 1 . The moving end of the push rod 19 can move laterally to the chassis 1 . The push rod 19 adopts a double push ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com