High-speed floating ring bearing and rotor system support manner

A floating ring bearing and rotor support technology, applied in the rigid bracket, bearing, liquid cushion bearing and other directions of bearing components, can solve the problems affecting the high-speed stability of the air bearing, high operation and maintenance costs, and harsh environmental requirements, and avoid poverty. Oil-lubricated state, reduced installation costs, and high bearing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

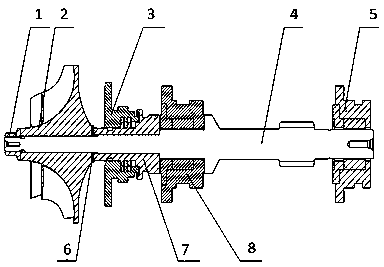

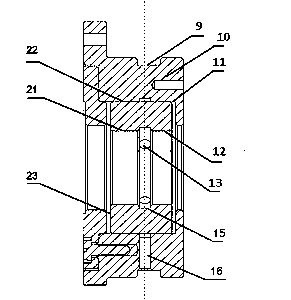

[0029] as attached figure 1 As shown, the high-speed floating ring bearing-rotor system shown in this embodiment includes a lock nut 1, a centrifugal impeller 2, a seal ring 3, a rotor 4, a high-speed floating ring bearing 5, an adjusting pad 6, a thrust plate 7, a floating ring and Thrust combination bearing 8. The high-speed floating ring bearing 5 and the combined floating ring and thrust bearing 8 are set at both ends of the rotor system to support and transmit torque. The high-speed floating ring bearing 5 bears the radial load, and the combined floating ring and thrust bearing 8 bears the radial and axial loads, which can not only greatly save the installation space, but also reasonably arrange the layout of the bearings, and at the same time meet the needs of the rotor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com