Hydraulic buffering system and equipment comprising hydraulic buffering system

A hydraulic buffer and hydraulic technology, applied in mechanical equipment, fluid pressure actuating devices, springs/shock absorbers, etc., can solve problems such as reducing the energy efficiency of the hydraulic buffer system, and achieve the effect of improving energy utilization efficiency and reducing heat generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the following, some embodiments of the present invention will be described in more detail with reference to the accompanying drawings in order to better understand the basic idea of the present invention.

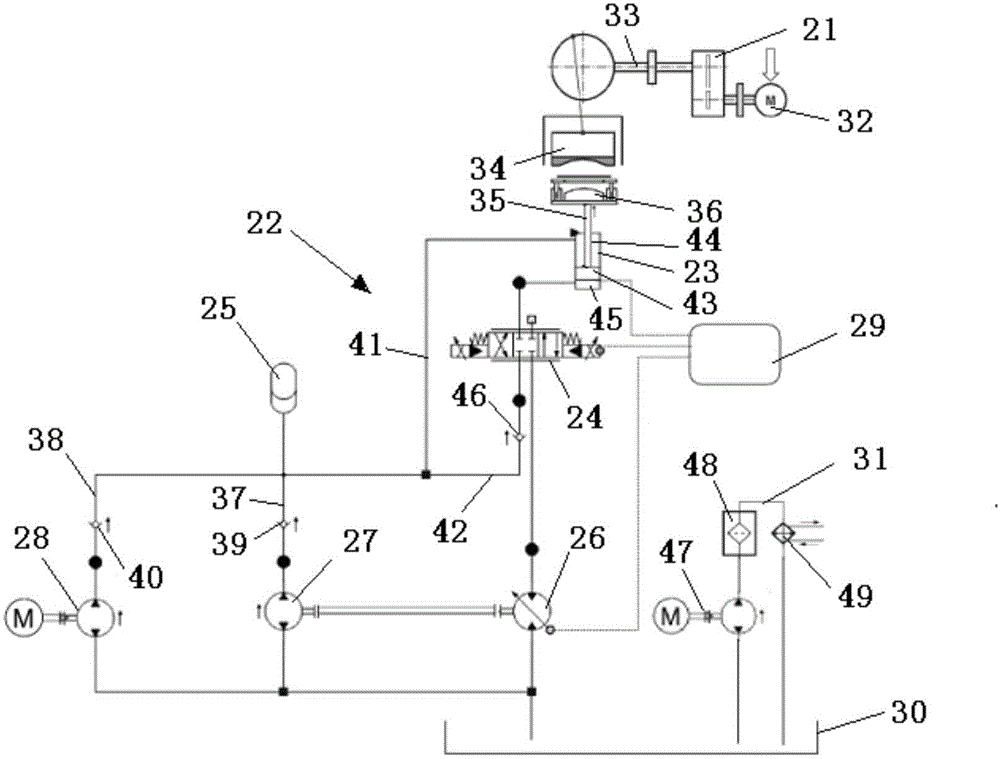

[0034] figure 2 A hydraulic schematic diagram of a hydraulic buffer system 22 used in conjunction with a stamping unit 21 according to an exemplary embodiment of the present invention is shown.

[0035] Such as figure 2 As shown, the hydraulic buffer system 22 includes a hydraulic cylinder 23, a proportional valve 24, an accumulator 25, a hydraulic motor 26, a main pump unit 27, an auxiliary pump unit 28, a motion and force controller 29, an oil tank 30, and a filter and cooling unit 31.

[0036] Such as figure 2 As shown, the stamping unit 21 includes: a motor 32 , a transmission mechanism 33 , an upper mold 34 connected to the transmission mechanism 33 and a lower mold 36 fixed at the top end of the piston rod 35 of the hydraulic cylinder 23 . The rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com