Horizontal rotating weft-guiding transmission mechanism for weaving machine

A technology of flat-spin weft insertion and transmission mechanism, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of high production cost, high resistance and high processing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

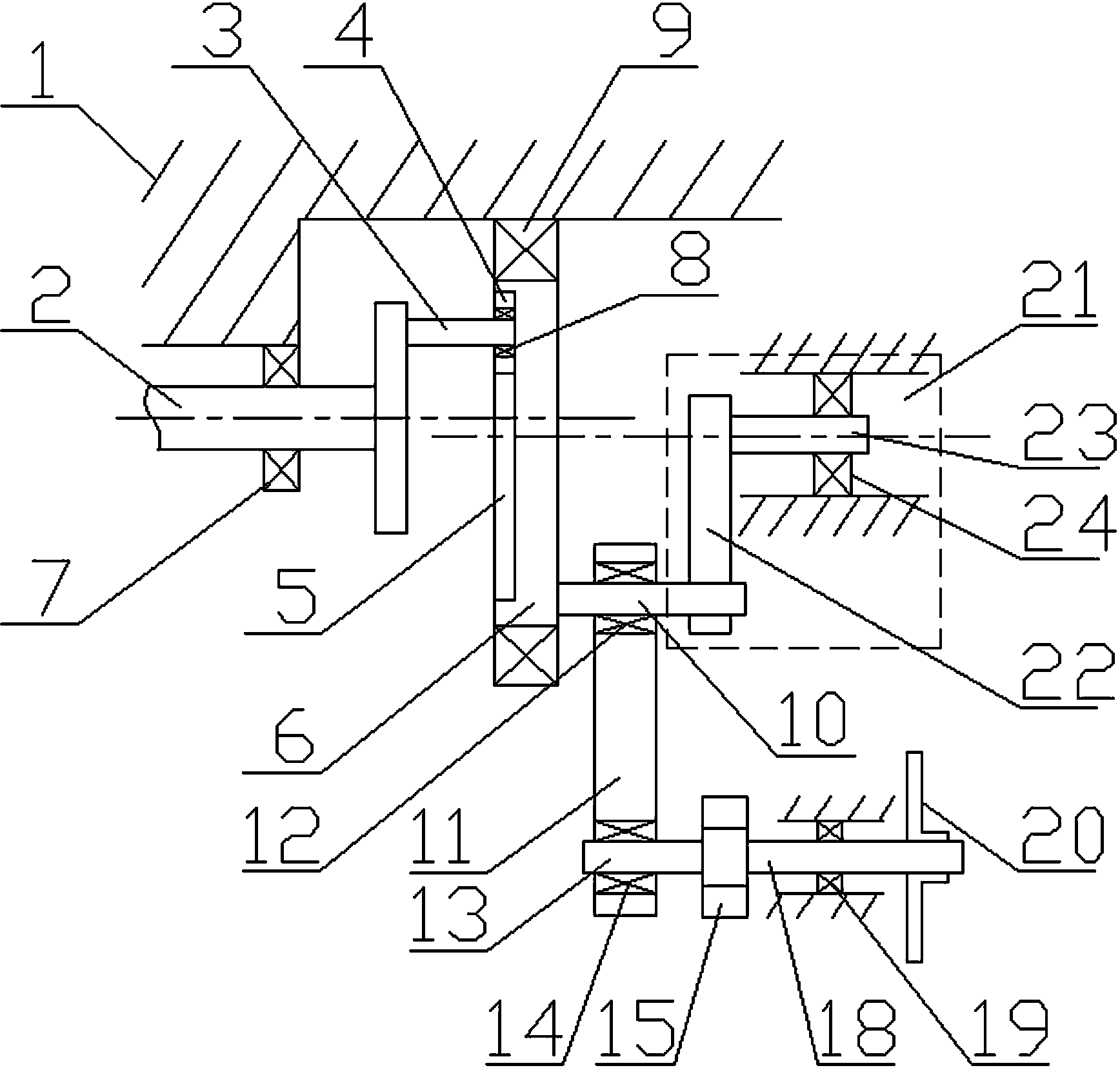

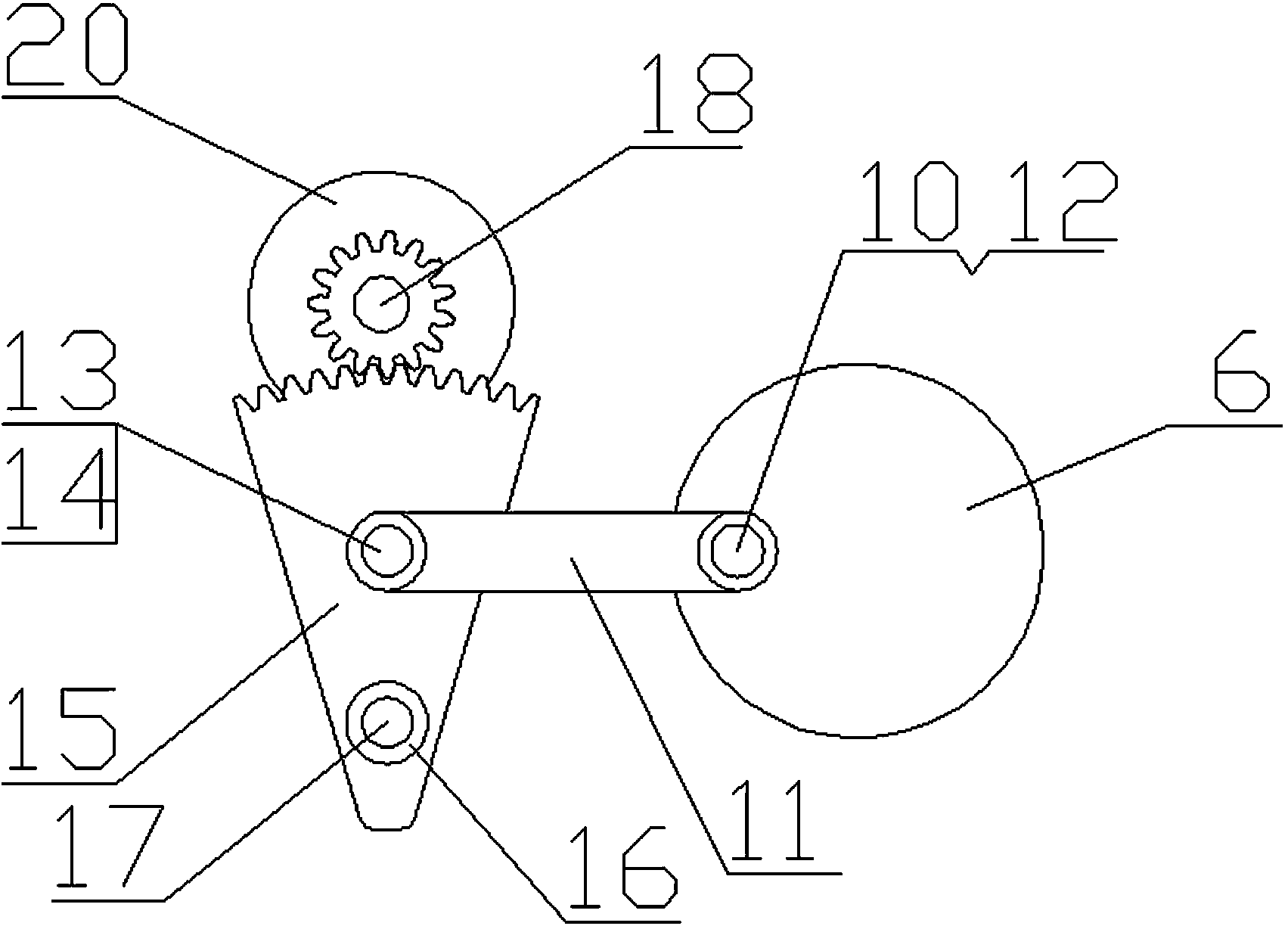

[0017] figure 1 , 2 As shown, a weft insertion transmission mechanism of a loom includes a frame 1, a driving shaft 2, a primary eccentric shaft 3, a driving roller 4, a chute 5, a passive disk 6, a driving shaft bearing 7, and a primary eccentric shaft. Shaft bearing 8, passive disk bearing 9, secondary eccentric shaft 10, weft insertion link 11, weft insertion link bearing 12, connection support shaft 13, fulcrum bearing 14, reciprocating tooth arm 15, tooth arm bearing 16, tooth arm Rotary support shaft 17, output gear shaft 18, output gear shaft bearing 19, transfer sword wheel 20 and secondary eccentric shaft stabilizing mechanism 21. The driving shaft 2 and the passive disk 6 are rotatable and parallel to the center lines of the circle, and the center lines are not on the same center. 3. The primary eccentric shaft 3 is socketed with the driving roller 4 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com