Gas atomization preparation method of metal power with low satellite ball rate and for 3D printing

A 3D printing and metal powder technology, which is applied in the fields of additive manufacturing and powder metallurgy, can solve problems such as industrial production problems, and achieve the effects of good fluidity, low composition and high sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

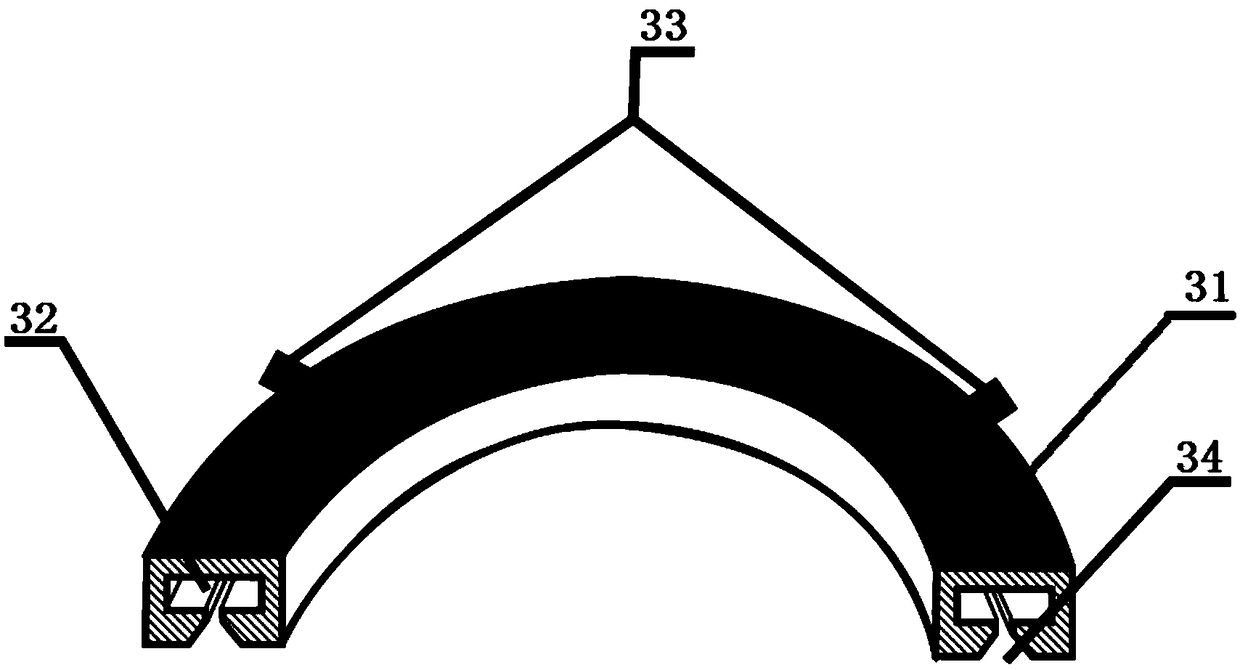

[0029] A gas atomization preparation method of low-satellite metal powder for 3D printing. In the ultrasonic close-coupled vacuum air atomization process, an annular inflator is installed at the upper end of the atomization chamber, and an external airflow is introduced to improve the trajectory of the return gas in the atomization chamber. Reduce the probability of solidified particles re-entering the area and colliding with high-temperature particles during the aerosolization process, and realize the preparation of spherical metal powders with low satellites and high fluidity for 3D printing.

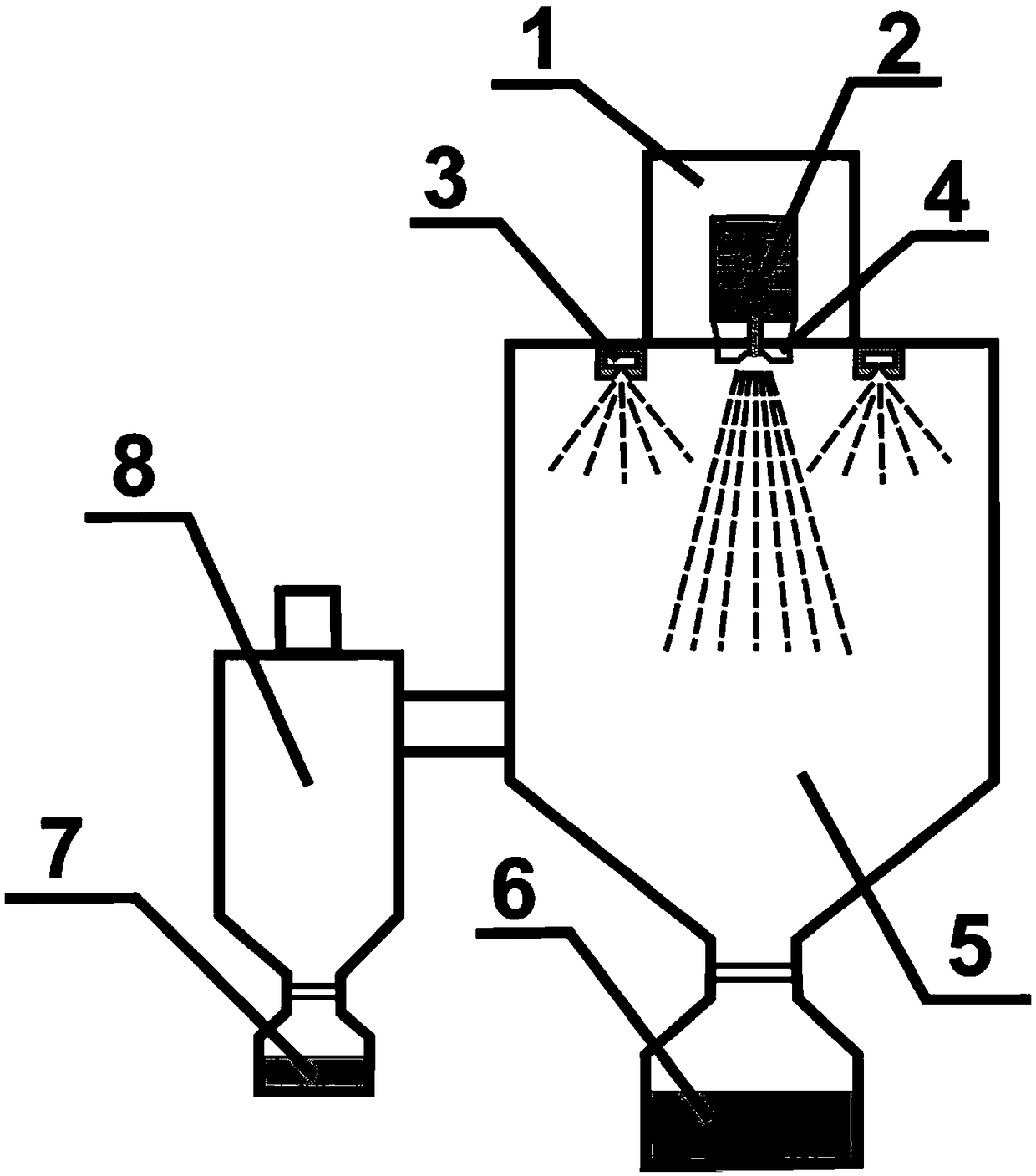

[0030] refer to figure 1 , using an ultrasonic close-coupled gas atomization device to carry out the ultrasonic close-coupled vacuum air atomization process, the ultrasonic close-coupled gas atomization device includes an atomization chamber 5, a melting chamber 1 is arranged above the atomization chamber 5, and a melting crucible is arranged in the melting chamber 1 2. The outlet of ...

Embodiment 2

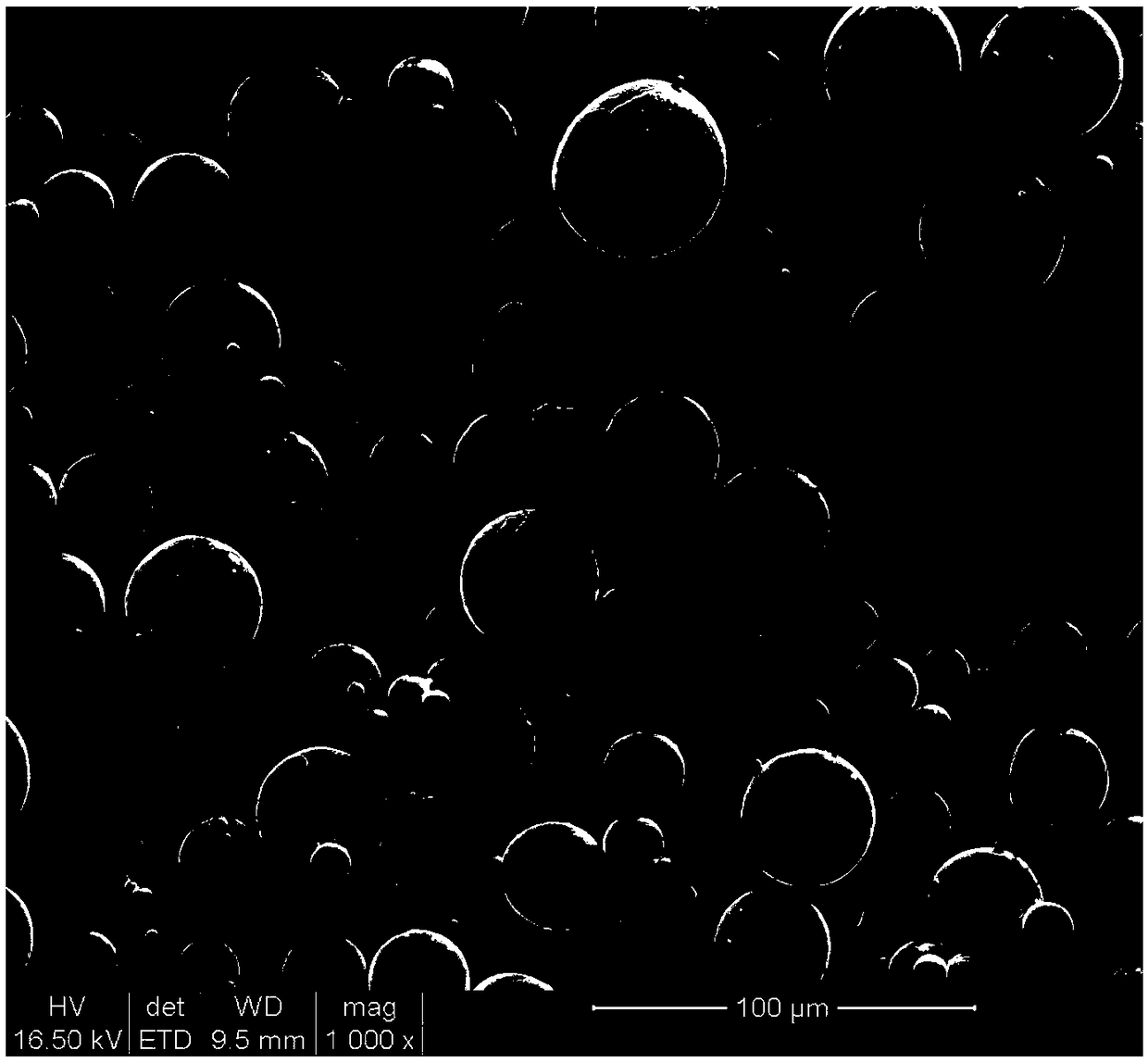

[0034] The method of the invention prepares the Inconel 718 high-temperature alloy powder with low satellite sphere, high sphericity and good fluidity. The alloy is smelted under protective gas at a melting temperature of 1500°C. High-purity argon is used for atomization, and the atomization pressure is 4MPa. At the same time as the atomization, start the ring gas filling device, the filling gas is high-purity argon, and the filling pressure is 1MPa. The diameter of the annular inflatable device is 1.4m, and the divergence angle is 50 degrees. After the atomized powder is collected by the cyclone separation system, the metal powder with a particle size of 15-106 μm is screened out through the screening device, and the yield reaches 75%. Observation by scanning electron microscope shows that the prepared powder has high sphericity and few satellites. The fluidity was measured by a Hall flow meter to reach 11s.

[0035] The prepared Inconel 718 superalloy powder scanning elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com