Transition section optimization method based on three-dimensional free bending technology

A transition section and bending technology, applied in the field of transition section optimization based on three-dimensional free bending technology, can solve problems such as transition section errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

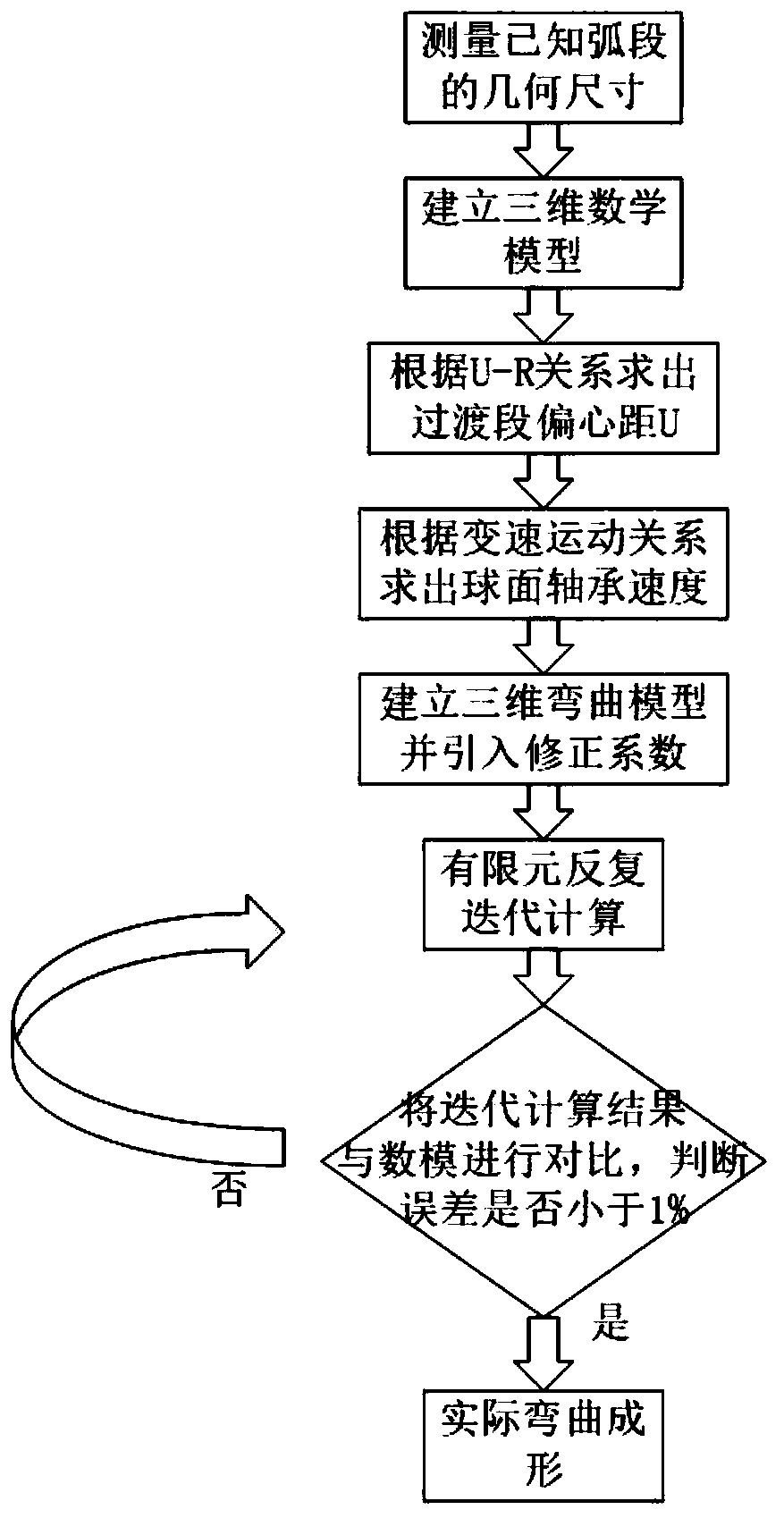

Method used

Image

Examples

Embodiment 1

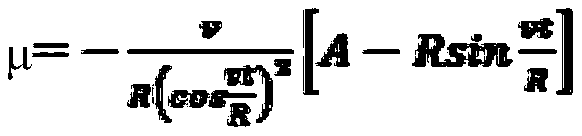

[0026] The first step is to establish a model and analyze the process of a curved pipe with an outer diameter of 15mm, a bending angle of 45°, and a bending radius of 90mm, and calculate the eccentricity U of the transition section according to the U-R relationship (the central axis of the guide mechanism and the bending die) The distance between the central axes is the eccentricity U):

[0027]

[0028] Movement speed of bending die spherical bearing

[0029] sport time

[0030]

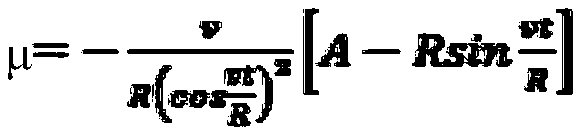

[0031] In the second step, the finite element method is used to establish a three-dimensional bending model, and the correction coefficient k is introduced into the quantitative relationship described in the first step. The formula after the correction coefficient is introduced is as follows:

[0032] Movement speed of bending die spherical bearing

[0033] The third step is to use the quantitative relationship after introducing the correction coefficient k as described in the second s...

Embodiment 2

[0037] The first step is to establish a model and process analysis for a curved pipe fitting with an outer diameter of 15mm, a bending angle of 90°, and a bending radius of 90mm.

[0038] Movement speed of bending die spherical bearing

[0039] sport time

[0040]

[0041] In the second step, the finite element method is used to establish a three-dimensional bending model, and the correction coefficient k is introduced into the quantitative relationship described in the first step. The formula after the correction coefficient is introduced is as follows:

[0042] Movement speed of bending die spherical bearing

[0043] The third step is to use the quantitative relationship after introducing the correction coefficient k as described in the second step as the bending parameter, take the initial value of k as 1, start the repeated iterative calculation of the bent pipe finite element, import the calculation results into the geometric software CATIA for processing, and ...

Embodiment 3

[0047] In the first step, model building and process analysis are carried out for the curved pipe fittings with an outer diameter of 15mm, a bending angle of 180°, and a bending radius of 90mm.

[0048] Movement speed of bending die spherical bearing

[0049] sport time

[0050]

[0051] In the second step, the finite element method is used to establish a three-dimensional bending model, and the correction coefficient k is introduced into the quantitative relationship described in the first step. The formula after the correction coefficient is introduced is as follows:

[0052] Movement speed of bending die spherical bearing

[0053] The third step is to use the quantitative relationship after introducing the correction coefficient k as described in the second step as the bending parameter, take the initial value of k as 1, start the repeated iterative calculation of the bent pipe finite element, import the calculation results into the geometric software CATIA for pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com