Residence time distribution method and apparatus for operating a curvilinear pressure vessel where transport phenomena take place

a curvilinear pressure vessel and distribution method technology, applied in mechanical apparatus, separation processes, physical/chemical process catalysts, etc., can solve the problems of two-phase polymer deposition in the bed, cost-effective event in terms of production and clean-up costs, and inability to achieve anything like plug flow of solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

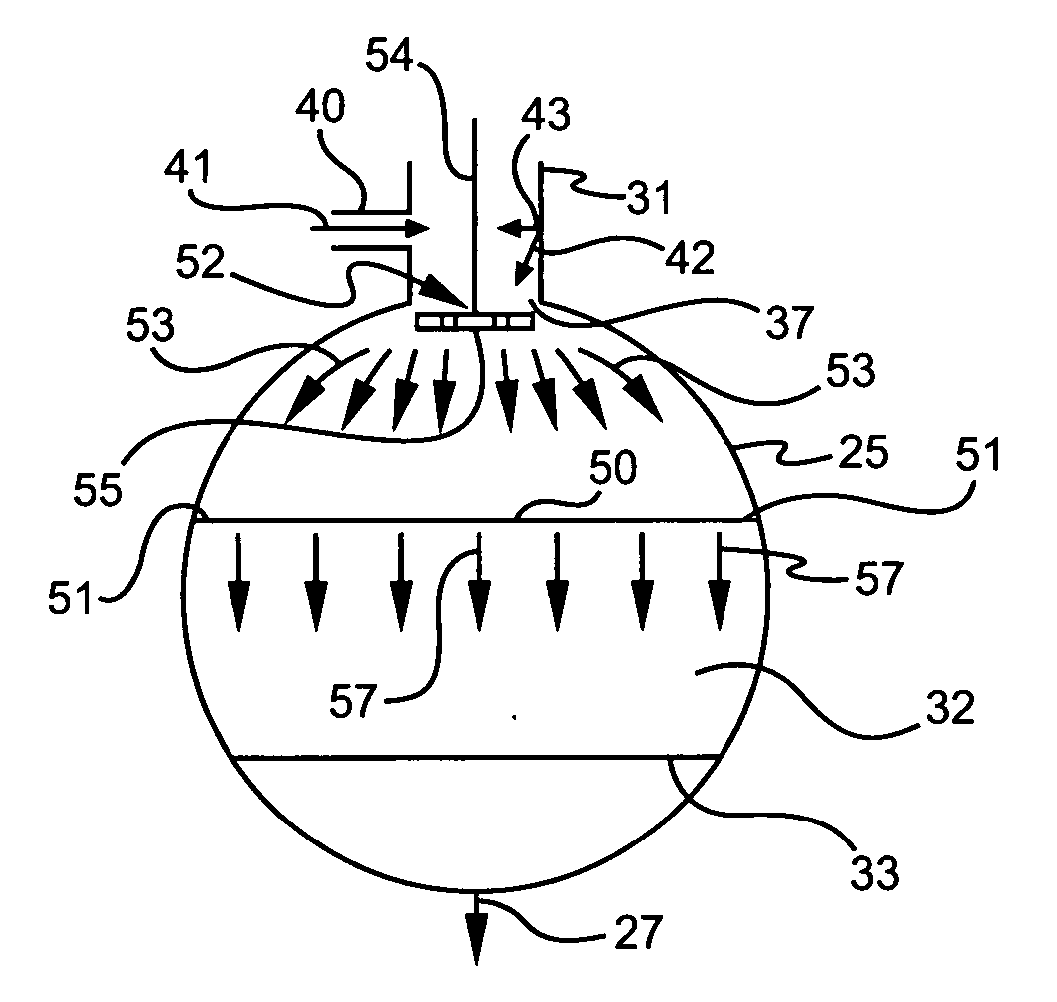

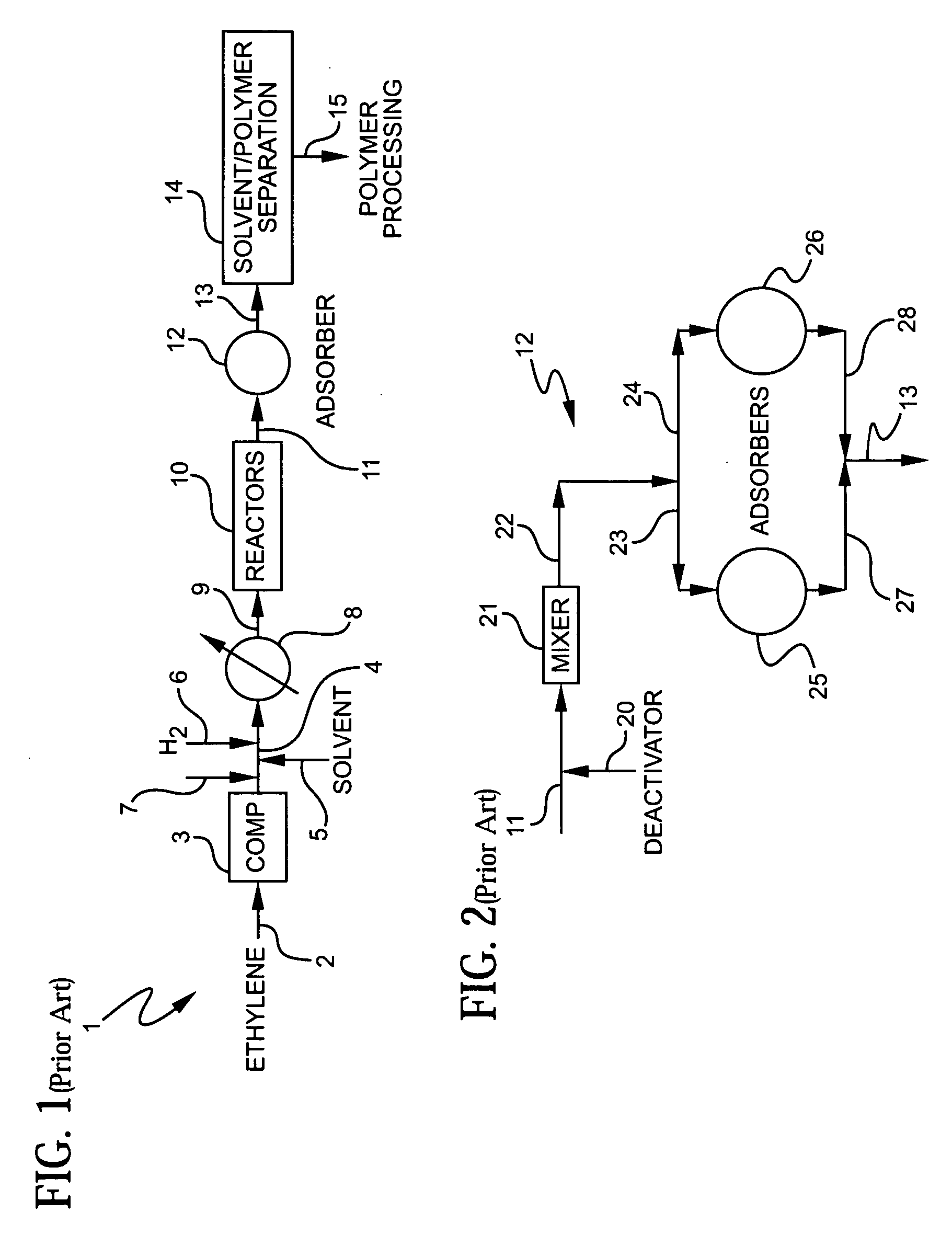

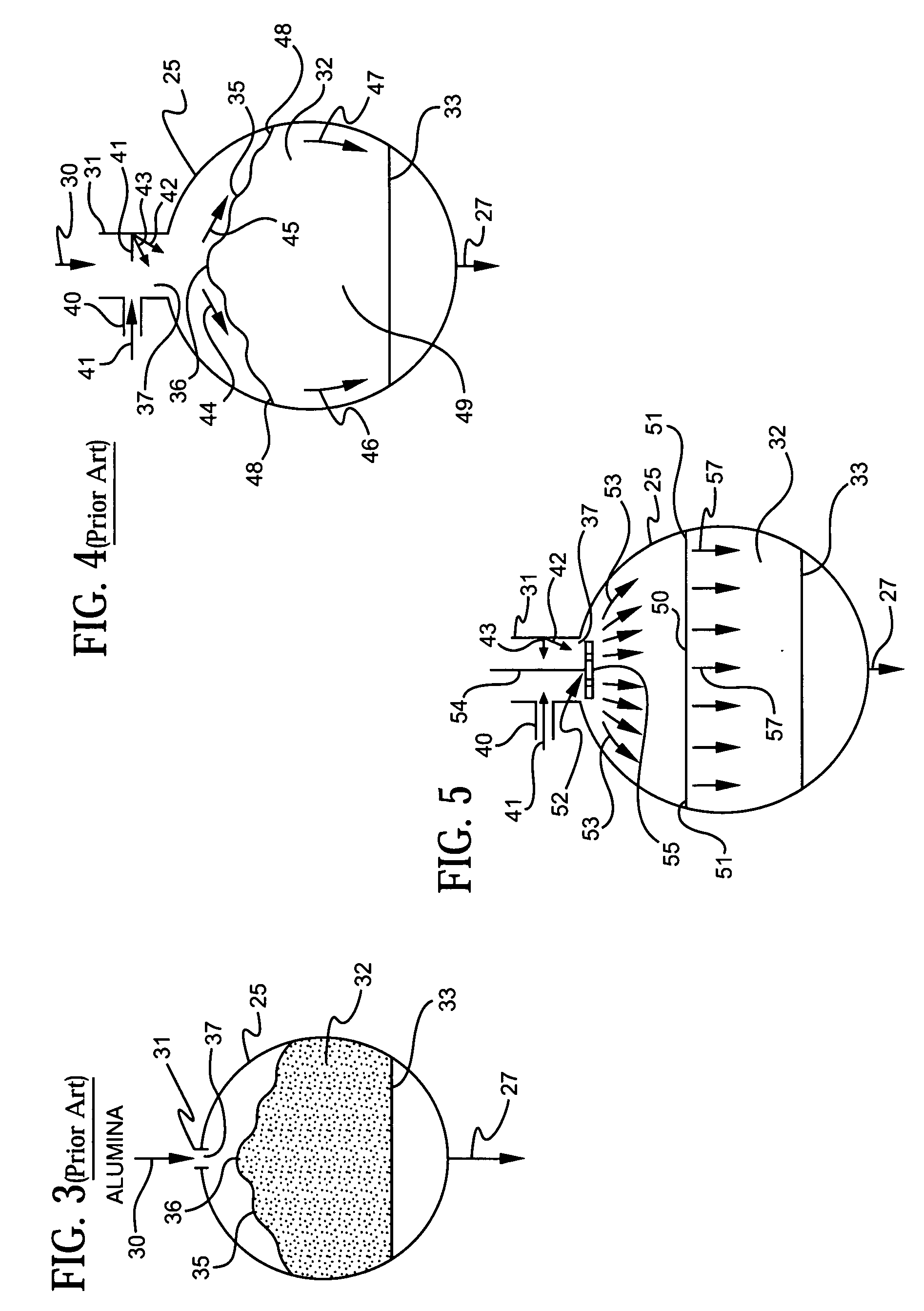

[0022]FIG. 1 shows an ethylene polymerization process 1 wherein an ethylene monomer stream 2 is compressed at 3 and the compressed product removed into line 4. Solvent 5 and molecular hydrogen 6 are added to stream 4. One or more co-monomers 7 can also be added to this stream, if desired. Stream 4 is then heated by heat exchanger 8 to form the desired single phase solution, which is then conducted via line 9 to reactor unit 10. Unit 10 conventionally contains two continuous, stirred reactors (not shown) working in parallel and both feeding a single, continuous, stirred reactor (not shown), which, in turn, feeds a tubular reactor (not shown).

[0023] The single phase solution product containing polyethylene formed in reactor unit 10 is passed by way of line 11 to adsorber unit 12. Acetylacetone is injected (see FIG. 2) upstream of adsorber 12. The single phase solution minus the catalyst and deactivator materials adsorbed by the alumina bed of unit 12 is passed by way of line 13 to a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com