Integrated experiment system for measuring tank reactor amplification effect

The technology of a kettle type reactor and experimental system is applied in the field of reactor analysis to achieve the effects of reducing loss, convenient operation and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

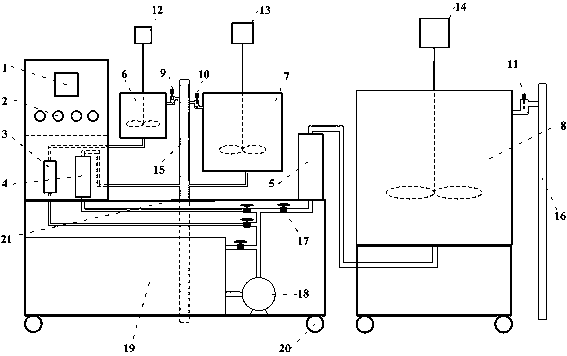

[0007] Embodiment 1: as figure 1 As shown, an integrated experimental system for measuring the amplification effect of a kettle reactor according to the present invention includes a control panel on which a conductivity display (1), a system power switch (2), a small flow meter (3 ), medium-sized flowmeter (4). It includes three stirred tank reactors, namely a small reactor (6) with a volume of 1L, a medium reactor (7) with a volume of 5L, and a large reactor (8) with a volume of 50L. The inlet of the small reactor (6) is equipped with The small flowmeter (3), medium-sized flowmeter (4) is installed at the inlet of the medium-sized reactor (7), and the large-sized flowmeter (5) is installed at the inlet of the large-scale reactor (8); the three stirred reactors are respectively equipped with agitator A (12), agitator B (13), agitator C (14); the small reactor (6), the medium reactor (7) and the large flowmeter (5) are fixed on the console (21), and the large flowmeter (5) Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com