Method for measuring solid particle residence time distribution in fluidized bed based on image recognition principle and test bed thereof

A technology of image recognition and residence time, applied in particle suspension analysis, acquisition/recognition of microscopic objects, measurement devices, etc. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080]The method of the present invention for measuring the residence time distribution of solid particles in a fluidized bed based on the principle of image recognition includes the following steps:

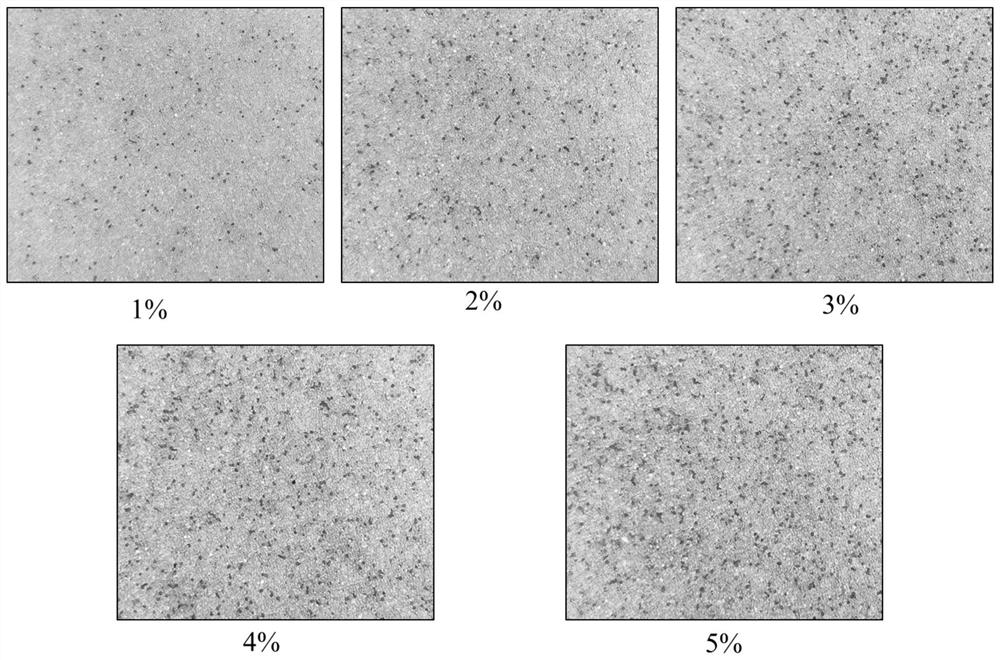

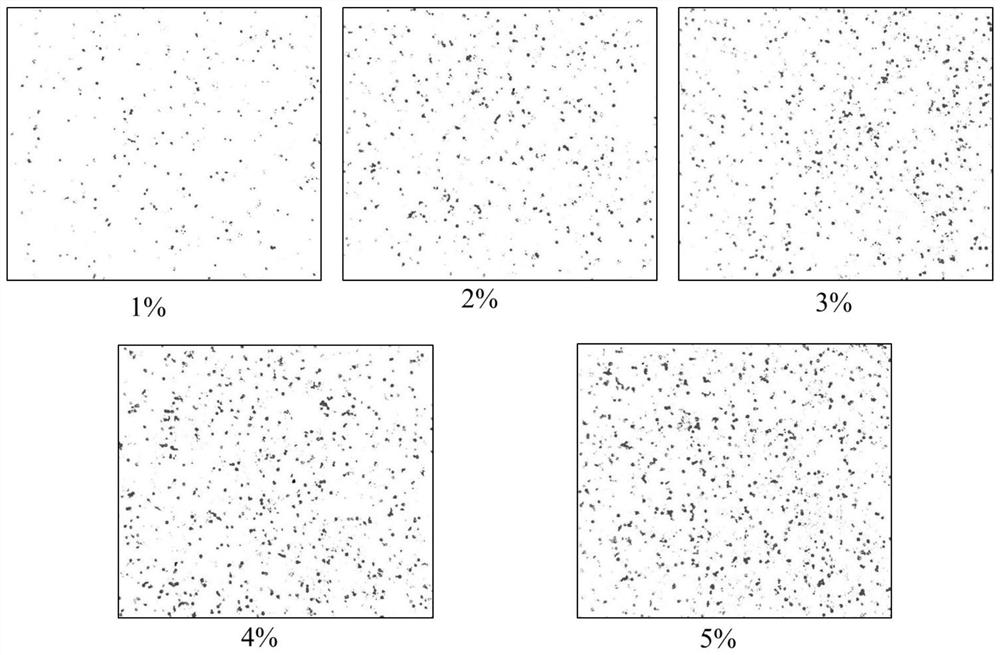

[0081]Step 1: Use translucent glass beads with a diameter of 0.3-0.35 mm as the solid bed material, and dye the glass beads red with carmine reagent as the tracer particles. Since the added amount of tracer particles is generally within 5% of the output volume, only samples with tracer particle concentrations of 1%, 2%, 3% to 5% need to be prepared. Prepare three sets of samples, fully stir all the samples and take pictures under the same light source conditions, and import the pictures into the computer. The original picture of the first set of tracer particle samples with different concentrations is as followsfigure 1 Shown.

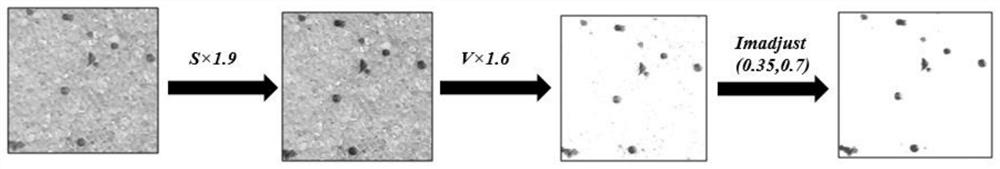

[0082]Step 2: Write a program in MATLAB to process the image taken in step 1. In the HSV color space, the S value of the image is magnified by 1.9 and the V value i...

Embodiment 2

[0091]Step 1: Design and build a test bench, the design drawing of the test bench is as shown inFigure 5 , The dimensions of the test bench are shown in Table 2.

[0092] Bed height Bed length Bed width Number of baffles 0.9m0.22m0.11m2 Baffle length Number of hood openings Number of wind hood Hole diameter of hood 0.9m6120.002m

[0093]Table 2

[0094]Such asFigure 5 As shown, the test bench includes a fluidized bed, a tracer particle silo, a material silo, a screw feeder, a bag filter, a sampler, a gas supply system, and an oil-water separator; the fluidized bed is respectively provided with inlet Feed port and sampling port; the sample output pipeline of the tracer particle silo is combined with the sample output pipeline of the material silo to communicate with the feed port of the fluidized bed, and the sample output pipeline of the tracer particle silo is installed The particle control valve, the sampling pipeline of the material silo is connected with the power output end of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| True density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com