Method for polishing ion beam with high-gradient mirror surface

An ion beam, high steepness technology, used in grinding/polishing equipment, optical surface grinders, grinders, etc., can solve the problems of high processing cost, difficulty in dwell time control and accurate calculation, and high processing difficulty. The effect of generality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0064] A method for ion beam polishing of a high-steep mirror surface of the present invention, comprising the following steps:

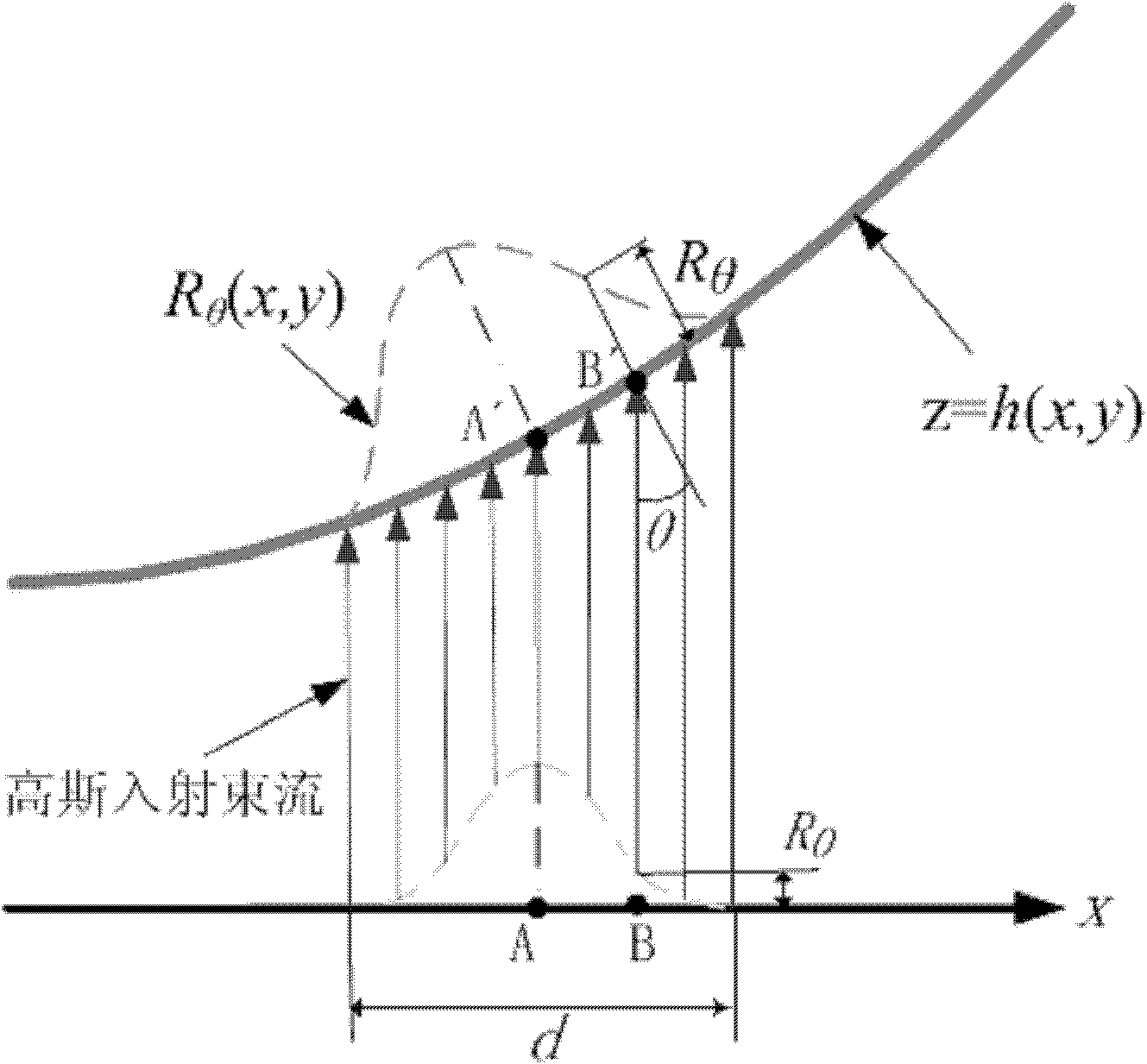

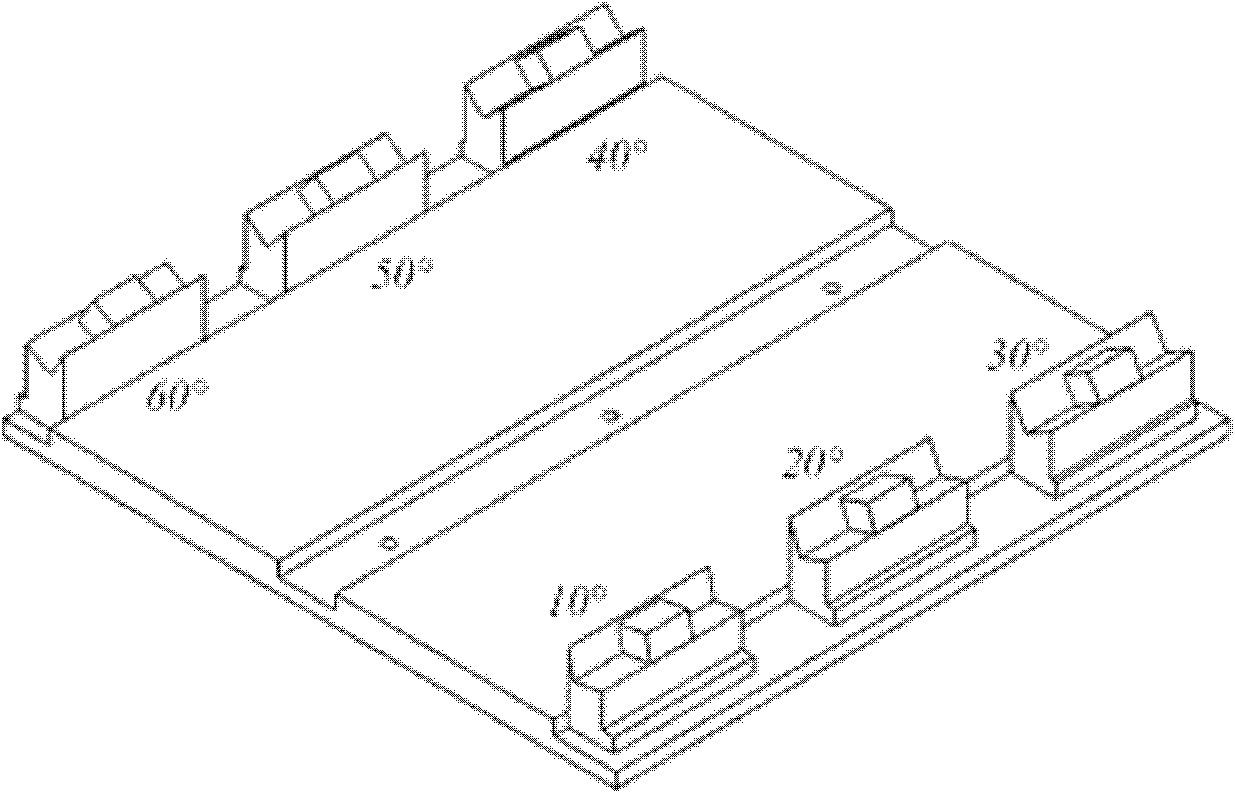

[0065] (1) Measuring the angle of incidence: take a workpiece to be polished with a high-steep mirror surface, the workpiece to be polished is a convex spherical mirror with a vertex radius of curvature of 16mm and a diameter of 21.3mm, the maximum angle of incidence is 41.7°, and its f value is 0.75, establish an X-Y rectangular coordinate system in a plane perpendicular to the optical axis of the workpiece, and calculate the angle between the normal line of each processing point on the mirror surface and the vertically incident ion beam according to the surface equation z=h(x, y) of the high-steep mirror surface , that is, the incident angle θ;

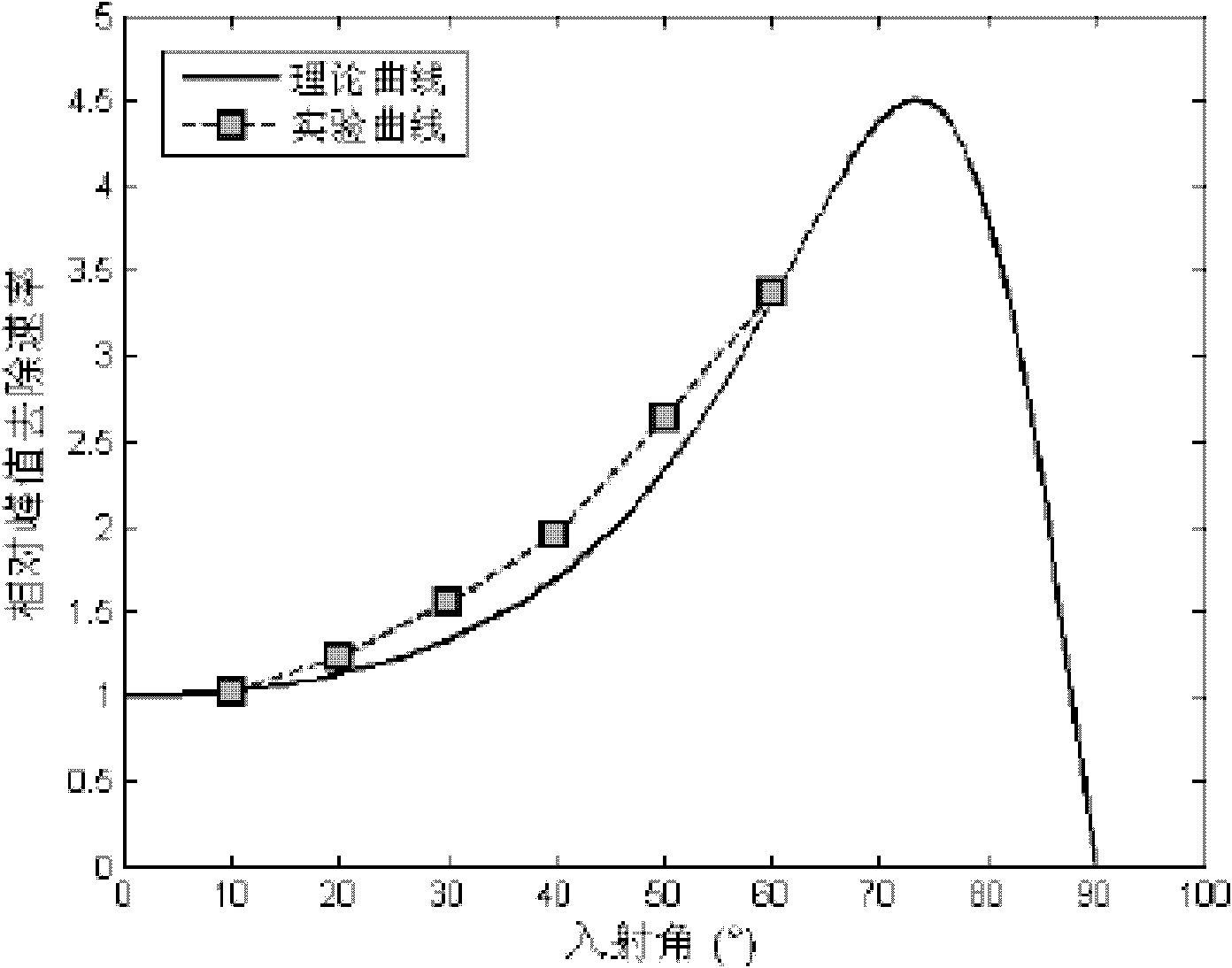

[0066] (2) Determine the compensation coefficient distribution: according to the model P(x, y)=(1 / n)Y 0 (θ)cosθf(xcosθ, y) determines that the compensation coefficient of each processing point of the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com