Rocker arm type polishing device and method for full-caliber deterministic polishing of planar part

A polishing device and deterministic technology, applied in the field of polishing, can solve the problems of lack of polishing pad control ability, low utilization rate of polishing pad, and slow convergence speed of plane parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] The present invention will be further described below in conjunction with the drawings and specific implementation methods.

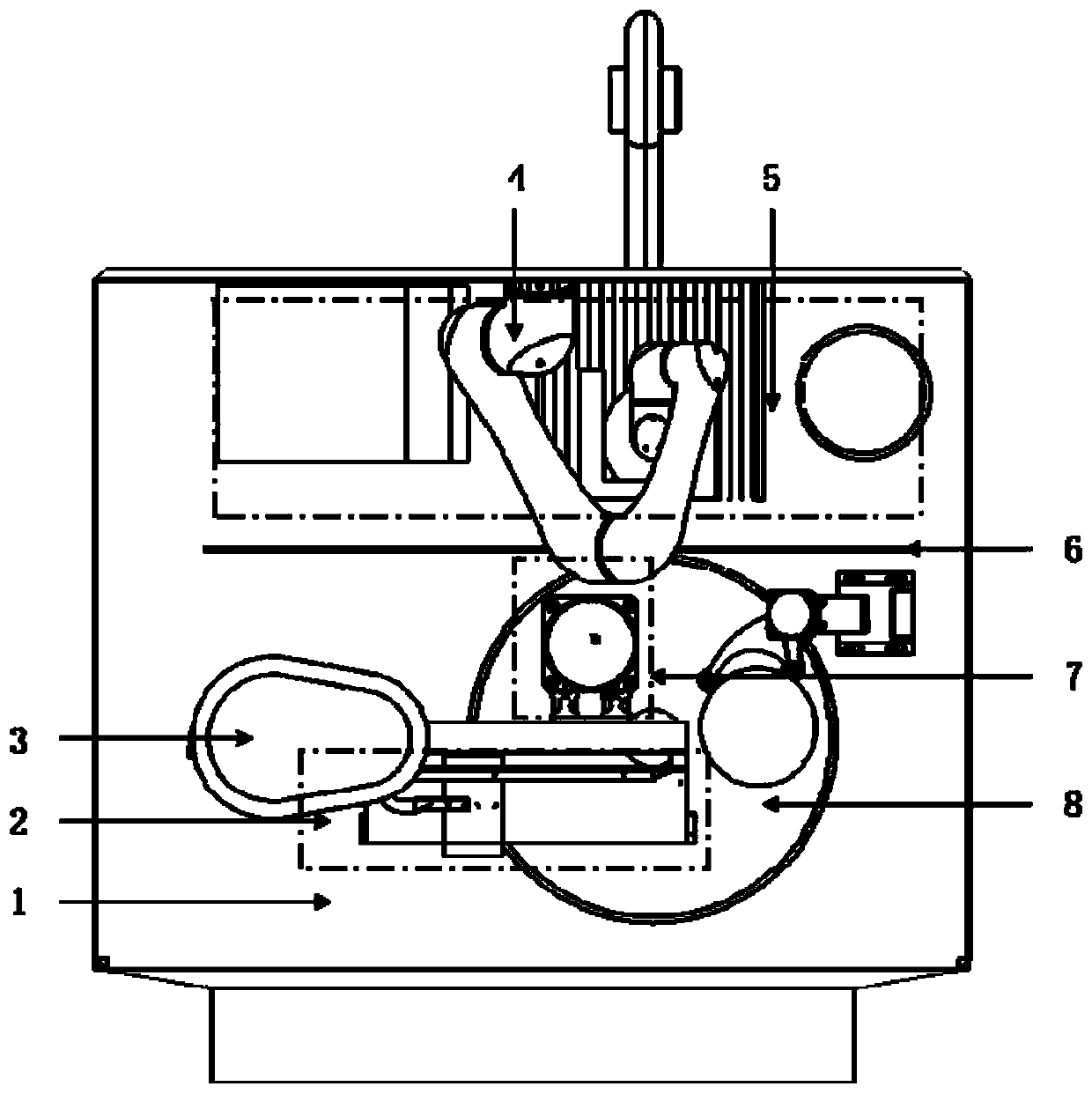

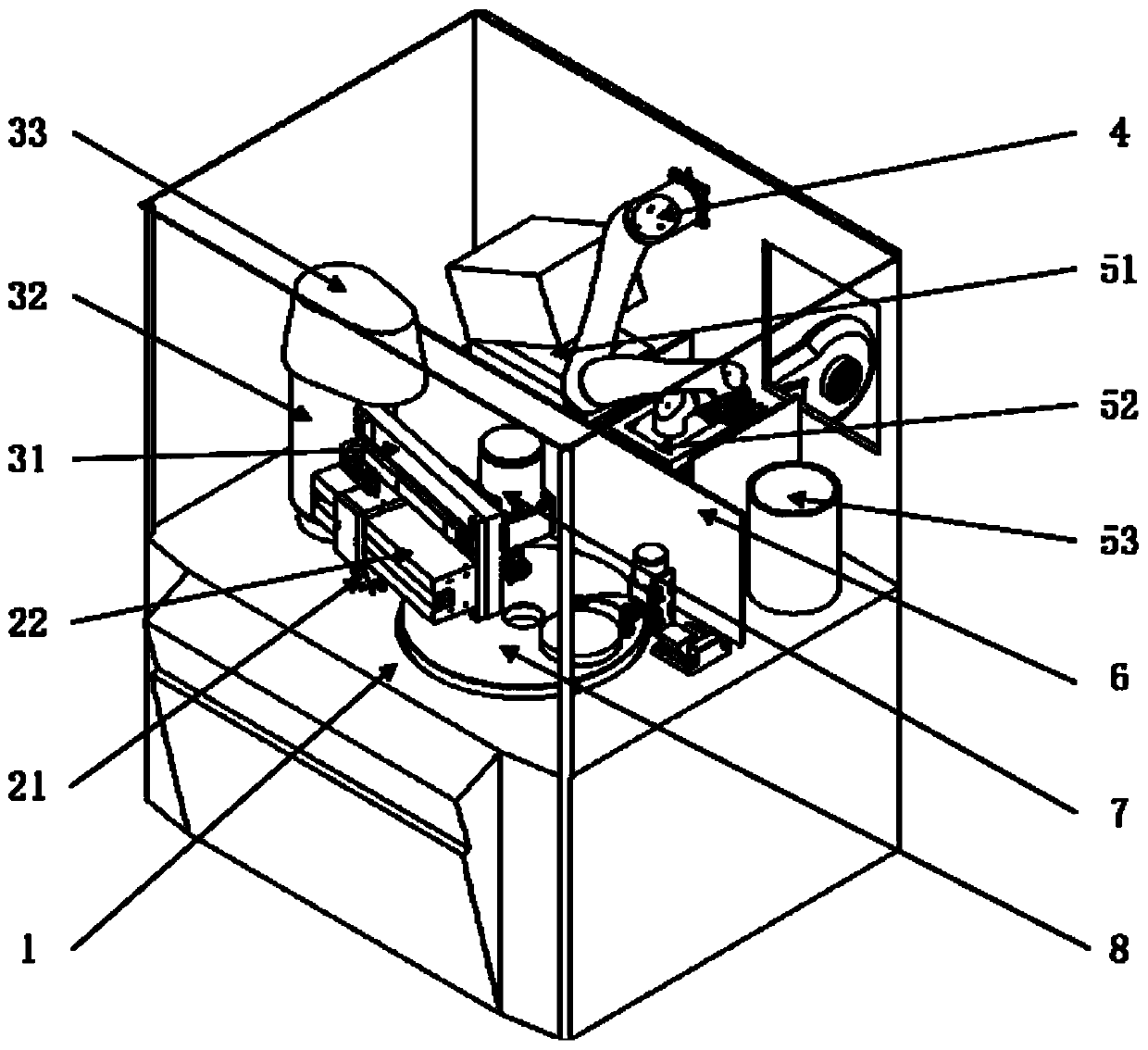

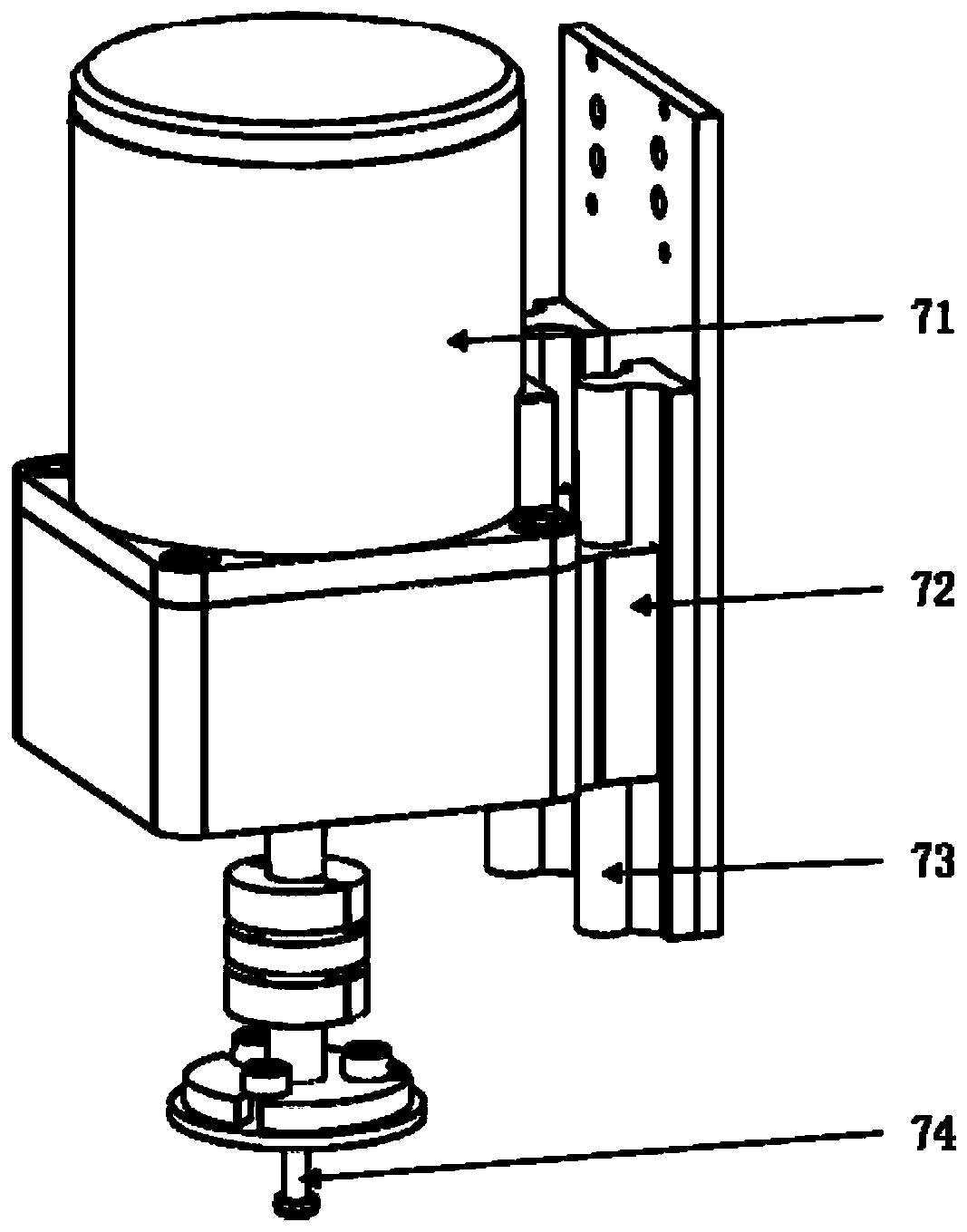

[0092] The present invention is mainly aimed at the processing of plane parts 88. Through accurate analysis of the material removal rate and precise control of the surface profile of the polishing pad, the surface profile of the plane parts 88 can be quickly converged, and stable and efficient processing of large quantities of plane parts 88 can be realized. In the present invention, a base 1 is added to the traditional ring polishing equipment. A rocker mechanism 3 is installed on the base 1 by means of a column 32, and a diamond dresser 74 capable of maintaining a constant pressure is installed on the rocker 31 side of the rocker mechanism 3. A linear guide 22 is mounted on the other side of the rocker arm 31 and a laser displacement sensor 21 is mounted. The rocker arm 31 is adjusted to a position that enables the probe of the laser displacement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com