Positive and negative blade electrodes alternated type electrorheological buffing device

A positive and negative alternating, polishing device technology, applied in polishing tools, blade electrode positive and negative alternating electrorheological polishing tools field, can solve the problem of difficult integration of positive and negative electrodes of tools, low removal rate, etc., to achieve higher shear pressure. It has the effect of stability and consistency, continuous electric field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] specific implementation plan

[0029] In order to better illustrate the purpose and advantages of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

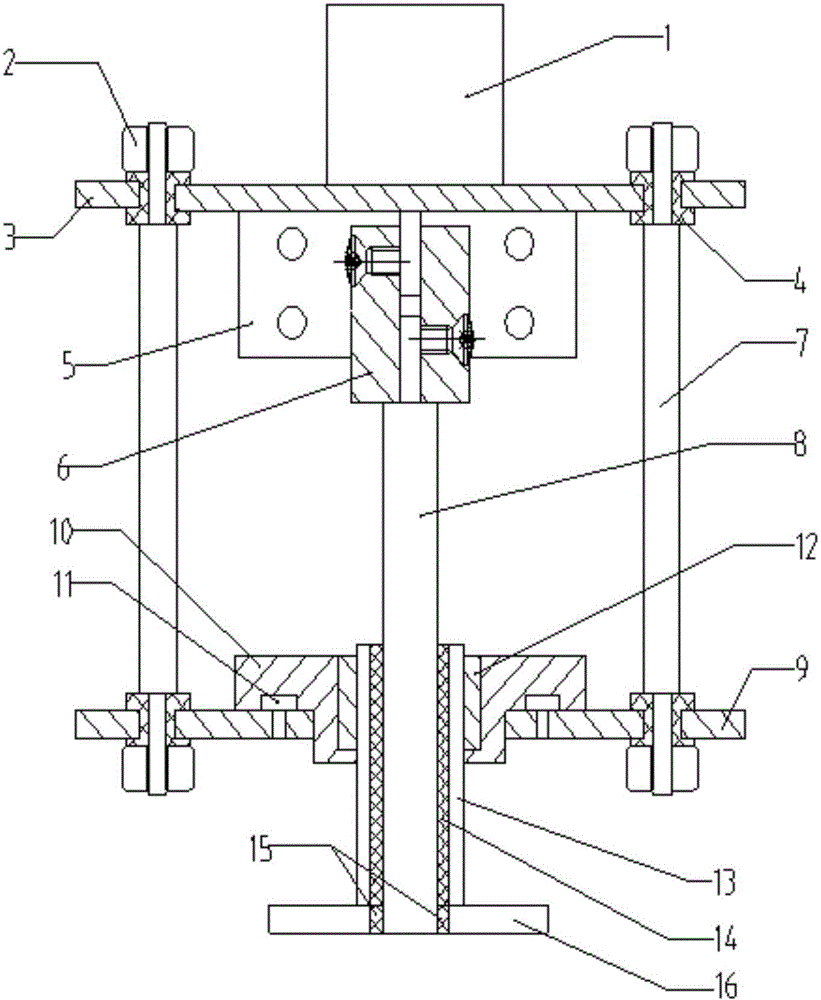

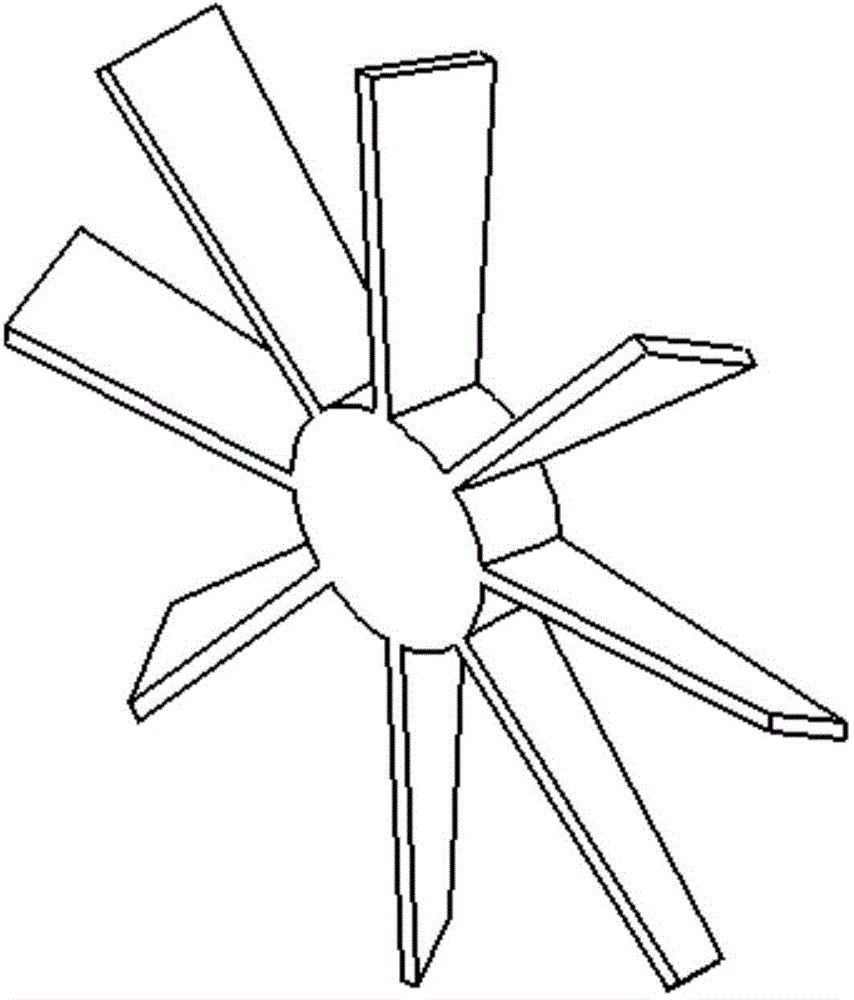

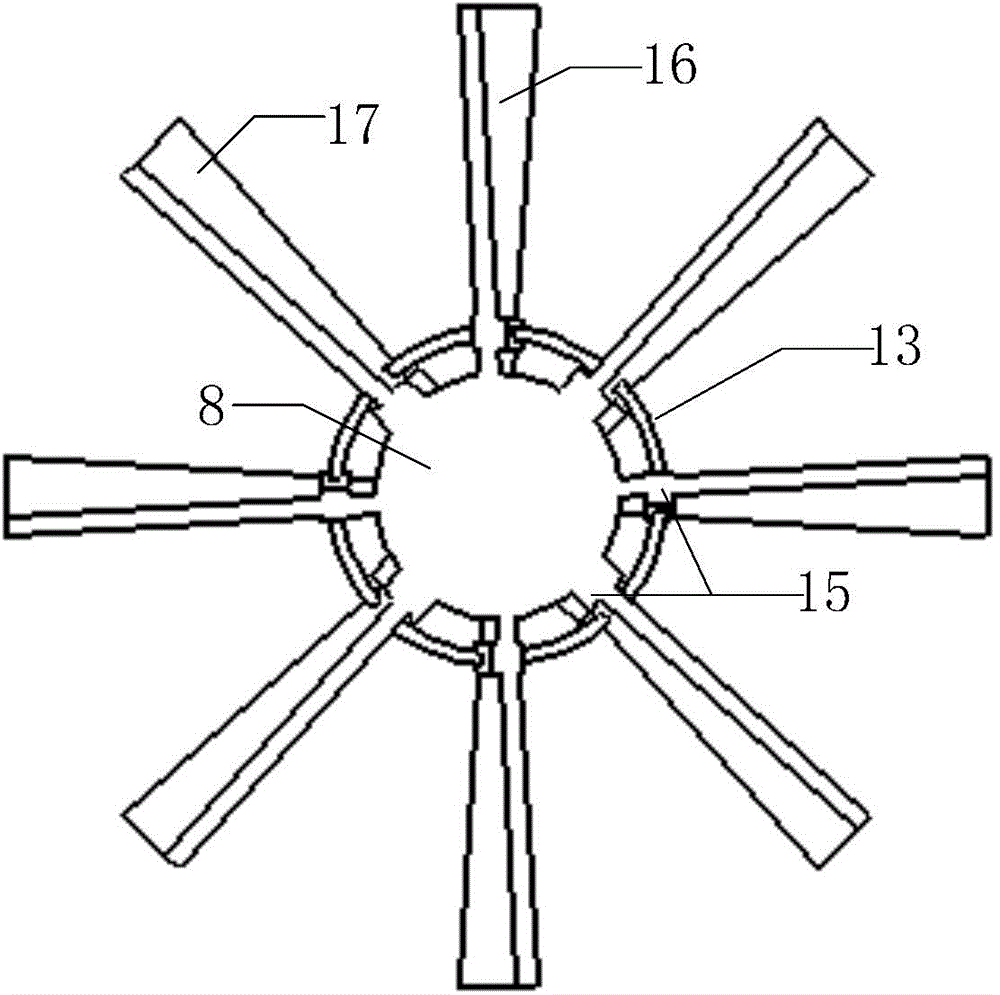

[0030] Such as figure 1 As shown, the polishing device in the embodiment of the present invention includes a motor 1, a nut 2, a bracket 3, an insulating sleeve 4, an adapter plate 5, a coupling 6, a support rod 7, a rotating shaft 8, a base 9, a brush cover 10, Screw 11, ring brush 12, anode conductive cylinder 13, insulating cylinder 14, blade insulating sleeve 15, cathode polishing blade 16; motor 1 is installed on bracket 3 through positioning groove and screw; bracket 3 passes through the The adapter plate 5 is fixed on the ultra-precision CNC machine tool so as to control the movement of the bracket according to a certain trajectory; the upper end of the rotating shaft 8 is connected to the rotating shaft of the motor 1 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com